Perhaps I didn't pose the question correctly.

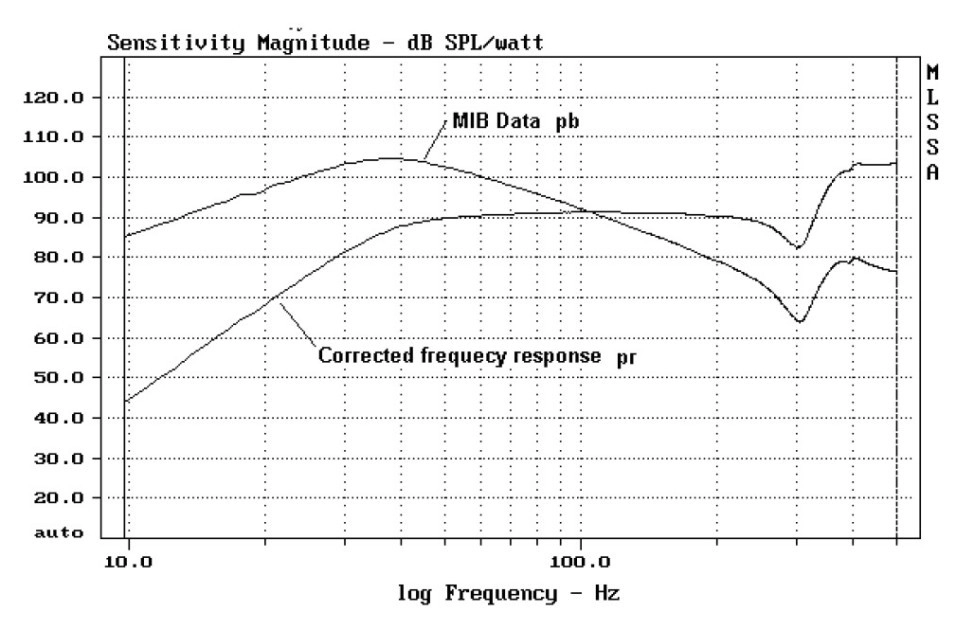

I understand that the measurement gives the 2pi farfield response AFTER the correction. factor.

But it still observes a HIGHER spl than real 1m SPL. eg. almost 30dB at 20Hz:

So unless your microphone can with-stand 160dB, like B&K 4191 capsule that Joe uses, I see no advantage for measuring distortion at low frequencies.

I understand that the measurement gives the 2pi farfield response AFTER the correction. factor.

But it still observes a HIGHER spl than real 1m SPL. eg. almost 30dB at 20Hz:

So unless your microphone can with-stand 160dB, like B&K 4191 capsule that Joe uses, I see no advantage for measuring distortion at low frequencies.

Last edited:

A 1/4" mic can do that. Also noisefloor should be ok to do so, just barely.How can a microphone measure distortion at < -70 or -80 dB, when it is observing some 116dB? *

It's daily life when doing acoustic measurements to ask EXACTLY these questions! Am I able to perform the measurements I need?

M215 could do at 100dBSpl. So for a groundplane measurement they are fine, also 30cm distance is fine.

I have no idea why people think they buy a €50,- microphone and can measure a €500,- top of the line chassis. Just get useful tools, it saves a lot of time (and money in the long run).

Well your data is the first to show that whilst the ECM8000 has many uses, it is NOT suited to measuring nearfield distortion at frequencies below Schroeder.

Thank you @IamJF

The next question we hope is answer is, HOW can we measure distortion in frequencies below Schroeder in the nearfield? Can it be done with anything less than $/€1300 Earthworks M50, or a 1/4 B&K or G.R.A.S capsule? (Pricing On Application- 4 figures)

But to answer your question, doing more with less, has always been the question of engineers...

Thank you @IamJF

The next question we hope is answer is, HOW can we measure distortion in frequencies below Schroeder in the nearfield? Can it be done with anything less than $/€1300 Earthworks M50, or a 1/4 B&K or G.R.A.S capsule? (Pricing On Application- 4 figures)

But to answer your question, doing more with less, has always been the question of engineers...

