Good morning gentlemen,

concerning mounting the transistor on the heatsink surface:

I can see, in all your pictures, two possibilities:

- press on the heatsink with a small beam or

- fix with a screw through a washer

Which of this option is the most effective? Maybe a beam of wood for a better insulation?

Thank you

Musically yours

concerning mounting the transistor on the heatsink surface:

I can see, in all your pictures, two possibilities:

- press on the heatsink with a small beam or

- fix with a screw through a washer

Which of this option is the most effective? Maybe a beam of wood for a better insulation?

Thank you

Musically yours

TYM, unfortunately, I think the answer is 'it depends'

I don't pretend to be a materials science major with a minor in thermodynamics, but for the purposes of heat conduction, either approach will work.

- If you're building a one-off to see how it performs, then the 'beam' mount seems like it'd be easier. I can imagine bolting the beam to your heat sink without making any holes in the heat sink. It would also allow you to try more easily different transistors, if that's your thing. The beam really shouldn't be the heat conductor, but should be sturdy enough to cause the transistor to have even contact across its reverse face.

- If you're building the amp to be The Power Amp for you, and you are comfortable using a tap to create screw threads in your heat sink, then the fixed screw method might be better, as a tidier and more 'permanent' solution. The washer + lock washer is pretty all required, as the lock washer helps you regulate the pressure, and the washer spreads the pressure out over the entire body of the transistor. (props to ZenMod for that advice)

Kind regards,

Drew

I don't pretend to be a materials science major with a minor in thermodynamics, but for the purposes of heat conduction, either approach will work.

- If you're building a one-off to see how it performs, then the 'beam' mount seems like it'd be easier. I can imagine bolting the beam to your heat sink without making any holes in the heat sink. It would also allow you to try more easily different transistors, if that's your thing. The beam really shouldn't be the heat conductor, but should be sturdy enough to cause the transistor to have even contact across its reverse face.

- If you're building the amp to be The Power Amp for you, and you are comfortable using a tap to create screw threads in your heat sink, then the fixed screw method might be better, as a tidier and more 'permanent' solution. The washer + lock washer is pretty all required, as the lock washer helps you regulate the pressure, and the washer spreads the pressure out over the entire body of the transistor. (props to ZenMod for that advice)

Kind regards,

Drew

hardly anything of my own invention there ........ I'm just hysterical enough , to scream all the time what's proper engineering practice from Yore - split washer and big washer , wherever you have heat-cycling present

That is absolutely outstanding! Well done!!

🙂 🙂 🙂

😀 😀 😀

Congratulations and enjoy listening to your new amplifier!

🙂 🙂 🙂

😀 😀 😀

Congratulations and enjoy listening to your new amplifier!

I just finished my MOFO + BA-3 integrated amp. It is a beautiful sound amp ,like tube but don't be worried on degradation. Thank you Michael.

Fugly!

There's a lot of discussion, I'm eager to build this MoFo, 193V was very expensive and hard to find, guess Im going to build some chokes.

You might want to check out the CH-4 Bel Signal choke. I built a MoFo with these and they work fine. Granted, about half the inductance, but also about half the price. You can see my build at post #1880.

CH-4 Bel Signal Transformer | Mouser

CH-4 Bel Signal Transformer | Mouser

There's a lot of discussion, I'm eager to build this MoFo, 193V was very expensive and hard to find, guess Im going to build some chokes.

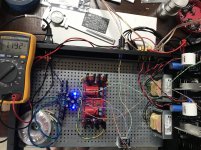

Another MoFo Up and Running

After a short hiatus I jumped back on my MoFo build. Got it up and running today along with the BA3 Preamp. The combination sounds great so far. Playing on my 0.53x mini-karlsonators the BA3 and MoFo go plenty loud. The combo is also dead silent with no turn on thump. This is turning out to be a great integrated project. Still have to get the phono stage soldered up but that’s another project for another day. In the meantime I’m going to get some more listening time on the MoFo. Thank you Michael for a fantastic amplifier and thanks again to 6L6 for the BA3.

After a short hiatus I jumped back on my MoFo build. Got it up and running today along with the BA3 Preamp. The combination sounds great so far. Playing on my 0.53x mini-karlsonators the BA3 and MoFo go plenty loud. The combo is also dead silent with no turn on thump. This is turning out to be a great integrated project. Still have to get the phono stage soldered up but that’s another project for another day. In the meantime I’m going to get some more listening time on the MoFo. Thank you Michael for a fantastic amplifier and thanks again to 6L6 for the BA3.

Attachments

Good to hear, @jwjarch. I am heading toward a similar config, but with an AKSA/Lender preamp. Working now on the 0.53 Karlsonators, so beautifully shepherded by @xrk971.

I found foam board with one sticky side at a national craft supply chain.

Drew

I found foam board with one sticky side at a national craft supply chain.

Drew

Last edited:

Good to hear, @jwarch. I am heading toward a similar config, but with an AKSA/Lender preamp. Working now on the 0.53 Karlsonators, so beautifully shepherded by @xrk971.

I found foam board with one sticky side at a national craft supply chain.

Drew

I found foam board with one sticky side at a national craft supply chain.

Drew

Hi Drew. You won’t be disappointed. I have also built the AKSA/Lender pre. I have it driving an Alpha 20 right now and it’s a great combination as well. I may try swapping it in to my MoFo as some point to compare vs the BA3.

@thompsontechs from the BA3 thread. The CPU coolers are Megahalems by Prolimatech, LGA 1156 type. I believe there good up to 120 watts of dissipation each. The heat pipes barely get warm with the MoFo biased at 1.19 volts at the 159zc inductors. I still have to add a resistor to take down the fan speed to ultra quiet.

@thompsontechs from the BA3 thread. The CPU coolers are Megahalems by Prolimatech, LGA 1156 type. I believe there good up to 120 watts of dissipation each. The heat pipes barely get warm with the MoFo biased at 1.19 volts at the 159zc inductors. I still have to add a resistor to take down the fan speed to ultra quiet.

- Home

- Amplifiers

- Pass Labs

- Build This MoFo!