From the simulation, a 447mV peak input results in 386mV output (-8dB) so with my 104dbV headphones, from my calculations that's 97dB. However there's amp room to increase the output by changing operating points.

So I've just ordered the valves and wiring.

For the caps and resistors I'm taking the approach that I will be upgrading and messing with it over time.

0.1uF decoupling caps - I'll go for Auricap XO 450V

10uF output cap - Auricap XO 450V

330uF output cap I'm still researching the best option for this, but I'm leaning towards low ESR Panasonic/Nichicon 450V electrolytic in parallel.

470uF 450V electrolytic caps - Panasonic / Nichicon / KEMET

1000uF 450V electrolytic reserve cap - KEMET

In terms of resistors:

Metal film - probably Vishay for the signal path, and TKD for the power.

The thermistor I will go for an Ametherm.

I'll order some cheap 10W ceramics as the initial test load.

For the caps and resistors I'm taking the approach that I will be upgrading and messing with it over time.

0.1uF decoupling caps - I'll go for Auricap XO 450V

10uF output cap - Auricap XO 450V

330uF output cap I'm still researching the best option for this, but I'm leaning towards low ESR Panasonic/Nichicon 450V electrolytic in parallel.

470uF 450V electrolytic caps - Panasonic / Nichicon / KEMET

1000uF 450V electrolytic reserve cap - KEMET

In terms of resistors:

Metal film - probably Vishay for the signal path, and TKD for the power.

The thermistor I will go for an Ametherm.

I'll order some cheap 10W ceramics as the initial test load.

Last edited:

Only thing is to ensure that the current from start up is low enough (or paralleled) to they'll go pop on startup.

Still wrestling with this.

Still wrestling with this.

I've been hard at work simulating but with all four ecc99s at full 60mA the system sucks 560mA (maximum peak-to-peak) for all valves.

I've been trying RC filters, however the 300ohm voltage drop drives up the transformer power requirements for a 200B+ rail. I've managed current etc to the maximum draw of some of the candidate power transformers I have identified (including startup), but all cause issues so far. So I'm now looking back at the LT3080 LDO Maida/Christian option to see if it can be modelled with less drop out.

Three RC filters in series (300ohm with 470uF) gives a lovely output with low ripple but the voltage drop and power loss is horrendous.

I've been trying RC filters, however the 300ohm voltage drop drives up the transformer power requirements for a 200B+ rail. I've managed current etc to the maximum draw of some of the candidate power transformers I have identified (including startup), but all cause issues so far. So I'm now looking back at the LT3080 LDO Maida/Christian option to see if it can be modelled with less drop out.

Three RC filters in series (300ohm with 470uF) gives a lovely output with low ripple but the voltage drop and power loss is horrendous.

Last edited:

I’ll need to confirm this but the LTSpice transformer getting hammered AC 5A at 220V peak.

Average p=iv where i = Ipeak/sqr(2) and v = Vpeak/sqr(2)

P = 3.53 * 155 = 550W average.

Although the 540mA is probably red plating and melting tubes, 550W is a bit nuts.

Instant power is 5 * 220 = 1100W which seems I’ve not got the model right.

Average p=iv where i = Ipeak/sqr(2) and v = Vpeak/sqr(2)

P = 3.53 * 155 = 550W average.

Although the 540mA is probably red plating and melting tubes, 550W is a bit nuts.

Instant power is 5 * 220 = 1100W which seems I’ve not got the model right.

I've been looking at the power supply more carefully.

Broskie does a similar amp using a 50W transformer for the B+ line (2x12ax7+4xecc99s):

More OLT Design

There are a few caveats to this:

* 60Hz gives 20% more power so the transformer is 60W.

* running a 120V transformer to give 150V B+ lines

* amp specced for 300ohm headphones with parallel but smaller current swing

* amp PSU is specced for idle current with capacitance providing swing & transient.

* different front end tubes are lower mA

"The reality is that the two transformers still run hotter than I like." sounds like this setup is pushing the boundary of the transformers. Add to that he added a small fan in a small case..

