Does anyone know where to find the kit chassis dimensions?

Oh I found it after my coffee....here it is in case anyone else wants it too

What are the chassis specifications?

Galaxy 230x170 full aluminum chassis, anodized black with white printing

Internal dimensions 40x210x170mm

LED hole ø2mm

Left switch

Hole ø6.5mm

15mm x 15mm square rear recess, 7mm deep

Right switch

Hole ø6.5mm

15mm x 24mm rectangular rear recess (allows for switch and LED), 7mm deep

Potentiometer hole ø10mm, with ø32mm round recess in the front ø8mm deep

Rear RCA holes ø10mm

Rear power switch hole ø11mm

Oh I found it after my coffee....here it is in case anyone else wants it too

What are the chassis specifications?

Galaxy 230x170 full aluminum chassis, anodized black with white printing

Internal dimensions 40x210x170mm

LED hole ø2mm

Left switch

Hole ø6.5mm

15mm x 15mm square rear recess, 7mm deep

Right switch

Hole ø6.5mm

15mm x 24mm rectangular rear recess (allows for switch and LED), 7mm deep

Potentiometer hole ø10mm, with ø32mm round recess in the front ø8mm deep

Rear RCA holes ø10mm

Rear power switch hole ø11mm

Last edited:

I added the to the new guide but will place it here --

(If the photos are huge, reload the page and the forum software should resize them.)

