Is this an acceptable sub for OK1,OK2? The sharp part appears to be discontinued

https://www.digikey.ca/en/products/detail/onsemi/FOD817D/1049688

https://www.digikey.ca/en/products/detail/onsemi/FOD817D/1049688

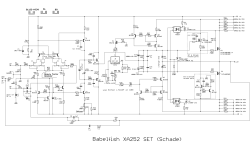

Building for SET mode.

1. Post 119 lists r46 to be changed to 33r, but shows 100r in the "SET" schematics sent to me which is correct?

2. ZD2 and ZD3 show 5v6 with a note to change to 6v2, which is right?

3. R26, R47 and GBR are 0 Ohm which means I just install a jumper?

Thank you

1. Post 119 lists r46 to be changed to 33r, but shows 100r in the "SET" schematics sent to me which is correct?

2. ZD2 and ZD3 show 5v6 with a note to change to 6v2, which is right?

3. R26, R47 and GBR are 0 Ohm which means I just install a jumper?

Thank you

there is a link in post #1 leading to post #624

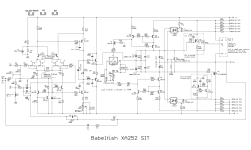

there you'll find separate schematic for each iteration

note - refer to schematic, Note on same can be misleading, I obviously forgot to delete them for SET and SIT

well, that beside spelling Babelfish with two "L"

there you'll find separate schematic for each iteration

note - refer to schematic, Note on same can be misleading, I obviously forgot to delete them for SET and SIT

well, that beside spelling Babelfish with two "L"

The schematic you linked to shows zd1,2 at 22v and zd3,4 5v6. But the schematic you emailed me shows zd1,2 12v and zd3,4 6v2. Which one should I follow?

In ZM's World ookups are permanent thing

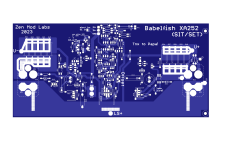

though, simple pic of your pcbs (few gens, but I took care of no change to previous parts nomenclature), should solve all dilemmas

last gen is having BSS170 cascode in place of upper zener above CCS and, yes, 12V zener bellow CCS ...... (so, just one 12V zener, not two)

now - protecting zeners for mosfet and SIT gates - anything from 5V6 to 12V will work there

though, if I sent you set of schematics, why looking for same in thread?

though, simple pic of your pcbs (few gens, but I took care of no change to previous parts nomenclature), should solve all dilemmas

last gen is having BSS170 cascode in place of upper zener above CCS and, yes, 12V zener bellow CCS ...... (so, just one 12V zener, not two)

now - protecting zeners for mosfet and SIT gates - anything from 5V6 to 12V will work there

though, if I sent you set of schematics, why looking for same in thread?

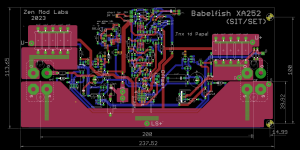

Attachments

-

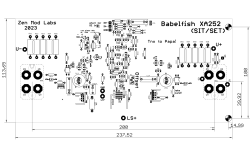

XA252 Eagle sshot.png57.9 KB · Views: 451

XA252 Eagle sshot.png57.9 KB · Views: 451 -

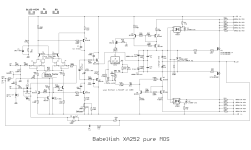

XA252 SIT schematic.png103.9 KB · Views: 196

XA252 SIT schematic.png103.9 KB · Views: 196 -

XA252 SET schematic.png104.7 KB · Views: 184

XA252 SET schematic.png104.7 KB · Views: 184 -

XA252 render top.png154.2 KB · Views: 181

XA252 render top.png154.2 KB · Views: 181 -

XA252 render bottom.png99.5 KB · Views: 196

XA252 render bottom.png99.5 KB · Views: 196 -

XA252 pure MOS schematic.png93.5 KB · Views: 189

XA252 pure MOS schematic.png93.5 KB · Views: 189 -

XA252 parts placement.png121 KB · Views: 201

XA252 parts placement.png121 KB · Views: 201 -

XA252 parts placement.pdf42.1 KB · Views: 177

Was just trying to figure out which one to follow. I think I figured it out, maybe I have the 2023 version which only has zd1,2,3. The schematics you just posted above are what I have. Sorry for the confusion I guess the older versions had ZD1,2,3,4(which you basically told me above, thanks again)

Zenmod, you included in my parts these nice little connectors. I have searched PC connectors and have yet to find ones like these. What are these called, I would like to order quantity. Maybe mouser/digikey not have? I will begin with Newark.

Much thanks in advance,

Russellc. 😺

Much thanks in advance,

Russellc. 😺

Attachments

These intended to be crimped right? Normally I heat and remove plastic, solder and shrink wrap but....I did just got a nice Kline

crimper. Looks like it would munch the plastic. Crimp or solder?

Thanks once more!

Russellc

crimper. Looks like it would munch the plastic. Crimp or solder?

Thanks once more!

Russellc

"The best crimped connection is one that has been soldered..." 😀Crimp or solder?

yup, wrote numerous times - heat to remove plastic junk, crimp slightly gently to wire, solder to wire , heatshrink with adequate color

Properly crimped is said to be more gas free connection than solder. I still solder."The best crimped connection is one that has been soldered..." 😀

I only say it because of my own experience dealing with, and having to repair some so called "properly crimped" connections from the OE at my workplace (railway electronics). I haven't seen the failure a lot over the past twenty years of repairing thousands of units, but I have had to fix some of them for sure..Properly crimped is said to be more gas free connection than solder. I still solder.

"I only say it because of my own experience dealing with, and having to repair some so called "properly crimped" connections from the OE at my workplace (railway electronics). I haven't seen the failure a lot over the past twenty years of repairing thousands of units, but I have had to fix some of them for sure.."

