Updated original post with some info on the bandsaw friendly redraw

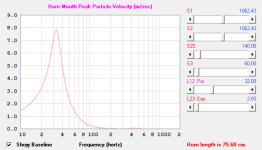

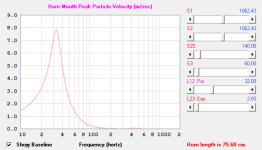

Correct, that would be the case normally, but a 30Hz or so tune in a 30L box makes for some massive and long ports and models in HR as a bad TL. Experimenting here to see how flares affect gustiness for narrow ports that keep the length in rein. Hr is predicting the following for the bandsaw redraw. Pipe is 60cm2, exit is 500cm2 and entry is 140cm2I would use a minimum port surface area of about 1/4 of driver Sd, about 133 cm2 for a 12" driver, so your numbers seem a bit off.

For home audio (and non-flared ports) I think 17 m/sec in HR is a good value.

Correct, that would be the case normally, but a 30Hz or so tune in a 30L box makes for some massive and long ports and models in HR as a bad TL. Experimenting here to see how flares affect gustiness for narrow ports that keep the length in rein.

On such small subs it's a lot better to use a passive radiator. It will not have port noises, the vent doesn't reduce the volume of the sub and you can easily change the tuning by adding or removing weight.

Updated original post with more detail

Couldn't afford them this time around. Will have to try for the best BR I can until that situation changesOn such small subs it's a lot better to use a passive radiator. It will not have port noises, the vent doesn't reduce the volume of the sub and you can easily change the tuning by adding or removing wei

Couldn't afford them this time around. Will have to try for the best BR I can until that situation changes

Got a fried driver laying around? Remove the magnet, add weight to the membrane (hot glue, silicone, large washers etc) and you have one for practically free.

I understand and I sincerely hope you succeed, I really like your design 🙂Correct, that would be the case normally, but a 30Hz or so tune in a 30L box makes for some massive and long ports and models in HR as a bad TL. Experimenting here to see how flares affect gustiness for narrow ports that keep the length in rein. Hr is predicting the following for the bandsaw redraw. Pipe is 60cm2, exit is 500cm2 and entry is 140cm2

However, I know if I approximate the updated design in post 1 as a rear loaded configuration, you'll run into problems well before 250 W continuous.

I have one design with a very similar approach (77 L external), for a 12" driver that I recommend for use up to 500 W. Another design of 64 liter external without the flare (also 12" and 500 W). The non flared design has a port length around 60 cm, I can share details in private.

Updated the original post with full details and HR predictions for the bandsaw special. She is now modelled to the mm and ready to cut

I currently have a capable 7" sub, 105dB system that I have everything on hand to multiply by 4 i.e. 4x7" which I am guessing would yield a solid 123db. I am happy with the size of 4 of those cabs stacked to rebuild a quad

I do know that over the past 25yrs, a very similar JL Audio cab in my car has been soaking up 1kwrms and always feels like it wants twice the power. That JL is not as massive a driver as the ZXI12.4D project driver

My DATSv3 should be here today or tomorrow and with all parts on hand and 3D model complete, the next few days should be interesting

Rademakers, thank you for the sentiment and kindness. I must say that I have now put months of effort in learning and modelling and will see it through. It will be a learning experience anyway. I do have a fallback plan if this doesn't workI understand and I sincerely hope you succeed, I really like your design 🙂

However, I know if I approximate the updated design in post 1 as a rear loaded configuration, you'll run into problems well before 250 W continuous.

I have one design with a very similar approach (77 L external), for a 12" driver that I recommend for use up to 500 W. Another design of 64 liter external without the flare (also 12" and 500 W). The non flared design has a port length around 60 cm, I can share details in private.

I currently have a capable 7" sub, 105dB system that I have everything on hand to multiply by 4 i.e. 4x7" which I am guessing would yield a solid 123db. I am happy with the size of 4 of those cabs stacked to rebuild a quad

I do know that over the past 25yrs, a very similar JL Audio cab in my car has been soaking up 1kwrms and always feels like it wants twice the power. That JL is not as massive a driver as the ZXI12.4D project driver

My DATSv3 should be here today or tomorrow and with all parts on hand and 3D model complete, the next few days should be interesting

Now to finally setup refurb high end laptop from eBay for home speaker lab. Catch up to some yard work and tidy up the work area

Hmmm so it not a box to port function. It's a cone displacement to port functionf what I see in from sims and modelling cabs is correct. Then the port tuning is a box to port function and doesn't use driver T/S. It's basically up to the driver to fill those two holes

Updated original post with some info on the bandsaw friendly redraw

Correct, that would be the case normally, but a 30Hz or so tune in a 30L box makes for some massive and long ports and models in HR as a bad TL. Experimenting here to see how flares affect gustiness for narrow ports that keep the length in rein. Hr is predicting the following for the bandsaw redraw. Pipe is 60cm2, exit is 500cm2 and entry is 140cm2

View attachment 1339228

What is the throat velocity?

