The standard for audio relays has been gold over silver bifurcated crossbar contacts. This uses a sharp contact method that has four points of contact for each switch. The gold is burned off of the silver if the relay is used for a too high signal level that should have been using the higher current silver contacts anyway!

For longer life relays other metals are used. But as most audio gear is not designed for 100 year life with hundreds of contact usages daily, gold over silver is usually adequate.

Many of the relay models suggested are indeed bifurcated crossbar style units.

The other concern on small densely packed relays might be crosstalk. A biggie for telephone use, not so much here.

(Many years ago on a long distance telephone call I did get some crosstalk from folks engaged in illegal activities.)

For longer life relays other metals are used. But as most audio gear is not designed for 100 year life with hundreds of contact usages daily, gold over silver is usually adequate.

Many of the relay models suggested are indeed bifurcated crossbar style units.

The other concern on small densely packed relays might be crosstalk. A biggie for telephone use, not so much here.

(Many years ago on a long distance telephone call I did get some crosstalk from folks engaged in illegal activities.)

Maybe those NEC exist in the known good version and in a modern Chinese made version?! Would not be the first time people get fooled by a brand name and expected performance. Expensive equipment does not say much about the relay quality as designers are humans and they make choices. The device will not be 100$ more expensive by chosing a 10 cent more expensive relay but chances are likely they simply chose a known type and don't bother. And even very good parts can have a short life when they are implemented wrongly. Cheap parts can live quite long in optimal situations. One of the factors I discovered is lead free solder baths/methods that are having a direct influence on the relays longevity as temperature is higher. Sealed relays don't like heat at all! When replacing a defective one for a new one that is soldered manually with good old 60/40 the issue does not return (FWIW).

Brands like SMSL, Topping etc. use a SGM3710 muting IC which is exactly the muting part that dies. The SGM3710 is an IC that manages to be way more unreliable than any relay 😀 The muting transistors in previous models never died, still they use the SGM3710 in every new model so it probably is ... cheap.

http://www.visvie.com/static/upload/file/20220121/1642747164583685.pdf

Using non linear parts for switching audio signals is a choice.

Brands like SMSL, Topping etc. use a SGM3710 muting IC which is exactly the muting part that dies. The SGM3710 is an IC that manages to be way more unreliable than any relay 😀 The muting transistors in previous models never died, still they use the SGM3710 in every new model so it probably is ... cheap.

http://www.visvie.com/static/upload/file/20220121/1642747164583685.pdf

Using non linear parts for switching audio signals is a choice.

Last edited:

One of the often missed issues on small relays is they come in sealed packages for installation and soldering. However after installation there is a small plastic bump on the top of the package that is meant to be removed to allow the relay to get fresh air! That prevents buildup of ionized gas and premature relay failures!

I see lots of relays in gear still sealed! Apparently almost nobody knows to open them!

I see lots of relays in gear still sealed! Apparently almost nobody knows to open them!

The following questions need to be clarified. Do the manufacturers all mean the same thing? What is an Alloy? Is there really only silver processed or also nickel, which makes a THD? I see nickel and palladium critically, it should make a lot of THD.

Omron G6K: Bifurcated crossbar Ag (Au-alloy contact)

Fujitsu NA: Material Gold overlay silver alloy (AgPd)

Fujitsu FTR-B4: Z: gold overlay silver nickel (standard), P: gold overlay silver palladium

Kemet EC2/EE2: Silver alloy with gold alloy overlay

Omron G6K: Bifurcated crossbar Ag (Au-alloy contact)

Fujitsu NA: Material Gold overlay silver alloy (AgPd)

Fujitsu FTR-B4: Z: gold overlay silver nickel (standard), P: gold overlay silver palladium

Kemet EC2/EE2: Silver alloy with gold alloy overlay

Usually the relays that require air are the compact units intended to switch a bit of current. Signal relays don’t arc and contaminate the inners. In fact they prefer to stay sealed to keep the contacts clean.My sealed micro relays are sealed.

The THD of alloys 🙂 The beloved semis are made of what!?! Questioning very long existing parts that are least intrusive is odd. About the same alloys were used in rotary switches like those by Elma for many decades. Sound better than semi based switching. Simple test to do if you haven’t done such.

Contact materials are an art and often very old knowledge. I know a guy at a large brand switches and there the knowledge walked out the door when the last one that knew retired.