Last edited:

Sorry guys. But I am really gonna play devil's advocate here.

I have used all kinds of microphones from the cheapest Dayton/Beringer/Superlux till some very expensive GRAS microphones.

Basically this comes down back to my previous post to put it all in context.

The majority of a loudspeaker system can be predicted beforehand.

Especially when 3rd party data like distortion and Klippel LSI data is available.

Even more so from multiple different sources.

On the list of priorities there are tons of things far more important than just distortion.

All these things are dependent on the linearity of the frequency response of the microphone.

So good calibration (verification actually) is absolutely mandatory.

But I am totally disagreeing with the idea that someone needs a more expensive microphone for a more expensive system.

Because that argument depend entirely on the idea that distortion is the major factor.

But totally dismisses the fact that there plenty of other things that are important as well.

It also dismisses the end goal of the user entirely.

Since we have 3rd party data, we can compare different drivers in a relative way.

With logic deduction we can than easily conclude that some speakers will have a lower distortion based on those measurements. Therefore the speaker we want to design will perform better by definition of that.

This doesn't change if your driver is 40 bucks or 500 bucks.

Same principles apply.

Besides the fact that there are 40 dollar drivers out there that outperform some 500 dollar drivers even.

I have used all kinds of microphones from the cheapest Dayton/Beringer/Superlux till some very expensive GRAS microphones.

Basically this comes down back to my previous post to put it all in context.

The majority of a loudspeaker system can be predicted beforehand.

Especially when 3rd party data like distortion and Klippel LSI data is available.

Even more so from multiple different sources.

On the list of priorities there are tons of things far more important than just distortion.

All these things are dependent on the linearity of the frequency response of the microphone.

So good calibration (verification actually) is absolutely mandatory.

But I am totally disagreeing with the idea that someone needs a more expensive microphone for a more expensive system.

Because that argument depend entirely on the idea that distortion is the major factor.

But totally dismisses the fact that there plenty of other things that are important as well.

It also dismisses the end goal of the user entirely.

Since we have 3rd party data, we can compare different drivers in a relative way.

With logic deduction we can than easily conclude that some speakers will have a lower distortion based on those measurements. Therefore the speaker we want to design will perform better by definition of that.

This doesn't change if your driver is 40 bucks or 500 bucks.

Same principles apply.

Besides the fact that there are 40 dollar drivers out there that outperform some 500 dollar drivers even.

This conclusion missed two important nuances.ECM8000 has many uses, it is NOT suited to measuring nearfield distortion at frequencies below Schroeder.

Such microphones are perfectly capable of measuring the relative distortion, but just ONLY below certain sound pressure levels.

If it's near-field or not is totally irrelevant.

We can just simply turn down the volume so we know we are not "clipping" the microphone (read be in the high distortion range).

Which brings me to the second very important nuance, and that is that I have done this with these type of microphones hundreds of times and the results from these microphones footprint perfectly mimicks the distortion footprint from results from mics that are actually capable.

Sure the absolute values are different, but that's absolutely not important for making a good crossover.

Only thing we care about, is where certain distortion peaks are or where the distortion starts rising.

I totally agree on many points.

I’m not going to go out to buy a $1000 microphone or a $10,000 microphone, just because it exists.

But what we are talking about it getting

more accurate measurements, more conveniently. The minimum viable solution.

Or when you need to measure drivers that do not have any published data, or when designing your own drivers.

I’m not going to go out to buy a $1000 microphone or a $10,000 microphone, just because it exists.

But what we are talking about it getting

more accurate measurements, more conveniently. The minimum viable solution.

Or when you need to measure drivers that do not have any published data, or when designing your own drivers.

Last edited:

Than you first have to define that idea.But what we are talking about it getting

more accurate measurements, more conveniently. The minimum viable solution

More or accurate data most certainly doesn't mean better results.

In fact, there is even a argument to be made we don't need an expensive microphone for expensive well performing drivers, since we know they will perform top of the line anyway.

Unless you like to spend time showing and verifying results that are obvious.