Vs

* 200V gives more flexibility. B+ regulated and 50Hz

* 32ohm headphones means more current capacity

* 2x larger mA on the front end with 12bh7a

* capacity for a second pair of 12bh7a so make that 4x front load (although this eats into the continuous current capability)

* a little scope to switch topologies. I have plans for differential and PP in the future.

* specced able to supply continuous current at max load and transients for the above.

Yes it's over specified, 180VA would probably happily power it leaving things to the capacitors in normal use, even when adding a second set of 12bh7. 220VA would support tinkering better.

Broskie does a similar amp using a 50W transformer for the B+ line (2x12ax7+4xecc99s):

More OLT Design

There are a few caveats to this:

* 60Hz gives 20% more power so the transformer is 60W.

* running a 120V transformer to give 150V B+ lines

* amp specced for 300ohm headphones with parallel but smaller current swing

* amp PSU is specced for idle current with capacitance providing swing & transient.

* different front end tubes are lower mA

"The reality is that the two transformers still run hotter than I like." sounds like this setup is pushing the boundary of the transformers. Add to that he added a small fan in a small case..

Vs

* 200V gives more flexibility. B+ regulated and 50Hz

* 32ohm headphones means more current capacity

* 2x larger mA on the front end with 12bh7a

* capacity for a second pair of 12bh7a so make that 4x front load (although this eats into the continuous current capability)

* a little scope to switch topologies. I have plans for differential and PP in the future.

* specced able to supply continuous current at max load and transients for the above.

Yes it's over specified, 180VA would probably happily power it leaving things to the capacitors in normal use, even when adding a second set of 12bh7. 220VA would support tinkering better.

Last edited:

The secondary/transformer reserve capacitor soft start is working, but just need to tune it increase a little slower so the current draw is reduced a little more.

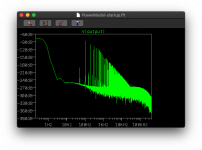

So a 61GB run of the power model:

Top is the input into the VR, and the blue is the secondary winding current. The red is the input into the VR.

The large reservoir cap inrush current is smoothed down from 14+Amps to 6A, I can possible smooth this further, I'd prefer to get this to 1A or less.

If you use the below careful of the grounding. It works by first following the positive up and the mosfet follows it up so the drain of the mosfet raises to B+ first. The mosfet gain is positive, same as the source and so the mosfet starts conducting and the output drifts down to zero. If you ground this and leave the output floating, the ground in the amp will jump to 240V before foating down to zero.

As it stands it copes with the 450V 4 or 6mF large capacitor - I just need to get around to smoothing the time it takes for the mosfet to start conducting. For this brief period it it can probably cope with the current but the transformer may not.. that's next on the hit list. Getting that inrush spike to under 1Arms.

Top is the input into the VR, and the blue is the secondary winding current. The red is the input into the VR.

The large reservoir cap inrush current is smoothed down from 14+Amps to 6A, I can possible smooth this further, I'd prefer to get this to 1A or less.

If you use the below careful of the grounding. It works by first following the positive up and the mosfet follows it up so the drain of the mosfet raises to B+ first. The mosfet gain is positive, same as the source and so the mosfet starts conducting and the output drifts down to zero. If you ground this and leave the output floating, the ground in the amp will jump to 240V before foating down to zero.

As it stands it copes with the 450V 4 or 6mF large capacitor - I just need to get around to smoothing the time it takes for the mosfet to start conducting. For this brief period it it can probably cope with the current but the transformer may not.. that's next on the hit list. Getting that inrush spike to under 1Arms.

Last edited:

Something else to investigate with the ecc99s once up and running - use of ferrites and grid stoppers.

Now I can inrush limit just using a simple tuneable design:

This simulates a flat reservoir and a hot set of tubes (thus current draw could occur immediately as the B+ rises).

The result:

Centre - blue and green are the load voltage and current.

Bottom - current draw for the secondary - this is AC (red) and current limiter output (teal).

Top - power dissipation is AC so not as bad as it looks:

This is probably around 30W dissipation but still quite a large amount.

This simulates a flat reservoir and a hot set of tubes (thus current draw could occur immediately as the B+ rises).

The result:

Centre - blue and green are the load voltage and current.

Bottom - current draw for the secondary - this is AC (red) and current limiter output (teal).

