Some manufacturer change the version without changing the name and some database specify "2015" version "2021" version ...This isinterestingfrustrating

Parts Express shows Qms of 3.22 which isn't meaningfully different from 2.9 but I wondered why the difference. I checked the official LaVoce data sheet at Parts Express and it also said 3.22.

So, I went to toutlehautparleur.com and checked, and sure enough they show 2.9 and have an official LaVoce data sheet that says 2.9.

So I went to LaVoce's home page. And they show on their product page as well as an official LaVoce data sheet Qms = 5.36.

I won't translate for those non-English speakers, but WTF?

That was the same for example with the 15OB350 from sb audiance.

I'm pretty sure that PA manufacturer are doing a big bunch of cone that are all consistant because done with the same machine at the same time and same settings and then they are manufacturing driver with this bunch of cone.

I guess that when they arrive out of stock they make new batch of cones and change the datasheet according to the new samples.

I have for example an 18 sound 8nmb420 that has been done in 2023 but the cone has been manufactured in 2019

THLP do not seems to take care of this and do not update datasheets (by the way they might not be aware of modifications when there is some ...)

Here for example on THLP the datasheet has been made in 04/2018 and it is written "All specifications subject to change without notice_B.a"

The one on lavoce has been made in 2024 ans it is written "All specifications subject to change without notice_H.a"

The voice-coil does no seems to be the same (LE 1.3 and 1.21). I can understand that manufacturer change something for example to improve FR. But they should specify the revision of the driver in the name. It is probably not a big issue for PA since they will EQ almost every time. But it's not the same for Home Audio ...

Here you just can't know what you will get when buying the driver. New or older revision ...

Here you just can't know what you will get when buying the driver. New or older revision ...

And that's the biggest concern of mine when going with LaVoce woofers.

I've been eyebaling some 15" woofers of theirs at one time. Few months later i was about to order but went on manufacturer website (instead of tlhp) and the difference was massive. Not being able to replicate the design is one thing but woofers not being marked what revision it was, you have to trust the distributor that it is a fresh batch. Imagine if there was one remained on stock, distributor restock them and you get one old and one new.

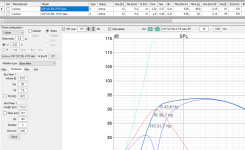

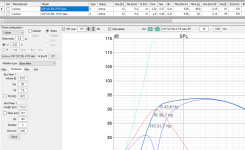

Hi, differences in Lavoce data are not meaningful in practice it seems. I took data from TLHP datasheet and also from parts express site and here they are overlaid in simulator. Difference in same box is about invisible, this image has the other driver as overlay and the other active, and the dashed line is barely visible.

Qms describes stiffness of suspension. I speculate datasheet value is likely some average arrived with test methods they use at the factory and then nicely rounded. PE data is likely measured by them, perhaps using just one driver, because it's given with one more decimal. Anyway, their test method likely differs a bit and the suspension wasn't perhaps warmed / stretched similarly. Anyway, the data seems to be close enough to be within very good tolerance it seems, because the actual response in a box (simulated) doesn't change basically at all.

Qms describes stiffness of suspension. I speculate datasheet value is likely some average arrived with test methods they use at the factory and then nicely rounded. PE data is likely measured by them, perhaps using just one driver, because it's given with one more decimal. Anyway, their test method likely differs a bit and the suspension wasn't perhaps warmed / stretched similarly. Anyway, the data seems to be close enough to be within very good tolerance it seems, because the actual response in a box (simulated) doesn't change basically at all.

Last edited:

There is a little bit more differences with the datas on LAVOCE website.

But it's true there is not much differences with TS parameters

Measurements on datasheets are different even if they are saying they do it the same way with same klippel.

Old one

New one. (closer to 89db by the way ...)

But it's true there is not much differences with TS parameters

Measurements on datasheets are different even if they are saying they do it the same way with same klippel.

Old one

New one. (closer to 89db by the way ...)

If I am not mistaken it's the inverse "lossyness" of suspension.Qms describes stiffness of suspension.

Stiffness affects compliance.

There is a little bit more differences with the datas on LAVOCE website.

But it's true there is not much differences with TS parameters

View attachment 1423487

Measurements on datasheets are different even if they are saying they do it the same way with same klippel.

