Da5id4Vz said:Brian,

Did you actually make your own button caps for membrane switches?

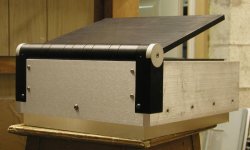

Here is a picture of what I got milled for this. The buttons fit in 1/2" holes, spaced 1" apart. My friend and I did the designs for this, and worked with the machine shop at school to get stuff milled.

--

Brian

Attachments

wazzup said:Hey Brian,

That looks great! I like the way u mounted the cd-pro2 drive. How does it sound?

I`m hoping to complete mine next month. I will use a marble block/plate on which I will mount the cd-pro2, but the way u mounted it, is also very cool.

If u have any more pictures, post them!

Look at my other thread for other pictures:

http://www.diyaudio.com/forums/showthread.php?s=&threadid=21475&highlight=

As for the sound... I haven't had time to give it a detailed listening yet. I had it hooked up to a 2x120W leach amp and my jordan jx92s speakers today for our demo, and it sounded alright. The output of my dac is lacking in voltage, due to the lack of a proper I/V stage. This dac needs lots of work sonically, in terms of the dac.

Picture of testing setup:

--

Brian

Attachments

Another picture.. I would post a direct link to my gallery, but I have been getting using too much bandwidth lately with my gallery, and it is hosted on my friend's server.

I am going to work on getting a sliding top, and illumination with blue leds in the inside.

--

Brian

I am going to work on getting a sliding top, and illumination with blue leds in the inside.

--

Brian

Attachments

Member

Joined 2002

Brian when i get my new Coppermine gallery up if you want you can put all your pictures on my site too. that way you can have 2 link's

Yeah and make 2 for me one to use and one for spare..

ANd hurry up..

Yeah and make 2 for me one to use and one for spare..

ANd hurry up..

Da5id4Vz said:Well thats just beutiful.

Are you thinking of engraving or silk screening for the labels?

The labels are temporary.. I added them last night for the demo. I talked to the machine shop, and am thinking about getting the middle anodized black, and the rest clear. Then I can look into some sort of silkscreen over the black anodized part.

This project was my school project for this semester, which I organized a couple of friends to do with me. We had 5 members, including myself. One guy worked with me doing the microcontroller code, and another guy helped me with the chassis. The other 2 members did nothing, but work on the presentation and webpage, making up a bunch of marketing and other bullsh*t.

webpage for project:

http://www.ece.gatech.edu/academic/courses/fall2003/ece4006/g03/

--

Brian

Which cables should I use for internal cabling of the CD-Pro2?

Hi there CD-Pro community,

I have finally bashed a working power into working to spec and have now ordered the units at Nico's.

I have now to think about the internal cabling and I have 0 idea of what should I be looking for.

Any of you have any idea?

Thanks,

Andrew

Hi there CD-Pro community,

I have finally bashed a working power into working to spec and have now ordered the units at Nico's.

I have now to think about the internal cabling and I have 0 idea of what should I be looking for.

Any of you have any idea?

Thanks,

Andrew

Hi! BrianGT

Hi!BrianGT :

Can you share the Code of MCU for CDproII contronl?

also the schematic of them?

Thanks a lot!

Kello

ikello@126.com

Hi!BrianGT :

Can you share the Code of MCU for CDproII contronl?

also the schematic of them?

Thanks a lot!

Kello

ikello@126.com

How`s the new cd-pro2 spring based coming together Daniel? I want to see pictures!

I`m in the procces of finishing my own cd pro2, this week I hopfully can connect everything and play some music...

I e-mailed a friend who is willing to make a case from copper But I`m still thinking of a way to get the -2mm max- plate to really form strenght. I thought of one plate for the bottom front and rear, flanged on every possible edge Or I could go with the "4 square blocks" to attach all the plates to seperatly. The "problem" with either is, that the bottom would not really suit the weight of my massive transformers and pcb`s I think.

The way u mounted your cd pro2, Daniel with the hole on the top, and the wood beneith is also very good, but how do you cope with taking the lid of -really long wires?- or is yours standing on spikes or something?

Lots a stuff to think about...

I`m in the procces of finishing my own cd pro2, this week I hopfully can connect everything and play some music...

I e-mailed a friend who is willing to make a case from copper But I`m still thinking of a way to get the -2mm max- plate to really form strenght. I thought of one plate for the bottom front and rear, flanged on every possible edge Or I could go with the "4 square blocks" to attach all the plates to seperatly. The "problem" with either is, that the bottom would not really suit the weight of my massive transformers and pcb`s I think.

