gedlee said:

This is not the correct experiment. Its biased to highlight the advantages of your approach. Put two rods across the box and glue them at the center. Now which one yields the most strength for weight and volume of the stiffener? And when you use very flimsy materials then the stiffness increase does not show up for the rod as well as when the materials are stronger. You need a fair test to make judgements from.

Structure is structure, no matter what you use.

I think it's pretty obvious that mine would still be vastly stronger.

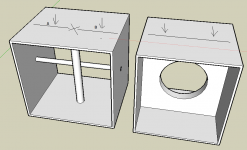

All of the panels are effective cut in half, driving resonance up. Consider force applied at points A and B on both boxes.

Attachments

gedlee said:

And you ignored the part about joining two or three rods at the center - now they can't move in ANY direction. Net result - enormous lowering of cabinet wall motion with very little added weight or loss of interior volume. There simply is no more effective method of stiffening than this - trust me! (or don't I don't care.)

They can move, they can rotate. Could be of partial interest if intersection is not exactly axial (in fact it isn't) and if the loading is not symmetric (I think this could happen for frequencies where one or more box dimensions are comparable to the wavelenght). I don't know if this is REAL problem. If it is, anyway, there is no easy solution.

Bearing capacity of the 1'x1' rod under compession is given usually more by its slenderness ratio. I want to point out that if only two are fixed the slenderness ratio remains virtualy the same. Only if three braces are fixed they behaves as a 3D structure, the slenderness of each is lowered, say, 4 times at least. Bearing capacity of material could be taken into account only if slenderness is no longer limiting factor.

Can you tell how thick/compliant CL you use/makes sense?gedlee said:

But this too I deal with by simply making the front baffle two pieces of MDF 3/4" and 1/2" glued together with a well damped glue. The baffle doesn't move from mechanical forces and the walls don't move from pressure forces. Thats what an enclosure is supposed to do.

MJL21193 said:

Structure is structure, no matter what you use.

I think it's pretty obvious that mine would still be vastly stronger.

All of the panels are effective cut in half, driving resonance up. Consider force applied at points A and B on both boxes.

If I can use the same amount of material as in second box, you'll loose. 🙂 The braces with circular window is very ineffective. Weak where they should be strong and strong where not needed.

MethMan said:

If I can use the same amount of material as in second box, you'll loose. 🙂 The braces with circular window is very ineffective. Weak where they should be strong and strong where not needed.

Wow. There seems to be a real lack of basic structural design understanding on this forum.

What more can I say? You guys have all of the answers - the wrong ones.

MJL21193 said:

Structure is structure, no matter what you use.

I think it's pretty obvious that mine would still be vastly stronger.

All of the panels are effective cut in half, driving resonance up. Consider force applied at points A and B on both boxes.

Just put a single additional brace from the center of the + to one of the inside edges in the same plane as the + brace. Then we can all live in harmony.

bridges are built with truss structures. they aren't rectangular open sections, they are always triangular. no degrees of freedom.

I think the big debate is that you're arguing different points. the center rods will prevent box expansion, ie all panels flexing either out or in. The sheet brace (which could be optimized, I agree) braces against shear and same-direction flex in opposing panels.

I suppose if you had a box that had no net force on it other than inside and outside pressure, the orthogonal rods would be plenty.

y8s said:

Just put a single additional brace from the center of the + to one of the inside edges in the same plane as the + brace.

The circular cut out doesn't need braces across., it uses a pretty old and well known design feature: the arch.

I might not agree with Dave's stance on MDF, but I'll give him this: he seems to have a pretty good understanding of how to make a strong enclosure.

pooge said:

Hmmm. I didn't expect this response. Since it is pretty well known that bending stiffness is a lot better for a curved panel than a flat panel, so I'm not sure if we are on the same subject.

I see what you are talking about now. Not very easy to do, especially to solve a problem thats not really a problem.

Lots of patents out there - how many address a real problem with an effective solution? 10%, 5%, 1% ? Maybe more in the corporate world I suppose.

Well, I like the old method of reinforcing all corners/joints with solid wood sticks...and if you like sticks anywhere else...stick to that...personally I thought I had gone a little further...well, maybe not 😀

btw...there is such a "stick" in a violin, called "the soul"...it connects top to bottom, with a light pressure...the funny thing is that without it the violin says next to nothing...ahh, yes the top and bottom are strongly curved...but also very thin(3-5mm)...oh my, different kind of wood incorporated too...and it still sings

btw...there is such a "stick" in a violin, called "the soul"...it connects top to bottom, with a light pressure...the funny thing is that without it the violin says next to nothing...ahh, yes the top and bottom are strongly curved...but also very thin(3-5mm)...oh my, different kind of wood incorporated too...and it still sings

MJL21193 said:

The circular cut out doesn't need braces across., it uses a pretty old and well known design feature: the arch.

