Hmmm... never an easy topic. At least for some, and I include myself as it took time for me to find a tool that suited me.

Sometimes it works very easily, sometimes it doesn't, especialy if working on some mass produced "soldered/glued" boards.

I have the blue pump since decades (bought 2 due to the solid tip wearing in fact) and with some practice (that is avoiding to burn everything) it works reasonably well. Reasonably well on good boards (read the ones from Pass here) with usual through hole parts. For me it doesn't work great on parts with big legs (eg lots of solder, such as big coils with big mass plans that need massive heating) and it doesn't neither on the lastest very small SMD parts (eg the latest bits with 1000 legs per mm).

For the former, I used an electrical professional desoldering station, that helped. Cost a fortune, is as big and heavy as my power amp and as loud as my music. And it also has its limits as I found out. I moved on...

Now, both for reasonably big solder joints (say up to LS level) and for very small parts (SMDs size of LT3045 but of course without under part soldering point, I use this)

https://www.amazon.com/Engineer-SS-02-Solder-Sucker/dp/B002MJMXD4

Yes, it is expensive for a hand pump. Yes, it has a soft tip that doesn't burn and that makes a massive difference as it sucks far more efficiently, you just put the pump tip on the part while heating it with the soldering iron and it follows form... and sucks everything.

It is very well built (metal, good joints for the vacuum, something average on the plastic pumps I had) and very handy (weight, balance in hand, spring is hard but action slow and soft / long so it doesn't jump in your hand when triggeting it, important when working on tiny parts, ergonomics are great... if anything I find it a bit small for my hands, but then access is easier).

Wick? Never worked for me. Ok, I have 2 with flux, it helps removing big solder plumps, say getting a messy job started. Never 100% until the end, apart from the odd lucky part removal. Good to have though, in case of. The metal pump I mentioned here (no commecial link to them) worked though great each time... for me and even for a beginner friend of mine. So I try it first on normal works.

When I began decades ago I was on the verge of burning small sensitive tracks on "OKish" boards, with the blue pump or the wick. I wish I would have had this pump...

Just my experience, I am not a professional, just a few occasional builds here and there over decades - I just hope it helps someone

Claude

Sometimes it works very easily, sometimes it doesn't, especialy if working on some mass produced "soldered/glued" boards.

I have the blue pump since decades (bought 2 due to the solid tip wearing in fact) and with some practice (that is avoiding to burn everything) it works reasonably well. Reasonably well on good boards (read the ones from Pass here) with usual through hole parts. For me it doesn't work great on parts with big legs (eg lots of solder, such as big coils with big mass plans that need massive heating) and it doesn't neither on the lastest very small SMD parts (eg the latest bits with 1000 legs per mm).

For the former, I used an electrical professional desoldering station, that helped. Cost a fortune, is as big and heavy as my power amp and as loud as my music. And it also has its limits as I found out. I moved on...

Now, both for reasonably big solder joints (say up to LS level) and for very small parts (SMDs size of LT3045 but of course without under part soldering point, I use this)

https://www.amazon.com/Engineer-SS-02-Solder-Sucker/dp/B002MJMXD4

Yes, it is expensive for a hand pump. Yes, it has a soft tip that doesn't burn and that makes a massive difference as it sucks far more efficiently, you just put the pump tip on the part while heating it with the soldering iron and it follows form... and sucks everything.

It is very well built (metal, good joints for the vacuum, something average on the plastic pumps I had) and very handy (weight, balance in hand, spring is hard but action slow and soft / long so it doesn't jump in your hand when triggeting it, important when working on tiny parts, ergonomics are great... if anything I find it a bit small for my hands, but then access is easier).

Wick? Never worked for me. Ok, I have 2 with flux, it helps removing big solder plumps, say getting a messy job started. Never 100% until the end, apart from the odd lucky part removal. Good to have though, in case of. The metal pump I mentioned here (no commecial link to them) worked though great each time... for me and even for a beginner friend of mine. So I try it first on normal works.

When I began decades ago I was on the verge of burning small sensitive tracks on "OKish" boards, with the blue pump or the wick. I wish I would have had this pump...

Just my experience, I am not a professional, just a few occasional builds here and there over decades - I just hope it helps someone