If we talk within the context of getting better measurements, I highly ask you to join the DIY Klippel NFS topic and brainstorm along with us.

In the entire chain, that's by far much more significant than distortion measurements.

Unless you like to just spend time comparing drivers.

Which is also great, but since we only have so many hours in a day, keep in mind you have less time left designing systems. That's just the practically of it all.

I like the way you challenge my thinking @Boden It certainly helps me refine my thoughts.

The question of adequate or sufficient is different to the question of more accuracy or precision.

Whether you want to precisely measure a mass of 1 kilogram or whether I want an approximation to get my luggage onto an airplane, I understand. Building the world's quietest anechoic chamber doesn't mean the ability to design a better speaker, I get that.

But unless we can accurately measure what we are talking about, then one must be careful of drawing too many conclusions.

In this post, I made no proposal about what the future research should be. To be sure, repeated tests have already shown that H2 and H3 (and thus THD) ARE NOT related to listening preferences. Personally, I would say that is pretty obvious, and doesn't even need empirical testing. Why? Because H2 and H3 are musically related. It's like saying, Do you like the C an octave above middle C, OR do you like the G an octave above middle C? (H2 and H3 are both musically related- an octave, and 1 octave and a perfect 5th above the fundamental respectively)

So I fail to see how it EVER be correlated with strong preferences towards one (H2) or the other (H3) in any population sample.

But suppose there is other distortion (not THD, H2 or H3) that has some relevance, then it's important that tests are done appropriately. For instance, in this post @shrub0 works hard to test IMD. I had concerns about the methodology, but I did not yet have a better proposal. In the first instance, the frequency responses should be equalized to be the same. But if a tester would like to test IMD, it should NOT be done at 1.5m- It should be done as close as practically possible to eliminate room influences. But not too close that the microphone is clipping. I can give you a handful of websites that publish distortion measurements of drivers, but it turns out the problem was the microphone. Better no data than bad data.

I leave it readers to decided whether IMD should be done at all, and whether the driver should be mounted in a quasi-IB, or a box, and what size box etc.

I also leave it to other readers and people with more experience than me to propose alternative or better methods than IMD, or multi-tone, M-noise, or IEC 60268-21...

But don't distort the microphone if you're trying to take distortion measurements <-> don't take distortion measurements if your microphone/method can't take them properly! Don't ask me how I know!🤣

The question of adequate or sufficient is different to the question of more accuracy or precision.

Whether you want to precisely measure a mass of 1 kilogram or whether I want an approximation to get my luggage onto an airplane, I understand. Building the world's quietest anechoic chamber doesn't mean the ability to design a better speaker, I get that.

But unless we can accurately measure what we are talking about, then one must be careful of drawing too many conclusions.

In this post, I made no proposal about what the future research should be. To be sure, repeated tests have already shown that H2 and H3 (and thus THD) ARE NOT related to listening preferences. Personally, I would say that is pretty obvious, and doesn't even need empirical testing. Why? Because H2 and H3 are musically related. It's like saying, Do you like the C an octave above middle C, OR do you like the G an octave above middle C? (H2 and H3 are both musically related- an octave, and 1 octave and a perfect 5th above the fundamental respectively)

So I fail to see how it EVER be correlated with strong preferences towards one (H2) or the other (H3) in any population sample.

But suppose there is other distortion (not THD, H2 or H3) that has some relevance, then it's important that tests are done appropriately. For instance, in this post @shrub0 works hard to test IMD. I had concerns about the methodology, but I did not yet have a better proposal. In the first instance, the frequency responses should be equalized to be the same. But if a tester would like to test IMD, it should NOT be done at 1.5m- It should be done as close as practically possible to eliminate room influences. But not too close that the microphone is clipping. I can give you a handful of websites that publish distortion measurements of drivers, but it turns out the problem was the microphone. Better no data than bad data.

I leave it readers to decided whether IMD should be done at all, and whether the driver should be mounted in a quasi-IB, or a box, and what size box etc.