Top - power dissipation is AC so not as bad as it looks:

This is probably around 30W dissipation but still quite a large amount.

So I've looked around at current limiting - trying to find options that:

* inline current limiting - protecting the transformer from seeing

* normal operational load handling

* short load handling

Looking at the technology:

* JFET - mA and so not suitable here (although two JFETS make a nice bi-directional current limiter!)

* BJT - these have a positive coefficient, meaning as they heat up they allow more current thus there is the possibility of thermal runaway. However they also have a low impedance but low 'switching' speed. Less sensitive to transients. Low cost

* MOSFET - these have negative coefficient, but they have high impedance and fast switching speed. Sensitive to transients. High cost.

* PWM - this could be an option, it's possible to make an simple square-ish wave to make a PWM-MOSFET that ramps to continuous current then is bypassed.

This is my most 'dependable' design:

To reduce the per-device dissipation, the current is split using parallel PNPs. This means the max AC power seen limiting a possible 30A+ cap inrush is about 24W per PNP and then in operation this drops to 20W in the modelling. The NPN is sitting there in the sub 1W dissipation.

This reduces the thermal load on the PNP with a desire to reduce the likelihood of thermal runaway.

So 20W / 1.414 gives 14W, 14W*3 => 42W dissipation (max <400mA in this model) with ideal LTSpice PNPs.

If the system isn't seen as an open circuit, then it's only going to drawing what it needs - so an option for efficiency over 'always on' is to use a SSR to switch out the circuit except the sensing NPN. Down side is switching in/out at the right point on the AC cycle is more complex.

* inline current limiting - protecting the transformer from seeing

* normal operational load handling

* short load handling

Looking at the technology:

* JFET - mA and so not suitable here (although two JFETS make a nice bi-directional current limiter!)

* BJT - these have a positive coefficient, meaning as they heat up they allow more current thus there is the possibility of thermal runaway. However they also have a low impedance but low 'switching' speed. Less sensitive to transients. Low cost

* MOSFET - these have negative coefficient, but they have high impedance and fast switching speed. Sensitive to transients. High cost.

* PWM - this could be an option, it's possible to make an simple square-ish wave to make a PWM-MOSFET that ramps to continuous current then is bypassed.

This is my most 'dependable' design:

To reduce the per-device dissipation, the current is split using parallel PNPs. This means the max AC power seen limiting a possible 30A+ cap inrush is about 24W per PNP and then in operation this drops to 20W in the modelling. The NPN is sitting there in the sub 1W dissipation.

This reduces the thermal load on the PNP with a desire to reduce the likelihood of thermal runaway.

So 20W / 1.414 gives 14W, 14W*3 => 42W dissipation (max <400mA in this model) with ideal LTSpice PNPs.

If the system isn't seen as an open circuit, then it's only going to drawing what it needs - so an option for efficiency over 'always on' is to use a SSR to switch out the circuit except the sensing NPN. Down side is switching in/out at the right point on the AC cycle is more complex.

Let no one tell you tube amps are not easy on the wallet.

Tubes ...

Power Transformers £100

Capacitors £100-140 - 2x£44 of that is the 330uF 330V PP film caps! The 5.6mF 450V res cap another £40 to get low voltage ripple.

The resistors are reasonable, except the NTC (£9 .. to cope with the Joules in that res cap).

I have the majority of the list ready, just waiting until tomorrow to have a second look over the list.

The initial 'test setup' I think will be made from a steel oven baking tray.. I also need to remodel the amp then see if I can do without some of the bits until later.

Inrush I can do with 50W resistors and a big toggle switch bypass, do without the regulators for the time being. A switch for B+ on/off, for heaters on/off & inrush. and variable resistors for the dev setup of bias, plate resistor and cathode resistors.

It will be noisy initially with the voltage ripple but I'll try to reduce that with the passive filters for now.

Tubes ...

Power Transformers £100

Capacitors £100-140 - 2x£44 of that is the 330uF 330V PP film caps! The 5.6mF 450V res cap another £40 to get low voltage ripple.

The resistors are reasonable, except the NTC (£9 .. to cope with the Joules in that res cap).

I have the majority of the list ready, just waiting until tomorrow to have a second look over the list.

