One thing just occurred to me which may have been addressed before but I've never seen it mentioned (possibly it was thrown out early on for good reasons?) - instead of the slider (manifold) ending in mid air over the platter could it not continue to the other side of the platter to another support post on that side?

Possible Advantages:

- It may reduce any vibration that results from single point support.

- It may allow a second connection to the pump from this new end which could double the airflow & allow a smaller (quieter?) pump

- could it make some adjustments easier

Disadvantages:

- it would prevent on-the-fly VTA adjustment

- would it make more difficult the placement of record on platter?

Possible Advantages:

- It may reduce any vibration that results from single point support.

- It may allow a second connection to the pump from this new end which could double the airflow & allow a smaller (quieter?) pump

- could it make some adjustments easier

Disadvantages:

- it would prevent on-the-fly VTA adjustment

- would it make more difficult the placement of record on platter?

I'm working on my own special blend of this air bearing madness right now, but one thought. If you put a knife edge into a V, dust and stuff can accumulate in the contact area. If you invert the thing and face the knife edges up, it won't get dirty. When you own a dog and heat with wood, you learn all sorts of things

Stew... all those dimensions are on the terminator website. If you have a look in the manual and scroll down towards the bottom, he has them all in there. More than enough to reverse engineer it. Total manifold length is 310mm, carriage is 130mm IIRC, arm hangs 50mm below top of manifold arm wand total length is about 180mm, and right now pivot point to stylus tip on mine is 80mm.

That last bit is adjustable.

Have a look at the terminator site.... You need to spread the 2 hanging brackets further apart and have the pivot block sitting between them down lower with the knives sticking out either end.

Looks like I'm going to have to learn sketchup!

Fran

That last bit is adjustable.

Have a look at the terminator site.... You need to spread the 2 hanging brackets further apart and have the pivot block sitting between them down lower with the knives sticking out either end.

Looks like I'm going to have to learn sketchup!

Fran

jkeny said:One thing just occurred to me which may have been addressed before but I've never seen it mentioned (possibly it was thrown out early on for good reasons?) - instead of the slider (manifold) ending in mid air over the platter could it not continue to the other side of the platter to another support post on that side?

Since I designed my plinth with the standard Ladegaard in mind, this is how I am building the terminator. VTA and leveling adjustments are not as convenient as with this design, and the arm will be a little longer.

Stagerlee,

One of the main sonic advantages attributed to the Terminator is the shortened arm.

I wonder if supporting by two end posts would allow for the whole mechanism to slide over the record for as short an arm length as desired. Experimenting with different shortened arms would be possible which might be it's biggest advantage.

It could also allow for the whole mechanism to slide out of the way for record mounting but would need an easy way to slide back to the exact correct play position to avoid having to redo adjustment for each record change.

Problems:

- Complicates the construction with two slide tracks either side of the platter that the posts slot into

- less solid a base for the posts than fixed posts

One of the main sonic advantages attributed to the Terminator is the shortened arm.

I wonder if supporting by two end posts would allow for the whole mechanism to slide over the record for as short an arm length as desired. Experimenting with different shortened arms would be possible which might be it's biggest advantage.

It could also allow for the whole mechanism to slide out of the way for record mounting but would need an easy way to slide back to the exact correct play position to avoid having to redo adjustment for each record change.

Problems:

- Complicates the construction with two slide tracks either side of the platter that the posts slot into

- less solid a base for the posts than fixed posts

Fran i think yo made a mistake.

The length of the carriage is 180mm not 130mm.

You can cont the holes in the manifold,

In total the manifold 14 holes at 20mm distance you can still see 6 holes so there is 180 mm left.

Sew

Your drawing looks very nice bud is the counter weight not touching the record whe is t liftit?

