metalman said:the side panels as Dave has designed them are very stiff in both lateral and vertical bending, showing nearly negligible difference between axis in 3 point bend testing.

Thanx Terry.

How are things going in Calgary?

dave

I got this one through searching on "viscoelastic" in wikipedia :

http://quietsolution.com/html/quietglue.html

http://quietsolution.com/html/quietglue.html

metalman said:

Second, the side panels as Dave has designed them are very stiff in both lateral and vertical bending, showing nearly negligible difference between axis in 3 point bend testing.

B]

So the side walls of Dave's Fonken are stiff enough? They don't resonate?

metalman said:

Direct support (i.e. a pole brace to transmit force) is always more effective that an arch support.

One support on one bearing surface is better than two or more? Interesting.

metalman said:

Yes, the romans did amazing things with arches, but look at where they used them:

a) to span a gap where no central load supporting point was avalaible,

b) to leave an open span as a passageway, and

c) to minimize material usage in a solid structure. Also keep in mind that the Romans were very fond of columns as well. As Gedlee has correctly pointed out, for equivalent load support, a direct support will always use less mass and smaller cross-section than an arch support.

a),b) and c) My point wasn't about arches. It's about triangular bracing, using a full panel. If it has circular holes in it then it has arches.

planet10 said:

B&W seems fine with multiple layers of thin plywood along with heroic bracing.

dave

That was the first thing that came to mind. If you look, I think that you'll find that there will be little surface area facing the driver that might create reflections, but it's not always thin plywood. The braces are oriented such that any side-to-side or top-to-bottom bracing has only an edge facing the driver. The examples shown of simple shelf braces or even those with curves have far more reflective area than any of those in the B&W boxes. Most of the brace is occluded from the perspective of the driver in their boxes, essentially being very similar to the area of simple rods.

If you read their paper on the 800D you'll see some interesting comments and pictures.

"The inertness of the cabinet is further enhanced by using 38mm thick panels, also contributing significant mass.". This certainly doesn't look like they're much for thin panels with a lot of bracing. They like thick, massive panels with significant bracing, not necessarily light, either. The pictures makes it look like a 3/8" or 1/2" thick composite material in the matrix.

"In general, at low frequencies the stiffness of the walls dominates their behavior, while at high frequencies it is their mass which rules."

"The mass of panels can be increased simply through the use of dense material...but these are all definitely for the DIY enthusiast." I read that to say that increased mass may work easily or better, but that it's not an option for a large OEM, probably due to shipping costs and the fact that some buyers just don't want to have to handle the weight.

"By increasing both the mass and the stiffness, the lowest point in the curve corresponding to the minimum transmission loss may be brought up to reasonable levels.". This doesn't sound like light, but braced philosophy, it sounds to me like thick (enough) and braced.

"The B&W CM1 for instance traded mass for stiffness by using a rigid phenolic resin cabinet, which shifts the resonances well out of band.". Intentional use of resonance to make it insignificant for the application (bandpass of the driver). Not haphazard, that's for sure.

There's a lot more interesting reading including more than one reference to "strategic" placement of bracing. In the end, it's all in the execution for the level of performance desired with whatever tradeoffs (non-optimal methods, but sufficient) may be necessary.

Dave

peufeu said:I got this one through searching on "viscoelastic" in wikipedia :

http://quietsolution.com/html/quietglue.html

I have used GE clear silicone caulking for the glue in my CLD. It's a strong adhesive and it's resilient, providing a lossy layer between sheets.

Worked very well.

Attachments

MJL21193 said:So the side walls of Dave's Fonken are stiff enough? They don't resonate?

Of course they resonate. That can never be completely eliminated. However, their resonance frequence is relatively high, and resonably damped. Further bracing would not have a significant impact on either.

One support on one bearing surface is better than two or more? Interesting.

Oversimplifying what I posted. For an equivalent increase in panel reinforcement, an arch reinforcement will have to be larger, creating a greater impact on internal cabinet acoustics.

a),b) and c) My point wasn't about arches. It's about triangular bracing, using a full panel. If it has circular holes in it then it has arches.

This is essentially semantics. I would consider corner bracing to be a subset of an arch. The point in an unsupported panel of greatest amplitude movement is the center. By placing a direct support at that point, it maximizes the supports ability to restrain that resosnance. Corner supports will also restrain that resononce, but must be larger as they are applying restrain via a moment arm rather than directly.

But then again, I'm not to proud to say that I may be missing your point. If perhaps you could reword your thoughts in a different example, I may grasp your arguement better.

Originally posted by planet10

Thanx Terry.

How are things going in Calgary?

Things are going pretty good. I miss the coast though, and my diyAudio buddies there (Hey Cal!). I just finished building a pair of Troels Gravesens CNO's (well at least far enough for them to be playable, much finishing work still left) and am in the process of breaking in the drivers. Sounds pretty promising so far. Otherwise my new job has been keeping me way too busy, and renovating the new house has taken most of the rest of my time.

Keep me in the loop for the next IslandFest, and I'll try to arrange a trip over with goodies to play with.