The initial 'test setup' I think will be made from a steel oven baking tray.. I also need to remodel the amp then see if I can do without some of the bits until later.

Inrush I can do with 50W resistors and a big toggle switch bypass, do without the regulators for the time being. A switch for B+ on/off, for heaters on/off & inrush. and variable resistors for the dev setup of bias, plate resistor and cathode resistors.

It will be noisy initially with the voltage ripple but I'll try to reduce that with the passive filters for now.

A small delay, work priority unfortunately (15 hour day yesterday).

So I'm doing a cooking baking sheet style test setup - the sheet is steel (once the non-stick is removed), so I can setup an initial setup but have it easy to access. Then once I have a working version then re-home.

I've been modelling the power supply inrush and negative biasing for startup - trying to limit to protect the secondary other components and ensure I have enough manual switches.

I've also been researching the caps - specifically the larger audio caps. Given the cost of large PP, I may for the initial step go with nicicon or Panasonic bi-polar caps for the large caps (actually Auricap XOs are actually bi-polar). Only issue there is ensuring that there's a maximum of 50V across it without resorting to chained caps.

The last point is that it's possible that I may need to give each ecc99 it's own output cap, a 210/220uF and cathode resistor to get a balanced output between the variances of each tube. At a later date this also allows each tube to have it's own CCS for example.

However let's keep it super simple - I will have a lot of issues to solve so let's not add fuel to it.

The first build will be completely cut to the bone. Even the large 6mF cap will be ordered but not used initially. Just having some filtering in the B+ line.

I spent the last weekend making a bill of materials but through I would then take a break and recheck before hitting order. So I'm expecting to be able to order his week 😀.

So I'm doing a cooking baking sheet style test setup - the sheet is steel (once the non-stick is removed), so I can setup an initial setup but have it easy to access. Then once I have a working version then re-home.

I've been modelling the power supply inrush and negative biasing for startup - trying to limit to protect the secondary other components and ensure I have enough manual switches.

I've also been researching the caps - specifically the larger audio caps. Given the cost of large PP, I may for the initial step go with nicicon or Panasonic bi-polar caps for the large caps (actually Auricap XOs are actually bi-polar). Only issue there is ensuring that there's a maximum of 50V across it without resorting to chained caps.

The last point is that it's possible that I may need to give each ecc99 it's own output cap, a 210/220uF and cathode resistor to get a balanced output between the variances of each tube. At a later date this also allows each tube to have it's own CCS for example.

However let's keep it super simple - I will have a lot of issues to solve so let's not add fuel to it.

The first build will be completely cut to the bone. Even the large 6mF cap will be ordered but not used initially. Just having some filtering in the B+ line.

I spent the last weekend making a bill of materials but through I would then take a break and recheck before hitting order. So I'm expecting to be able to order his week 😀.

I made a slight boo-boo detected as I went through the design checking the wattage ratings.

The anode max wattage for the ecc99 is 3.5W per triode. Ie at 150V 25mA is 3.5W, boosting that to 200V goes above 3.5W. So I'm revisiting the power - I still think a 220VA 220V transformer offers a better long term transformer and power (given regulators added later will reduce the voltage). It means in the short term I need to drop the voltage but with ~500mA being dropped 50+Vrms.. that's at least 25W of heat but when you think of peak.. that's more.

There's a lot of transformers at 115V and 220-240V but few between those designed for higher current audio without going specialist.

Lastly I figured a way of getting negative bias voltage a low current from a transformer rather than boosting the cathode voltage - both work so I may look at what falls out of look at the transformers.

The anode max wattage for the ecc99 is 3.5W per triode. Ie at 150V 25mA is 3.5W, boosting that to 200V goes above 3.5W. So I'm revisiting the power - I still think a 220VA 220V transformer offers a better long term transformer and power (given regulators added later will reduce the voltage). It means in the short term I need to drop the voltage but with ~500mA being dropped 50+Vrms.. that's at least 25W of heat but when you think of peak.. that's more.

There's a lot of transformers at 115V and 220-240V but few between those designed for higher current audio without going specialist.

Lastly I figured a way of getting negative bias voltage a low current from a transformer rather than boosting the cathode voltage - both work so I may look at what falls out of look at the transformers.