BTW my experience is that signal relays that switch voltages are good parts for the purpose. Relays that need to switch loads so current is a very different application where semis can perform better/more reliable. Please let’s make that distinction to not further tarnish the reputation of meanwhile unknown and apparently undesired parts.

Contact materials are an art and often very old knowledge. I know a guy at a large brand switches and there the knowledge walked out the door when the last one that knew retired.

BTW my experience is that signal relays that switch voltages are good parts for the purpose. Relays that need to switch loads so current is a very different application where semis can perform better/more reliable. Please let’s make that distinction to not further tarnish the reputation of meanwhile unknown and apparently undesired parts.

Last edited:

Image of a relay that has a removable seal.

https://www.ebay.com/itm/1711671352...phUOrDrd_cs5lpkQqJzxQ0EhppSEkc5AeBgyaIXS5yWQc

https://www.ebay.com/itm/1711671352...phUOrDrd_cs5lpkQqJzxQ0EhppSEkc5AeBgyaIXS5yWQc

It is funny to question proven parts that are simple, reliable and made of good materials for audio. One could argue but have a look at the pin material of tubes/valves.

Since simple parts made of metal/copper are heavier and more expensive to produce and to ship they will at the end be made too cheap with recycled metals (bad) and eventually die out.

Imagine near future audio devices made exclusively with SMPS, semis/caps/resistors with plated steel wires, semi switching with charge pump based ICs, no muting and probably many will be satisfied as they see the brand name 🙂 Transformers, switches and relays!? Bleh that’s bad stuff, boomer!

Since simple parts made of metal/copper are heavier and more expensive to produce and to ship they will at the end be made too cheap with recycled metals (bad) and eventually die out.

Imagine near future audio devices made exclusively with SMPS, semis/caps/resistors with plated steel wires, semi switching with charge pump based ICs, no muting and probably many will be satisfied as they see the brand name 🙂 Transformers, switches and relays!? Bleh that’s bad stuff, boomer!

Last edited:

I just get really tired of some people arguing a class of component is bad when they are focused on either poor quality relays, or relays misapplied or used. Relays in this case.

This probably comes from people reading material written by poorly informed, untrained people who claim knowledge or experience. It will never end and drives those of us who actually do know what reality is nuts.

Sure rschmitt100, short your relays. Then tell others how much better it sounds (it won't unless the relays are bad). Yup, manufacturers install parts that are not necessary or for no reason. That makes great financial sense doesn't it? Maybe some common sense might help here.

Now, protection isn't necessary these days? Every component has a failure rate, some failures will present full supply voltage across the load. I have seen the results of amplifier failures that resulted in 4 separate fires in a room (during a dance - each speaker went up in flames). No protection in that amplifier "because it impacted sound quality". Well, it doesn't, and it wasn't a great sounding amp anyway. It was meant for DJ use in fact. Yes, the amplifier also had a small fire in it. This isn't an isolated incident. I've also seen headphone amps wipe out expensive headphones.

-Chris

This probably comes from people reading material written by poorly informed, untrained people who claim knowledge or experience. It will never end and drives those of us who actually do know what reality is nuts.

Sure rschmitt100, short your relays. Then tell others how much better it sounds (it won't unless the relays are bad). Yup, manufacturers install parts that are not necessary or for no reason. That makes great financial sense doesn't it? Maybe some common sense might help here.

Now, protection isn't necessary these days? Every component has a failure rate, some failures will present full supply voltage across the load. I have seen the results of amplifier failures that resulted in 4 separate fires in a room (during a dance - each speaker went up in flames). No protection in that amplifier "because it impacted sound quality". Well, it doesn't, and it wasn't a great sounding amp anyway. It was meant for DJ use in fact. Yes, the amplifier also had a small fire in it. This isn't an isolated incident. I've also seen headphone amps wipe out expensive headphones.

-Chris

Hi claudio,

That's because sometimes the actuator also carries the signal current. Some constructions can cause distortion. With normal relays, the signal current isn't connected to the magnetic circuit in any way.

Some power relays like "contactors" also suffer from the design where the signal current travels through the actuator with the same results.

That's because sometimes the actuator also carries the signal current. Some constructions can cause distortion. With normal relays, the signal current isn't connected to the magnetic circuit in any way.

Some power relays like "contactors" also suffer from the design where the signal current travels through the actuator with the same results.

It will sound better anatech.

Signal will always travel better through solid wire and soldered connections, compared to some sort of alloy contacts, that are only connected by tiny amounts of metal contact, along with metal oxides and varying amounts of who knows what other types of sprayed metal compounds.

