I may have missed it, but I did scroll through the thread looking before asking...Here is the box , besides the actual dimensions - the volume is within a few liters of the "FLEX-8" spec (22L).

Port is 18+ CM long- 60mm flared.

I cut my Mission 763i's down from 35L , now they are big bookshelf speakers. The specs of the DS-215-8 worked out best with around 20L.

Can you provide:

- the box dimensions...H x W x D

- Thickness of cabinet wall material (presumably 1/2" or 3/4")

- Layout of the baffle - i.e., tweeter center from top of baffle and woofer center from the tweeter center

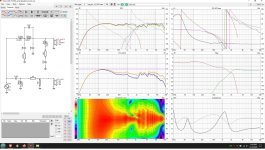

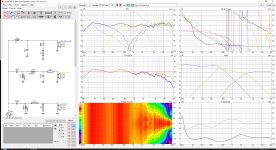

NICE ! Just a few resistors. Cool ! I'll have to order them. Thanks.The 2.5K dip is generated by the interference between W and T in 1-2K range, also you need to smooth the woofer peak at 1.5K and reduce the dip on the 500-1K caused by the LCR. You can add a resistor in series with first cap and increase the resistor of the LCR notch and then pad down the Tw as you like by adjusting the parallel resistor. The TW filter slope is LR4 acoustic.

OS

-10" X 11" X 21"Can you provide:

- the box dimensions...H x W x D

- Thickness of cabinet wall material (presumably 1/2" or 3/4")

- Layout of the baffle - i.e., tweeter center from top of baffle and woofer center from the tweeter center

- much thicker 1" front 3/4" (the rest) with a few braces.

Top to bottom ... tweeter - woofer (centered) 2.25" port below).

Just a big bookshelf (Now) Real heavy ! 20KG each.

(below) - These cut off to 21". Cut right below the pinstriping.

The Dayton drivers fit perfectly.

PS- Mission is supposed to be a HQ English OEM , original drivers were quite junky ??

Box was overbuilt .

OS

Attachments

Yes , COOL. I'll even be able to add the new 3.3R right next to the existing C2 PCB pads.

2db is smooth enough.

OS

2db is smooth enough.

OS

Yup , nice.... (below).

Even designed a 3-way (25hz to 20K) - I'm hooked. PE has all the models.

-GRS 10SW-4E , RS125P-4 , the same RST28f....

PS - need a pair to go with my 125W/8R - 250W/4R Wolverine (party amp).

These Mission's are a perfect match for my 70W Sonance 260 , Wolverine would fry them !

OS

Even designed a 3-way (25hz to 20K) - I'm hooked. PE has all the models.

-GRS 10SW-4E , RS125P-4 , the same RST28f....

PS - need a pair to go with my 125W/8R - 250W/4R Wolverine (party amp).

These Mission's are a perfect match for my 70W Sonance 260 , Wolverine would fry them !

OS

Attachments

Last edited:

How important is it to place crossover components onto a circuit board then firmly glue and fasten them down as most manufacturers and hobbits seem to do. I just solder components to the drive unit solder tags. Is this wrong to leave the components flapping in the wind, would this affect sound quality

Not necessarily, but it is a consideration since components suspended by their leads can succumb to metal fatigue over time due to vibration. It's especially a consideration with electronics where there is any chance of danger if leads break or move around.

That said, there could potentially be concerns from the microphonic properties of inductors as well as interactions between them.

That said, there could potentially be concerns from the microphonic properties of inductors as well as interactions between them.

I mostly use straps to hold them in place, at least untill i'm sure that the crossover is fully ok. Leaving them loose is a receipe for bad/breaking connections in the crossover. Most of the components, especially inductors can weight a lot and should be fixed in place. With resistors and smaller caps it's less an issue, but still...

Thanks! How would you fix the crossover components into the speaker cabinet. Most manufacturers use circuit boards then use some kind of " legs " to lift the board up from the wood to minmize contact vibration ( I think ). Is this a good move or overkill

Would something like dynamat be good, or wrapping the crossover components in that white wadding stuff

Would there be anything wrong with hot glue alone by itself.

Would placing the crossover components far away from the drvers be good, IE near the input terminals

Would something like dynamat be good, or wrapping the crossover components in that white wadding stuff

Would there be anything wrong with hot glue alone by itself.

Would placing the crossover components far away from the drvers be good, IE near the input terminals

It may help to use flexible leads from any heavy components that may move with respect to others.

I think it very much depends:Would there be anything wrong with hot glue alone by itself.

Is it a PA speaker that will be driven hard or are you listening at high levels creating lots of heat and vibration?