I might not agree with Dave's stance on MDF, but I'll give him this: he seems to have a pretty good understanding of how to make a strong enclosure.

I understand the arch. distributes the load at the center to the sides.

I think earl's biggest criticism is the large flat sheets in there. his 'rods' are nearly acoustically invisible (test it with a broom handle in front of your speakers sometime).

now if you were able to make your arch of thin steel rod or even a hoop of steel that touched all four walls, that'd be neat and not obstruct anything. a spherical skeleton inside a rectilinear box.

OK, since I have modelled in FEA, built and mechanically tested in multiple axis the side panel construction presented by Dave (planet10), and furthermore am a Professional Engineer registered in both the USA and Canada, let me make a couple of comments.

First of all, yeah, I know, with the anonymity of the internet anybody can claim to be anything, so my statement of qualifications etc... aren't worth anything, so let's not beat that dead dog to death all over again.

Second, the side panels as Dave has designed them are very stiff in both lateral and vertical bending, showing nearly negligible difference between axis in 3 point bend testing. MJL21193 made the analog to cardboard structure to argue that the bracing would only add support in the lateral axis. However, in bending collapse, the critical stress level (not load, I really mean stress) for buckling is dependent on the wall thickness of the outer sandwich layers. Because the outer layers of Dave's sidewall design has substantial thickness in realation to the total sandwich thickness, the effect of the directional orientation of the core bracing becomes negligibly small.

The third comment I will make is that it is possible for an internal brace to increase the stiffness of Dave's sidewall panels, but in order for the difference to be non-negligible, the brace would be dimensionally large enough that it would create substantial internal acoustic interference that would negate any benefit that the brace might achieve.

Lastly, I'll enter the dangerous waters of the Gedlee vs. MJL21193 argument over direct versus arched support bracing. I have to agree with Gedlee, and long history of structures supports this. Direct support (i.e. a pole brace to transmit force) is always more effective that an arch support. Yes, the romans did amazing things with arches, but look at where they used them: a) to span a gap where no central load supporting point was avalaible, b) to leave an open span as a passageway, and c) to minimize material usage in a solid structure. Also keep in mind that the Romans were very fond of columns as well. As Gedlee has correctly pointed out, for equivalent load support, a direct support will always use less mass and smaller cross-section than an arch support.

Now, MJL21193 will reargue that this only applies if the cabinet walls are moving outward in phase, but provide no support if one wall is moving outward while the opposite is moving inward. And he'll be right. Except that pressure waves inside a box will push evenly on all local surfaces. Yes, I know that pressure will vary at different positions inside a speaker cabinet at any given moment, but again the panel thickness comes into play, and unless the wavelength of the pressure wave is roughly four times the thickness of the panel or greater, the panel will nicely average the pressure across the panel surface. Which for any half-decently designed speaker cabinet means that for any frequency that could induce parallel side panel movement, the wavelenght is long enough that the internal cabinet surfaces will be seeing pressure or vacuum, but in a relatively uniform fashion. Thus oppositely located wall will move outward in phase, making a direct brace effective.

Well, my two cents. I now return you to your regularly scheduled discussions.

Terry

First of all, yeah, I know, with the anonymity of the internet anybody can claim to be anything, so my statement of qualifications etc... aren't worth anything, so let's not beat that dead dog to death all over again.

Second, the side panels as Dave has designed them are very stiff in both lateral and vertical bending, showing nearly negligible difference between axis in 3 point bend testing. MJL21193 made the analog to cardboard structure to argue that the bracing would only add support in the lateral axis. However, in bending collapse, the critical stress level (not load, I really mean stress) for buckling is dependent on the wall thickness of the outer sandwich layers. Because the outer layers of Dave's sidewall design has substantial thickness in realation to the total sandwich thickness, the effect of the directional orientation of the core bracing becomes negligibly small.

The third comment I will make is that it is possible for an internal brace to increase the stiffness of Dave's sidewall panels, but in order for the difference to be non-negligible, the brace would be dimensionally large enough that it would create substantial internal acoustic interference that would negate any benefit that the brace might achieve.