Claude

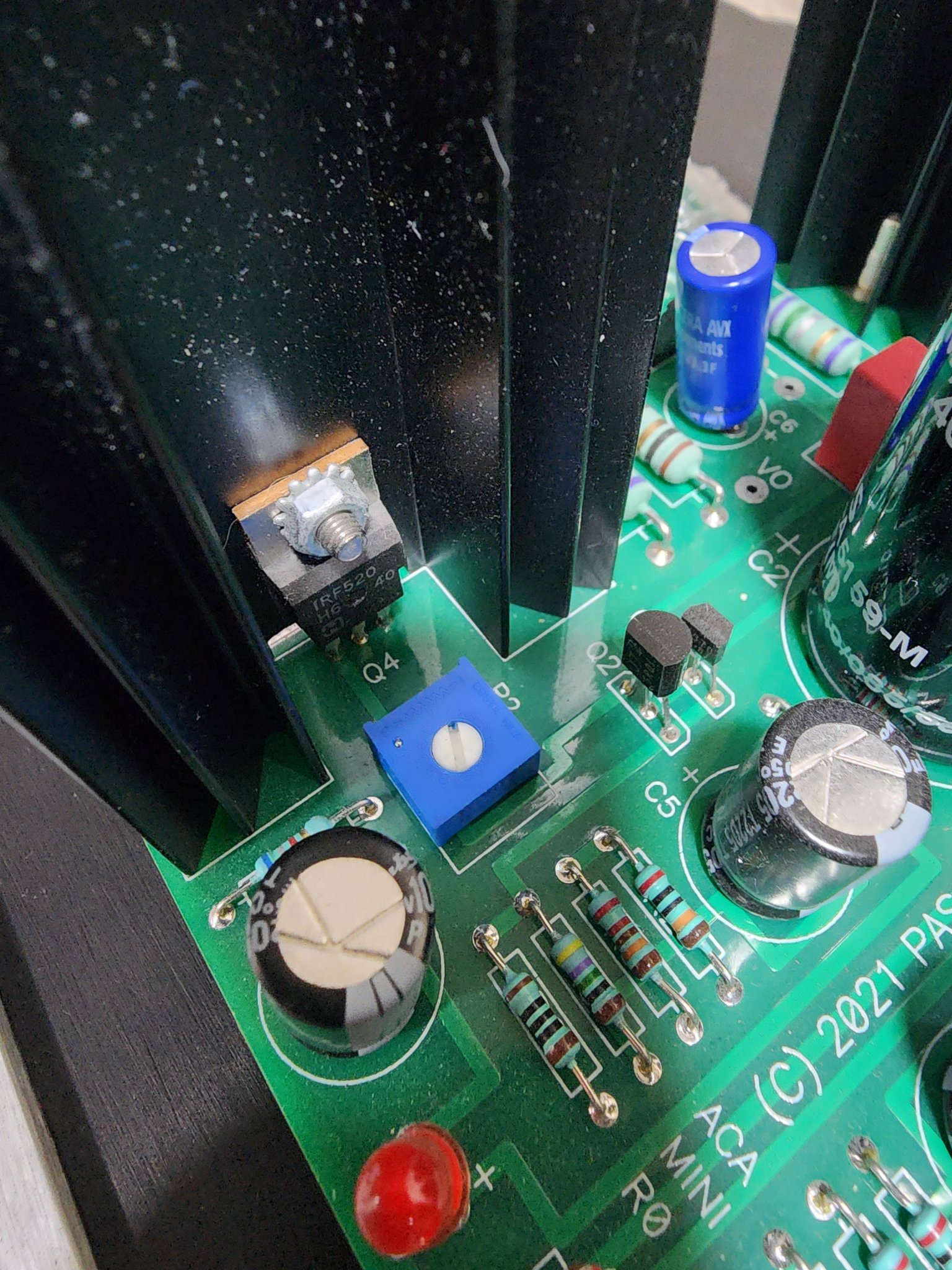

1/4W is more than adequate for R2 and R3.Your kit there appears to have 1/4W resistors.

Hi builders,

My completions kit came with 6.8K resistors for R4. I have some 22K 1/4W resistors in my inventory. Is 1/4W rating OK for R4.

Also, my kit has the 1K trimpots. Should I try to set the bias using them, or just order some 2K pots. I do not like to de-solder components if I don't have to. Thanks for the help.

MM

My completions kit came with 6.8K resistors for R4. I have some 22K 1/4W resistors in my inventory. Is 1/4W rating OK for R4.

Also, my kit has the 1K trimpots. Should I try to set the bias using them, or just order some 2K pots. I do not like to de-solder components if I don't have to. Thanks for the help.

MM

check the updated BOM! https://www.diyaudio.com/community/threads/diy-aca-mini.379037/post-7373835Hi builders,

My completions kit came with 6.8K resistors for R4. I have some 22K 1/4W resistors in my inventory. Is 1/4W rating OK for R4.

Also, my kit has the 1K trimpots. Should I try to set the bias using them, or just order some 2K pots. I do not like to de-solder components if I don't have to. Thanks for the help.

the BOM says that its 1k pots and the 6.4k resistor is only for R0.

Hopefully, that helps you avoid my earlier mistake!

Happy Building!

Jose

@Jacruzer787

Thanks, I am aware of that BOM. I have used one of the 6.8K resistors I received for R0.

Could someone let me know if 1/4 W rated resistor's be used at R4 ?.

Some builders have experienced trouble when trying to set the bias with 1K trim pots. I prefer not de-soldering components, hence I am asking if one should just purchase some 2K trim pots and be done with it ?.

