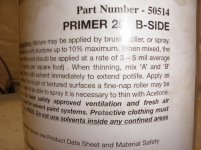

This is what i will be using to coat the stats, it is a two part mixture, but will show off the steel panels as it will be somewhat clear. No, i am not using 2000psi, just a regular paint gun, diluting the mix with acetone, not only will it bond better to the metal, this was designed specic for bare metal and as you read, the coating will be @ 10 mills, and very, very smooth as i was concerned anout the 3m tape sticking to rhino lining(the black stuff).

i am getting so close to finish, makes me feel a little giddy.

but here are the pics, i had to take two as the cans had the labels wrapped all the way around.

please let me know what you think. Mav

i am getting so close to finish, makes me feel a little giddy.

but here are the pics, i had to take two as the cans had the labels wrapped all the way around.

please let me know what you think. Mav

Attachments

Hi,

this is what I meant how to cut the sheet´s rims:

[IMG=http://img112.imageshack.us/img112/5567/lochblechkanten5bt.th.jpg][/IMG]

Sanding won´t tackle the problem of Your sheet´s rims.

jauu

Calvin

this is what I meant how to cut the sheet´s rims:

[IMG=http://img112.imageshack.us/img112/5567/lochblechkanten5bt.th.jpg][/IMG]

Sanding won´t tackle the problem of Your sheet´s rims.

jauu

Calvin

Thank you Calvin, I understand that your words are worth gold on building ESLs. I meant grinding them, which i about to leave and do that now. just so i understand 100% the left side og this pic is what ALL sides and edges should look like.

Calvin, do you have any pics of your builds, if so, would like to them.

Calvin, do you have any pics of your builds, if so, would like to them.

Attachments

Mavric,

The long edges of your panels look OK. Below is a pic you posted earlier showing one of your panel ends... if you can make the other panel ends look like this one, I think that would be fine.

http://www.diyaudio.com/forums/atta...22347-different-ideas-esl-panels-p3210275.jpg

The long edges of your panels look OK. Below is a pic you posted earlier showing one of your panel ends... if you can make the other panel ends look like this one, I think that would be fine.

http://www.diyaudio.com/forums/atta...22347-different-ideas-esl-panels-p3210275.jpg

I cleaned up those edges as best i could, since they are stagered, a little more difficult than i thoght. It was getting late so only took one pic, will have to resolder all contacts and smooth the edges from grinding, other than that, what do you think? good to go?

Attachments

Charlie, did you get the pic for the tv stand?

Yes, I got the pic and we can cut the pieces on your next visit (Sunday?) if you have the time after assembling your panels. My diaphragm stretching jig isn't wide enough for your panels so you will have to heat-shrink the film... I've never done it but it looks pretty easy and I have a really good heat gun.

Now that you've ground the points off those stator panel ends, a little smoothing over with sandpaper will ensure you've got the best possible edges before coating. It's a good thing you posted those pics and Calvin stepped in to help out. I think you're gonna have some really nice sounding speakers!

I have been having some fun finely!

Funny you should mention,heat gun?

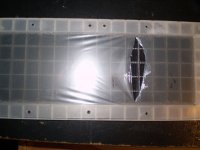

Here is what happens when you hold it in one spot for more than 2 seconds at 4 inches diatance.note the pinhole from an arc over.Gonna give them 2 or 3 coats of clear acrylic enamel.

This will also be my first chance to try the new crystal clear lichron spray coating for the diagphram.

I finished my bais supply and tried stacking transformers.

Works great!

I can get fullrange at a low level and down to 200hz with 18 turns (1:77 ratio) and 400hz with 9 turns (1:154 ratio)at full power.heck I have ten of these things tomorrow I'll stack 1 or 2 more.I'm hoping 3 will get me full range at ful power (100watts) but 4 will defintely do it.

Also just as I suspected the ratios of the two identical transformers were not the same.

As much as 10% difference was found between the two of them.

Luckiley all of the windings are seperated from each other and could be wired with a balanced eqeal output per stator.

This might have been the cause some peculiar happenings that caused me to get out my heat gun in the first place. jer

Funny you should mention,heat gun?

Here is what happens when you hold it in one spot for more than 2 seconds at 4 inches diatance.note the pinhole from an arc over.Gonna give them 2 or 3 coats of clear acrylic enamel.

This will also be my first chance to try the new crystal clear lichron spray coating for the diagphram.

I finished my bais supply and tried stacking transformers.

Works great!

I can get fullrange at a low level and down to 200hz with 18 turns (1:77 ratio) and 400hz with 9 turns (1:154 ratio)at full power.heck I have ten of these things tomorrow I'll stack 1 or 2 more.I'm hoping 3 will get me full range at ful power (100watts) but 4 will defintely do it.

Also just as I suspected the ratios of the two identical transformers were not the same.

As much as 10% difference was found between the two of them.

Luckiley all of the windings are seperated from each other and could be wired with a balanced eqeal output per stator.