I also leave it to other readers and people with more experience than me to propose alternative or better methods than IMD, or multi-tone, M-noise, or IEC 60268-21...

But don't distort the microphone if you're trying to take distortion measurements <-> don't take distortion measurements if your microphone/method can't take them properly! Don't ask me how I know!🤣

Last edited:

@tktran303

You're forgetting some extremely important parameters;

- The minimum amount of resolution needed (in decibels) to be actually able to detect correlated distortion as well as uncorrelated distortion. (or poorly correlated)

Besides all the technical numbers, we also have to take psycho-acoustics into consideration with things like masking and placebo effects.

Without quantifying ANY of the above, all is nothing more than just a wild guessing game without holding any actual objective data. Including the importance of certain (even or uneven) harmonics.

To put that again in some context.

If the background noise in a room is already about 30dB(A) (= totally uncorrelated noise), I don't really see how distortion levels that are even 24dB lower than that are of much significance?

These are totally being swallowed up and therefore masked by the background noise.

I think most people are even having a difficult time to be able to hear much of anything 6-12dB below the background noise.

Again, it's not about how accurate you CAN measure things.

It's about getting a good definition about how much accuracy is needed!

That definition here is poor at best, mostly being blurred by peoples subjective believes than anything else.

That's a totally personal, vague and subjective word at this point.

I have used cheaper mics for these kind of purposes in the past and they were totally fine predicting the loudspeakers behavior enough for designing adequate crossover filters.

Were the absolute numbers accurate?

No, but that is also absolutely not needed to design a good crossover filter and predicting a loudspeaker's performance etc.

You're forgetting some extremely important parameters;

- Background noise of the room

- Self-noise of our ears

- Distortion of our ears as function of SPL and frequency

- The minimum amount of resolution needed (in decibels) to be actually able to detect correlated distortion as well as uncorrelated distortion. (or poorly correlated)

Besides all the technical numbers, we also have to take psycho-acoustics into consideration with things like masking and placebo effects.

Without quantifying ANY of the above, all is nothing more than just a wild guessing game without holding any actual objective data. Including the importance of certain (even or uneven) harmonics.

To put that again in some context.

If the background noise in a room is already about 30dB(A) (= totally uncorrelated noise), I don't really see how distortion levels that are even 24dB lower than that are of much significance?

These are totally being swallowed up and therefore masked by the background noise.

I think most people are even having a difficult time to be able to hear much of anything 6-12dB below the background noise.

And so therefor this statement isn't true I think.But unless we can accurately measure what we are talking about, then one must be careful of drawing too many conclusions.

Again, it's not about how accurate you CAN measure things.

It's about getting a good definition about how much accuracy is needed!

That definition here is poor at best, mostly being blurred by peoples subjective believes than anything else.

And again, define "properly" ?But don't distort the microphone is you're trying to take distortion measurements. (don't take distortion measurements if your microphone/method can't take them properly!)

That's a totally personal, vague and subjective word at this point.

I have used cheaper mics for these kind of purposes in the past and they were totally fine predicting the loudspeakers behavior enough for designing adequate crossover filters.

Were the absolute numbers accurate?

No, but that is also absolutely not needed to design a good crossover filter and predicting a loudspeaker's performance etc.

Last edited:

Yes. Almost any back-electret capsule will do, provided that the internal JFET gain stage can be modified to be a follower (the famous Linkwitz mod, but he references an HP engineer named Lyman Miller as the original inventor of the mod).The next question we hope is answer is, HOW can we measure distortion in frequencies below Schroeder in the nearfield? Can it be done with anything less than $/€1300 Earthworks M50, or a 1/4 B&K or G.R.A.S capsule? (Pricing On Application- 4 figures)

See also https://www.firstpr.com.au/rwi/mics/2009-09-b/, where a specific gain drift phenomenon was observed one has to be aware of when using self-polarized capsules.

Personally I'm happy owner of a Mikrotechnik Gefell MK301 1/4" capsule with a B&K 2639 clone mic-body preamp + supply unit. The MK301 was tested as one of the lowest distortion capsules ever in German magazine "Production Partner" in 2009.