Old one

View attachment 1423488

New one. (closer to 89db by the way ...)

View attachment 1423489

If we presume that both frequency response are accurate for transducers from that period, crossovers for those would be different and not by a small amount, esoecially if you move crossover frequency up.

yeah, it would be a good thing to select ~consistent drivers for a project like this, where a person is supposed to be able to skip testing the drivers they have bought, along with adjusting the crossover accordingly, without much penalty in performance. Conversely everyone could accept there is some error anyway, unless everything is tweaked per measurements of actual unit at hand. +-1db performance isn't achieved anyway even if everything was matched to teeth and measured just due to edge diffraction alone. These are all compromises that come with such project and no need to agonize over, some error is gonna be there and thats ok because main goals is the classic look and affordable cost and ease of build and so on, a fun project. Last millimeter measured performance would be completely different project, where looks and cost are by necessity things that very likely get sacrifized to get the performance.

Last edited:

I believe there is a misunderstanding of what Qms is and how/where it's important.Hi, differences in Lavoce data are not meaningful in practice it seems....

Qms describes stiffness of suspension.

For box tuning, you're mainly concerned with Qts, which in turn is mainly determined by Qes with most drivers. Qms usually has little effect on Qts. This is why the box tuning will not be sensitive to Qms.

Qms is NOT a measure of the suspension stiffness. Qms describes the mechanical losses within the driver. High Qms means low mechanical loss (and vice versa). You'll want to keep the mechanical losses within driver as low as possible because these loss processes (friction!) tend to be highly non-linear and therefore affect sound quality.

Electrical loss is typically less non-linear is therefore not critical.

Hi, yeah thanks for correcting the terms. In case anyone is confused always resort to data online:

https://en.wikipedia.org/wiki/Thiele/Small_parameters

https://en.wikipedia.org/wiki/Thiele/Small_parameters

These are context dependent aren't they? Suspension non-linearities affect (distortion) performance at the resonance but not much above, while motor non-linearities affect the whole bandwidth. So for a bass woofer the suspension is important, but for a mid not much so other than for it's ability to dampen any cone resonances, right? Perhaps motor distortion isn't that meaningful either other than if the driver does both bass and mid. And, when the system is capable enough none of the non-linearities matter much because non-linear distortoin is low enough not to be audible, but damping of cone resonances likely would as they do not depend on excursion and SPL, so lossy surround? For live sound progressively stiff surround would likely save the driver killing itself when the weekend warrior cranks it. So, question is then what's suitable for this particular application and high Qms could be good choise as it's for a three way speaker for home use.u'll want to keep the mechanical losses within driver as low as possible because these loss processes (friction!) tend to be highly non-linear and therefore affect sound quality.

Electrical loss is typically less non-linear is therefore not critical.

Last edited:

I don't agree. If the mechanical-loss processes are not isolated to resonance. They happen at non-resonant frequencies, too.Suspension non-linearities affect (distortion) performance at the resonance but not much above, while motor non-linearities affect the whole bandwidth.

Again, don't consider Qms as a parameter of high relevance for box tuning (which is about tweaking the resonant behaviour). Instead, consider Qms as a parameter that reflects the mechanical "lossyness" of the driver (I hope there is a better English word!).

^^ I thought the suspension has very little effect above resonance, where mass dominates response of the system over the compliance.

Apparently stiffening suspension can change the apparent mass though, so you are right effects ought to span also above main resonance. Especially when there is high excursion due to lows.

Quote below from https://audioxpress.com/article/beyond-thiele-small-dumax-and-klippel-driver-measurement-systems

"

For force factor, whether in the mass loaded or compliance loaded range, in order for diaphragm motion to be linear, the driving force must be linear across the desired range of movement. If the driving force produced by the voice coil/magnet structure for a given drive signal changes as the coil moves through its excursion range, the force on the coil, and therefore the diaphragm, will not be linear, resulting in distortion.

For compliance, you might think that because the driver is mass loaded above resonance, compliance nonlinearities would only matter below resonance. While they are certainly very important in this range, they can also affect the driver above resonance.

