Ummm, while some folks is running off playing with their sims late at night ...

Sounds like you are trying to imply someone here doesn't know what they are doing with these newfangled simulation machines. Care to shed some insight for those of use that don't understand?

In short, you get a Behringer DCX2496, like a whole lot of those on DiYaudio.

Mini dsp is a lot cheaper and if you pick the right one it should be able to do everything the Behringer can do, if not more.

It does the As I said before, you need to sort out system design (including considering your room) before fussing over horn mouth size.

Ben

I'm not sure how this part has escaped you, since it's been referenced about 200 times so far, but this horn is an outdoor installation. This was made clear in the first sentence of the first post and the whole discussion has been an extension of that.

Most of the system details have been sorted out - he's got amps and he's narrowing in on a horn design. The mains design can come later, although it's already been discussed at a basic level. The only thing he needs is an active crossover that can do delay (as much in the digital domain as possible) and a way to get power out into the yard. Driver selection and horn design is being discussed at length.

Maybe try to pay attention to what's going on instead of using your "helpful" posts as a guise and vehicle to passive aggressively poke at the sim people in a discussion that you clearly are not following.

Question: if I go with a single mono bass horn, how exactly do I go about getting my mono signal? I primarily listen to CD recordings.

Given what GM said: "pretty much all consumer recordings were summed mono below 150 Hz and movies are mono below 120 Hz", the bass signal should already be in mono.

So if using 4 woofers on a single bass horn, you could send left signal to one driver pair and right signal to the other driver pair.

Worst case scenario: you have one recording where the signal is not mono - say a 30Hz tone panned 100% to the right. You'd expect to lose 3dB for that tone. I wouldn't cry a bayou over that.

Given what GM said: "pretty much all consumer recordings were summed mono below 150 Hz and movies are mono below 120 Hz", the bass signal should already be in mono.

So if using 4 woofers on a single bass horn, you could send left signal to one driver pair and right signal to the other driver pair.

Worst case scenario: you have one recording where the signal is not mono - say a 30Hz tone panned 100% to the right. You'd expect to lose 3dB for that tone. I wouldn't cry a bayou over that.

That's not the worst case scenario - if it's panned hard to one side and it's set up as you suggest (not summed) the entire horn will be "out of tune". If only half the drivers are playing you have a whole different design basically, different frequency response, different behavior. If you want an example you can look at really quick, take a dual driver sealed box and sim it. Then sim it again with only one active driver and the other one as a passive radiator. It's a completely different design with completely different behavior.

The worst thing that could probably happen is if all the drivers are sharing the same sealed chamber. If half of them aren't working they likely won't "feel" the same loading and you could very well shoot right past xmax and damage the drivers, since the sealed chamber size has effectively doubled. I'm not even sure if I could accurately sim this effect with the horn connected as the inactive drivers are going to be passive radiators probably tuned really high. I could probably sim it without the horn - then it's just a sealed box with 2 drivers vs a sealed box with one driver and a passive radiator.

If each of the drivers have their own separate sealed rear chamber then it won't be a passive radiator situation but the inactive drivers will act as tuned bass traps to some extent, at least in this case you probably won't damage anything but it's certainly not ideal. And I can't imagine you want to build a separate rear sealed chamber for each driver anyway.

In other words, don't do this. It's easy enough to sum your L+R channels into mono. Do it anyway, even if it's almost always mixed in mono. Don't just assume the signal is always going to be mono and leave it to the drivers to work out on their own.

Last edited:

I can't imagine you want to build a separate rear sealed chamber for each driver anyway.

The usual design mantra is to give each driver its own box.

I'm genuinely curious - why would you not, in this situation?

For a horn to use multiple drivers, there will have to be some compromise. For a simple arrangement, using a quad of drivers, all equally distant from the mouth:

a) If the horn is straight, two drivers will be vertical, so their cones will sag.

b) If all drivers are to be horizontal, the horn would need a 90-degree curve.

I imagine both effects are only small deviations from the ideal, and a) has probably been better quantified than b).

Personally, I'd be tempted to go with b) because it would have other benefits, such as making it easier to build the driver & throat section separate to the horn body, and then lower it on when done.

a) If the horn is straight, two drivers will be vertical, so their cones will sag.

b) If all drivers are to be horizontal, the horn would need a 90-degree curve.