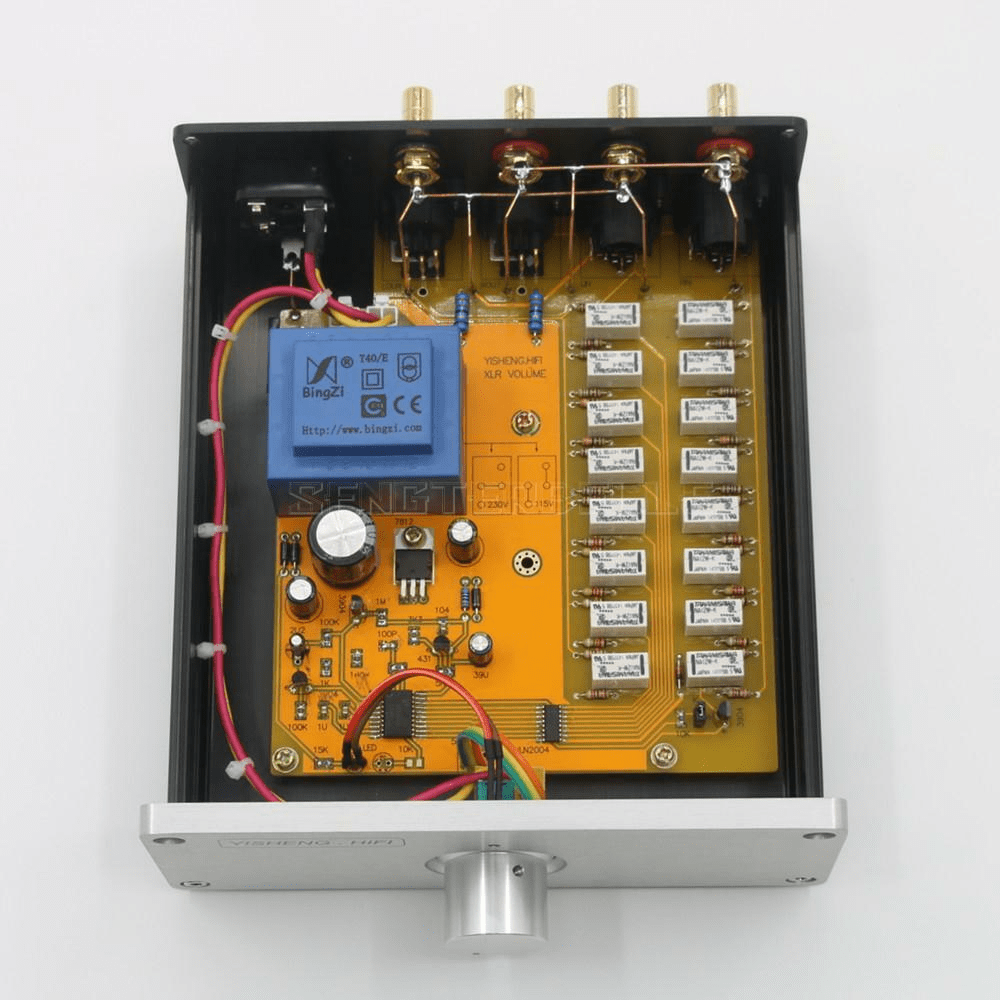

But maybe you guys should just all buy one of these. Check out all those relays. No doubt it will sound better

Signal will always travel better through solid wire and soldered connections, compared to some sort of alloy contacts, that are only connected by tiny amounts of metal contact, along with metal oxides and varying amounts of who knows what other types of sprayed metal compounds.

But maybe you guys should just all buy one of these. Check out all those relays. No doubt it will sound better

HiFi Advanced Relay Volume Controller Balanced Preamplifier / Passive Preamp

Passing a signal through quality passive contacts of a relay has way less signal deterioration over an active Silicon device. I have never liked using analog (active devices) switches but then that is just my own bias. That is the nice thing about DIY, you are free to try anything you want and evaluate its sound.

Hi rschmitt100,

Some relay contacts are better than a connector, and better than some traces.

One thing you are not doing is taking into account circuit conditions. You are doing a thought experiment only as you cannot hear what you are talking about unless there is something wrong with the connection. We can easily measure 35 dB below what the human body can perceive, lower if were careful. I routinely do this by the way. The impedance level of the circuit compared to resistance variations from contacts is such a massive difference that there is no practical issue. You simply cannot even perceive it, never mind actually hear it. All you can do is think you hear a difference. That is the truth of audio measurements these days, we easily measure way beyond what can be heard - and we look at the spectrum, not a meter pointer. Believe me, we can easily see the least amount of noise. I can see noise even if everything sounds clean, and my bench monitors are 99 db/watt. Measured extremely flat in their mounted locations.