FIGHTING MICROPHONICS

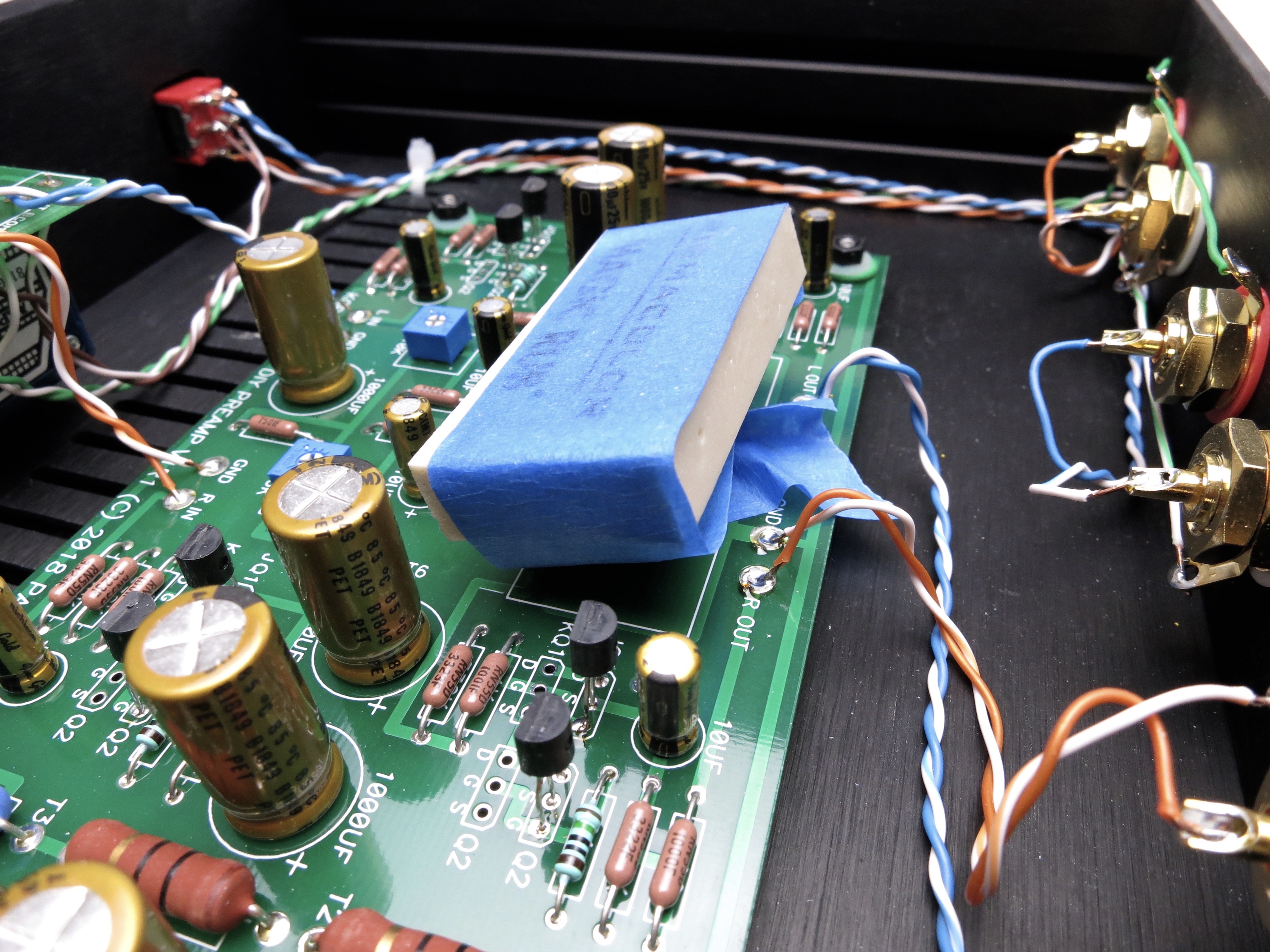

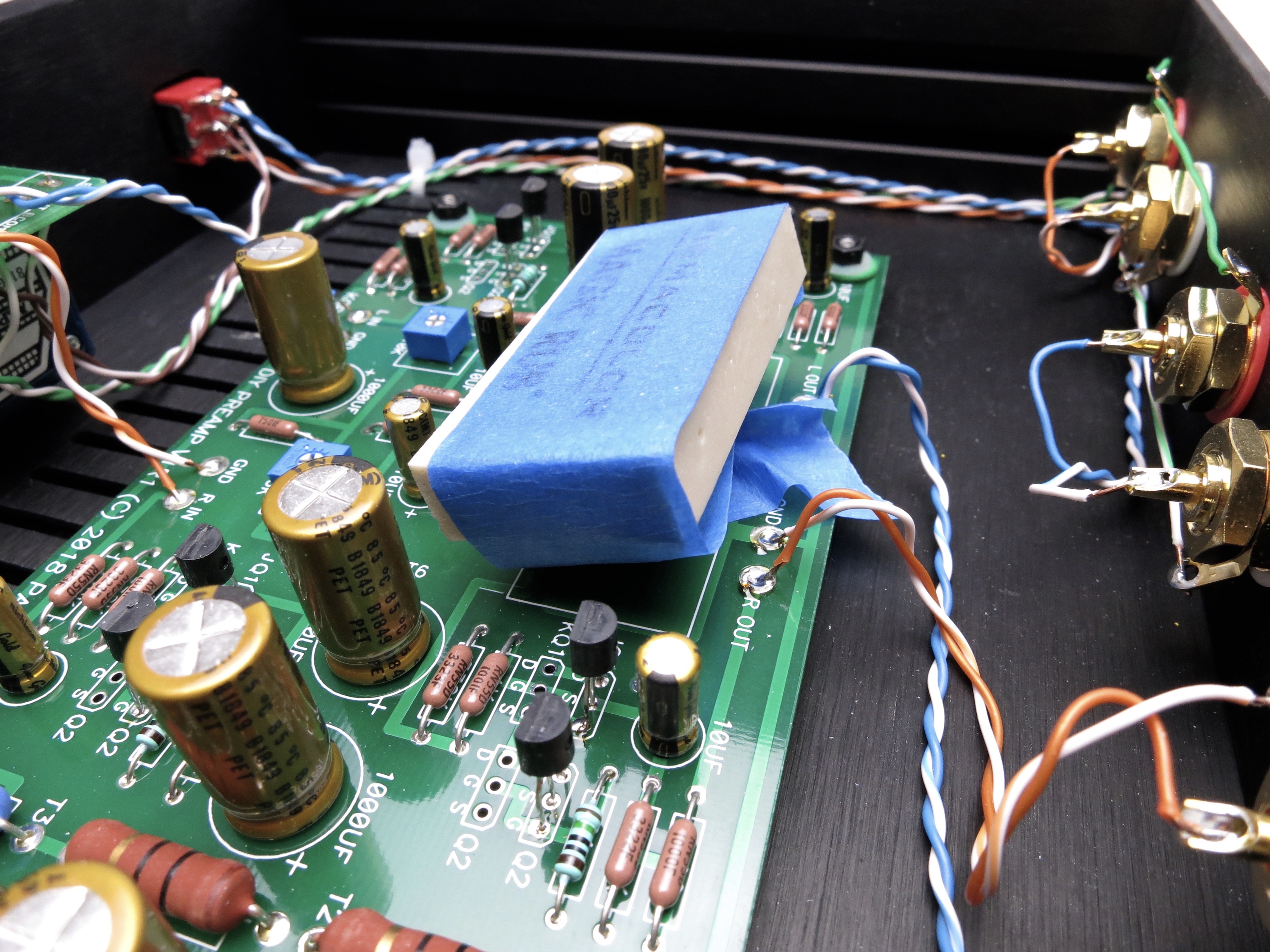

The Nutube can be microphonic. Everybody will hear it when they flip a switch, but some of the Nutube themselves are worse than others, it seems to be the vagaries of production. I tried a number of different solutions and the best results were to take a white latex pencil eraser to the to top of the glass, and then seal up the vent holes in the chassis. Newer chassis will not have vent holes.

Eraser trimmed to width. Taping it in place seems to damp better than something sticking directly on the surface. (Yes, it is counterintuitive...)