I imagine both effects are only small deviations from the ideal, and a) has probably been better quantified than b).

Personally, I'd be tempted to go with b) because it would have other benefits, such as making it easier to build the driver & throat section separate to the horn body, and then lower it on when done.

Attachments

The usual design mantra is to give each driver its own box.

I'm genuinely curious - why would you not, in this situation?

Because if you do you have 4 stubby little boxes poking out in all directions. It's just generally easier to make 1 larger box than 4 smaller boxes. They don't have individual boxes on the front, why would they need them on the back? Unless it's impossible to make the rear chamber small enough to house in a single box, that's the easiest way and there's not a whole lot of downside.

For a horn to use multiple drivers, there will have to be some compromise. For a simple arrangement, using a quad of drivers, all equally distant from the mouth:

a) If the horn is straight, two drivers will be vertical, so their cones will sag.

Doesn't matter, you can visually inspect the spider after a few months. If there is any sag just switch the 2 vertical drivers so they can sag back in the other direction.

b) If all drivers are to be horizontal, the horn would need a 90-degree curve.

I imagine both effects are only small deviations from the ideal, and a) has probably been better quantified than b).

Personally, I'd be tempted to go with b) because it would have other benefits, such as making it easier to build the driver & throat section separate to the horn body, and then lower it on when done.

That curve you are showing would have no effect at all at subwoofer frequencies. You could fold the horn up with a dozen 180 degree bends and the effect would be minimal at subwoofer frequencies. In fact it might even be beneficial, as the bends filter out higher frequency garbage.

A third option, option C, would be to do a diamond shape, then none of the drivers are horizontal or vertical, they are all on an angle.

A fourth option, option D, would be not to worry about it. If OP uses the drivers we've been talking about they probably won't have to much issues with sag. The cones are very light and the suspension is probably pretty stiff. I'd have to look at the t/s again to verify the suspension stiffness but it's probably pretty stiff.

It's just generally easier [...] that's the easiest way and there's not a whole lot of downside.

Yeah, that's why you were so approving when I suggested doing something the easy way 🙂

But seriously, cutting corners and doing it "the easiest way" is not really the focus of this project. Subdividing 1 big box into 4 parts shouldn't be a huge deal, and the subdivisions would act as bracing.

Also: by the "worst case" logic put forward earlier, this would be essential to stop one driver failure from cascading onto the others (when one driver dies, the others would start operating, effectively, in a larger airspace).

I have noticed that if I measure a woofer pointing up or down, I get slightly different parameters to when it is horizontal. No need to wait a few months.Doesn't matter, you can visually inspect the spider after a few months. If there is any sag just switch the 2 vertical drivers so they can sag back in the other direction.

Exactly. That's what I was thinking - if a bend did no harm, and some good, then why not incorporate it? It would be the lesser of two (small) evils.That curve you are showing would have no effect at all at subwoofer frequencies.

A vertical section would also filter out literal garbage - and thereby protect the drivers / throat area from dust, windblown junk and small animals.In fact it might even be beneficial, as the bends filter out higher frequency garbage.

A fourth option, option D, would be not to worry about it. If OP uses the drivers we've been talking about they probably won't have to much issues with sag. The cones are very light and the suspension is probably pretty stiff. I'd have to look at the t/s again to verify the suspension stiffness but it's probably pretty stiff.

Absolutely. It would only be a small improvement. But it is an improvement that can be made at the design stage, without adding any complications / expense / moving parts. I like those. In your own words, the bend would have "no effect at all", but driver orientation does have some effect (you can check for yourself with a woofer tester).

Here is a guide to how much sag to expect:

http://stereointegrity.com/wp-conte...dsuitabilityforverticalmountingsubwoofers.pdf

I imagine the design & expense of the motor is also a factor in how bad it would be: a slight offset in the cone's resting position is probably worse in a cheap and/or badly designed woofer than in a fancy one.

Last edited:

If one is going to provide a sealed box loading for the horn drivers, then to me it only makes sense if each driver has it's own box.The usual design mantra is to give each driver its own box.

I'm genuinely curious - why would you not, in this situation?

Given what GM said: "pretty much all consumer recordings were summed mono below 150 Hz and movies are mono below 120 Hz", the bass signal should already be in mono.

