Hi Jim, some simple questions. I have seen that the air consumption of these NewWay bushing is quite low - 1,5 - 3 LPM. I have a common painting compressor, but i would feel its noise even if kept outside on the terrace (and my neighbors even more!); instead i was thinking of my scuba tanks that are sleeping in the garage from years.

An usual 15 l x 200 atm tank = 3000 liters = > 200 hours of completely silent operation. Ten atmospheres come out of the first stage of the scuba regulator, and may be applied to a common compressor regulator to get the needed pressure - the refill air is already filtered and dry. Even using it daily, maybe no more than one recharge per month.

I have seen that there are both ceramic and carbon versions, starting from 1/4 inch inner diameter, and fairly low weight. Which are best for our goals, where to buy them, and at what cost?

carlo

sorry if this matter was previously treated

An usual 15 l x 200 atm tank = 3000 liters = > 200 hours of completely silent operation. Ten atmospheres come out of the first stage of the scuba regulator, and may be applied to a common compressor regulator to get the needed pressure - the refill air is already filtered and dry. Even using it daily, maybe no more than one recharge per month.

I have seen that there are both ceramic and carbon versions, starting from 1/4 inch inner diameter, and fairly low weight. Which are best for our goals, where to buy them, and at what cost?

carlo

sorry if this matter was previously treated

?'s

Hi Jim,

Do you have another cartridge to try?

Are we sure it is not a simple a simple azimuth problem ?

(sorry for the simple questions as I don't know yet how to read square waves)

tia,

dennis h

Hi Jim,

Do you have another cartridge to try?

Are we sure it is not a simple a simple azimuth problem ?

(sorry for the simple questions as I don't know yet how to read square waves)

tia,

dennis h

Another idea, that I have thought about for years, is a big cylinder, as part of the Turntable stand, maybe 1,5 m high with a high mass piston that is lifted by a motor, while shifting the LP on the turntable, to the top of the cylinder and then released when starting the turntable. The pressure from the piston inside the cylinder should produce sufficient pressure and air flow.. Maybe.Hi Jim, some simple questions. I have seen that the air consumption of these NewWay bushing is quite low - 1,5 - 3 LPM. I have a common painting compressor, but i would feel its noise even if kept outside on the terrace (and my neighbors even more!); instead i was thinking of my scuba tanks that are sleeping in the garage from years.

An usual 15 l x 200 atm tank = 3000 liters = > 200 hours of completely silent operation. Ten atmospheres come out of the first stage of the scuba regulator, and may be applied to a common compressor regulator to get the needed pressure - the refill air is already filtered and dry. Even using it daily, maybe no more than one recharge per month.

I have seen that there are both ceramic and carbon versions, starting from 1/4 inch inner diameter, and fairly low weight. Which are best for our goals, where to buy them, and at what cost?

carlo

sorry if this matter was previously treated

What is the pressure needed ? 40 PSI?

Hi Carlo,

Although Newway air bearing requires low flow but its pressure requirement is high. High air pressure will require high flow as well. I had tried different air pressures with Newway air bearing. The ideal pressures are 50-65 psi. It can even run at higher air pressure, but any high pressures over 65 psi don’t make any difference. In order to use a low pressure air compressor, I tried to use 15 psi with Newway air bearing. It is still workable. I don’t know how long your scuba tanks can hold the pressure. You may need to do some calculations.

I know there are two places you may get Newway air bearings. Motionusa.com or oavco.com. I bought a 3/4” from motionusa before. It costed me $365. It is not cheap. And, the shaft costed me $150 for 9” long. I would not recommend 1/4” air bearing. In my experience, 1/2” may be the smallest air bearing you may use. Large diameter air bearing does sound better. If you want a 1/2” air bearing, please let me know. I have two spare 1/2”.

Another option is to use different style of air bearing arm. Please see attached image. This kind of air bearing arm may only need less than 2 psi air pressure.

Hope this helps.

Jim

Although Newway air bearing requires low flow but its pressure requirement is high. High air pressure will require high flow as well. I had tried different air pressures with Newway air bearing. The ideal pressures are 50-65 psi. It can even run at higher air pressure, but any high pressures over 65 psi don’t make any difference. In order to use a low pressure air compressor, I tried to use 15 psi with Newway air bearing. It is still workable. I don’t know how long your scuba tanks can hold the pressure. You may need to do some calculations.

I know there are two places you may get Newway air bearings. Motionusa.com or oavco.com. I bought a 3/4” from motionusa before. It costed me $365. It is not cheap. And, the shaft costed me $150 for 9” long. I would not recommend 1/4” air bearing. In my experience, 1/2” may be the smallest air bearing you may use. Large diameter air bearing does sound better. If you want a 1/2” air bearing, please let me know. I have two spare 1/2”.

Another option is to use different style of air bearing arm. Please see attached image. This kind of air bearing arm may only need less than 2 psi air pressure.

Hope this helps.