Originally posted by gedlee

And thanks Metalman. No one but me may believe you, but at least the two of us agree But if science were a democracy, we would probably be voted out.

Seems all us engineers end up with the same pattern of thought process that makes it easier to understand one another.

Cheers,

Terry

Cheers

metalman said:Keep me in the loop for the next IslandFest, and I'll try to arrange a trip over with goodies to play with.

http://www.diyaudio.com/forums/showthread.php?s=&threadid=118743

dave

metalman said:

Oversimplifying what I posted. For an equivalent increase in panel reinforcement, an arch reinforcement will have to be larger, creating a greater impact on internal cabinet acoustics.

Hi Terry,

I see it like that though. I see that single pole and say "what's happening around it". I like Dave's reference to the ring radiator tweeter. Looks like he's seeing it too.

Here's what I know: It is always better to end up with a stronger stiffer construction, one that spreads loads rather than concentrates them.

I look at things from a building construction view: What's the best way to support a floor? With a single post, or a full load bearing wall? I'll leave the guess work out and give the answer - a full load bearing wall, because it spreads the load. Not only does it support the floor, it also gives lateral support, making the structure stronger.

Using the same analogy, walk around on the floor that is supported but a single post. It deflects (bounces) in areas away from the post. Do you see what I'm saying?

Full panel bracing doesn't have to have a negative impact on acoustics. If carefully done and allowed for, it will do much more good than harm.

metalman said:

This is essentially semantics. I would consider corner bracing to be a subset of an arch.

Corner bracing is forming a triangle. A triangles virtue in this case is that it's angles will not change unless the length of it's sides change - it will maintain the 90* angle in the corner.

An arch is not the same thing.

metalman said:

The point in an unsupported panel of greatest amplitude movement is the center. By placing a direct support at that point, it maximizes the supports ability to restrain that resonance. Corner supports will also restrain that resonance, but must be larger as they are applying restrain via a moment arm rather than directly.

Yes, greatest amplitude is the centre. But when you support that, you make new centres, the point I was making above. True, the resonance will be pushed higher, but it can go higher still, by transferring the load from a single point to a broad axis.

How do you minimize resonance? By either damping it or restraining it in the first place.

The pole support only goes part of the way there.

OK, first let me thank you for rephrasing your position. I think I have a better understanding now of what your concept. Your constuction anaology of a single post versus a bearing wall was, er, well, constructive! I now see that the "arches vs. triangles vs. rods" hasn't really been the real root of the discussion.

I think everyone can agree that more bracing is better, up to a practical point where acoustics are impinged upon. I believe that gedlee and I were trying to argue bang for the buck while you were arguing more is better, which was confusing things.

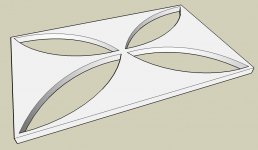

Drawing inspiration from your sketchup drawings, I would ask your comments on this bracing concept. It follows your "supporting wall" concept, but in my opinion will provide more effective panel restraint than concentrating the braing inthe corners. I will comment that I sketched this quickly, and have by no means "optimized" it. Just a concept for discusion purposes.

I think everyone can agree that more bracing is better, up to a practical point where acoustics are impinged upon. I believe that gedlee and I were trying to argue bang for the buck while you were arguing more is better, which was confusing things.

Drawing inspiration from your sketchup drawings, I would ask your comments on this bracing concept. It follows your "supporting wall" concept, but in my opinion will provide more effective panel restraint than concentrating the braing inthe corners. I will comment that I sketched this quickly, and have by no means "optimized" it. Just a concept for discusion purposes.

Attachments

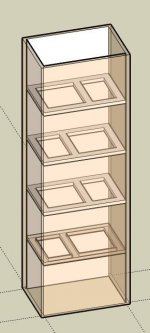

Also for discussion, I created an approximate sketch of how I braced a speaker cabinet I recently constructed.

One concept we haven't touched on yet is where does the point of diminished returns start to come into play. I think that is another one where gedlee and I weren't expressing ourselves wery well.

So the question I am asking is:

At what point does a further increase in cabinet bracing yield a negligible decrease in panel vibration?

Cheers,

Terry

One concept we haven't touched on yet is where does the point of diminished returns start to come into play. I think that is another one where gedlee and I weren't expressing ourselves wery well.

So the question I am asking is:

At what point does a further increase in cabinet bracing yield a negligible decrease in panel vibration?

Cheers,

Terry

Attachments

metalman said:

One concept we haven't touched on yet is where does the point of diminished returns start to come into play. I think that is another one where gedlee and I weren't expressing ourselves wery well.

So the question I am asking is:

At what point does a further increase in cabinet bracing yield a negligible decrease in panel vibration?

I think that we (I) were clear on the diminishing returns concept, but yes I tend to agree hat the other side is taking the "do everything that can be done" approach. As engineers we simply never think this way - we'd be fired if we did! The different points of view of the engineer and the hobbiest is often a point of contention. It was here a few posts back.

