Yes 😉

BTW I see you solder first and cut excess lead wire off later. This is less good than cutting first and solder later. You put mechanical stress on joints which is not optimal for reliability. Makes sense when you think about it, costs nothing and makes stuff better. Make the switch !

Will do

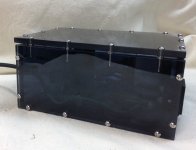

It's Finished

It's finished & it works 🙂 thanks

I had the Polycarb laying around so I thought I'd use that.

I have used shielded (grounded to earth) twisted pair cable for the 5V & put a thingy ma jig (the right name escapes me)on the input end for good luck, might redo the heat shrink though, look pretty crappy.

I have previously built a switching devices so that I will be able to play two synchronised Squeezeboxes into two identical amps and seamlessly switch between the two. Obviously one SQBX with have the regular PSU & the other will have the new one. I already had it setup to AB test a buffer but have been waiting for the son to come around as my ears a a bit worn out and he's are fairly new 🙂

It's finished & it works 🙂 thanks

I had the Polycarb laying around so I thought I'd use that.

I have used shielded (grounded to earth) twisted pair cable for the 5V & put a thingy ma jig (the right name escapes me)on the input end for good luck, might redo the heat shrink though, look pretty crappy.

I have previously built a switching devices so that I will be able to play two synchronised Squeezeboxes into two identical amps and seamlessly switch between the two. Obviously one SQBX with have the regular PSU & the other will have the new one. I already had it setup to AB test a buffer but have been waiting for the son to come around as my ears a a bit worn out and he's are fairly new 🙂

Attachments

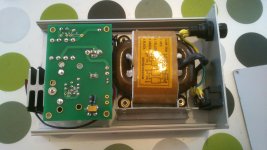

My PSU

Transformer is not fastened yet.

Does the transformer actually need to be grounded/connected to PE ?

(core is glued, no ground connection screw on it - no problem so far in testing)

BR

Pilsern

An externally hosted image should be here but it was not working when we last tested it.

Transformer is not fastened yet.

Does the transformer actually need to be grounded/connected to PE ?

(core is glued, no ground connection screw on it - no problem so far in testing)

BR

Pilsern

With the Nomex in place

backside

with cover

I have reused the chassi and some parts of an old medical power supply.

BR

Pilsern

An externally hosted image should be here but it was not working when we last tested it.

backside

An externally hosted image should be here but it was not working when we last tested it.

with cover

An externally hosted image should be here but it was not working when we last tested it.

I have reused the chassi and some parts of an old medical power supply.

BR

Pilsern

The Nomex will hamper the working of the heatsink severely that way. Please change that to avoid overheating etc. Shorter standoffs for instance.

*Regarding PE: I would connect the case to PE but not GND to PE. So the case connected to PE for safety, just like it is now. The transformers frame will connect to PE to when you use one of those special washers (don't know their name) that cut through the paint and touch the metal. PE regulations may differ in some countries but I like it best this way for audio devices.

Is that the case of a medical isolation transformer ? I use one of those to have a floating mains supply with good results.

*Regarding PE: I would connect the case to PE but not GND to PE. So the case connected to PE for safety, just like it is now. The transformers frame will connect to PE to when you use one of those special washers (don't know their name) that cut through the paint and touch the metal. PE regulations may differ in some countries but I like it best this way for audio devices.

Is that the case of a medical isolation transformer ? I use one of those to have a floating mains supply with good results.

Last edited:

The Nomex will hamper the working of the heatsink severely that way. Please change that to avoid overheating etc. Shorter standoffs for instance.

*Regarding PE: I would connect the case to PE but not GND to PE. So the case connected to PE for safety, just like it is now. The transformers frame will connect to PE to when you use one of those special washers (don't know their name) that cut through the paint and touch the metal. PE regulations may differ in some countries but I like it best this way for audio devices.

Is that the case of a medical isolation transformer ? I use one of those to have a floating mains supply with good results.

Will cut down a bit on the Nomex, though the heatsink did not get particularly hot during test period - lots of holes in the chassi for cooling.

My chassi is low so the transformer must lie down - I don't want screw-holes on the front so my plan was to glue it to the chassi.

Pilsern

Well that make sense, I fell asleep at the wheel 🙂

"Asleep at the Wheel" Wasn't that a country band from the 80's?

I had the Polycarb laying around so I thought I'd use that.

Nice looking enclosure. I like the way you spaced out the polycarb for cooling slots. If you close it up, run it for a while, then check the heatsink, does it stay pretty cool that way?

Jac

Nice looking enclosure. I like the way you spaced out the polycarb for cooling slots. If you close it up, run it for a while, then check the heatsink, does it stay pretty cool that way?