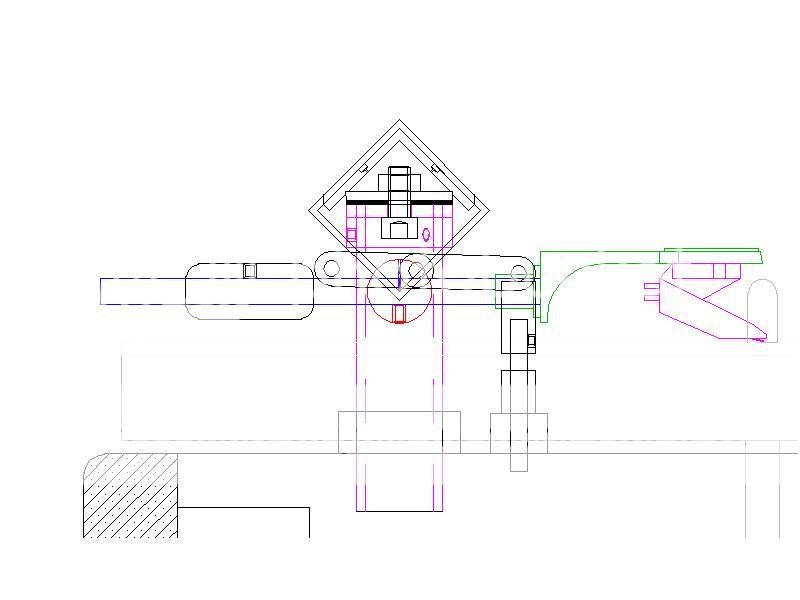

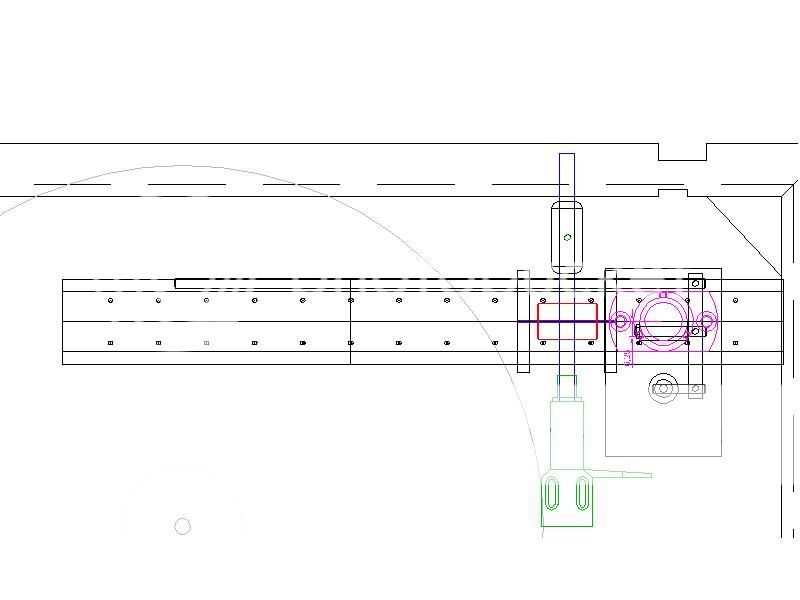

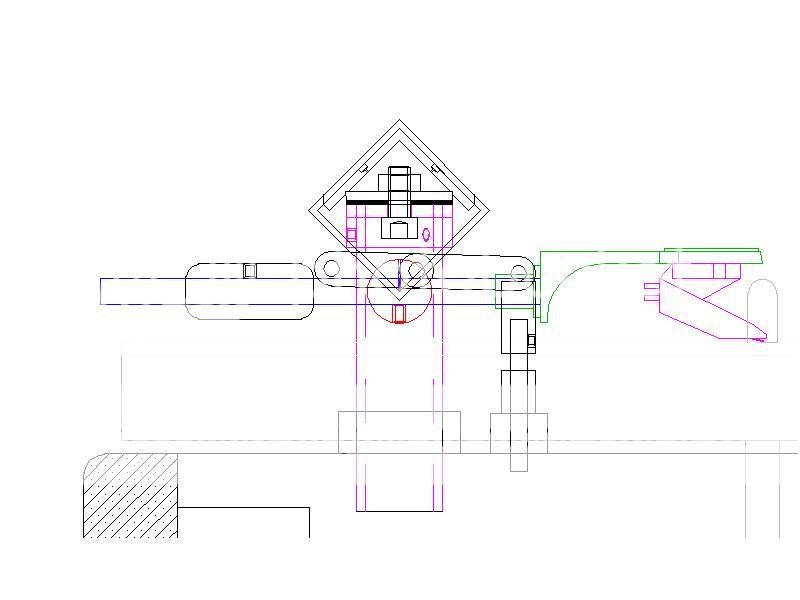

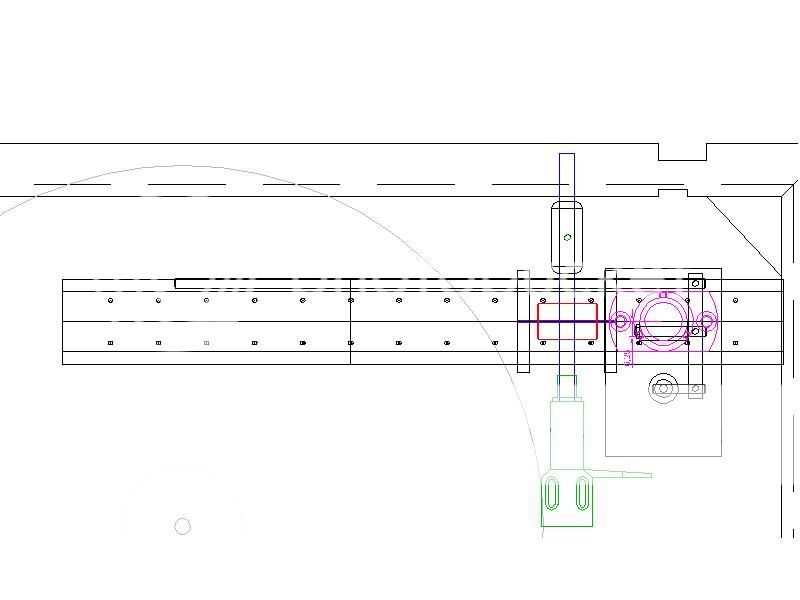

Here is an preview of my project

The plan is to fit it on a Thorens 160MKII.

Probably i have to stabilize the sub frame a bit but we will see how it works

Another thing is i like to use the lift from the Torens, i am hoping that it is strong enough.

George

The length of the carriage is 180mm not 130mm.

You can cont the holes in the manifold,

In total the manifold 14 holes at 20mm distance you can still see 6 holes so there is 180 mm left.

Sew

Your drawing looks very nice bud is the counter weight not touching the record whe is t liftit?

Here is an preview of my project

The plan is to fit it on a Thorens 160MKII.

Probably i have to stabilize the sub frame a bit but we will see how it works

Another thing is i like to use the lift from the Torens, i am hoping that it is strong enough.

George

Geosto: you are probably right, that was just from memory. In fact I think the carriage is about half the lenght of the manifold...

Stew:

both from trans-fi.com

Fran

Stew:

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

both from trans-fi.com

Fran

Nice work there on the DIY terminator! Nice Sketchups, Nanook...

I had an idea today for which I would like some feedback - a modified Laadegard approach (not a Terminator style, it would be tricky to invert it, I think).

While the Laadegard and Terminator arms use right-angle Alu stock and a knife edge pivot, couldn't a similar DIY air-bearing be constructed out of two concentrically matching half-round cross-section pieces? The arc would point upwards (rainbow) and if the armwand attached directly to the upper piece, you could get rid of the knife-edge pivot. The air-bearing track would be the pivot! The stationary track could actually remain a hollow tube, the arm-bearing track a semi-circular cross-section piece riding on top.

