I'm slightly behind your progress Gary, LatFets and boards (also in blue) are in hand. Just finalizing a monster Mouser parts order that includes this one and a few others....busy upcoming winter  .

.

Thanks for the additional info Tombo 😉.

.

.Thanks for the additional info Tombo 😉.

You might jump ahead of me then Vunce as I have to get the LatFets form the UK, also need to sort a chassis. Good luck with all your planned Winter projects.

It should would work very well, but results will be slightly to considerably worse (scratch that ultimate word).

During development, for months, on the bench was measured and listened amplifier with ECX10 equivalents (ALF08 as in FW F7).

With ECX, distortion will be 6 dB higher at low levels and considerably worse at full power. You won’t get 20 W to 4Ω at all because it will clip before. With ECW, amplifier drives less than 2Ω load without a hitch.

Harmonic profile will be the same up to several W power but close to 8 -10 W it is considerably worse.

Required changes are: R16/R17 to 100Ω, R10 to 220-270Ω as ECX require some 0.6 V more Vgs and have less input capacitance. You can assemble amplifier with ECX at hand and decide if it is worth to order ECW later.

My only concern is that I haven’t tested that version assembled on PCB and can’t say for sure that phase margin and stability with capacitive loads will be the same. Parasitics are different on the breadboard. But, increasing slightly C6 can solve any stability problem. Though, scratch that ultimate word again. 😉

During development, for months, on the bench was measured and listened amplifier with ECX10 equivalents (ALF08 as in FW F7).

With ECX, distortion will be 6 dB higher at low levels and considerably worse at full power. You won’t get 20 W to 4Ω at all because it will clip before. With ECW, amplifier drives less than 2Ω load without a hitch.

Harmonic profile will be the same up to several W power but close to 8 -10 W it is considerably worse.

Required changes are: R16/R17 to 100Ω, R10 to 220-270Ω as ECX require some 0.6 V more Vgs and have less input capacitance. You can assemble amplifier with ECX at hand and decide if it is worth to order ECW later.

My only concern is that I haven’t tested that version assembled on PCB and can’t say for sure that phase margin and stability with capacitive loads will be the same. Parasitics are different on the breadboard. But, increasing slightly C6 can solve any stability problem. Though, scratch that ultimate word again. 😉

Thanks for the comprehensive answer on that, I think I will stay with the devices as per your design to be safe.

It is basically the same version optimized for lower voltages. First design goal was to cover wide voltage range an that results with some performance compromises. Version for lover voltages (up to 35V) uses the same major parts (sorry there are no new easily available MOSFETs) but has about 10 dB better PSRR (actually measured) at low frequency. I assembled for this amplifier low voltage regulators using same PCBs as for standard version.

@tombo56 : Hi ... Very interesting design, thanks for sharing 😉 ..

I was considering simulating the amplifier in LTSpice and to this end did a Google search for spice files for the Exicon transistors, however, no result. Any chance you have some spice models of these MOSFETs that you can share?

Cheers & have a fine day,

Jesper

I was considering simulating the amplifier in LTSpice and to this end did a Google search for spice files for the Exicon transistors, however, no result. Any chance you have some spice models of these MOSFETs that you can share?

Cheers & have a fine day,

Jesper

Here are very good models for several lateral MOSFETs by IanHegglun and keantoken. With these models, LTSpice calculates 1W/8Ω distortion as 0.00004% and my latest measurement is 0.00007%.

Results for frequency response, rise time and noise are close to real circuit measurements.

Results for frequency response, rise time and noise are close to real circuit measurements.

Attachments

As already explained in post #64, single pair could work very well but performance will be degraded and amplifier stability with capacitive loads should be thoroughly examined.

For two output pairs, a new PCB would be required.

For two output pairs, a new PCB would be required.

We can always ask. 🙂 On the serious side, no.

In my view, it is right to publish only thoroughly tested designs and I don’t intend to build this amplifier with two output MOSFET pairs.

