Good luck. I have the same grand plan. So far I have only made small 1Khz horns, I have some European Oak and some American Cherry just waiting to be glued up and turned into something larger.

If I get it set up right, I can turn a horn with a mouth opening of 84" I think it would take a week or two just to hog out the inside. But I will start with a 1khz horn as you did.

I have been looking for a shop press to use as a glue up station. It would be a lot easier to use one shop press then handfuls of clamps.

You definitely wouldn't make a 84" horn from solid, I was looking at compound turning, joining lots of mitred bits together, far more efficient use of wood. Or have them like staves of a barrel, requires far more complex geometry and accuracy. I need to get my ones glued up...

If you find any tips please let me know

If you find any tips please let me know

Wouldn't that be something to turn an 84" horn. I don't think I'd be tackling that too soon. Yes, most of the horns will have to be glue ups. I could turn them out of solid logs, but the splitting would be an issue.

A 1khz horn could be turned out of a log though. That is small enough.

A 1khz horn could be turned out of a log though. That is small enough.

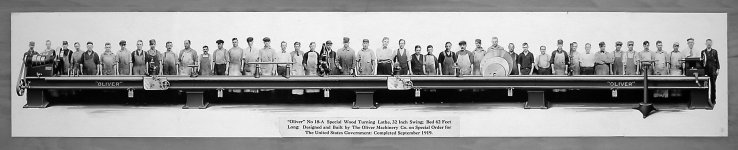

Your lathe can turn 64feet long?The compound slide is very heave duty for a wood lathe. This was never meant to be a metal lathe. It was used to make round parts to make molds in a foundry. With the bed extension it can turn a piece 30 inches in diameter and 64 feet long. Yep 64 FEET. I think they only made 3 of those bed extensions.

Ha Ha, it's April !st again.😀

How does one get an 84" mouth to pass through the doorway?

Or does one build the house around it/them?

Or does one build the house around it/them?

The compound slide is very heave duty for a wood lathe. This was never meant to be a metal lathe. It was used to make round parts to make molds in a foundry. With the bed extension it can turn a piece 30 inches in diameter and 64 feet long. Yep 64 FEET. I think they only made 3 of those bed extensions.

A 30 inch diameter log of lightweight Basswood 64 feet long would weigh 11,000lb approx. Think about it.

How does one get an 84" mouth to pass through the doorway?

Or does one build the house around it/them?

I think it would have to be done in sections.

A 30 inch diameter log of lightweight Basswood 64 feet long would weigh 11,000lb approx. Think about it.

Cool ah?

Yep, I am running a 5hp rotary phase converter too. Between the two my electric bill should go up a bit. I don't have plans to build guards for the band saw YET, but until I do, I will be the only person using it. No one else will be allowed near it.

But you only need a capacitor...anything is better than a single phase motor!

Nice find.

I've always been fascinated by big horns, but never gotten around to actually making a pair, though I have the equipment for it.

Magura 🙂

I've always been fascinated by big horns, but never gotten around to actually making a pair, though I have the equipment for it.

Magura 🙂

Very nice find. Well done, sir. What are your plans for a first, tractrix , Le Cleac'h?

I am thinking about the Tractrix profile.

But you only need a capacitor...anything is better than a single phase motor!

It has a 3 phase motor and I only have single phase so that is why I needed the rotary converter.

Nice find.

I've always been fascinated by big horns, but never gotten around to actually making a pair, though I have the equipment for it.

Magura 🙂

Can't hurt anything by turning a pair and see how it goes. The worst thing that can happen is you make really good looking firewood

Can't hurt anything by turning a pair and see how it goes. The worst thing that can happen is you make really good looking firewood

True, however it will prove very time consuming 😉

If the quality of the wood has to be reasonably good, it's gonna be pretty expensive as well.

A horn from 400Hz to 20kHz, would be awesome though.

Magura 🙂

The best wood to turn horns from is Poplar. It is stable, easy to turn, takes a stain very well, and the best part, it is not that expensive.

P.S., I really like the looks of your amps. The look very chic.

P.S., I really like the looks of your amps. The look very chic.

Last edited:

The best wood to turn horns from is Poplar. It is stable, easy to turn, takes a stain very well, and the best part, it is not that expensive.

P.S., I really like the looks of your amps. The look very chic.

Poplar is pretty expensive around here, as just about any other type of respectable wood is, unfortunately.

I'd wish I still knew somebody from the U.S. Forces stationed around here, as they got that sort of stuff shipped over for free.

...oh, and thanks for the compliment, not everybody thinks they're all that nice.

Magura 🙂

Don't listen to them. They just don't recognize art when they see it. How about plywood? The top of the line TAD horns are made from glued up plywood.

Don't listen to them. They just don't recognize art when they see it. How about plywood? The top of the line TAD horns are made from glued up plywood.

That may be an option.

Plywood, a good router, and lots of glue.

Magura 🙂

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Bought a lathe so I can turn horns