Potential challenges include: trying to mount the armwand as close as possible to the centerline of the bearing, and of course lapping or somehow conforming the inner and outer bearing surfaces (or even finding closely matching tube to cut down the middle in the first place!) But it seems to me that there would be added simplicity and tangential rigidity by doing it this way.

I'm gonna try it! Unless I missed something tragically obvious as to why this might not work so well...

I had an idea today for which I would like some feedback - a modified Laadegard approach (not a Terminator style, it would be tricky to invert it, I think).

While the Laadegard and Terminator arms use right-angle Alu stock and a knife edge pivot, couldn't a similar DIY air-bearing be constructed out of two concentrically matching half-round cross-section pieces? The arc would point upwards (rainbow) and if the armwand attached directly to the upper piece, you could get rid of the knife-edge pivot. The air-bearing track would be the pivot! The stationary track could actually remain a hollow tube, the arm-bearing track a semi-circular cross-section piece riding on top.

Potential challenges include: trying to mount the armwand as close as possible to the centerline of the bearing, and of course lapping or somehow conforming the inner and outer bearing surfaces (or even finding closely matching tube to cut down the middle in the first place!) But it seems to me that there would be added simplicity and tangential rigidity by doing it this way.

I'm gonna try it! Unless I missed something tragically obvious as to why this might not work so well...