Oh I get it, but there are loads of bad crimpers out there, not where you want to scrimp. My other problem with crimp depends on what you crimped to. If it is a press fit deal, there's a service problem waiting to happen. That said, a properly done joint with a proper tool does create a gas free joint in a perfect world. Improper crimps no doubt lead to much service work. Same with solder joints that werent done properly.

I always grab crimp connector with needle nose, waive plastic end in stove flame and scrap off with butter knife. Solder and use heat shrink. I will see if I can find the article I spoke of. I bought this thing for the woofer section of one of X's speaker projects. It has 8 woofers per side, wired everywhich way and reversed phase hook up on half the drivers. Plenty of places for me to get a connection buggered. Once correct and working, solder joints all around.

I trust my solder work.

Russellc

Oh I get it, but there are loads of bad crimpers out there, not where you want to scrimp. My other problem with crimp depends on what you crimped to. If it is a press fit deal, there's a service problem waiting to happen. That said, a properly done joint with a proper tool does create a gas free joint in a perfect world. Improper crimps no doubt lead to much service work. Same with solder joints that werent done properly.

I always grab crimp connector with needle nose, waive plastic end in stove flame and scrap off with butter knife. Solder and use heat shrink. I will see if I can find the article I spoke of. I bought this thing for the woofer section of one of X's speaker projects. It has 8 woofers per side, wired everywhich way and reversed phase hook up on half the drivers. Plenty of places for me to get a connection buggered. Once correct and working, solder joints all around.

I trust my solder work.

Russellc

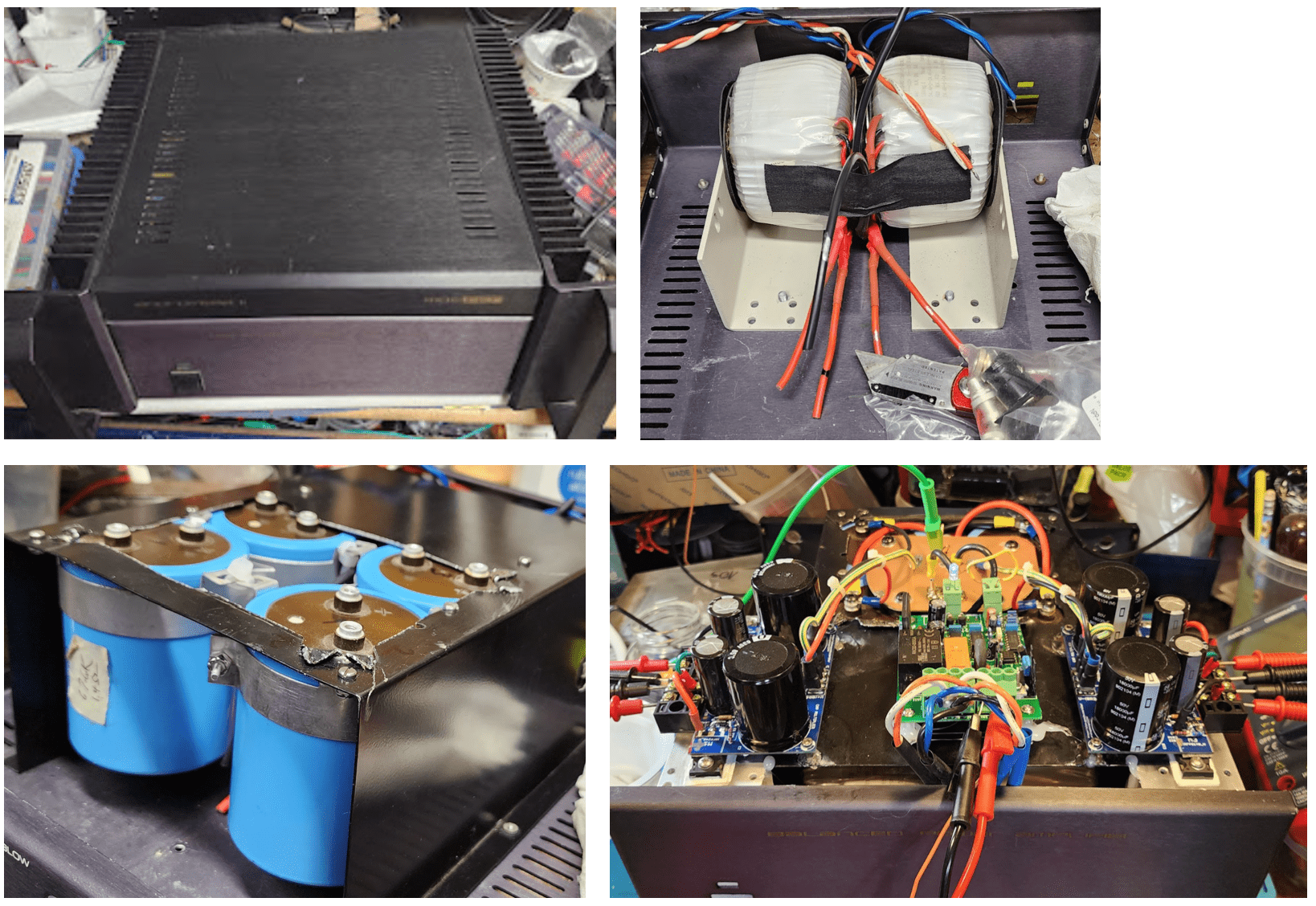

Made a start on my XA252 - picked up a non functional andromeda 2 as a donor chassis and built the power supply - rock solid 33.7V DC

..dB

..dB

- Home

- Amplifiers

- Pass Labs

- Babelfish XA252 / Babelfish XA252 SIT / Babelfish XA252 SET