So if using 4 woofers on a single bass horn, you could send left signal to one driver pair and right signal to the other driver pair.

No, do like the pioneers did, use dual coil VCs [DVC] and considering the app, mobile audio drivers are what you need, which commonly have either DVC as standard or as an option.

GM

If one is going to provide a sealed box loading for the horn drivers, then to me it only makes sense if each driver has it's own box.

This is a good plan for when the drivers are being pushed to their limits since if one blows, then the cab's net Vb [air mass spring] just got larger/weaker and rest go up in smoke from overdrive if not quickly dealt with, but in this app he doesn't need to stress the drivers, so a common cab is sufficient as long as the driver's specs are reasonably consistent [all from the same batch]; just 'down the road' if any need to be re-coned, then worst case, all will need to be replaced, which when using mobile audio drivers is a real probability if > 4-5 yrs.

All that said, the compression chambers required for high Qt drivers will be fairly large, so the only practical way that comes to mind ATM to use individual cabs for multiple drivers will require building a stub 'HF' horn array [W.E. multi-cell concept] to attach to the 'LF' portion of the horn.

GM

That's not the worst case scenario - if it's panned hard to one side and it's set up as you suggest (not summed) the entire horn will be "out of tune". If only half the drivers are playing you have a whole different design basically, different frequency response, different behavior. If you want an example you can look at really quick, take a dual driver sealed box and sim it. Then sim it again with only one active driver and the other one as a passive radiator. It's a completely different design with completely different behavior.

That sim would only match the real-world condition if the driver that wasn't playing any bass was actually disconnected from the amplifier.

It's a good idea to use separate chambers for each driver anyway.

Also: by the "worst case" logic put forward earlier, this would be essential to stop one driver failure from cascading onto the others (when one driver dies, the others would start operating, effectively, in a larger airspace).

This is a good plan for when the drivers are being pushed to their limits since if one blows, then the cab's net Vb [air mass spring] just got larger/weaker and rest go up in smoke from overdrive if not quickly dealt with, but in this app he doesn't need to stress the drivers, so a common cab is sufficient as long as the driver's specs are reasonably consistent [all from the same batch]; just 'down the road' if any need to be re-coned, then worst case, all will need to be replaced, which when using mobile audio drivers is a real probability if > 4-5 yrs.

GM

The possibility of driver failure shouldn't be an issue, as GM points out. OP wants the lowest possible distortion so he shouldn't be pushing his drivers anywhere near xmax and the power each driver will see is extraordinarily low.

If there's any concern at all about stressing the drivers, more drivers should be added to the design, that's the only way to keep it low distortion. And of course that will also make it easier on the drivers.

I have noticed that if I measure a woofer pointing up or down, I get slightly different parameters to when it is horizontal.

Have you simulated the effect of the slightly different t/s from horizontal vs vertical position? It doesn't add up to much.

A vertical section would also filter out literal garbage - and thereby protect the drivers / throat area from dust, windblown junk and small animals.

A small screen would do the same, most compression tweeter have a screen.

Here is a guide to how much sag to expect:

I believe that's only for instantaneous sag. As heat increases with time if the voltage is not stopped, I think sag will also increase with time since gravity isn't going anywhere.

Anyway, some drivers are infamously bad at sag issues, some have no problems. I think OP's chosen driver will probably fall in the latter camp.

No, do like the pioneers did, use dual coil VCs [DVC] and considering the app, mobile audio drivers are what you need, which commonly have either DVC as standard or as an option.

GM

No don't do like the pioneers did. The pioneers didn't have the cheap and plentiful electronics we have.

I have a bottom of the line Technics AVR from about 10 years ago, even it has a "sub" rca line out - just one sub out, summed to mono. And probably any active crossover/dsp unit that is actually required for this application will be able to do the same.

If you use DVC and wire one channel to each coil of each individual driver and the bass is panned hard to one side you effectively have different t/s parameters (very different) which leads to different frequency response and totally different behavior. It's less likely in this case that something will be damaged but it's still a really bad idea. Especially when the associated electronics that are required can do the mono summing, why not just use it?

That sim would only match the real-world condition if the driver that wasn't playing any bass was actually disconnected from the amplifier.