Sure it will work - most of the commercial air bearing arms are done like this. Have a google for kuzma, ET, cartridgeman, arms. Heres a pic to help you on your way:

BTW, there are speciality manufacturers out there who will make the 2 sizes of tubing needed for this jobwith whatever clearance you need. If someone was willing to go for a group buy I reckon you'd get a few arms out of it, prob have the cost for the tubing down to about 40-50 a person.

That would allow for a neater style of arm compared to the terminator. Sonically I don't know, but all those commercial arms are well regarded.

Fran

An externally hosted image should be here but it was not working when we last tested it.

BTW, there are speciality manufacturers out there who will make the 2 sizes of tubing needed for this jobwith whatever clearance you need. If someone was willing to go for a group buy I reckon you'd get a few arms out of it, prob have the cost for the tubing down to about 40-50 a person.

That would allow for a neater style of arm compared to the terminator. Sonically I don't know, but all those commercial arms are well regarded.

Fran

Fran,

yeah, I'm well aware of many of these designs, which of course use a tube-within-a-tube design. The barrier to DIY there being of course the precision fit required between the two.

My idea is a stop-gap between the Ladegaard and these pro air-bearings. I figure if the angle stock approach can yield results by careful selection and lapping to improve the fit with the Ladegaard then why not try some cylindrical stock? With the carrier being only half-round, it seems to me that the fit could be tuned DIY without the difficulty or expense of matching concentric tubes. The fit should be at least 50% more forgiving!!! (gotta love my math - you can tell I have a PhD in physics)

Seriously, it seems like this approach wold look more elegant and even simplify some matters of construction (no knife-edge, primarily) and so I was just surprised, once I thought about it, why I haven't seen this approach before, DIY or commercial.

But thanks for the air-bearing porn - just adds fuel to my fire, you know!!! Cheers.

yeah, I'm well aware of many of these designs, which of course use a tube-within-a-tube design. The barrier to DIY there being of course the precision fit required between the two.

My idea is a stop-gap between the Ladegaard and these pro air-bearings. I figure if the angle stock approach can yield results by careful selection and lapping to improve the fit with the Ladegaard then why not try some cylindrical stock? With the carrier being only half-round, it seems to me that the fit could be tuned DIY without the difficulty or expense of matching concentric tubes. The fit should be at least 50% more forgiving!!! (gotta love my math - you can tell I have a PhD in physics)

Seriously, it seems like this approach wold look more elegant and even simplify some matters of construction (no knife-edge, primarily) and so I was just surprised, once I thought about it, why I haven't seen this approach before, DIY or commercial.

But thanks for the air-bearing porn - just adds fuel to my fire, you know!!! Cheers.

Yeah, I know audio porn!

Anyway, heres a link to a youtube vid and I think there are pics on this site somewhere.

http://www.youtube.com/watch?v=UZS0rVqEp4M

This fella used pipe for the manifold and then cut away a hlf section of the same pipe and then spread it a bit, lapped it and used it to carry the arm wand. Seems it would achieve what you are after wrt to the pivoting motion. Seems like it would be easier to build too. Wonder why more DIYers haven't gone that route?

Actually, I'm just answering that last question for myself - I just copied what was already out there as an experiment. It would be a lot easier to do it with tube I think.

If you have a go please takes pics and let us know how it sounds. I might even be persuaded to have a go myself!

Fran

Anyway, heres a link to a youtube vid and I think there are pics on this site somewhere.

http://www.youtube.com/watch?v=UZS0rVqEp4M

This fella used pipe for the manifold and then cut away a hlf section of the same pipe and then spread it a bit, lapped it and used it to carry the arm wand. Seems it would achieve what you are after wrt to the pivoting motion. Seems like it would be easier to build too. Wonder why more DIYers haven't gone that route?

Actually, I'm just answering that last question for myself - I just copied what was already out there as an experiment. It would be a lot easier to do it with tube I think.

If you have a go please takes pics and let us know how it sounds. I might even be persuaded to have a go myself!

Fran

innernerd said:The original Dennesen air bearing arm (ablt-1) used this half- round design. Google it or look on Vinyl Engine.

Interesting. Looking at this image , it would seem matching would be even easier if you don't use aluminum for both surfaces. The carrier appears to be some sort of plastic.

again on the Dennisen tangent, look at the third photo down, that appears to be part of the arm lift? What is the purpose of the two black pads. or maybe they are actually magnets?

http://www.klang-projekt.com/dennesen.htm

http://www.klang-projekt.com/dennesen.htm

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- DIY Air bearing tangent tone arm