This mic is of course very low sensitivity but more importantly the mic-body is really horribly sensitive to shock and vibration and needs extreme care in use to avoid vibration pickup spoiling the measurements.

I use the Palmer PAN 48.2 - always works perfectly. It's actually not hard to make a proper 48V supply - use a useful regulator and big enough cap (before the resistors of course.) Every metal lfilm resistor has low enough resistance and since they need to be symmetrical they need to be AT LEAST 1% tolerance.For measurements, I've built a battery source as 48V phantom supply consisting of 5 x 9V Duracell batteries in series fed by 6.8k holco resistors and filtered with 10uF stacked plate PP caps. The feed resistors alone can contribute a few dB of self noise depending on the current draw of the mic and rejection ratio of the mic's internal preamp.

But when you introduce a few dB of noise with the phantom power ... there is something really wrong with your circuit.

There was the practice to use a 300-500R resistor, then your filter cap and then the 6k8 feeding resistors. But you don't have a correct suppy that way, when the mic draws a lot of current you loose some supply voltage. You already are on the very low side with 5x9V (44-52V is the range when I remember right)Its important to understand that all 9V batteries are capable of producing a little LF noise - I prefer the Duracell brand because they have spot welded cell contacts as opposed to contacts made by simply just stacking individual cells loosly on top of each other. The contact resistance causes measurable noise, which easily worsens an electret mic's noise floor. Something as simple as a battery can hurt mic performance. Its also important not to place the filter caps after the 6.8k resistors, as this can cause discharge current transients in the FET preamp circuits. I read some of these potential problems in a paper written by Rupert Neve himself.

You can lower the 6k8 to compensate but that will give a little more load to your mic - probably no big problem cuase they should be designed for 1-2,2K input impedance of mic preamps.

Yes, this improves the mic capsule an performance a lot!Yes. Almost any back-electret capsule will do, provided that the internal JFET gain stage can be modified to be a follower (the famous Linkwitz mod, but he references an HP engineer named Lyman Miller as the original inventor of the mod).

I also have a few of these preamps + capsules somewhere around. Even built a power supply ... let's see if this still works.Personally I'm happy owner of a Mikrotechnik Gefell MK301 1/4" capsule with a B&K 2639 clone mic-body preamp + supply unit. The MK301 was tested as one of the lowest distortion capsules ever in German magazine "Production Partner" in 2009.

👍Besides all the technical numbers, we also have to take psycho-acoustics into consideration with things like masking and placebo effects.

YOUR room and the average room may be 30dB(A) noise ... but we are not talking about average systems here?To put that again in some context.

If the background noise in a room is already about 30dB(A) (= totally uncorrelated noise), I don't really see how distortion levels that are even 24dB lower than that are of much significance?

A dedicated home cinema room is dampened and can go down way lower, esp in the evening. In a proper built house not in the city with no air condition on 10dB(A) at night should be relatively easy possible.

I'm not aiming at average living rooms with my designs - so I need better electronics with less noise. And lower THD would be good too.

6-10dB below noise you should be able to hear sinusoid signals without to much problems. But THD is way harder to hear.I think most people are even having a difficult time to be able to hear much of anything 6-12dB below the background noise.

How boring ... 🤓Again, it's not about how accurate you CAN measure things.

It's about getting a good definition about how much accuracy is needed!

Seriously - when I do developments I need to measure the performance of the speaker. I need to do a datasheet, do quality control when building a few of them. I need at least a 10dB better measurement chain as what I want to measure.

At least 10dB better as what you want to measure to have a "measurement". 20dB to get serious.That definition here is poor at best, mostly being blurred by peoples subjective believes than anything else.

And again, define "properly" ?

Adding for e.g. a 20dB and 30dB uncorrelated signal you get 30,5dB - already 0,5dB error. 17dB difference keeps you <0,1dB error.

Good enough for DIY filter designing - yes!I have used cheaper mics for these kind of purposes in the past and they were totally fine predicting the loudspeakers behavior enough for designing adequate crossover filters.