The way u mounted your cd pro2, Daniel with the hole on the top, and the wood beneith is also very good, but how do you cope with taking the lid of -really long wires?- or is yours standing on spikes or something?

Lots a stuff to think about...

It's coming pretty good. Finally I decided on enclosure type. The bottom is mqde of 2.5" acrylic, sides are 1/2 aluminum. 1" from the bottom, acrylic is milled 0.1" deep and that's the reference for all side panels. I'm not be using any feet with that probably.

I'm tempted to leave transport as a stand alone unit and make PS in separate enclosure. Additional wood panels would be added to the sides.

The wiring is always short, I used spikes with a previous one.

I'm tempted to leave transport as a stand alone unit and make PS in separate enclosure. Additional wood panels would be added to the sides.

The wiring is always short, I used spikes with a previous one.

Attachments

And here's the complete rear view. I decided to go with a clear anodizing for the panels. It makes a nice match to the black lid. As I mentioned before, there will be additional wooden panels on the sides, or if I decide to go with one box, PS towers will be attached there.

Attachments

Member

Joined 2002

yes yes the gallery is up for those who liked looking at Anthony's stuff

http://24.70.80.252/gallery/index.php

http://24.70.80.252/gallery/index.php

How do u guys cope with the 9 volt section? I can`t seem to find resistor values which make 9 volt. The closest I get is 9.5 volt with the lm317t

Can I just parallel these resistors, or is 9.5 volt ok for the motor drive?

Can I just parallel these resistors, or is 9.5 volt ok for the motor drive?

Is that because the motor is pulsed in a wider range -so it can spin up to speed faster- ?

Btw, I like your progress on the new cd-pro-cu I`m really intressted in the sound differences compared to your other 🙄 cd pro.

Btw, I like your progress on the new cd-pro-cu I`m really intressted in the sound differences compared to your other 🙄 cd pro.

Hello guys, check out my progress on my CDPRO2 Player at the link below.

http://24.70.80.252/gallery/view_album.php?set_albumName=album04&page=1

I am using two different DACs within the assembly, a TDA1541A with tube ouput and a Jukka DAC with balanced outputs. A front panel switch will select which one I wish to use for a given CD.

Both will be driven by the I2S output, and there will be an SPDIF input for the DAC not being used for another source.

Regards

Anthony

http://24.70.80.252/gallery/view_album.php?set_albumName=album04&page=1

I am using two different DACs within the assembly, a TDA1541A with tube ouput and a Jukka DAC with balanced outputs. A front panel switch will select which one I wish to use for a given CD.

Both will be driven by the I2S output, and there will be an SPDIF input for the DAC not being used for another source.

Regards

Anthony

Hello Peter Daniel,

I am dropping in very late in this discussion. First of all your project is an impressive achievement. Congretulations! Secondly I may be of some help in fine tuning your project. One of the things that is criticaly important is proper shielding, earthing and HF signal separation. It can make or brake the performance. On some pictures I saw the PCb on the CDPRO mechanism. I have a feeling that shielding there might be an improvement. If you can look at the HF signal (non-clipped) with an oscilloscope you can actually see how clean your HF is and how your "improvements" work out.🙂

I saw you also struggle with damping of the cd mechanism. Well you are not the first one... I remember that for the first Philips car application the designgroup completly weared out a Volswagen Golf. Only to find out that when they started with their second Volkswagen, Volkswagen had improved their product as well and all the work....

Of course a home player is not a car player. But the simple rubbers and springs used in CD players are not so simple after all. So yes you can experiment a lot with different types of damping material. You have the advantage there that cost (criticaly important for a mass-product) is of less importance.

Succes!

Ward

I am dropping in very late in this discussion. First of all your project is an impressive achievement. Congretulations! Secondly I may be of some help in fine tuning your project. One of the things that is criticaly important is proper shielding, earthing and HF signal separation. It can make or brake the performance. On some pictures I saw the PCb on the CDPRO mechanism. I have a feeling that shielding there might be an improvement. If you can look at the HF signal (non-clipped) with an oscilloscope you can actually see how clean your HF is and how your "improvements" work out.🙂

I saw you also struggle with damping of the cd mechanism. Well you are not the first one... I remember that for the first Philips car application the designgroup completly weared out a Volswagen Golf. Only to find out that when they started with their second Volkswagen, Volkswagen had improved their product as well and all the work....

Of course a home player is not a car player. But the simple rubbers and springs used in CD players are not so simple after all. So yes you can experiment a lot with different types of damping material. You have the advantage there that cost (criticaly important for a mass-product) is of less importance.

Succes!

Ward

- Status

- Not open for further replies.

- Home

- Source & Line

- Digital Source

- CD PRO 2 - The making of a high end CD Transport