Another good reason to choose based on the pioneer's way, so for me the highest XO point would be < ~1081 Hz, right around its off axis roll-off.However response variations in the pistonic region are more straightforward to deal with.

Me too! Chosen like the pioneers did this wouldn't be much of an issue, assuming one at all within our audible hearing acuity.I disagree. Any response can be made flat with the right filter. What we need is a driver with well behaved breakup, and I'm not talking about the on-axis peak.

Again 😉, limited to acoustic power matched XO, much of a multi-way speaker driver's 'uniqueness' becomes a mostly moot point in an otherwise well designed/built driver and better to use 'wide/full-range' drivers for 1st order.Many say they like the uniqueness of the Audax. It is already developing its own character by around 1600Hz and i'd guess it's probably going to be difficult to find another which sounds like it.

Stiction is derivative of friction (..layers moving against each other).About the contrast between static friction and dynamic friction, the term is stiction.

While there certainly is friction as a part of the suspension/diaphram/VC on the air-load, and some very small amount of *internal friction as the already mentioned solid parts deform, friction overall isn't what is being described.

*this is part of the elastic modules, not stiffness/compliance.

Instead it's predominately Stiffness (or inversely Compliance). This looks to a structural change (like a spring expanding) rather than a material change (as with internal friction), though of course there will be some amount of material change as well. Mechanically I'd expect that the driver's "resting resistance" is the point before an amount of force applied as strain starts to deform the structure (..the structure in this instance being the driver's spider and surround shape with their deformation being some amount of extension).

..and of course the left side of the Kms(X) graph represents stiffness/force applied.

Last edited:

Well, model the differences! 😉something like Faital 15fh500 would seem perfect in my application then?

https://usspeaker.com/faital pro 15FH500-1.htm

Note: it's added efficiency should make for a bit better baffle-step compensation (though it likely will alter the upper-bass/lower mid. balance you already have with your current crossover design). Subjectivly added efficiency (assuming a corrected flat freq. response has already been factored-in) tends to have slightly increased clarity and "dynamic" results (..all-else-equal).

BTW, I wouldn't put to much faith in either driver's set of T/S parameters - really it's something you have to measure for yourself to get an accurate model (..manufacturer's numbers tend to be a bit "off" - so it's really only a starting-point for modeling).

Last edited:

I wondered how you could define resistance without movement. Unless you're suggesting that pressure is applied to a surmountable barrier until it lets go, in which case you would afterward see a temporary increase in acceleration due to the driving Voltage being ahead of the cone position compared to the remainder of the cycle.I'd expect that the driver's "resting resistance" is the point before an amount of force applied as strain starts to deform the structure

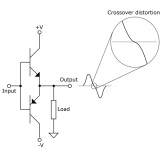

I can't help thinking you'd be able to identify something just a little like crossover distortion?

Of course to the degree that a speaker is a linear system there will always be movement, less pressure would just mean less movement in proportion so there won't be this slowing down near the zero crossing.

Last edited:

I looked, couldn't find anything. I think it's basically Tensile Stress up to the point of Strain.

Presumably though that Tensile Stress is a build-up of Internal Friction - so I guess we could be right back to Stiction, though with the major exception being that we are looking at as an overall structural/mechanical process and not a friction/material change.

I'm not sure crossover distortion is quite "right" as an analogy because the waveform itself is already "in-movement" (positive crossing-into negative).

I think another way to look at it (as a "bulk value" for a driver) is a particular (and my guess significant) loss in efficiency.

Presumably though that Tensile Stress is a build-up of Internal Friction - so I guess we could be right back to Stiction, though with the major exception being that we are looking at as an overall structural/mechanical process and not a friction/material change.

I'm not sure crossover distortion is quite "right" as an analogy because the waveform itself is already "in-movement" (positive crossing-into negative).

I think another way to look at it (as a "bulk value" for a driver) is a particular (and my guess significant) loss in efficiency.

I think the "behaveier" is with and without xover, and that a xover can`t correct the cone movement in that matter, but again my own thought.I can't help thinking you'd be able to identify something just a little like crossover distortion?

Quite often like to read post´s of you educated/knowledgeable/engineer's with ton´s of knowledge people, that also have the mathematical skills like Einstein, BUT often you also "over-do" most things and analyzing things it to infinity, and just that don`t make a speaker to sound good OT the best dialogue.

I this case we can ( i can) call it "electrical friction" for me, because it need a mount of power/Volt/ampere to "overcome" it....suspension, spider, voice coil, cones surround.

The stronger it is, the more "current" to overcome it.....Like a 2000 kg flat stone on ice, 15 people give it a push and it moves a bit.

But the stone need´s a force of XXX to been moved, and under that value the stone don´t move.

No offence!

/Jawen

Maybe it is more a language restriction

Or that "the fat lady haven?t sing" 😉

Explain yourself please!

/Jawen

I suspect that whether it starts out like this but doesn't do it during the next crossing is an important part of what you're trying to demonstrate.I'm not sure crossover distortion is quite "right" as an analogy because the waveform itself is already "in-movement" (positive crossing-into negative).

I think whether it falls into the linear category and is therefore irrelevant is what I'm trying to find out, as it seems you're saying it's a non-linear effect.

In any case I tend to hear the same at low levels as higher, unless thermal effects or gross distortion come into play.

Perhaps I was just hoping to be shown a distortion plot or something. I don't understand the part of what you say that I've quoted.I think the "behaveier" is with and without xover, and that a xover can`t correct the cone movement in that matter,

- Home

- Loudspeakers

- Multi-Way

- Audax PR170MO. For those who have moved on.....