At an approximate guess I'd say 800ma ( 8x 100ma at full output )

So your multiplier is full wave 8x. And the rest of the circuit probably draws another 50-100ma. in stereo. Just doing a rough calculation on the power transformation ratio for 8x, 350W/80v=4.375A/8=.55A without other losses. If I'm figuring that right you could be overloading the PT by the time you transform the current rating down.

Thanks for the explanation and help 20to20 ! So it seems I'll need one of these torroidals per side then .

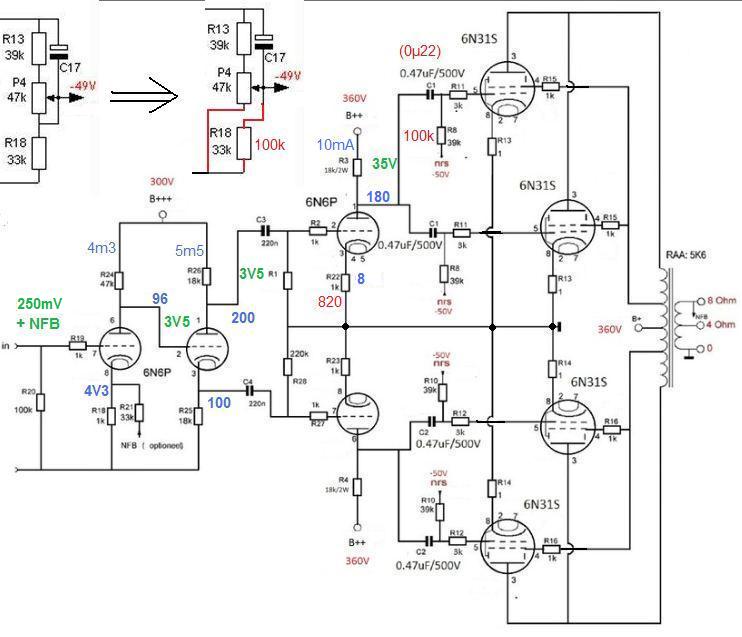

Tomorrow or Thursday I'm going to build a little tester for the 6N6P's seeing that I don't have access to a tester . I'll use unbalance ( per side ) tubes for the input / splitter tube and balanced tubes for the driver/s tube .

Tomorrow or Thursday I'm going to build a little tester for the 6N6P's seeing that I don't have access to a tester . I'll use unbalance ( per side ) tubes for the input / splitter tube and balanced tubes for the driver/s tube .

Last edited:

Thanks for the explanation and help 20to20 ! So it seems I'll need one of these torroidals per side then .

Tomorrow or Thursday I'm going to build a little tester for the 6N6P's seeing that I don't have access to a tester . I'll use unbalance ( per side ) tubes for the input / splitter tube and balanced tubes for the driver/s tube .

Stepping up the voltage means stepping down the current. I can't speak from experience of building one of those. Looks like a fun PS engineering experiment, though. Put a conservative fuse on it at first and if it blows you'll have your answer. Maybe someone else will post to confirm or dispute my numbers.

Yeah - I'm enjoying it , nothing like practice to show you what's happening . I tried to understand it theoretically , but couldn't quite figure what the results would be . Now - I see . 🙂

There was a 10A fuse in the IEC socket , I put a 5A fast blow in now , and will get some 2A time delay ones tomorrow . I guess the power rating would stay the same , so 350V would be about 1A . Which is rather cutting it fine for 2 channels .

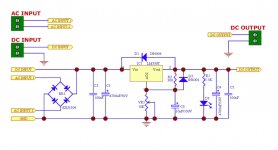

The filament current on the 6P31S is ~1.5A/tube , that sounds ridiculous ! So 8x is 1.5 is 12A + another 200mA for the 4x 6N6P ( that's 2 channels ) . That's 80VA for the 6.3V ! The transformer has a 15V tap @ 3A = 45VA , I should be able to configure that for 1 channel then at least , maybe rectified to 21V , then regulated to 19V and then split 3 ways to 6,3V .