Lastly, I'll enter the dangerous waters of the Gedlee vs. MJL21193 argument over direct versus arched support bracing. I have to agree with Gedlee, and long history of structures supports this. Direct support (i.e. a pole brace to transmit force) is always more effective that an arch support. Yes, the romans did amazing things with arches, but look at where they used them: a) to span a gap where no central load supporting point was avalaible, b) to leave an open span as a passageway, and c) to minimize material usage in a solid structure. Also keep in mind that the Romans were very fond of columns as well. As Gedlee has correctly pointed out, for equivalent load support, a direct support will always use less mass and smaller cross-section than an arch support.

Now, MJL21193 will reargue that this only applies if the cabinet walls are moving outward in phase, but provide no support if one wall is moving outward while the opposite is moving inward. And he'll be right. Except that pressure waves inside a box will push evenly on all local surfaces. Yes, I know that pressure will vary at different positions inside a speaker cabinet at any given moment, but again the panel thickness comes into play, and unless the wavelength of the pressure wave is roughly four times the thickness of the panel or greater, the panel will nicely average the pressure across the panel surface. Which for any half-decently designed speaker cabinet means that for any frequency that could induce parallel side panel movement, the wavelenght is long enough that the internal cabinet surfaces will be seeing pressure or vacuum, but in a relatively uniform fashion. Thus oppositely located wall will move outward in phase, making a direct brace effective.

Well, my two cents. I now return you to your regularly scheduled discussions.

Terry

metalman said:

Well, my two cents. I now return you to your regularly scheduled discussions.

Terry

The full panel need not have a single large hole, but could have many small hole ( Dave's holy brace). It could have the holes shaped like triangles, or squares or kidney beans. It doesn't have to be of significant mass, with much of this taken away with the holes. It doesn't need to be oriented vertically either, but as I originally proposed, horizontally, therefore not providing a reflective surface.

If you all feel the best way to stop side walls of cabinets from resonating is to us a wood dowel, that's fine. Chances are I'll never have to hear one of your creations anyway.

If the points I have made don't sit well with you, that's cool also. Some of the points I did make are so common and established in my world that sometimes I forget that there are others who don't grasp things in the same way.

Earl, you have your way of doing things and I apologize for being critical of it. It is not my purpose here to show up anyone or belittle their knowledge.

HiFiNutNut said:Dr. Gedlee,

What glue do you use for CLD?

Regards,

Bill

I've used different kinds and find different results. In theory I would prefer a glue like Liquid Nails for sub floors because of its high damping. But I found this glue to not be dimensionally stable and would crack with humidity, etc. Then I used Polyurethane glue, same result with dimensional stability, but not nearly as bad. Then Epoxy, which is the best so far, but tends to be very rigid with no damping.

I discovered a way to modify the epoxy to make it more flexible and well damped and I am using this at the moment, but don't have a lot of experince with it.

Given its ready availability I would recommend epoxy - go to US Composites for this at great prices.

I should mention that for Stictly CLD, Liquid nails does work well if you don't have to rely on its for stability. That means for corners etc. its isn't good, but to bond two panels it does work very well.

And thanks Metalman. No one but me may believe you, but at least the two of us agree 🙂 But if science were a democracy, we would probably be voted out.

These guys might be useful at sometime.

http://www.masterbond.com/index.html

Somehow or another I got on their mailing list and i get a monthly newsletter which is often really interesting so I've never canceled it.

http://www.masterbond.com/index.html

Somehow or another I got on their mailing list and i get a monthly newsletter which is often really interesting so I've never canceled it.

Originally posted by pooge On the other hand, 1/8 in hardboard would be much cheaper, easier to work with, and still might have very adequate tensile strength.

B&W seems fine with multiple layers of thin plywood along with heroic bracing.

dave

CLD adhesives

Polysulfide-epoxy alloys worked well for elastomeric but stable bonding when I was at Bell Aerospace back in the late '70's, when we needed stable but flexible bonds for fairings, etc. I believe Masterbond has such formulations available commercially.

John L.

Polysulfide-epoxy alloys worked well for elastomeric but stable bonding when I was at Bell Aerospace back in the late '70's, when we needed stable but flexible bonds for fairings, etc. I believe Masterbond has such formulations available commercially.

John L.

gedlee said:If I connect the side walls, for example, with an oak rod at the centers, then for all practical purposes the centers of those walls can't move.

Makes me think of a giant one of these:

An externally hosted image should be here but it was not working when we last tested it.

dave

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Discussion arising from Geddes loudspeaker