Jim

Attachments

Hi Warrjon,

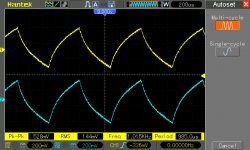

I have the CBS test LP, too. How did you connect the oscilloscope with the cartridge? I tried it before and got triangular waves.

Jim

Hi Jim,

The CBS ST112 is cut without RIAA if you scope the output of the phono preamp you will get a sawtooth wave.

Best way to do this is to leave the TT connected to the phono preamp and scope the input to the preamp. The scope will add some capacitance my Tektronix is 33pf.

I didn't do it this way because my RCA leads from the TT are very short to keep C down

Hi Jim,

Do you have another cartridge to try?

Are we sure it is not a simple a simple azimuth problem ?

(sorry for the simple questions as I don't know yet how to read square waves)

tia,

dennis h

Hi Dennis,

The leading edge of the square wave is the high frequencies and the flat top/bottom is low frequencies.

If you look at Jims post #454. The 1st square wave has slight overshoot which indicates some ringing but this is a good result for a phono cartridge. The 2nd has a rounded leading edge which increases the rise time of the pulse, this indicates a rolloff of high frequencies. Increasing the capacitance loading would give similar results to the 2nd square wave.

The top flat being sloped indicates low frequency rolloff.

Hi Jim,

The CBS ST112 is cut without RIAA if you scope the output of the phono preamp you will get a sawtooth wave.

Best way to do this is to leave the TT connected to the phono preamp and scope the input to the preamp. The scope will add some capacitance my Tektronix is 33pf.

I didn't do it this way because my RCA leads from the TT are very short to keep C down

I see. I am going to get a digital pre or a microphone pre and try it again. The preamplifier I have now is Audio Research Ref 2. I don't like to use tube pre to do the test. Tubes have too much noise.

If you have a MM cartridge you can leave the TT connected to the preamp and scope the input to the preamp, an LOMC cartridge would need a MC pre as noise would be an issue scoping directly with such low signal level.

Thanks for the explanation and advice, Jim.

50 PSI is not an high pressure = 3.4 atm, normally used for painting. (PSI = 0.07 ATM - ATM = 14.7 PSI). Inside a full charged scuba tank there are more or less 3000 Psi.

Probably the air consumption depends more on the tolerances of the bearing than on the pressure itself, and the tolerances of the NewWay bushings are minimal, a few microns. In fact they declare a consumption of 2 liters per minute for the 1/2 inch, on which I had made my calculations.

I don't know if I would ever do an air bearing LT, but certainly not a low pressure one: a friend of mine, excellent builder, had made a Terminator clone, and I heard and saw it, unfortunately. (also my friend, who sent it to the garbage). Long ago, In a listening room, i have also heard some famous ones, unfortunately.

carlo

The price is certainly high, probably due the constructive level: it would be interesting to build something like, for example starting from usual sintered bronze bushings. Someone who can work with great precision could attempt the challenge

50 PSI is not an high pressure = 3.4 atm, normally used for painting. (PSI = 0.07 ATM - ATM = 14.7 PSI). Inside a full charged scuba tank there are more or less 3000 Psi.

Probably the air consumption depends more on the tolerances of the bearing than on the pressure itself, and the tolerances of the NewWay bushings are minimal, a few microns. In fact they declare a consumption of 2 liters per minute for the 1/2 inch, on which I had made my calculations.

I don't know if I would ever do an air bearing LT, but certainly not a low pressure one: a friend of mine, excellent builder, had made a Terminator clone, and I heard and saw it, unfortunately. (also my friend, who sent it to the garbage). Long ago, In a listening room, i have also heard some famous ones, unfortunately.

carlo

The price is certainly high, probably due the constructive level: it would be interesting to build something like, for example starting from usual sintered bronze bushings. Someone who can work with great precision could attempt the challenge

Hi Carlo,

Although your scuba tank can hold the air up to 3000 psi, you won't proably do it except you use special service. Most air compressors can work at maximum 200 psi only. The flow rate for a 3/4" air bushing is 7-9.6 SCFH at 60 psi under given tolerances. An air bearing arm needs high pressure and less flow. If you run pressure lower than 60 psi, the required flow rate will be lower as well.

Jim

Although your scuba tank can hold the air up to 3000 psi, you won't proably do it except you use special service. Most air compressors can work at maximum 200 psi only. The flow rate for a 3/4" air bushing is 7-9.6 SCFH at 60 psi under given tolerances. An air bearing arm needs high pressure and less flow. If you run pressure lower than 60 psi, the required flow rate will be lower as well.

Jim

Last edited:

Of course, a workshop compressor is completely useless. Here it is easy to refill the scuba tanks (for 3 - 5 $ each) at every dive shop, with a Bauer or similar compressors, up to 300 atm.

Otherwise it is even possible to rent oxygen or nitrogen tanks for welding or medical use, regulator included (200 atm).

c

Otherwise it is even possible to rent oxygen or nitrogen tanks for welding or medical use, regulator included (200 atm).

c

Last edited:

I would consider oxygen too dangerous to use with lp's that are cut with hot sizzling highs. 🙄

Ray K

Ray K

The high pressure in SCUBA tanks gets tamed by regulators. What's in them is usually just compressed filtered air, because you end up breathing it.