I would start with an 1/3 of Sd throat.

550cm2 / 3 = 183cm2.

No idea man, I kept en eye on the exit velocity only. I tried all increments from 60cm2 and up in 10cm2 steps. 180 is good but needs a longer port again going into the pipe resonance issues. Trying to keep the pipe short so it is a true BR insted of a bad TLWhat is the throat velocity?

I would start with an 1/3 of Sd throat.

550cm2 / 3 = 183cm2.

But

See that curved baffle that seamlessly forms the exit flare and the rest of the port slot upper? I will keep this a bolt in job and keep one side panel as a bolt on access. This will let me try out different flare rates over that same port length

The panel saw at Bunnings is always out of order as the guys just find it too hard to follow people's instructions, drawings and such. The timber head left for greener pastures, and the better floor manager moved upwards and sideways to a store manager's position elsewhere. It's sad to see shops change like this. So I did a click and collect on a cheap Ozito cordless 165mm circular saw to add to the battery family. A decent Diablo 65T will be fitted once the stock blade is worn

My offcuts are a bit off after being stored in the carport. Sometimes Bunnings have cap sheets which are 16mm MDF as well as single wood shave skin too and let you have it for $2 each. That's almost free high quality veneer as it's nice grained and looks like birch. But don't tell anyone, keep it diyAudio!!!!

In this BR design, we have a basic test box that can be sealed to the correct size. A port and baffle that can changed and is in the size and tuning targets. Will be interesting to see what this sounds like with some 30hz drivers

The task is to see if chuffing can be managed by doing this for a short 31Hz port. Anyone see any other issues that are remarkable before chopping up a sheet into planks for my smaller saws?

My offcuts are a bit off after being stored in the carport. Sometimes Bunnings have cap sheets which are 16mm MDF as well as single wood shave skin too and let you have it for $2 each. That's almost free high quality veneer as it's nice grained and looks like birch. But don't tell anyone, keep it diyAudio!!!!

In this BR design, we have a basic test box that can be sealed to the correct size. A port and baffle that can changed and is in the size and tuning targets. Will be interesting to see what this sounds like with some 30hz drivers

The task is to see if chuffing can be managed by doing this for a short 31Hz port. Anyone see any other issues that are remarkable before chopping up a sheet into planks for my smaller saws?

So what real, measured TSP does your chassis have?

The Dayton rig should give you this data in a minute. For preparation, just carefully move the cone with your hands a few times, up and down to it's limit. No fancy "burn in" requiered. This has been shown by various tests.

You will have some sticky stuff layin around and some scale, so you can put a defined weight on the cone for the second measurement. A round ring of mastic, placed at the point where dust cap meets cone, usually works best. You will get a feel how you can make it stick, supporting the area with your finger from the rear works quite good.

How much mass will depend on the stiffness of the suspension. Soft drivers may get away with 20g, a hard suspension may even need 150g with a 12" chassis. 50g is a good start, you will get a response if it is not heavy enough. So no need to build a "test box" which will have to much variables to get a clean result.

Hang the driver in free air in a silent environment with no surface too near to it.

The program has to get two impedance curves that have a clear difference to calculate all TSP. The extra mass lowers Fs.

PS I use some non permanent, sticky putty, normally used to get posters and notes on a wall. It doesn't leave any residue.

I have a box with rolls of different weights, so I only use the precission scale once, Always got 10, 20, 50 and 100g ready to use.

The Dayton rig should give you this data in a minute. For preparation, just carefully move the cone with your hands a few times, up and down to it's limit. No fancy "burn in" requiered. This has been shown by various tests.

You will have some sticky stuff layin around and some scale, so you can put a defined weight on the cone for the second measurement. A round ring of mastic, placed at the point where dust cap meets cone, usually works best. You will get a feel how you can make it stick, supporting the area with your finger from the rear works quite good.

How much mass will depend on the stiffness of the suspension. Soft drivers may get away with 20g, a hard suspension may even need 150g with a 12" chassis. 50g is a good start, you will get a response if it is not heavy enough. So no need to build a "test box" which will have to much variables to get a clean result.