You got me, I wasn't thinking of all the variables. This probably makes it completely impossible to sim the reality of what would happen. Regardless, it shouldn't be an issue, just mono sum the signal with the electronics before it gets to the drivers and it's done.

It's a good idea to use separate chambers for each driver anyway.

Ok guys, I'm outvoted. Do it the hard way and use separate chambers for each driver. There's no consequences. There's also very little benefit since the drivers will never be stressed in this application, but go ahead and do it if that's what you want to do.

Actually, there are several benefits to using separate chambers for each driver, among them reduced "bleed" from the reflected waves of other drivers "leaking" through the cones. The single driver compression chamber is also stiffer for a given amount of bracing, which makes for more (and more defined) response in the top of the pass-band. And the fail safe failure mode of individual chambers for each driver is not a small deal, even the best drivers may stop working- I was happy that my "Chorns" were all separate as 3 of four LAB12 drivers suffered a crimp failure every two weeks or so. Eminence fixed the drivers under warranty, but had they shared enclosures, the dead driver could have taken out the working one, or at best made the dual cabinet sound like crap.Ok guys, I'm outvoted. Do it the hard way and use separate chambers for each driver. There's no consequences. There's also very little benefit since the drivers will never be stressed in this application, but go ahead and do it if that's what you want to do.

The only disadvantage to using separate chambers for each driver are the increased parts count and weight, though considering Eric plans to build out of concrete, those factors are obviously not an issue to him ;^).

Art

Actually, there are several benefits to using separate chambers for each driver, among them reduced "bleed" from the reflected waves of other drivers "leaking" through the cones.

I don't really see that as being an issue - it's the same issue whether it's one driver in one chamber or 4 drivers in a 4x larger single chamber - either way it's the same thing.

The single driver compression chamber is also stiffer for a given amount of bracing, which makes for more (and more defined) response in the top of the pass-band.

I also don't see this being an issue. Pressures in the chamber are already extraordinarily low and bracing isn't really an issue. The corners of every box are already very strong. The only "big" panels are going to be the driver access panels. They aren't going to be big at all and any bracing that you can apply to them can be applied regardless of whether you use a single chamber or separate chambers.

And the fail safe failure mode of individual chambers for each driver is not a small deal, even the best drivers may stop working- I was happy that my "Chorns" were all separate as 3 of four LAB12 drivers suffered a crimp failure every two weeks or so. Eminence fixed the drivers under warranty, but had they shared enclosures, the dead driver could have taken out the working one, or at best made the dual cabinet sound like crap.

Planning in advance for fail modes is indeed good design and good practice. But unless OP royally screws something up the drivers are not going to fail during use.

IF he designs as he says he wants to, keeping distortion at low single digit percentages, the drivers will never be mechanically or thermally stressed in any way. And drivers that are not defective to begin with and are not used under stress don't fail. Maybe after a few decades you'll get a glue failure or something, but for a single session, if they are working at the beginning and are not abused they simply will not stop working.

It's entirely possible that OP could have an oopsy moment and momentarily drive the drivers WAY past xmax by accident, but that's the only possible abuse I can imagine. And in that case it's likely that if one driver fails, all the drivers will fail, regardless of separate chambers or not. It's almost inconceivable that OP can do anything to thermally stress the drivers, as even at xmax they are only getting a tiny fraction of their rated power. It would have to be a colossal misstep to thermally stress the drivers. (At least in the horn we have been looking at so far - OP did mention he redesigned it very recently and hasn't shared those details yet.)

What i would do

1 - Single horn in the middle of the "Soundfield"

2 - Mono bass

3 - One back chamber for All drivers

4 - Back chamber tuned to 20Hz, or less, ported into horn

5 - Drivers mounted vertically

*

Re - Driver Sag

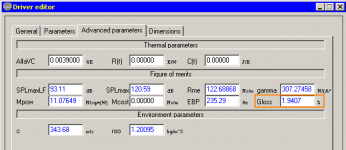

WinISD can estimate DS = Gloss. From the helpfile

Eg - B&C 12NW76, Go to, Driver Editor/Advanced Parameters

1 - Single horn in the middle of the "Soundfield"

