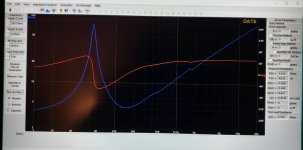

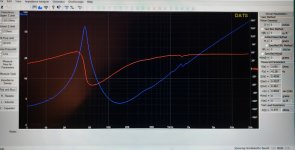

Having some issues with a new pair of B&C 18NW100s. Both TSPs measure significantly different than the factory specs. Fs is very high on both drivers as are Qts. The driver with slightly lower Fs has been run in with a 15V 10hz sine, pushing the driver up to xmax for a total of 1hr. After that I've seen only 2 hz drop, when it should end up at about 33 hz. The other driver with higher Fs is still like it was right out of the box.

I also measured the lower Fs driver right after disconnecting it from the test amp, being 35 - 36 hz with a slightly warm motor.

The below posted measurments were after cooling down over night.

Anyone else see this on their 18NW100s?

I also measured the lower Fs driver right after disconnecting it from the test amp, being 35 - 36 hz with a slightly warm motor.

The below posted measurments were after cooling down over night.

Anyone else see this on their 18NW100s?

Attachments

Forgot to mention I also manually measured Fs with a drop resistor to confirm the PC measurement.

@stv This is hard to do with a large driver that has a stiff suspension. Thats why I drive them harder with a low frequency sine. Its what I usually do to loosen up new PA drivers.

We'll see what PE says when I call them. They usually try to wiggle themselves out of a product defect claim by stating its normal to have a "reasonable" variation in production tolerances.

I'd warm them up for at least a few more hours.

I have a pair of NOS Meyer 15"s, still never put in service, that take hours every time I want to just measure them.

I luv truly stout suspensions ---once they break in LOL

I have a pair of NOS Meyer 15"s, still never put in service, that take hours every time I want to just measure them.

I luv truly stout suspensions ---once they break in LOL

What's the temperature in the room you are testing? Some parts of the US are getting pretty cold right now.

Did you try your box sim with the new params and see if it is much different?

What was your T/S measurement voltage and what could be the factory measurement voltage of B&C? Lower measurement voltage typically lead to higher Fs and Qts and lower Vas.

@cowanaudio Temp isn't an issue, as I'm in AZ. Daytime temps in mid 70s, 50s at night.

@HeadShake My sims are preliminary but the target ratios are off with the measured TSPs. I was going to test them sealed to determine Vas, as added weight guesstimate never seems to work properly.

@YSDR @Patrick Bateman I use.Dats V3 for quick and dirty measurments. If that doesn't look right, I break out Clio and plot the.impedance curve manually with 8V on larger pro LF drivers. All three methods agree with each other. I also heat the VC at min impedance first, than sweep with other measurement methods.

I dont understand why pretty much all the other companies get it reasonably close. Its always B&C that has issues if there are any.

@HeadShake My sims are preliminary but the target ratios are off with the measured TSPs. I was going to test them sealed to determine Vas, as added weight guesstimate never seems to work properly.

@YSDR @Patrick Bateman I use.Dats V3 for quick and dirty measurments. If that doesn't look right, I break out Clio and plot the.impedance curve manually with 8V on larger pro LF drivers. All three methods agree with each other. I also heat the VC at min impedance first, than sweep with other measurement methods.

I dont understand why pretty much all the other companies get it reasonably close. Its always B&C that has issues if there are any.

The B&C 18NW100-4 Xmax is 9mm, 15V seems low to see an 18mm peak to peak movement.The driver with slightly lower Fs has been run in with a 15V 10hz sine, pushing the driver up to xmax for a total of 1hr. After that I've seen only 2 hz drop, when it should end up at about 33 hz.

I applied a 50 volt, 11 Hz sine wave to a series pair of the BC18SW115-4 for two hours to loosen up the suspension.

Open air, they still did not exceed the 14mm Xmax figure, started at about 25 mm peak to peak, and were at 27 mm two hours later. That little break in does not seem to do much.

I did a push-up with my hands spread around the dust-cap of a B&C 18TBW100-4, which is a bit closer to the 18NW100-4. My push-up exerts 98 pounds on the bathroom scale, it seemed that weight could push the cone to Xlim (near as I could tell looking down) which is a one way deflection of 27mm.

While I have not measured the B&C 18NW100-4, a 5-6Hz variance from the published Fs at low drive levels does not seem out of line for a high-power, relatively low Vas driver.I also measured the lower Fs driver right after disconnecting it from the test amp, being 35 - 36 hz with a slightly warm motor.

As an example, I performed a drop resistor test on a brand new B&C 8NDL64-8 and measured it's Fs at 87 Hz, 7 Hz higher than the spec sheet rating of 80 Hz.

I then “broke in” the speaker by pushing the cone in and out by hand to around Xlim (as far as the suspension would allow) several times, then repeated the test, the Fs dropped to 78 Hz.