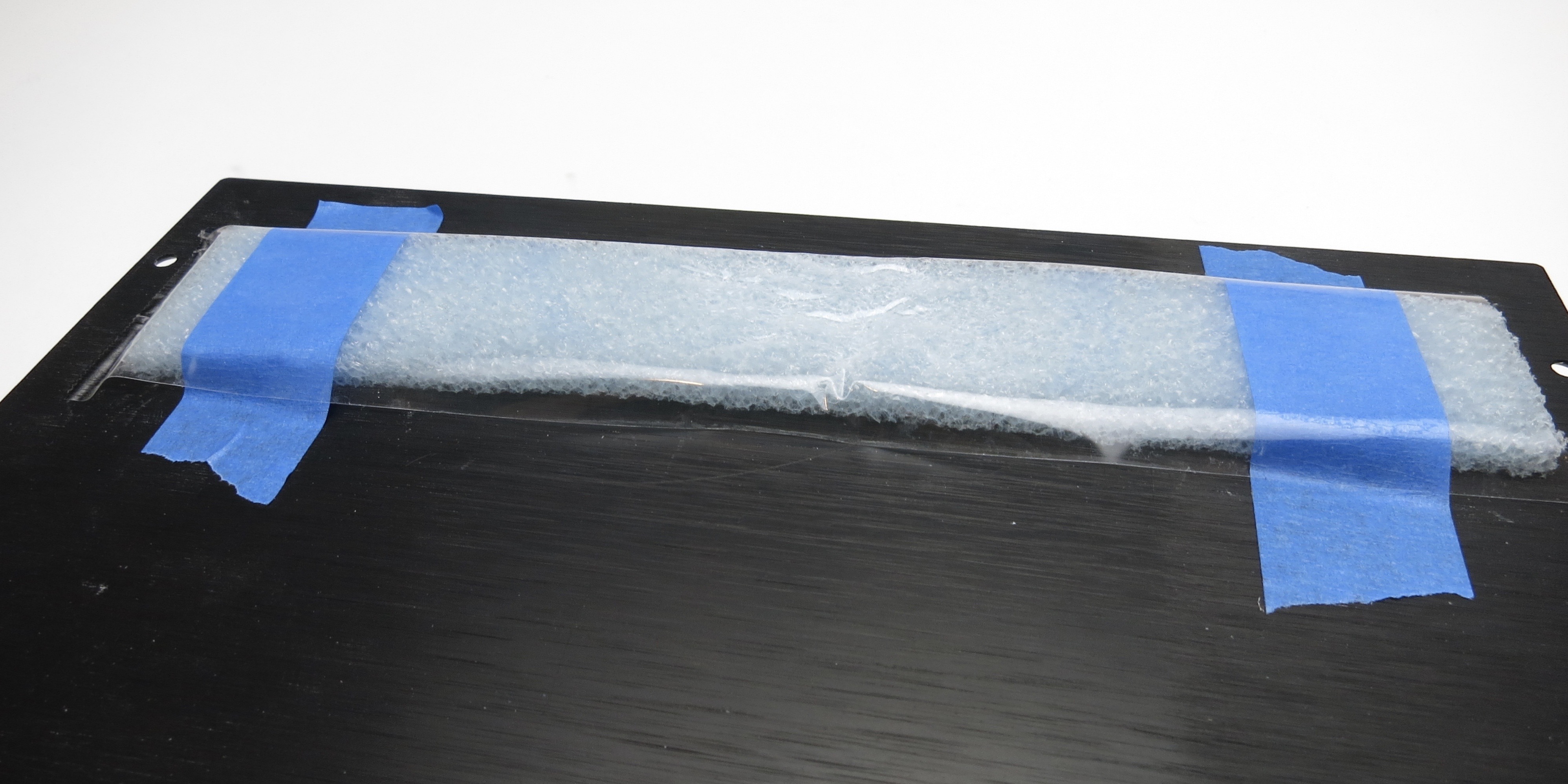

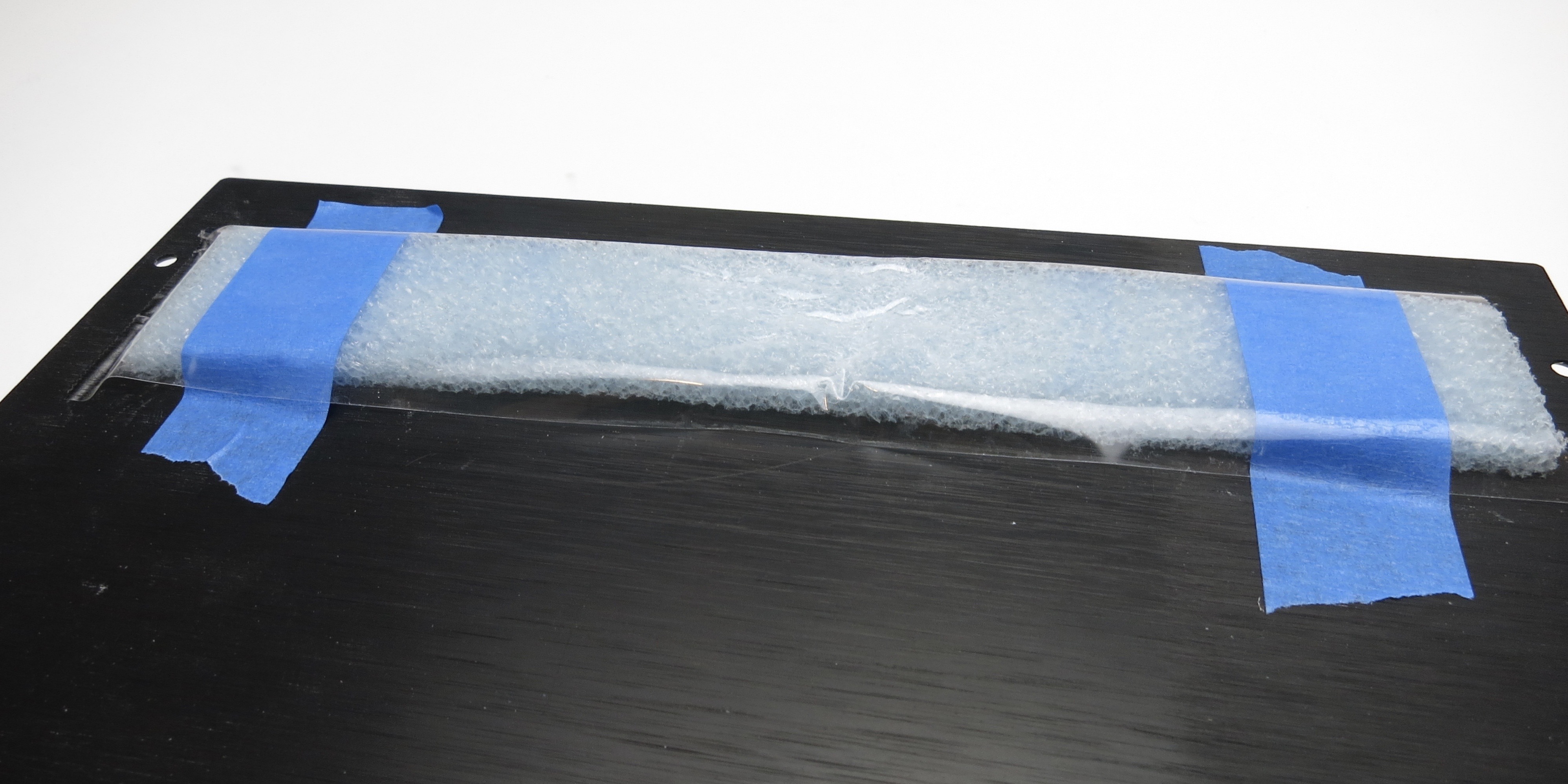

This is a self-adhesive rubberized material similar to Dynamat.

This is just some closed-cell shipping foam taped to the inside of the vents. Both it and the sticky foil-backed material worked well. Blocking it seems to be more important than absorbing or damping.