There was a 10A fuse in the IEC socket , I put a 5A fast blow in now , and will get some 2A time delay ones tomorrow . I guess the power rating would stay the same , so 350V would be about 1A . Which is rather cutting it fine for 2 channels .

The filament current on the 6P31S is ~1.5A/tube , that sounds ridiculous ! So 8x is 1.5 is 12A + another 200mA for the 4x 6N6P ( that's 2 channels ) . That's 80VA for the 6.3V ! The transformer has a 15V tap @ 3A = 45VA , I should be able to configure that for 1 channel then at least , maybe rectified to 21V , then regulated to 19V and then split 3 ways to 6,3V .

The filament current on the 6P31S is ~1.5A/tube , that sounds ridiculous ! So 8x is 1.5 is 12A + another 200mA for the 4x 6N6P ( that's 2 channels ) . That's 80VA for the 6.3V ! The transformer has a 15V tap @ 3A = 45VA , I should be able to configure that for 1 channel then at least , maybe rectified to 21V , then regulated to 19V and then split 3 ways to 6,3V .

6n6p heater draws 600ma each tube, so 4x0.6=2.4amps on top of your 8x1.5A

6n6p heater draws 600ma each tube, so 4x0.6=2.4amps on top of your 8x1.5A

You're right , the datasheet I just looked at reckon 750±70mA 9 let's make it 800mA to be safe . So that's 12A + 2.4A for both channels = 14.2A x 6.3 = 89.46VA , let's make it 90W , so I still need at least 45W , make it 50W per channel , that's a hell of a lot more than I was counting on .

Thanks for pointing that out rotaspec !

I have 2 identical ( made in China ) transformers here TX30M1515 . On the label it states " Output 15V-0-15V 3A " .

So should I take that as " 15V x 3A " or " 30V x 3A " ?

EI is 64mm x 53mm and 33mm thick ( under the metal casing ) .

I have 2 identical ( made in China ) transformers here TX30M1515 . On the label it states " Output 15V-0-15V 3A " .

So should I take that as " 15V x 3A " or " 30V x 3A " ?

EI is 64mm x 53mm and 33mm thick ( under the metal casing ) .

30v @3A or if you want you can have (+)15v and (-)15v @3A each with a CT ground.

Last edited:

Can anybody please tell me whether 6V is OK for filaments ? And what the difference would be functionally , if I rather used 6.3V ?

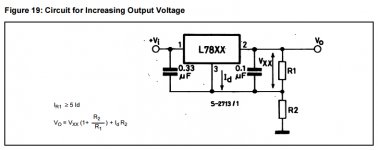

The L7806 has this option to increase voltage - if I can get my head round that equation .

View attachment 557532

6v is fine for 6.3v filaments and sometimes you will read that a tube can produce better specs with a "starved" heater.

Gruddammit ! The L7806 switches off @ 550mA , couldn't even see a 6N6P glowing .

Can someone please recommend a drop in substitute ( same thing , higher current rating ) ? Please .

.

Can someone please recommend a drop in substitute ( same thing , higher current rating ) ? Please

.

.6v is fine for 6.3v filaments and sometimes you will read that a tube can produce better specs with a "starved" heater.

Thanks 20to20 ! Progress is super-slow , but eventually I'll get there .

Gruddammit ! The L7806 switches off @ 550mA , couldn't even see a 6N6P glowing .

Can someone please recommend a drop in substitute ( same thing , higher current rating ) ? Please.

Heatsink required to get full output current, but even then a 7806 may shut down at switch-on due to the surge of a cold filament.

LT1083 or 1084 is a high current adjustable, same pinout as 317

Heatsink required to get full output current, but even then a 7806 may shut down at switch-on due to the surge of a cold filament.

LT1083 or 1084 is a high current adjustable, same pinout as 317

Thanks Rotaspec ! I was going to get LM338T , but LT1083 is far more impressive , I'll be sure to get heatsinks too , just in case ! I don't want to do this again .

- Status

- Not open for further replies.

- Home

- Amplifiers

- Tubes / Valves

- Classic 4 valve PPP circuits