I had used around 4V for the two initial tests, after a few minutes used 1V (”small signal”) and read around 82 Hz, 4 Hz higher..

Bringing the voltage back up to 4V, the Fs dropped to 80Hz.

Anyway, if your B&C woofer's suspension has not ever been stretched well past Xmax, and hot tested with over 2volts, the Fs and the rest of the related parameters will probably be off.

I forgot to mention, when using the 8 ohm version of 18NW100, the TSPs were very close to factory data. These 4 ohm drivers don't follow any standards, not to mention B&C can't agree on official TSPs for it either. I looked all over the web for some logical answers to no avail. Its like they make this woofer in 4 ohms but it officially doesn't exist in their source of data.

@weltersys Hey Art, thanks for the reply. I understand what your saying. Do you find an actual factory specified Fs for the 4 ohm 18NW100? I went by the 8 ohm version (31 hz) and deduced that an extra 30 grams of Mms (likely due to the heavier 4 ohm VC windings) should be even lower than this. Still being over 11 hz higher than expected spec after some run in, there was something wrong. I'm not so worried about Qes and the resulting Qts being higher, as this will come down somewhat on its own.

I totally get that some of these PA drivers with there stiff double spider suspensions need serious manhandling to get within factory spec. This one is just not responding as much as expected compared to others I've dealt with.

I measured positive static xmax with a dial indicator and a 22V DC pulse, giving me an 8mm deflection. I went by the published BL and suspension compliance to calculate this. I wasn't comfortable going past this due to the motor becoming non-linear past 20V DC, so thats where I stopped.

The reason I suspect B&C screwed up on the specs is the fact the 8 ohm version of 18NW100 didn't require anywhere close to the effort to measure closer to published spec. The last time I had a discrepancy like this was with the 18PZB100, measuring 10 hz above the given 30 hz Fs. I also had some 8NDL51s measure why off spec. All the other B&C drivers were reasonably within their given specs.

I'll try to push the 18NW100s a little more for a longer time, but they were already straining in free air with a 15V 10 hz sine (21V peaks) generating some noticeable motor temp increase. The main reasons I chose this driver was the split winding VC and neo motor. The 18TBW100 is IMO a better driver, but the ferrite magnet makes it too heavy for portable use in a push-pull isobarik setup I had planned for it.

I totally get that some of these PA drivers with there stiff double spider suspensions need serious manhandling to get within factory spec. This one is just not responding as much as expected compared to others I've dealt with.

I measured positive static xmax with a dial indicator and a 22V DC pulse, giving me an 8mm deflection. I went by the published BL and suspension compliance to calculate this. I wasn't comfortable going past this due to the motor becoming non-linear past 20V DC, so thats where I stopped.

The reason I suspect B&C screwed up on the specs is the fact the 8 ohm version of 18NW100 didn't require anywhere close to the effort to measure closer to published spec. The last time I had a discrepancy like this was with the 18PZB100, measuring 10 hz above the given 30 hz Fs. I also had some 8NDL51s measure why off spec. All the other B&C drivers were reasonably within their given specs.

I'll try to push the 18NW100s a little more for a longer time, but they were already straining in free air with a 15V 10 hz sine (21V peaks) generating some noticeable motor temp increase. The main reasons I chose this driver was the split winding VC and neo motor. The 18TBW100 is IMO a better driver, but the ferrite magnet makes it too heavy for portable use in a push-pull isobarik setup I had planned for it.

Last edited:

Also don't forget that the Cms and Bl values changes significantly from even few millimeters of excursion.I measured positive static xmax with a dial indicator and a 22V DC pulse, giving me an 8mm deflection. I went by the published BL and suspension compliance to calculate this.

18TBW100-8 test

I would expect a considerably longer break-in time before Fs stabilises.xmax for a total of 1hr...

I'm going to mount the drivers on an open baffle and hook my GX8D up to push them for half a day. I've just never encountered a driver of this type needing so much break in time. Virtually all the other woofers that have passed through my hands measured so far off their published specs.

I meant to say "haven't measured so far off" in my last post. I've had out of spec issues like this with 8NDL51, 18PZB100, and now the 18NW100-8.

@6thplanet I'm sure they check the drivers for "rub and buzz" problems but not meeting advertised TSPs.

@6thplanet I'm sure they check the drivers for "rub and buzz" problems but not meeting advertised TSPs.

You have with this thread make me realize, that my own Faital pro 18 XL1600 must have the same problem.I've just never encountered a driver of this type needing so much break in time.

And thats why i was a little "disappointed" with mine.

Very likely i must force the cones to soften, because they are superstiff "lika a rock"

So thank you for making me realize that, soon i will take up that project again 👍

regards John

- Home

- Loudspeakers

- Multi-Way

- B&C 18NW100 TSPs way off