Were the absolute numbers accurate?

No, but that is also absolutely not needed to design a good crossover filter and predicting a loudspeaker's performance etc.

But there is more in the world of acoustic design and measurement as that. Just evaluating good drivers is already out of the task of a cheap measurement mic. These popular IMD measurements. Look what's above 20kHz. Everything low noise/high SPL.

The main reason I used batteries in my phantom supply was for portability and ground isolation. With the discharge curve of alkaline 9V batteries, you'd switch them out once they get close to 1.5V per internal cell. After that point I'd use the partially discharged batteries in other non-critical applications to reduce waste ie. in multimeters, etc.

Most phantom supplies were made with sloppy zener diode regs or ones with zener references, so they weren't as quiet as the battery setup. Shunt reg circuits worked the best, but needed more current for lower noise levels. With the 5 x 9V setup, battery life was good running a pair of small condensers for 10+.hrs until you reached 45V under load.

Other rechargeable batteries such as NI-mH were very noisy and had a bad discharge curve. Nowadays you have Li-on battery chemistry which is superior and very suited to audio use. Battery management can screw things up, but are necessary and unavoidable for safety reasons.

A decent DC-DC converter isn't that easy to design in terms of noise performance. Using an RC stage in front of the feed resistors is common practice. With alkaline batteries its not needed. Just a small organic polymer 10uF cap will do. The discharge curve wasn't an issue for me as the gradual discharge didn't noticeably affect mic performance at all. Loading the capsule properly makes the biggest difference in THD. Resistor quality also matters. You wouldn't want to use a high temp coefficient carbon film in series with a decent amount of voltage drop. It generates alot of noise.

Most inverter step up circuits I tried were susceptible to introducing noise. I used an LM3524 circuit a few times with reasonable success, but it wasn't as clean as the battery setup. TDK made decent DC-DC modules, but they were expensive and didn't regulate very tightly.

Most phantom supplies were made with sloppy zener diode regs or ones with zener references, so they weren't as quiet as the battery setup. Shunt reg circuits worked the best, but needed more current for lower noise levels. With the 5 x 9V setup, battery life was good running a pair of small condensers for 10+.hrs until you reached 45V under load.

Other rechargeable batteries such as NI-mH were very noisy and had a bad discharge curve. Nowadays you have Li-on battery chemistry which is superior and very suited to audio use. Battery management can screw things up, but are necessary and unavoidable for safety reasons.

A decent DC-DC converter isn't that easy to design in terms of noise performance. Using an RC stage in front of the feed resistors is common practice. With alkaline batteries its not needed. Just a small organic polymer 10uF cap will do. The discharge curve wasn't an issue for me as the gradual discharge didn't noticeably affect mic performance at all. Loading the capsule properly makes the biggest difference in THD. Resistor quality also matters. You wouldn't want to use a high temp coefficient carbon film in series with a decent amount of voltage drop. It generates alot of noise.

Most inverter step up circuits I tried were susceptible to introducing noise. I used an LM3524 circuit a few times with reasonable success, but it wasn't as clean as the battery setup. TDK made decent DC-DC modules, but they were expensive and didn't regulate very tightly.

It's disappointing to me that the M215 varies so much. I currently have a rather old ECM-8000 that was not calibrated. I'd like to get something better and had pretty much settled on the M215. In the past, I basically only cared about frequency response, phase and impedance. My frequency response measurements were relative. Moving forward, I'd like to add directivity and distortion as design parameters. It makes sense to me that doing distortion measurements implies (if not requires) absolute output level measurement, but that doesn't seem like a deciding factor between mics. With respect to distortion, I'm just trying to optimize my speaker for the drivers I've selected - which are quite low distortion according to the manufacturers and HiFiCompass data. So, perhaps I don't need distortion measurements that will push the mic into its limits. I certainly won't be driving the speaker above 105 dB very often, if ever.

Given all that, does the M215 variability matter for my use case(s)? Is there a better, similarly priced option? I don't think I want to get into DIY mics or mods. My soldering days are pretty much over. Should I send whatever I buy to Cross Spectrum Labs or purchase it through them?