Jac

Thanks

It's such a pain in the bum to pull apart I dont think I'll be doing that testing sorry 🙂

The design evolved as I was making it, I had cut most of the bits except for the top, and I was pondering how to ventilate it then this idea struck me, all good except I had to go out & buy some longer screws & as I say it's time consuming to pull apart.

Seems to be working well but ATM it's only connected to the garage system for a run in, proper testing later on.

DQ828,

Looking a bit closer. Is that your output minus wire running to the base of the transformer? If so, it may give you some hum. I would have thought running it to the minus connection (GND on the board) in the output junction block would be better.

Jac

Looking a bit closer. Is that your output minus wire running to the base of the transformer? If so, it may give you some hum. I would have thought running it to the minus connection (GND on the board) in the output junction block would be better.

Jac

DQ828,

Looking a bit closer. Is that your output minus wire running to the base of the transformer? If so, it may give you some hum. I would have thought running it to the minus connection (GND on the board) in the output junction block would be better.

Jac

Jac

No it's the cable shield, the output minus is very hard to see but it is there.

David

My SBT PSU

Here pics of my build. The box is from Conrad also the big cap. Helas a little to big but with a hole in the bottom it fits.

The transformer is on a subframe. The heatsink is adjusted to fit on the bottom and side of the box to make thermal contact. The box is working now for a couple of days and stays very cool. The DC-power connection is a Lumberg 2,5mm and no contact problems.

Difficult to compare with the standard PSU . I tested with a resistor for 2,5A load and no problems found, very small voltage reduction from 5.04 to 4,98V.

Thank you Jean-Paul for this nice project.

Regards, Loek

Here pics of my build. The box is from Conrad also the big cap. Helas a little to big but with a hole in the bottom it fits.

The transformer is on a subframe. The heatsink is adjusted to fit on the bottom and side of the box to make thermal contact. The box is working now for a couple of days and stays very cool. The DC-power connection is a Lumberg 2,5mm and no contact problems.

Difficult to compare with the standard PSU . I tested with a resistor for 2,5A load and no problems found, very small voltage reduction from 5.04 to 4,98V.

Thank you Jean-Paul for this nice project.

Regards, Loek

Attachments

OK, nice build but I would secure the board with at least 2 standoffs. Are you sure no contact can be made with the top cover ? It would make sense to add some ventilation in the case itself. It seems most heat will go to the case but it won't hurt to check the internal case temp with a temperature meter probe. BTW the board was meant to be used the ordinary way to allow for cooling of the diodes. I am curious what the extra capacitor at the output does ?!

I know it is difficult to compare as the Touch needs to boot up after switching PSU's and after such a time comparing is hard if not impossible. Only using them in parallel temporarily would be a solution but I did not take the risk. Switched a lot between both, the linear PSU was the better performing one IMO but it would be awkward if I wrote the contrary 😉

I know it is difficult to compare as the Touch needs to boot up after switching PSU's and after such a time comparing is hard if not impossible. Only using them in parallel temporarily would be a solution but I did not take the risk. Switched a lot between both, the linear PSU was the better performing one IMO but it would be awkward if I wrote the contrary 😉

Last edited:

One more semi finished. Need a case to put it in but couldn't wait to fire up my touch with it. Have had another psu brand for a couple of years but sold that one few weeks ago. So i had to use the original one since then and my what i regret that i sold it😕

So today one of my new built JP sbt psu was ready to take over!

😀 this is so good! In my room with my setup it's so much better again! Hard to say or compare with my other psu that i sold but all i can say this one is compareble or even better that my other one? One big advantage is for sure! It's dead quite construction🙂 No buzz or hum from the R-core or the cap! Had some of this noise before!

So thank's JP for a very nice sbt psu

So today one of my new built JP sbt psu was ready to take over!

😀 this is so good! In my room with my setup it's so much better again! Hard to say or compare with my other psu that i sold but all i can say this one is compareble or even better that my other one? One big advantage is for sure! It's dead quite construction🙂 No buzz or hum from the R-core or the cap! Had some of this noise before!

So thank's JP for a very nice sbt psu

It is old fashioned (so it will be in fashion again shortly 😉 ) but I try to design good performing stuff with good parts in single board config 🙂

Thanks for the feedback, it is appreciated. I started to wonder if I was the only one having the PSU working.

Thanks for the feedback, it is appreciated. I started to wonder if I was the only one having the PSU working.

Last edited:

After an early rush of progress life intervened and audio has been on a back burner. But the metalwork for the first PSU is nearly complete so I'm getting closer to a working unit.

I thought I'd read some discussion about cables but can't find it so I'm wondering if I dreamt it. I bought a cheapo DC power extension cable in order to cut off the connector and suitable length of wire - it's simply zip wire/fig 8, does it matter what the cable is? (I'm reluctant to cut off the wire from the SB wallwart.)