2 - Mono bass

3 - One back chamber for All drivers

4 - Back chamber tuned to 20Hz, or less, ported into horn

5 - Drivers mounted vertically

*

Re - Driver Sag

WinISD can estimate DS = Gloss. From the helpfile

Gloss

Gloss tells how many percent of Xmax driver cone will sag, if driver is mounted horizontally. This figure is only approximate, because surrounding air shifts resonance frequency to somewhat lower value. So result is somewhat over-pessimistic by some amount. Generally, figures of more than five percent tell you that driver in question shouldn't be mounted horizontally. Value of gravity acceleration used when calculating sag is 9.80665 m/s². LinearTeam

Eg - B&C 12NW76, Go to, Driver Editor/Advanced Parameters

Attachments

4 - Back chamber tuned to 20Hz, or less, ported into horn

Please show a comparison sim of how this would be beneficial. Sim the horn OP started with and show how porting the rear chamber into the horn makes it better.

I admit I've not done much (or any) work on chambers ported into horns because I see no need and if it's not done right it can do way more harm than good.

Anyway, if the back chamber is tuned to 20 hz it either needs to be HUGE or it needs a HUGE (very long) port. And unless it's HUGE there's not going to be any significant resonance, so not much benefit.

Originally Posted by weltersys

Actually, there are several benefits to using separate chambers for each driver, among them reduced "bleed" from the reflected waves of other drivers "leaking" through the cones.

1)The reflected waves of drivers using 4 times the chamber size will be four times longer, the issue is the same, but the effect is worse, and instead of single mode reflections, they are multiplied by 4 in a quad cabinet. A pair of my FLH L2 cabinets (one driver per chamber) sounded better than a functionally similar L4, in which 2 drivers shared a chamber on either side. I don't just make this stuff up as I go along, I experienced it back when I still had hearing good enough to hear subtle differences ;^).

2) The failure mode I described had nothing to do with stress or abuse, the tinsel lead crimps were simply defective, and randomly "gave up" on light duty jazz shows. The drivers would go open circuit, and the failures occurred after several months of use on shows far more demanding. The factory was aware of the issue, evidently someone had not been doing the tinsel lead crimps consistently. One of the four drivers, which had consecutive serial numbers to the failed drivers, never died, but please don't fool yourself into believing "if they (drivers) are working at the beginning and are not abused they simply will not stop working", as I have experienced too many drivers that simply fail for various reasons with no evidence of thermal or mechanical stress.

Just like with cars, every once in a while, you will run into "lemon" drivers if you own enough.

Art

Actually, there are several benefits to using separate chambers for each driver, among them reduced "bleed" from the reflected waves of other drivers "leaking" through the cones.

JAG,1)I don't really see that as being an issue - it's the same issue whether it's one driver in one chamber or 4 drivers in a 4x larger single chamber - either way it's the same thing.

2)Planning in advance for fail modes is indeed good design and good practice. But unless OP royally screws something up the drivers are not going to fail during use.

And drivers that are not defective to begin with and are not used under stress don't fail. Maybe after a few decades you'll get a glue failure or something, but for a single session, if they are working at the beginning and are not abused they simply will not stop working.

1)The reflected waves of drivers using 4 times the chamber size will be four times longer, the issue is the same, but the effect is worse, and instead of single mode reflections, they are multiplied by 4 in a quad cabinet. A pair of my FLH L2 cabinets (one driver per chamber) sounded better than a functionally similar L4, in which 2 drivers shared a chamber on either side. I don't just make this stuff up as I go along, I experienced it back when I still had hearing good enough to hear subtle differences ;^).

2) The failure mode I described had nothing to do with stress or abuse, the tinsel lead crimps were simply defective, and randomly "gave up" on light duty jazz shows. The drivers would go open circuit, and the failures occurred after several months of use on shows far more demanding. The factory was aware of the issue, evidently someone had not been doing the tinsel lead crimps consistently. One of the four drivers, which had consecutive serial numbers to the failed drivers, never died, but please don't fool yourself into believing "if they (drivers) are working at the beginning and are not abused they simply will not stop working", as I have experienced too many drivers that simply fail for various reasons with no evidence of thermal or mechanical stress.

Just like with cars, every once in a while, you will run into "lemon" drivers if you own enough.

Art

Last edited:

- Home

- Loudspeakers

- Subwoofers

- Concrete Bass Horn Design Question