Given all that, does the M215 variability matter for my use case(s)? Is there a better, similarly priced option? I don't think I want to get into DIY mics or mods. My soldering days are pretty much over. Should I send whatever I buy to Cross Spectrum Labs or purchase it through them?

No THE average room is around 30dB(A), 10dB(A) is far from being average.YOUR room and the average room may be 30dB(A) noise ... but we are not talking about average systems here?

A dedicated home cinema room is dampened and can go down way lower, esp in the evening. In a proper built house not in the city with no air condition on 10dB(A) at night should be relatively easy possible.

Just check all kinds of literature (as well as practical measurements) for this.

Great, perfect, wonderful and incredible if you're aiming for that that! 👍I'm not aiming at average living rooms with my designs - so I need better electronics with less noise. And lower THD would be good too.

But if we go back into the discussion, you were putting a general claim and statement (= average!) out there, that those kind of expensive mics are absolutely mandatory for more expensive systems.

Can we please agree on something for the future?

And this most certainly is not focused on you, but everyone else.

Make extremely clear from the beginning that what you're looking for is extremely specific and niche, specifically for YOUR needs.

Doesn't matter if those needs are subjective or objective.

Including your very specific environment as well.

But it's just extremely confusing, also for the average reader, to understand this when such strong statements are being made.

Me too, I do it on a regular basis since it's my job.Seriously - when I do developments I need to measure the performance of the speaker. I need to do a datasheet, do quality control when building a few of them. I need at least a 10dB better measurement chain as what I want to measure.

Can't say that I NEED all these kinds of measurements for the majority of designs.

Going from bluetooth solutions, hifi, studio all the way to sound-reinforcements (PA).

Sometimes I do, but in that case it's a lot more convenient and cheaper to get it done by a 3rd party instead of wasting my own time and the clients money for trying to reinvent the wheel for a day or two.

In the last 15 years, those occasions have been rare and very niche, but sure they do exist.

And the results of most of those occasions where rather confirmation than getting entirely new data out.

If that is something you enjoy doing, totally go for it.

But once again, going back to your previous statement that such equipment is absolutely necessary.

No, just no.

Oh and btw, I am not talking about "just a DIY-design"......

Although looking at results from guys like Erin's Klippel measurements as well as my own experience, the DIY community has been doing heaps better the last two decades than most professionals to be perfectly honest.

My test setup includes a Audio Precision APx 1701 transducer test interface and a assortment of GRAS and other microphones.

It looks to me that all this blustering, yes butting about microphone distortion in the woofer / sub-woofer Hz range is just a bunch of smoke. A measuring contest among the boys.

In my experience leave out the pressure chamber, room reflections, noise, you know all those distractions and measure distortion across a 0.1R resistor in series with the DUT. Distortion measured across a series resistor has a high correlation to driver acoustic distortion without the $10,000 plus investment in microphones and microphone amplifiers. This is current distortion I am speaking of.

Remember that X-Max for woofers is measured at 10% distortion. Makes 2% microphone distortion look small. Keeping the measuring contest among the boys in mind.

Thanks DT

It looks to me that all this blustering, yes butting about microphone distortion in the woofer / sub-woofer Hz range is just a bunch of smoke. A measuring contest among the boys.

In my experience leave out the pressure chamber, room reflections, noise, you know all those distractions and measure distortion across a 0.1R resistor in series with the DUT. Distortion measured across a series resistor has a high correlation to driver acoustic distortion without the $10,000 plus investment in microphones and microphone amplifiers. This is current distortion I am speaking of.

Remember that X-Max for woofers is measured at 10% distortion. Makes 2% microphone distortion look small. Keeping the measuring contest among the boys in mind.

Thanks DT

Given all that, does the M215 variability matter for my use case(s)? Is there a better, similarly priced option? I don't think I want to get into DIY mics or mods. My soldering days are pretty much over. Should I send whatever I buy to Cross Spectrum Labs or purchase it through them?