If anybody has suggestions or examples of what works, please share them! 🙂

(If the photos are huge, reload the page and the forum software should resize them.)

FIGHTING MICROPHONICS

The Nutube can be microphonic. Everybody will hear it when they flip a switch, but some of the Nutube themselves are worse than others, it seems to be the vagaries of production. I tried a number of different solutions and the best results were to take a white latex pencil eraser to the to top of the glass, and then seal up the vent holes in the chassis. Newer chassis will not have vent holes.

Eraser trimmed to width. Taping it in place seems to damp better than something sticking directly on the surface. (Yes, it is counterintuitive...)

This is a self-adhesive rubberized material similar to Dynamat.

This is just some closed-cell shipping foam taped to the inside of the vents. Both it and the sticky foil-backed material worked well. Blocking it seems to be more important than absorbing or damping.

If anybody has suggestions or examples of what works, please share them! 🙂

Got 6l6 and zenmod to thank for providing ideas..microphonic ..

Using screw and foam tape so applying a light pressure on the Korg , thick Plexi glass I cut it off my Plexi fan . Silicon wires, rubber stand off foam insulate from pcb to korg.Tube uses spring. So far no issue if I knock the casing or switch channel even case open

Also supply is seperated 2 ft away

There is a round rubber hole below the 6p1 . Was also stated not to cover it . It's some sort of heat dissipation.

I am magic rubbed

Maybe a fluke only tried one so ..but works wonderfully . It's just grazzy fun Korg b1 . Surprised it sounds palpable too. Depth, . No lost frequency...good tone like a tube preamp ..super super match for phono

Buddy say ..Korg b1 works so great for follower amp ..I will try it soon

Using screw and foam tape so applying a light pressure on the Korg , thick Plexi glass I cut it off my Plexi fan . Silicon wires, rubber stand off foam insulate from pcb to korg.Tube uses spring. So far no issue if I knock the casing or switch channel even case open

Also supply is seperated 2 ft away

There is a round rubber hole below the 6p1 . Was also stated not to cover it . It's some sort of heat dissipation.

I am magic rubbed

Maybe a fluke only tried one so ..but works wonderfully . It's just grazzy fun Korg b1 . Surprised it sounds palpable too. Depth, . No lost frequency...good tone like a tube preamp ..super super match for phono

Buddy say ..Korg b1 works so great for follower amp ..I will try it soon

Hi again

Here is a picture of my board, I triple checked but I can’t see any mistake that would explain why I can’t Bias the tubes propperly.

T5/6 won’t go higher than 0.5V and T7/8 won’t go lower than 15V.

Replacing the Bias Resistors by lower values ?

Thanks for your help !

Here is a picture of my board, I triple checked but I can’t see any mistake that would explain why I can’t Bias the tubes propperly.

T5/6 won’t go higher than 0.5V and T7/8 won’t go lower than 15V.

Replacing the Bias Resistors by lower values ?

Thanks for your help !

Attachments

Speaking about the microphonics... my amplifier sits on the bottom shelf of a console table.

The problem with vibrations is not only how to stop them from coming in, but mostly how to drain them out of your component. Soft footers lock vibrations inside the component and are the worst. You need a hard foot connection to a special "drainage" platform siting on semi-soft isolation blocks. Google MapleShade vibration isolation for details. (I have no association with MapleShade, just trying to help.)

newcomer!

dear all, I tried to catch with the discussion but it is really a huge 3D

can somebody point me where to find the following info about this project:

in/out impedance ?

gain ?

tnx!

dear all, I tried to catch with the discussion but it is really a huge 3D

can somebody point me where to find the following info about this project:

in/out impedance ?

gain ?

tnx!

Hi

Input impedance = your volume pot's impedance, anything between 20 and 100k seems to work fine

Output impedance = depends on your FETs, roughly from 160 to 250R

Gain is 16dB if I recall well.

Mate, you don't have to go through all the pages to find this out, it is all in one single paper I recommend you to read: the one Nelson issued on the B1 Korg. It has also a lot of other usefull bits...

I hope this helps

Claude

Input impedance = your volume pot's impedance, anything between 20 and 100k seems to work fine

Output impedance = depends on your FETs, roughly from 160 to 250R

Gain is 16dB if I recall well.

Mate, you don't have to go through all the pages to find this out, it is all in one single paper I recommend you to read: the one Nelson issued on the B1 Korg. It has also a lot of other usefull bits...