Are you going to move (and bump) the speaker a lot?

Here's a recommendation: http://www.troelsgravesen.dk/tips.htm#GlueWould there be anything wrong with hot glue alone by itself.

I use a dab of polyurethane "gorilla glue" or "Aqua seal" to keep things still.

The urethane will break away if you want to change components and not rip away any component materials.

Same as the "dabs" I use for big amp filter caps.

NO massive blobs of glue that the OEM's seem to use.

I mount everything in just one hole with a 50mm thick neoprene washer with a bolt through the PCB.

The one 4R padding 10W resistor on the Xover does get a little warm , I float the power resistors slightly above the board.

OS

The urethane will break away if you want to change components and not rip away any component materials.

Same as the "dabs" I use for big amp filter caps.

NO massive blobs of glue that the OEM's seem to use.

I mount everything in just one hole with a 50mm thick neoprene washer with a bolt through the PCB.

The one 4R padding 10W resistor on the Xover does get a little warm , I float the power resistors slightly above the board.

OS

I had one DIY class AB plate amp right inside a 12" sub with the port blowing right on it.

The worst I had to do was use larger "dabs" on the main filter caps. The small semi's or other

components were unchanged for a decade.

Scoping the amp with full sub power showed no microphonics at the circuit ?

OS

The worst I had to do was use larger "dabs" on the main filter caps. The small semi's or other

components were unchanged for a decade.

Scoping the amp with full sub power showed no microphonics at the circuit ?

OS

For Mid and Woofer, you should use the impedances of the drivers in box calculated by the Enclosure tool and not the ones given by the manufacturers.Yup , nice.... (below).

Even designed a 3-way (25hz to 20K) - I'm hooked. PE has all the models.

-GRS 10SW-4E , RS125P-4 , the same RST28f....

PS - need a pair to go with my 125W/8R - 250W/4R Wolverine (party amp).

These Mission's are a perfect match for my 70W Sonance 260 , Wolverine would fry them !

OS

You also need to calculate the baffle step loss with Diffraction tool.

LF section @ 10m

HF section @ 1m

And then merge LF and HF: check the item Directivity if you want off-axix FR.

?? Baffle step sort of has me slightly lost beyond it's general definition.calculate the baffle step loss

https://www.linkwitzlab.com/diffrac...creasing frequency, though, the,3" baffle (3).

Does it affect imaging ? How great is it's influence on general SQ ?

It seems to be applied on higher end units. Many OEM's just throw 3 speakers in a box - end .....

OS

That doesn't mean it isn't managed through choosing the sensitivity of each driver..

Baffle step is not a perfect situation and may be better avoided. Rearward energy gets mixed up in the room and the response/power are at risk. It's less of an imaging thing since it's usually at lower frequencies.

Baffle step is not a perfect situation and may be better avoided. Rearward energy gets mixed up in the room and the response/power are at risk. It's less of an imaging thing since it's usually at lower frequencies.

OEM's pay a lot of money for skilled developers, that then do constructions to their specification. Development times are sometimes a few days, like a two way with high quality drivers, sometimes month and longer for a high end multi way project.

Imagine a little girl sitting in front of a piano for the first time, it is fascinated how easy it is to produce beautifull, single notes. Compare it to a concert pianist, playing in front of an audience. Got the two pictures?

You have just looked at some helper tools used to design speakers, but your comment about baffle step shows you are about as far from serious constructions as the girl is from a concert. Sorry. You don't just throw some driver in a box and call it a day. There is a lot of theory, science and learning involved.

Imagine a little girl sitting in front of a piano for the first time, it is fascinated how easy it is to produce beautifull, single notes. Compare it to a concert pianist, playing in front of an audience. Got the two pictures?

You have just looked at some helper tools used to design speakers, but your comment about baffle step shows you are about as far from serious constructions as the girl is from a concert. Sorry. You don't just throw some driver in a box and call it a day. There is a lot of theory, science and learning involved.

Condescending ?You have just looked at some helper tools used to design speakers, but your comment about baffle step shows you are about as far from serious constructions as the girl is from a concert. Sorry. You don't just throw some driver in a box and call it a day. There is a lot of theory, science and learning involved.

I know 3 speakers haphazardly thrown into a box can't get you a 5K $$ product. No **** !

I made the statement that many OEM's don't seem to care or DON'T have skilled developers.

PS - I don't do this to DIY amp builders even if they don't design PPM units.

OS

Last edited by a moderator:

- Home

- Loudspeakers

- Multi-Way

- Crossover question?