Unfortunately I haven't got very far with the second (9V) supply. I wanted to try another R core so I ordered one from Selectronic, along with a couple more for a DAC project, but had a bad experience. I wasn't confident enough of my French to use the on line checkout so exchanged a few emails (mostly in English) and they were helpful and prompt. But after I paid by PayPal I never received another email or the goods. I gave up emailing in the end and had to reclaim my money through PayPal. PayPal have now found in my favour but I'm still waiting for the money to be refunded. They offered this reassurance, which doesn't actually reassure me I'll get my money back much at all 🙁

If the seller's account has insufficient funds to complete the refund owed to you, please be assured that we will take appropriate action against the seller's account, which may include limitation of the seller's account privileges.

I thought I'd read some discussion about cables but can't find it so I'm wondering if I dreamt it. I bought a cheapo DC power extension cable in order to cut off the connector and suitable length of wire - it's simply zip wire/fig 8, does it matter what the cable is? (I'm reluctant to cut off the wire from the SB wallwart.)

Unfortunately I haven't got very far with the second (9V) supply. I wanted to try another R core so I ordered one from Selectronic, along with a couple more for a DAC project, but had a bad experience. I wasn't confident enough of my French to use the on line checkout so exchanged a few emails (mostly in English) and they were helpful and prompt. But after I paid by PayPal I never received another email or the goods. I gave up emailing in the end and had to reclaim my money through PayPal. PayPal have now found in my favour but I'm still waiting for the money to be refunded. They offered this reassurance, which doesn't actually reassure me I'll get my money back much at all 🙁

If the seller's account has insufficient funds to complete the refund owed to you, please be assured that we will take appropriate action against the seller's account, which may include limitation of the seller's account privileges.

finished

Hi Jean-Paul. Thank for your comments.

The box is not a portable device so i think it is ok so.

As you could see the pcb is also fixed with the 2 pins soldered to the heatsink.

And next, the regulator is part of fixation.

Before with a closed box the diode temp was 42 degrees after a day in use.

But in between i made sleeves in bottom and sides for a lower result.

As extra i made a sink for the diodes. Now it stays 32 degrees.

I am happy with the result as it is now.

Regards, Loek

Hi Jean-Paul. Thank for your comments.

The box is not a portable device so i think it is ok so.

As you could see the pcb is also fixed with the 2 pins soldered to the heatsink.

And next, the regulator is part of fixation.

Before with a closed box the diode temp was 42 degrees after a day in use.

But in between i made sleeves in bottom and sides for a lower result.

As extra i made a sink for the diodes. Now it stays 32 degrees.

I am happy with the result as it is now.

Regards, Loek

Attachments

Triad Transformer Snubber?

I am finally getting around to ordering parts for my SBT PSU. I'm new to this type of input snubber. Can someone point me to a place to read up on how choose the values based on the transformer? My search so far has seemed to point to post-diode snubbers.

Or, those of you who have already figured this out for the Triad transformer could just share the values that you used for R1, C1. 🙂

Jac

I am finally getting around to ordering parts for my SBT PSU. I'm new to this type of input snubber. Can someone point me to a place to read up on how choose the values based on the transformer? My search so far has seemed to point to post-diode snubbers.

Or, those of you who have already figured this out for the Triad transformer could just share the values that you used for R1, C1. 🙂

Jac

A question for J-P.

In the BOM, you are quite specific about using a specific, common mode choke. No problem, I can get the specific model from Mouser on my next order. However, the parts order that I am currently working on is to Newark (Farnell) and will be a month or more before the Mouser order. Newark has a common mode choke that is very close to your specified choke. Please look at the datasheets and let me know if the Newark part is close enough.

Newark manufacturer part number - ACM12V-701-2PL-TL00

http://www.farnell.com/datasheets/1744609.pdf

Mouser manufacturer part number - ACM1211-701-2PL-TL01

http://www.mouser.com/ds/2/400/e9713_acm-16715.pdf

Thanks for your time.

Jac

In the BOM, you are quite specific about using a specific, common mode choke. No problem, I can get the specific model from Mouser on my next order. However, the parts order that I am currently working on is to Newark (Farnell) and will be a month or more before the Mouser order. Newark has a common mode choke that is very close to your specified choke. Please look at the datasheets and let me know if the Newark part is close enough.

Newark manufacturer part number - ACM12V-701-2PL-TL00

http://www.farnell.com/datasheets/1744609.pdf

Mouser manufacturer part number - ACM1211-701-2PL-TL01

http://www.mouser.com/ds/2/400/e9713_acm-16715.pdf

Thanks for your time.

Jac

- Status

- Not open for further replies.

- Home

- Amplifiers

- Power Supplies

- Building the SBT PSU