To visualize this, think of a driver above resonance with a magnetic structure having unlimited linear excursion capability. Also think of the suspension having a compliance that is totally linear throughout most of its range, but also having a “brick wall” change in compliance when it reaches a certain distance, much like having a mechanical stop on both sides of the voice coil. It is easy to visualize that, above resonance, until the “brick wall” compliance limit is reached, as drive level is increased, the mass being constant and dominant will result in linear output.

"

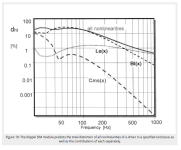

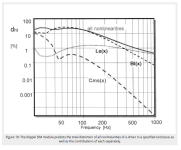

edit. here image from the above link that at least on this particular driver motor non-linearities seem to contribute order of magnitude more for most of the bandwidth indicating suspension issues are mostly on the lows. Do you have any info on audibility of these?

Apparently stiffening suspension can change the apparent mass though, so you are right effects ought to span also above main resonance. Especially when there is high excursion due to lows.

Quote below from https://audioxpress.com/article/beyond-thiele-small-dumax-and-klippel-driver-measurement-systems

"

For force factor, whether in the mass loaded or compliance loaded range, in order for diaphragm motion to be linear, the driving force must be linear across the desired range of movement. If the driving force produced by the voice coil/magnet structure for a given drive signal changes as the coil moves through its excursion range, the force on the coil, and therefore the diaphragm, will not be linear, resulting in distortion.

For compliance, you might think that because the driver is mass loaded above resonance, compliance nonlinearities would only matter below resonance. While they are certainly very important in this range, they can also affect the driver above resonance.

To visualize this, think of a driver above resonance with a magnetic structure having unlimited linear excursion capability. Also think of the suspension having a compliance that is totally linear throughout most of its range, but also having a “brick wall” change in compliance when it reaches a certain distance, much like having a mechanical stop on both sides of the voice coil. It is easy to visualize that, above resonance, until the “brick wall” compliance limit is reached, as drive level is increased, the mass being constant and dominant will result in linear output.

"

edit. here image from the above link that at least on this particular driver motor non-linearities seem to contribute order of magnitude more for most of the bandwidth indicating suspension issues are mostly on the lows. Do you have any info on audibility of these?

Last edited:

Just the same the acoustic impedance gets pretty dominant somewhere above the resonant frequency domain. Reducing the importance of Qms in the process.They happen at non-resonant frequencies, too.

Yes... but "damp(en)ing" smells like a mathematical terms from linear system analysis to me. That's exactly what I am not talking about.Damp(en)ing?

So, in a thought experiment where you operate a driver above resonance only, the suspension could be removed and the driver would still work the same? That's obviously not the case. The suspension is there, and the moving parts of the driver do move at all frequencies. The non-linear loss processes in the suspension material also still exist.I thought the suspension has very little effect above resonance

Not sure I get the idea here.Just the same the acoustic impedance gets pretty dominant somewhere above the resonant frequency domain. Reducing the importance of Qms in the process.

I'm considering this for myself. The Qms is real high. What do you guys think for a 300hz x-over?

https://www.parts-express.com/pedocs/specs/264-1654--tympany-sdf-250f75pr01-06-spec-sheet.pdf

.

https://www.parts-express.com/pedocs/specs/264-1654--tympany-sdf-250f75pr01-06-spec-sheet.pdf

.

@mbrennwa QMS is important for what you say, but in the total picture it's only a minor factor. That is why it's not a parameter that we check first, and if you need to compromise on it, it's effect is minimal. Also isolating a T/S parameter does not work, it's the balance between the parameters that make a speaker driver work or not work, and QMS is only one of the many, and by far not the most important one. CMS, RMS and Inductance are way more important for good sound than QMS within those mathematical parameters.

Just acting on your remark that the mechanical losses apply to a broader frequency range. That of course is true, but the acoustic damping (acoustic impedance, at frequencies where k.a>1 mainly resistive) on the cone exceeds Rms at higher frequencies. For a 12” woofer this (ballpark figures) is happening from 400-500Hz and up. For lower frequencies acoustic impedance is important too, but it gets a reactant component also (being the moving air in front of the cone). Rms mainly dictates the system at the resonance.Not sure I get the idea here.

- Home

- Loudspeakers

- Multi-Way

- Budget Classic 3-way Discussion Thread