In my view, it is right to publish only thoroughly tested designs and I don’t intend to build this amplifier with two output MOSFET pairs.

No matching is required.

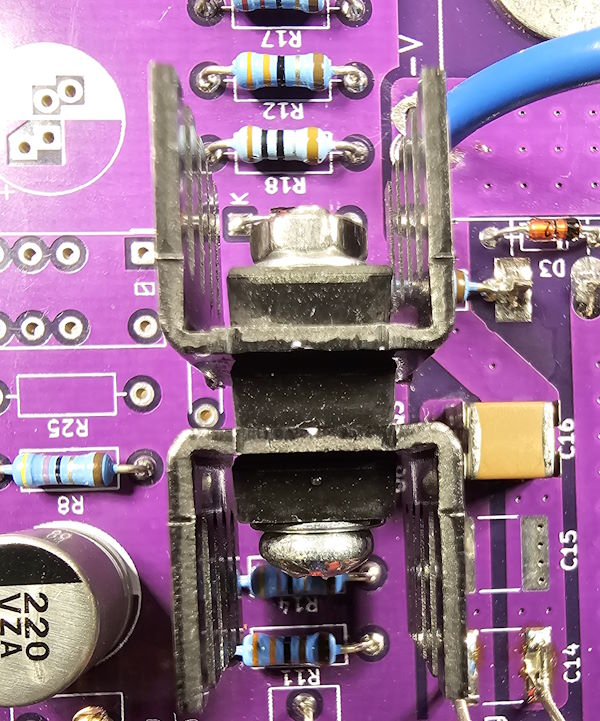

BJTs are tightened together with one screw and two flat washers. Here is picture from my development build. They should be provisionally stacked together with heatsinks before inserting them on the PCB. As a control point for orientation, BJT marking letters are facing toward PCB center for both BJT triplets.

After inserting one pack on the PCB, solder first just one central pin (middle BJT). Then adjust position (tilt) and then solder another to fix position, and if good solder the rest. Finally, align heatsinks and tighten assembly.

Now, when soldering is mentioned. This is a 4 - layer PCB with no thermal reliefs for easy soldering.

If soldering iron is indirect heating 60 W type (900M or similar) it will be real PITA to solder power MOSFETs and power/ground wires or fastons. Crank temperature above 400° C and use fattest tip you have.

With T12/T245 types, that have direct soldering tip heating and higher power, it is easier. Still, I had to wait 10 -20 s before solder would nicely flow at those spots.

BJTs are tightened together with one screw and two flat washers. Here is picture from my development build. They should be provisionally stacked together with heatsinks before inserting them on the PCB. As a control point for orientation, BJT marking letters are facing toward PCB center for both BJT triplets.

After inserting one pack on the PCB, solder first just one central pin (middle BJT). Then adjust position (tilt) and then solder another to fix position, and if good solder the rest. Finally, align heatsinks and tighten assembly.

Now, when soldering is mentioned. This is a 4 - layer PCB with no thermal reliefs for easy soldering.

If soldering iron is indirect heating 60 W type (900M or similar) it will be real PITA to solder power MOSFETs and power/ground wires or fastons. Crank temperature above 400° C and use fattest tip you have.

With T12/T245 types, that have direct soldering tip heating and higher power, it is easier. Still, I had to wait 10 -20 s before solder would nicely flow at those spots.

A great little amp! What impresses me most is the negligible difference in distortion between 4 and 8 ohms. What is the reason for this?

This amplifier has very good linearity. Required voltage or current for the same power at 4 or 8 Ω differ only 3 dB. Amplifier works for both loads at very close points of its linearity curve, so distortion differences are small. There are other details that help as separate signal and decoupling grounds and PCB design.What impresses me most is the negligible difference in distortion between 4 and 8 ohms. What is the reason for this?

I'm most impressed by its sound. 😀

- Home

- Amplifiers

- Solid State

- Building an ultimate low power class A amplifier – my way