Hang the driver in free air in a silent environment with no surface too near to it.

The program has to get two impedance curves that have a clear difference to calculate all TSP. The extra mass lowers Fs.

PS I use some non permanent, sticky putty, normally used to get posters and notes on a wall. It doesn't leave any residue.

I have a box with rolls of different weights, so I only use the precission scale once, Always got 10, 20, 50 and 100g ready to use.

Last edited:

you can make it diy and cheapUpdated original post with more detail

Couldn't afford them this time around. Will have to try for the best BR I can until that situation changes

https://www.diyaudio.com/community/threads/diy-passive-cone-drone-cone.410517/post-7632283

with two surrounds and a wood cutout

It's not the Vas calculation type test box. There is a severe size constraint as to how large a cab can be stored. The design published here is almost at the limits of the allowable footprint. This has been the case for the past few months and mentioned in all the related threads where I am working with the ZXI12.4DSo no need to build a "test box"

The test box is to check which of the prospective drivers can hit all the bass guitar frets note sweet in the allowable space. This is a biggering of the already proven 7" design that I did a while ago. Just need a driver that can go better than the one in the JL Gotham

you can make it diy and cheap

Indeed, I can, did you see the carbon/foam sandwich 8" that I did with huge roll surrounds?. I have the equipment to make the roll surround too. But I dont have time left to prototype a 12' or 15". That will happen later as I develop with the ZXI further and have more time for it. I am trying to get this cab live and working by the 7th

Is the DIY Audio Guy a member here? In one of his videos he states, quoting a couple of cookbooks, that Vb is a Vd function and the port is a Vd function, that since both are controlled by Vd, it creates a misconception. That Fb is not required to calculated portNot so per se, though do need some of the driver specs as I implied earlier.

Makes sense in a way. I can see a TL being as a port played by the cone

I might have to use smaller HF drivers since I am losing space for the PRO-ZT69s with this cubular box format. I have a pair of these linked below that I can run, but will a stereo pair fitted to this cab in its own volume on top be able to keep up with the ZXI12.4D? This is the type of compromise that I don't like. I don't want to run only a single PRO-ZT69. This will force downmixing stereo to mono. The reversed driver L shaped TL box will allow one pair of stereo PRO-ZT69 to be mounted along side the magnet forming a tapped horn With their sub enclosure sides

https://ds18.com/collections/3-5-co...peakers-with-glass-fiber-cone-120-watts-4-ohm

https://ds18.com/collections/3-5-co...peakers-with-glass-fiber-cone-120-watts-4-ohm

Are you confusing car audio with PA speaker building? Keep it apart and stay happy.

Why don't you measure your bass drivers TSP with the new Dayton, do a clean simulation and see what you get? Jumping from one theme to the next will not lead to a finished system at a specific date you mentioned. Maybe put away the digeridoo for a while, smoke a little less roiboos and try to make a solid plan? Then finish part one of it and then start part 2?

Doing all kind of thinkering with flat, high, low, round, oval, triangled, waved or whatever port will not get you anywhere, it all has been done before, Dumbledore did not find any magic in it. Also the material doesn't play even a 1% role for the result. You can make it from wood, foam, aluminum, steel, carbon fiber, glass composite or even bake one from sourdaugh (best smell & taste!), it will not change anything. Do a clean box according to solid simulation with no shortcut made, then, maybe, try out all your funny ideas.

It seems to me you try to reinvent the wheel. Right now you have triangles dangling from the axes and refuse to listen when people are telling you to try rounding them.

Have fun, anyway!

Why don't you measure your bass drivers TSP with the new Dayton, do a clean simulation and see what you get? Jumping from one theme to the next will not lead to a finished system at a specific date you mentioned. Maybe put away the digeridoo for a while, smoke a little less roiboos and try to make a solid plan? Then finish part one of it and then start part 2?

Doing all kind of thinkering with flat, high, low, round, oval, triangled, waved or whatever port will not get you anywhere, it all has been done before, Dumbledore did not find any magic in it. Also the material doesn't play even a 1% role for the result. You can make it from wood, foam, aluminum, steel, carbon fiber, glass composite or even bake one from sourdaugh (best smell & taste!), it will not change anything. Do a clean box according to solid simulation with no shortcut made, then, maybe, try out all your funny ideas.

It seems to me you try to reinvent the wheel. Right now you have triangles dangling from the axes and refuse to listen when people are telling you to try rounding them.

Have fun, anyway!

- Home

- Loudspeakers

- Subwoofers

- Chuffed, twin flare BR part 2