Now, a passive preamp is only a volume control. Please don't insult yourself by calling it a preamp. It has no gain, and no buffer. In fact, it prevents the source from driving the cable, connections and the input stage of the next thing in the chain. If anything, this class of device causes more trouble than it can possibly correct. So it has an input selector as well. Big whoop! The term "passive preamp" was coined so it would gain traction as an idea and sell better. It most often reduces high frequencies a touch. Want to avoid the active stages? Well, what do you think is in the source? How about the gear in the recording studio? Do you have any idea how many stages of amplification the signal goes through in a studio? The number would blow your mind. Most preamplifiers have much higher quality gain stages than seen in studio equipment, especially the outboard gear and effects units. Never mind the tape machine. I'm talking Studers, not old MCI, Ampex or Scully as so much early stuff was laid down on. Then there was the Denon PCM recorders.

You basically get all worried about nothing. Nothing in comparison, or if it is poor quality stuff that bugs you, the answer is easy. Use good stuff.

Some relay contacts are better than a connector, and better than some traces.

One thing you are not doing is taking into account circuit conditions. You are doing a thought experiment only as you cannot hear what you are talking about unless there is something wrong with the connection. We can easily measure 35 dB below what the human body can perceive, lower if were careful. I routinely do this by the way. The impedance level of the circuit compared to resistance variations from contacts is such a massive difference that there is no practical issue. You simply cannot even perceive it, never mind actually hear it. All you can do is think you hear a difference. That is the truth of audio measurements these days, we easily measure way beyond what can be heard - and we look at the spectrum, not a meter pointer. Believe me, we can easily see the least amount of noise. I can see noise even if everything sounds clean, and my bench monitors are 99 db/watt. Measured extremely flat in their mounted locations.

Now, a passive preamp is only a volume control. Please don't insult yourself by calling it a preamp. It has no gain, and no buffer. In fact, it prevents the source from driving the cable, connections and the input stage of the next thing in the chain. If anything, this class of device causes more trouble than it can possibly correct. So it has an input selector as well. Big whoop! The term "passive preamp" was coined so it would gain traction as an idea and sell better. It most often reduces high frequencies a touch. Want to avoid the active stages? Well, what do you think is in the source? How about the gear in the recording studio? Do you have any idea how many stages of amplification the signal goes through in a studio? The number would blow your mind. Most preamplifiers have much higher quality gain stages than seen in studio equipment, especially the outboard gear and effects units. Never mind the tape machine. I'm talking Studers, not old MCI, Ampex or Scully as so much early stuff was laid down on. Then there was the Denon PCM recorders.

You basically get all worried about nothing. Nothing in comparison, or if it is poor quality stuff that bugs you, the answer is easy. Use good stuff.

I do agree with this one statement "Some relay contacts are better than a connector, and better than some traces."

But as far as audible differences, well it depends where and how that relay is being used. Protection built in speakers have relay type devices, but those contacts affect sound quality!

Large and stoic amp manufactueres take pride in how much silicon is used to replicate sound with lowest impedance, it adds to the spaciousness I guess with sheer silicon conductig area and mass. Professional amp builders like nelson hint to this all the time. Also silicon and solid state devices are simply the 1 constant standardized material throughout all of the gain stages and power supply. So why manufactueres and techies arent for solid state protection just doesnt entirely make sense.

I dont know why these engineers are taught to use the good ol relay, unless its a general curriculum big ed pushes.

But as far as audible differences, well it depends where and how that relay is being used. Protection built in speakers have relay type devices, but those contacts affect sound quality!

Large and stoic amp manufactueres take pride in how much silicon is used to replicate sound with lowest impedance, it adds to the spaciousness I guess with sheer silicon conductig area and mass. Professional amp builders like nelson hint to this all the time. Also silicon and solid state devices are simply the 1 constant standardized material throughout all of the gain stages and power supply. So why manufactueres and techies arent for solid state protection just doesnt entirely make sense.

I dont know why these engineers are taught to use the good ol relay, unless its a general curriculum big ed pushes.

- Home

- Source & Line

- Analog Line Level

- Audio Switching Relay Recommendations