I hope this helps

Claude

thanks! You mean this document?

http://www.firstwatt.com/pdf/art_diy_nutube_preamp.pdf

didn't find in top google results! Thanks a lot

http://www.firstwatt.com/pdf/art_diy_nutube_preamp.pdf

didn't find in top google results! Thanks a lot

Well that sorts any lockdown boredom. Thank You again Mr Pass, 6L6 and all the contributors. You never fail to keep giving. Fantastic.

Hi again

Here is a picture of my board, I triple checked but I can’t see any mistake that would explain why I can’t Bias the tubes propperly.

T5/6 won’t go higher than 0.5V and T7/8 won’t go lower than 15V.

Replacing the Bias Resistors by lower values ?

Thanks for your help !

Bias resistor unless have diff voltage

Looks fine.. And correct Your pcb. Bottom pics?

Report on all test point voltage.. What type supply maybe the smarties will be tempted to comment.

Last edited:

Bias resistor unless have diff voltage

Looks fine.. And correct Your pcb. Bottom pics?

Report on all test point voltage.. What type supply maybe the smarties will be tempted to comment.

Thank you Anthony

Everything else measure as it should.

I use a low noise LPS, 24V sharp....

I will lower the Bias resistor values and see what happens.

Cheers

Got an email to preorder -- LOOKS GREAT!!

BUT -- c'mon!!! DUAL MONO VOLUME CONTROLS!!!

How many times I gotta say it??? So easy, so necessary in so many applications.............

BUT -- c'mon!!! DUAL MONO VOLUME CONTROLS!!!

How many times I gotta say it??? So easy, so necessary in so many applications.............

Not going to happen with the kit. (I like dual mono as well, but were are in the minority for sure). The chassis design is frozen for production.

This is DIY - this would be a great opportunity for you to make exactly what you are after!

This is DIY - this would be a great opportunity for you to make exactly what you are after!

If anybody has suggestions or examples of what works, please share them! 6L6

I built two boards after my first B1 Korg preamp to build a Balanced version. On one board the Nutube was soldered with a foam pad under the tube and the tube was pressed against the foam after soldering. On the second board, I did the same thing, however, after soldering the tube was raised off the pad and just floating in air after soldering. I didn't think much of it until the wife was complaining of a high pitched noise, sure enough it was from the completed Balanced B1 Korg preamp.

With the top cover of the case removed, I could press down on the tube and the noise would stop. So I used Nelson's suggestion and pressed the tube down against the foam and used hot glue to secure.

Haven't heard the ringing since and it's been a couple of months now. I went back and glued all the tubes down so they would never ring.

Thanks Nelson!

I built two boards after my first B1 Korg preamp to build a Balanced version. On one board the Nutube was soldered with a foam pad under the tube and the tube was pressed against the foam after soldering. On the second board, I did the same thing, however, after soldering the tube was raised off the pad and just floating in air after soldering. I didn't think much of it until the wife was complaining of a high pitched noise, sure enough it was from the completed Balanced B1 Korg preamp.

With the top cover of the case removed, I could press down on the tube and the noise would stop. So I used Nelson's suggestion and pressed the tube down against the foam and used hot glue to secure.

Haven't heard the ringing since and it's been a couple of months now. I went back and glued all the tubes down so they would never ring.

Thanks Nelson!

Not going to happen with the kit. (I like dual mono as well, but were are in the minority for sure). The chassis design is frozen for production.

This is DIY - this would be a great opportunity for you to make exactly what you are after!

Ach - that's the beauty of kits ! -- no need for 'custom fabrication'. but in this case, yeah -- just the boards please and we'll go with the de rigueur hammond box and drill...........

Who the heck DOESN'T want a dual mono, I've never understood. And all the decent pots don't charge more for that set up compared to stereo........

None of the commercial guys do it either -- I just don't get it. No downside, nothing but upside......Oh well -- my pet peeve.....

I have built two boards as well and noticed that one is ringing more/easier than the other ( tapping the wooden board it is sitting on). However when I mounted each board on rubber anti vibration standoffs, the ringing stopped. I couldn't get them to ring even tapping the wooden board. The nutubes are both mounted on the foam pads that came with the nutube.

Hi all

I was wondering if the new B1K kit will be a good match with my single ACA 1.6 ?

Sorry if this was ask before ,I couldn't find it

I was wondering if the new B1K kit will be a good match with my single ACA 1.6 ?

Sorry if this was ask before ,I couldn't find it

- Home

- Amplifiers

- Pass Labs

- B1 with Korg Triode