@Paul Ebert

CSL is on hiatus with electronic compensation files at the moment. And whilst no one is asserting that we need an AP or G.R.A.S. capsule to do crossover work, your question is exactly what I’m looking to answer. Which is why I reached out to @IamJF for his help.

In my preliminary survey, it appears that

0) ECM8000 works. Anyone who can design a crossover can work around lack of compensation file with this high value mic.

a) Sonarworks Xref20 / Sound ID Reference has a dependable frequency response compensation file from the manufacturer. The 2024 model has max SPL of 124dB and self noise of 29dB. The previous models released in 2015 (Xref20) and 2021 (Sound ID Reference) have 128dB and 24dB respectively.

If maximum SPL and noise floor doesn't matter to you, purchase any model. (~Є/USD 100)

b) Line Audio Omni1 doesn't come with a frequency response compensation file. But is specified at +/- 1dB across 20Hz to 20KHz. It has lower self noise, and can resolve H2 about 5-6dB better than the SoundID Reference. (~Є/USD 200)

c) Audix TM1 / TM1 Plus. The Plus model means that manufacturer supplies the frequency response compensation file. This microphone also appears to measure resolve distortion well. (~Є/USD 300)

Some experienced professionals in this thread seem to be suggesting that it doesn't really matter. Stick with your ECM8000.

Although they have laboratory grade precision equipment, it is not necessary at all to do a speaker design. I get that point of view.

Some people don't do measurements, I also get that point of view.

Last edited:

Could you please expand on this?My test setup includes a Audio Precision APx 1701 transducer test interface and a assortment of GRAS and other microphones.

It looks to me that all this blustering, yes butting about microphone distortion in the woofer / sub-woofer Hz range is just a bunch of smoke. A measuring contest among the boys.

In my experience leave out the pressure chamber, room reflections, noise, you know all those distractions and measure distortion across a 0.1R resistor in series with the DUT. Distortion measured across a series resistor has a high correlation to driver acoustic distortion without the $10,000 plus investment in microphones and microphone amplifiers. This is current distortion I am speaking of.

Remember that X-Max for woofers is measured at 10% distortion. Makes 2% microphone distortion look small. Keeping the measuring contest among the boys in mind.

Thanks DT

I would like to see more details on the pressure chamber. I'm interested in duplicating it. B&K's high SPL tester will go quite high but their focus is 4% distortion. I'm going through my microphones doing the full SPL and response calibration. It would be interesting to add HD. The IM testing Bwaslo mentioned is quite valid. Also Both HD and IM are symptoms of fundamental nonlinearity and the nonlinearity will cause both distortions.

The 4133 is spec'ed at 160 dB SPL for 4% THD. At those levels air is quite nonlinear so separating the origin of the distortion products is important.

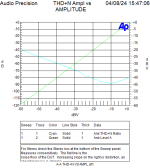

The distortion measurements struck me as unusually low. In my experience the preamps have more distortion before adding a transducer.

I have a pretty extensive collection of measurement microphones as well. I have measured B&K, HP and GR preamps.

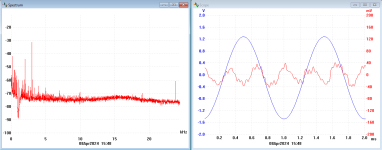

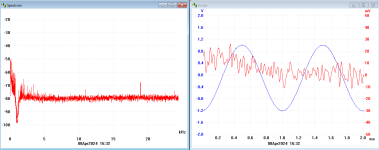

Here are measurements I just made of a B&K 2639 preamp + WB 1057 power supply.

The 4133 is spec'ed at 160 dB SPL for 4% THD. At those levels air is quite nonlinear so separating the origin of the distortion products is important.

The distortion measurements struck me as unusually low. In my experience the preamps have more distortion before adding a transducer.

I have a pretty extensive collection of measurement microphones as well. I have measured B&K, HP and GR preamps.

Here are measurements I just made of a B&K 2639 preamp + WB 1057 power supply.

Attachments

- Home

- Loudspeakers

- Multi-Way

- Distortion in Measurement Microphones - actual measurements