I usually cease to enter into the discussions when they get into the "everything that can be done" phase as there is no end to a discussion like that. I am most interested in what practical design approaches yield the best sound quality. If something has not been shown to be a "MAJOR" audible factor then I don't pursue it. Thats because I can name so many MAJOR factors that go uncontrolled that worying about the minor ones is simply not efficient. But thats just the engineer in me talking.

I once was asked to listen to a "mod" by a circuit designer at a major Hi-End electronics company. He played two examples - change, no change. They both sounded terrible. I asked him how I could possibly evaluate anything that sounded so bad. On further discussion it became quite apparent to me that he could only hear what he was listening for - the big picture, the total sound, had gotten completely past him. The fastidious focus on small insignificant factors is all too common in our business. Don't miss the whole forest looking on the ground for a small seedling to chop down for fire wood.

Now this is something very real.gedlee said:

I think that we (I) were clear on the diminishing returns concept, but yes I tend to agree hat the other side is taking the "do everything that can be done" approach. As engineers we simply never think this way - we'd be fired if we did! The different points of view of the engineer and the hobbiest is often a point of contention. It was here a few posts back.

I usually cease to enter into the discussions when they get into the "everything that can be done" phase as there is no end to a discussion like that. I am most interested in what practical design approaches yield the best sound quality. If something has not been shown to be a "MAJOR" audible factor then I don't pursue it. Thats because I can name so many MAJOR factors that go uncontrolled that worying about the minor ones is simply not efficient. But thats just the engineer in me talking.

I once was asked to listen to a "mod" by a circuit designer at a major Hi-End electronics company. He played two examples - change, no change. They both sounded terrible. I asked him how I could possibly evaluate anything that sounded so bad. On further discussion it became quite apparent to me that he could only hear what he was listening for - the big picture, the total sound, had gotten completely past him. The fastidious focus on small insignificant factors is all too common in our business. Don't miss the whole forest looking on the ground for a small seedling to chop down for fire wood.

I think bracing like B&W does is pretty much close to the diminished returns border.metalman said:Also for discussion, I created an approximate sketch of how I braced a speaker cabinet I recently constructed.

One concept we haven't touched on yet is where does the point of diminished returns start to come into play. I think that is another one where gedlee and I weren't expressing ourselves wery well.

So the question I am asking is:

At what point does a further increase in cabinet bracing yield a negligible decrease in panel vibration?

Cheers,

Terry

metalman said:OK, first let me thank you for rephrasing your position.

I think everyone can agree that more bracing is better, up to a practical point where acoustics are impinged upon.

Thank you, although something is still not clear. I'm not saying there should be more bracing , I'm saying the bracing can be more effective. That's the real difference between the full panel and the pole - effectiveness.

metalman said:

Drawing inspiration from your sketchup drawings, I would ask your comments on this bracing concept.

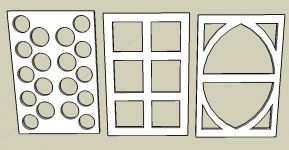

I like this one very much! It has the Gothic Maltese cross thing happening, so it get extra points for looking cool. 🙂

I whipped up a few quickly also, just for illustration. The one on the far right is my favourite.

Attachments

MJL21193 said:The one on the far right is my favourite.

More effective and easier, would be replacing the curved elements with straight elements connecting the same points.

Sheldon

metalman said:(Hey Cal!)

Hi Terry,

I've been meaning to say hi but it always seemed off topic so I didn't. I guess I should have emailed you by now to see how things are. If you have a chance snap a couple pics and show me where you live and stuff.

We now return to topic already in progress...

gedlee said:

I think that we (I) were clear on the diminishing returns concept, but yes I tend to agree hat the other side is taking the "do everything that can be done" approach. As engineers we simply never think this way - we'd be fired if we did! The different points of view of the engineer and the hobbiest is often a point of contention. It was here a few posts back.

Hmm,

There is a big difference between "doing everything that can be done" and "doing everything as effectively and efficiently as possible".

I detect a hint of snobbery in the above quote. That's to be expected of course.

Funny, I know quite a few engineers. I can actually fill a fair size room with the P.Eng's I know. They have this in common: they don't talk down to me or use a derisive tone when they refer to this "hobbyist".

I even know a few structural engineers, real structural engineers, you know, the ones that design structures? Well paid individuals, with the responsibility of peoples lives resting on their work. They don't last long in the position by doing what is merely "adequate"

Sheldon said:

More effective and easier, would be replacing the curved elements with straight elements connecting the same points.

Sheldon

You are correct, sir! IMO anyway. Thanks.

MJL21193 said:They don't last long in the position by doing what is merely "adequate"

Not looking to nit pick but when they go beyond the call they have budget overruns and henceforth often do only what is adequate or acceptable. Add to that those who get their degrees from the back of a cereal box who tend to under design in the name of the bottom line. I'll tell you it's no fun reviewing drawings that have critical omissions that no one caught until the building collapsed. Silly engineering mistakes that cost lives. You may be right about some but you sure can't lump them all together.

Sorry for the OT but it's a sensitive subject for me.

We now return you to your regularly scheduled program...

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Discussion arising from Geddes loudspeaker