When it comes to technical gases oxygen would be great fun. I agree with you there Ray. Pure nitrogen from a tank on the other hand ... interesting.

When it comes to technical gases oxygen would be great fun. I agree with you there Ray. Pure nitrogen from a tank on the other hand ... interesting.

Anyone willing to forgo a bit of precision to save a bunch of money while pursuing air bearings might be interested in this video. It's been haunting me for many weeks. I don't think I'll get away with a turntable that needs a compressor, but the idea of building from scratch an air bearing-based linear tracking arm, or an air-bearing for a platter, keeps sucking me in like a black hole. The fact that I have so many other incomplete projects is the only thing that's kept me away from the event horizon (so far).

A bearing better suited to a linear tracking arm is shown at 5:15 in this video. The author notes the bearing was harder to make.

i think adopting the radial bearing approach shown here would be easier to fabricate because the mounting method causes the bearings to self-align with the shaft and the pre-load can be adjusted. A little less fabrication precision might be compensated by the adjustability.

I hope someone here makes a linear tracking tonearm using this approach and reports on it so I can stop thinking about it and get some sleep.

Few

A bearing better suited to a linear tracking arm is shown at 5:15 in this video. The author notes the bearing was harder to make.

i think adopting the radial bearing approach shown here would be easier to fabricate because the mounting method causes the bearings to self-align with the shaft and the pre-load can be adjusted. A little less fabrication precision might be compensated by the adjustability.

I hope someone here makes a linear tracking tonearm using this approach and reports on it so I can stop thinking about it and get some sleep.

Few

Hi Few,

These videos are really interesting. However, it may not be easy to make one yourself and its final cost may be even higher.

In my opinions, it is not worth making an arm by using radial air bearings. First, you need to make 4 or 8 radial air bearings. It will require high air consumption. And, in the meantime, it is almost impossible to make all the bearings act the same without proper tools. Finally, for this kind of moving shaft air bearing arms, you almost can't get a low mass shaft for this kind of air bearing arm. Ideally, the moving shaft should be about 50 to 70 grams. So, you can sleep tight tonight.

Jim

These videos are really interesting. However, it may not be easy to make one yourself and its final cost may be even higher.

In my opinions, it is not worth making an arm by using radial air bearings. First, you need to make 4 or 8 radial air bearings. It will require high air consumption. And, in the meantime, it is almost impossible to make all the bearings act the same without proper tools. Finally, for this kind of moving shaft air bearing arms, you almost can't get a low mass shaft for this kind of air bearing arm. Ideally, the moving shaft should be about 50 to 70 grams. So, you can sleep tight tonight.

Jim

Last edited:

Easy? Since when is that a criterion for diyaudio projects?!😀 More seriously, I'm sure there would be a thousand unanticipated challenges, but that's half the fun (and frustration).

I do think some money could be saved starting from scratch. A block of suitable graphite, sufficient to make several false starts, is $22 US. The aluminum for the plenum and cartridge mount would cost less than that. I'd be inclined to try to make a moving-bearing (following Jim's approach, for the reasons he's already explained) rather than a stationary-bearing design although doing so would magnify the challenge. The first link I provided shows that making the bearings need not involve ultraprecise machinery, and I think the radial bearing approach would make everything much more forgiving, but I acknowledge that it would increase the complexity by increasing the number of parts.

Anyway, I should be clear that I'm very impressed by the work of everyone who has shared their linear-tracking arm projects, and I'm not suggesting making diy air bearings would be in any way "better." Just another approach that would involve an interesting challenge and that might yield a lot of satisfaction if successful. The fact that the financial investment would be fairly small if the whole idea proved to be inane makes it intriguing--at least to me. So I'm probably doomed to some more sleepless nights.

Sorry, I didn't mean to hijack this thread. All the air bearing discussions and exciting linear tracking results got me fired up!

Few

I do think some money could be saved starting from scratch. A block of suitable graphite, sufficient to make several false starts, is $22 US. The aluminum for the plenum and cartridge mount would cost less than that. I'd be inclined to try to make a moving-bearing (following Jim's approach, for the reasons he's already explained) rather than a stationary-bearing design although doing so would magnify the challenge. The first link I provided shows that making the bearings need not involve ultraprecise machinery, and I think the radial bearing approach would make everything much more forgiving, but I acknowledge that it would increase the complexity by increasing the number of parts.

Anyway, I should be clear that I'm very impressed by the work of everyone who has shared their linear-tracking arm projects, and I'm not suggesting making diy air bearings would be in any way "better." Just another approach that would involve an interesting challenge and that might yield a lot of satisfaction if successful. The fact that the financial investment would be fairly small if the whole idea proved to be inane makes it intriguing--at least to me. So I'm probably doomed to some more sleepless nights.

Sorry, I didn't mean to hijack this thread. All the air bearing discussions and exciting linear tracking results got me fired up!

Few

- Home

- Source & Line

- Analogue Source

- DIY Air Bearing Linear Arm