This might have been the cause some peculiar happenings that caused me to get out my heat gun in the first place. jer

Attachments

Calvin, i posted the wrong pic, not sure if you caught it. The stagered edges on the panels have heen ground down, difficult task as they are stagered holes. I like the link, a picture is worth a thousand words.

if anyone needs older pics from this build, i will be more than happy to repost.

As far as a heat gun, use one everyday for window tinting, only a fraction of a second is all you have, just worried a little about "rippling" on the diagphram, guess I should do it the right way with a stretcher using an intertube for a bicycle.

"Sunday" is in check.

the two part primer for coating is essential, i have used this before(not on stats) but there is no way you can go wrong, one coat, one finish, @ 10mills, perfect from what i have read.

Ger, keep up the engineering, you are one of a kind. let me knnow how four sound. 🙂

if anyone needs older pics from this build, i will be more than happy to repost.

As far as a heat gun, use one everyday for window tinting, only a fraction of a second is all you have, just worried a little about "rippling" on the diagphram, guess I should do it the right way with a stretcher using an intertube for a bicycle.

"Sunday" is in check.

the two part primer for coating is essential, i have used this before(not on stats) but there is no way you can go wrong, one coat, one finish, @ 10mills, perfect from what i have read.

Ger, keep up the engineering, you are one of a kind. let me knnow how four sound. 🙂

going to work again this weelend, will post pics as well as coments on the coating.

I think i have a rhino lined up friday or saturday, that way i can go ahead and spray the stat supports.

wish me luck, and thanks for everyones help.

I think i have a rhino lined up friday or saturday, that way i can go ahead and spray the stat supports.

wish me luck, and thanks for everyones help.

Can anyone comment on having the stats on a rotating or left.right, up down pedestal? There will be no vibration on the stat panels whats so ever. it is imaging or the sweet spot, I have a fixed location for the TL's, so would be nice to be able to possition them with else, let me know please.

Super incrediable, clean and balanced sound out of my latest creation,ur, configuration i mean.

Quadstacked transformers good until 150hz-180hz at full power.

Measured 160:1 ratio with 10 turn primary at 1 volt .

Somtimes I measure 130:1 at a higher voltage this may be due to losses within the transfromer itself.

The esl is run fullrange and I'm using my mixer as a makeshift crossover taking out all the highs out of the woofer I can with the parameteric eq"s it has.

I havn't tested at a high volume yet ,as i will do that tomorrow. jer

Quadstacked transformers good until 150hz-180hz at full power.

Measured 160:1 ratio with 10 turn primary at 1 volt .

Somtimes I measure 130:1 at a higher voltage this may be due to losses within the transfromer itself.

The esl is run fullrange and I'm using my mixer as a makeshift crossover taking out all the highs out of the woofer I can with the parameteric eq"s it has.

I havn't tested at a high volume yet ,as i will do that tomorrow. jer

Attachments

Mavric, just finished this whole tread start to finish, sorry I don't have any ESL experience but have to say, it's so refreshing to see a project by someone who has managed to be super dedicated and passionate about a build and at the same time is wide open to ideas and suggestions from others. It's easier to say than to do when you've spent ages planning a build eh!

Good luck and keep up the posts. Brian.

Good luck and keep up the posts. Brian.

Thanks Brian, that was an unexpected but welcome comment. thats why i have whatever you call it at the bottom of my posts. A wise man does not need advice but a fool wont take it.

coating the stats tomorrow using the two part epoxy from rhino, excited and and hope i have enough. i will have to dillute it a bit w/acetone but that is the material is very thick. Will be posting a panel or finished panels tomorrow, coated diagphram and all, arc testing before assembly and pray to GOD that everything is spec.

This is a little more work than i thought, but thats just me, hard headed and hard working, if it wasn't for Charlie, JerJR, Calvin and numerous others, I would probally still continue but quit after i fried everything i own, thats why i ask soooo many questions.

Mr, elctronic einstien, you know who are, give me a call and tell me more about your science project there, interesting, BTW, the other xlr adapters came in and will need some advice on set up if you dont mind. Thanks

coating the stats tomorrow using the two part epoxy from rhino, excited and and hope i have enough. i will have to dillute it a bit w/acetone but that is the material is very thick. Will be posting a panel or finished panels tomorrow, coated diagphram and all, arc testing before assembly and pray to GOD that everything is spec.

This is a little more work than i thought, but thats just me, hard headed and hard working, if it wasn't for Charlie, JerJR, Calvin and numerous others, I would probally still continue but quit after i fried everything i own, thats why i ask soooo many questions.

Mr, elctronic einstien, you know who are, give me a call and tell me more about your science project there, interesting, BTW, the other xlr adapters came in and will need some advice on set up if you dont mind. Thanks

of course some more pics. this is the meter I have to use for the apllication, yes it is dirty, that is why we are one less employee at work. but, there it is and maybe useful info for others.

dead accurate, thats 300grams of machined copper and steal. not off a bit.3

stay tuned

dead accurate, thats 300grams of machined copper and steal. not off a bit.3

stay tuned

Attachments

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Planars & Exotics

- different ideas for ESL panels