Code:

Signal path

2x 1x 1M ohm 1/4WW

2x 6x 300 ohm 1W

2x 1x 10M ohm 1W

2x 1x 0.1uF 450V PP (Aur OX)

2x 1x 10uF 450V PP

2x 1x 330uF 450V PP / 50V bi-polar electrolytic)

2x 1x cap clamp (if required)

2x 3x B9A valve sockets

Input Stage Power

2x 1x 700 ohm

2x 1x 8K ohm 10W

2x 2x 1K 5W

2x 2x 150uF 450V Electrolytic (Nichicon)

Output Stage Power

2x 1x 250K 1W

2x 1x 100 ohm 1W

2x 1x 5 ohm 1W

2x 1x 15K ohm 1W

2x 1x 55K ohm 1W

2x 1x 1K ohm 10W (1W if slow charge)

2x 1x 27K ohm 1W

2x 1x 80 ohm 5W

2x 4x 10 ohm 1-2W

2x 2x 2.1K ohm 20W

2x 2x 2K ohm 5W

2x 1x 10K ohm 1/2-1W

2x 1x 47uF 450V Electrolytic (Nichicon)

2x 1x 200uF 450V Electrolytic (Nichicon)

Output Jack

1x 1x Headphone socket

2x 1x 32ohm small speaker

Output Mute

2x 1x 23 ohm 1W

Output Startup Bias Control

2x 1x 1M ohm 1/4-1W

2x 1x 750K ohm 1/4-1W

1x 1x 10 ohm 1W

2x 1x 150uF 450V Electrolytic (Nichicon)

1x 4x 450V 10A switch (double throw - one throw for each channel)

Heater Power

1x 1x 10,000uF 63V Electrolytic (Nichicon)

1x 2x 10 ohm 50W

1x 1x 2K ohm 50W

1x 2x 450V 10A switch (bypass and heater on/off)

1x 1x 600V 10A Bridge Diode

1x 1x 240V - 12V 30VA transformer - 240V connects into primary mains-side power.

Secondary Main Power

1x 2x 10 ohm 50W

1x 2x 100 ohm 50W

1x 2x 500 ohm 50W

1x 2x 1K ohm 50W

1x 2x 2K 0hm 50W

1x 1x 6000uF 450V Electrolytic (Kemet)

1x 1x capacitor clamp

1x 1x 600V 10A Bridge Diode

1x 5x 450V 10A switch (bypass and main B+ on/off)

1x 1x 240V - 220V 1.3A 225VA Transformer

2x 1x fuse holder 2A.

Primary Main Power

1x 1x 450V 10A switch (bypass)

IEC socket + EMI filter + power switch + fuse

1x 1x Antherm NTC

1x 2x Chassis safety earthing lug

Development components

1x 4x 1K variable pot 5W 500V

1x 1x 10K variable pot 5W 500V

Wiring

Shielded signal wire

20AWG solid wire 600V power wiring

2x 2x solder tag board.

Janzen solderRecorded as channel x number per channel x thing.

Went back to the maths on the inrush.

With ten parallel 2Kohm 50W chassis mount resistors (equivalent of 200 ohm), I can get a max load of 50W on them during the startup with an initial Imax of 1.6A on the first cycle and then dropping off as the cap charges.

I calculated a 5RC time of about 11 seconds with the AC supply, so let's see in the simulation.

This simplifies and, to be honest, I think this with a single switch rather than having to attempt to time 4 or 5 switches just to get a higher current to shave of a couple of seconds is not worth the hassle. If the system can start in 10-15 seconds that fast enough.

With ten parallel 2Kohm 50W chassis mount resistors (equivalent of 200 ohm), I can get a max load of 50W on them during the startup with an initial Imax of 1.6A on the first cycle and then dropping off as the cap charges.

I calculated a 5RC time of about 11 seconds with the AC supply, so let's see in the simulation.

This simplifies and, to be honest, I think this with a single switch rather than having to attempt to time 4 or 5 switches just to get a higher current to shave of a couple of seconds is not worth the hassle. If the system can start in 10-15 seconds that fast enough.

- Home

- Amplifiers

- Headphone Systems

- Designing my headphone amp