Thanks again for the help.

MM

Thanks, I am aware of that BOM. I have used one of the 6.8K resistors I received for R0.

Could someone let me know if 1/4 W rated resistor's be used at R4 ?.

Some builders have experienced trouble when trying to set the bias with 1K trim pots. I prefer not de-soldering components, hence I am asking if one should just purchase some 2K trim pots and be done with it ?.

Thanks again for the help.

MM

I think I may have answered my own question about the 1K vs 2K trim pots. Only need to verify if 1/4W resistor okay for R4 ?.

Sorry about the confusion, should have searched farther.

MM

Hi Everyone, Santa is packing up lots of ACAmini Essentials (pcb + fets) for the Store, and

I want to inform customers that the Bill of Materials has been altered, changing the value of

the bias trim pots to 2 Kohm, up from 1 Kohm to accommodate the ranges we are getting

from the Mosfet/Jfet pairs. Previously we could work with up to 1K, but now the upper limit

is a little higher, and 2K is the next value pot on the scale of availability..

There is no performance hit. Completion kits from the store will reflect this change, and will

work fine with boards purchased previously.

Nelson,

Should I replace the 1K pots with the 2K? I just finished assembling the old kit

IRFP devices? Before doing that just see if you can achieve proper bias,

No need to worry. If the amp biases up then you're fine. On the next batch the margin between the Idss of the Jfets and Vgs of the Mosfets is thinner, although most of them will work with the original 1k pots.

Sorry about the confusion, should have searched farther.

MM

Just finished building a ACA-Mini the other night and I have to say I'm pretty impressed. Except for being a little confused by not looking at the updated BOM it went together fairly easy. Biasing was fairly straight forward. After it warmed up for an hour I finally connected it to some older Sony 89db sensitivity speakers and sound came out but it wasn't that good. I was satisfied the amp was working properly and connected to some Heresy IV. Wow. I was blown away by the difference in the soundstage between this amp and my Kenwood Class G 220w amp. At most listening volumes this little amp is more than adequate and sounds so refined. I had some old customer service plaques from Cisco Systems and they were the perfect size so I mounted it on one of them. Not sure of what type of wood but they are fairly heavy.

Attachments

Was able to get the resistors out. They are in rough shape. Plus I think I may have damaged the pcb!

Thanks to everyone’s suggestions!

This is too late but it may help you the next time you need to remove a part. It would have been much easier if you had cut the leads shorter. If you had intended to reuse the resistor, leave a few millimeters of the lead above the board. Then heat one lead until the solder melts and pull the resistor from the other side to pull the lead out of the hole. Do the same to the other lead. To clear the hole of solder, heat the solder in one of the holes and once the solder is molten, quickly tap the board sharply on a table. Repeat if necessary, then clear the other hole of solder. Done.

Looking at your solder joints, it looks like you are not applying enough heat.

Looking at your solder joints, it looks like you are not applying enough heat.

i could use some help figuring out with understanding how my speakers might vibe with the ACA mini.

I have Dynaudio Audience 42's. These are 4 ohm bookshelves rated at 86db sensitivity.

Should I go dual mono?

Should I consider a different amp altogether?

I have Dynaudio Audience 42's. These are 4 ohm bookshelves rated at 86db sensitivity.

Should I go dual mono?

Should I consider a different amp altogether?

Probably better served w/ the F5M. I am pretty familiar w/ Dynaudio and in general they aren't the easiest load. I used a Mini on a pair of Revel F226Be which are rated 8 ohm 90db, though they really like more than what the rating might indicate. Anyway, the Mini drove them reasonably well, clearly ran out of steam at modest volumes, but was lovely at softer levels. I'm no expert re. the various Pass amps, but it would seem like the F5M would be a much better match for those speakers.

It doesn't appear I used pads. I don't remember if I used "goop", but I'd say if you have some thermal paste (like for CPU to heat sink stuff, or the like), seems like a good idea.

R

Thanks Brother!!! It seems I am going to have to wait till tomorrow… 😩It doesn't appear I used pads. I don't remember if I used "goop", but I'd say if you have some thermal paste (like for CPU to heat sink stuff, or the like), seems like a good idea.

Step #14 in the build guide is very helpful...

It says... "A little heatsink goop is helpful if you have some."

https://guides.diyaudio.com/Guide/ACA+Mini/21?lang=en

It says... "A little heatsink goop is helpful if you have some."

https://guides.diyaudio.com/Guide/ACA+Mini/21?lang=en

I was moving along swiftly through the build, articles on one screen build guide on the other one, saw it, and stopped. Not making the same mistake again! I have goop, just not heatsink goopStep #14 in the build guide is very helpful...

It says... "A little heatsink goop is helpful if you have some."

Thanks Pat!

- Home

- Amplifiers

- Pass Labs

- DIY ACA mini