YESNo matter what wire or solder you use, you won't get a good joint if your components have oxidation. I keep a small piece of fine steel wool on the bench and clean the leads of my components right before installing and soldering them. For large joints, I also put on a little liquid flux. Cleanliness is key to a good solder joint.

Attachments

a lot recently on the JC Blowtorch thread re component cleaning and soldering in general. And do they get in a huff about it!

It simple to clean.

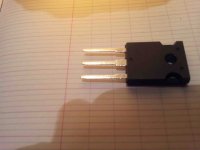

For IRFP i have use anti-static gloves for safety.

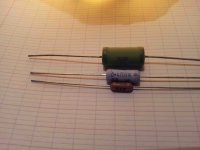

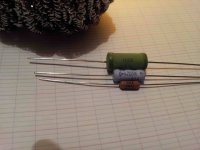

Images speaks him self.

Decker thank you for sharing

Have nice day😀

For IRFP i have use anti-static gloves for safety.

Images speaks him self.

Decker thank you for sharing

Have nice day😀

Thanks, soundhappy. Brianco, thanks for pointing out that part of the JC blowtorch thread. Interesting discussion. I notice that at least one person thinks that steel wool has contaminants that could interfere with soldering. Based upon this, I am thinking about trying brass wool instead. Or Scotchbrite pads.

My experience of metal 'wool' is that it is lightly oil coated to stop rust/oxygenation. I would not recommend it unless first really cleaned. I just scrape with an old blade. Works for me.

This one from last photos is INOX don't need be protected with oil.Old blade work i have try no chemicals needed is quick i like the resultMy experience of metal 'wool' is that it is lightly oil coated to stop rust/oxygenation. I would not recommend it unless first really cleaned. I just scrape with an old blade. Works for me.

I thought this was pretty good soldering/solder equipment and materials info.

EEVblog #180 - Soldering Tutorial Part 1 - Tools - YouTube

EEVblog #183 - Soldering Tutorial Part 2 - YouTube

EEVblog #186 - Soldering Tutorial Part 3 - Surface Mount - YouTube

EEVblog #180 - Soldering Tutorial Part 1 - Tools - YouTube

EEVblog #183 - Soldering Tutorial Part 2 - YouTube

EEVblog #186 - Soldering Tutorial Part 3 - Surface Mount - YouTube

Impressive 200k to 300k views ! That about 5% of the whole country . Love the accent make a dry subject fun for an old American . Go Kiwi !I thought this was pretty good soldering/solder equipment and materials info.

EEVblog #180 - Soldering Tutorial Part 1 - Tools - YouTube

EEVblog #183 - Soldering Tutorial Part 2 - YouTube

EEVblog #186 - Soldering Tutorial Part 3 - Surface Mount - YouTube

Last edited:

This inox wool is made to clean in kichen wet envirenment don't rust have put in the water no problem.

🙂

🙂

This inox wool is made to clean in kichen wet envirenment don't rust have put in the water no problem.

🙂

We call it "stainless".

Thanks is a excellent video!

Lets talk internal ideal wire for audio signal , diameter, magnetic shield for F4 , F5 , AlephJ your prefered brand and why?

Cheers

Lets talk internal ideal wire for audio signal , diameter, magnetic shield for F4 , F5 , AlephJ your prefered brand and why?

Cheers

Impressive 200k to 300k views ! That about 5% of the whole country . Love the accent make a dry subject fun for an old American . Go Kiwi !

I don't think that an Aussie will take kindly to being called a Kiwi😉

Last edited:

I do work with strain gauging ie extremely small signals and have discovered issues with crimped bnc connectors just for starters.

This is basic stuff for most people here but I thought you guys might like to see how we tackle this stuff.

http://www.vishaypg.com/docs/11051/tn501.pdf

This is basic stuff for most people here but I thought you guys might like to see how we tackle this stuff.

http://www.vishaypg.com/docs/11051/tn501.pdf

I ran the curser over his avatar and it said New Zeland thus the Kiwi .I don't think that an Aussie will take kindly to being called a Kiwi😉

Aussie/kiwi, close enough, may as well just call us ANZACs

Kiwis tend to have a greater appreciation for sheep than us though.

Kiwis tend to have a greater appreciation for sheep than us though.

I ran the curser over his avatar and it said New Zeland thus the Kiwi .

Oh, I see you were refering to the guy that posted the EEV Blog links. My mistake! I thought you were refering to EEV Blog Dave. I beg forgiveness.

Aussie/kiwi, close enough, may as well just call us ANZACs

Kiwis tend to have a greater appreciation for sheep than us though.

Sorry mates! I wanted to keep the sheep out of it! Just in case I ever get to visit that side.

Coming back to soldering though. How much of a benefit is hot air soldering? Is it worthwhile to get a hot air station in addition to a normal station?

Coming back to soldering though. How much of a benefit is hot air soldering? Is it worthwhile to get a hot air station in addition to a normal station?

I do almost all SMT with a pointy tip on an iron. Only the QFPs and such, and larger size things on a large copper plane do I use an air pencil and low temp paste. 😀

- Status

- Not open for further replies.

- Home

- Amplifiers

- Pass Labs

- Best solder and wire for Pass diy amplifiers ?