hey all.

I've pretty much nailed the supplier for all parts down. Right now, I am "guestimating" the cost for the bearing and the platter in the $450, but hoping for a further reduced price. It may be less, but I don't want to get everybody's hopes up just to find out that I can't get may hands on the the parts from my intended supplier.

As the supplier is offshore, there is always a chance that they don't fully understand the intension, and may make an error. That's the difficulty with the commercial portion of this product, so, I must keep this in mind and make some kind of allowance for this as well (or pay for a single custom bearing constructed here and sent to the supplier).

All, please take note, that some caution must occur to ensure no theft of intellectual property occurs (something that many offshore makers don't consider), and that any possible pricing break is relying on someone else to be able to negotiate. So keep your fingers (and toes) crossed. This could work out very well for all, or pretty bad.

Should the source of the parts not be able to comply, we can discuss other possibilities. If no consensus can be had, then any drawings will be offered to all to alter or have machined parts to whatever specification done on an individual basis by the machinist of your choice.

stew

I've pretty much nailed the supplier for all parts down. Right now, I am "guestimating" the cost for the bearing and the platter in the $450, but hoping for a further reduced price. It may be less, but I don't want to get everybody's hopes up just to find out that I can't get may hands on the the parts from my intended supplier.

As the supplier is offshore, there is always a chance that they don't fully understand the intension, and may make an error. That's the difficulty with the commercial portion of this product, so, I must keep this in mind and make some kind of allowance for this as well (or pay for a single custom bearing constructed here and sent to the supplier).

All, please take note, that some caution must occur to ensure no theft of intellectual property occurs (something that many offshore makers don't consider), and that any possible pricing break is relying on someone else to be able to negotiate. So keep your fingers (and toes) crossed. This could work out very well for all, or pretty bad.

Should the source of the parts not be able to comply, we can discuss other possibilities. If no consensus can be had, then any drawings will be offered to all to alter or have machined parts to whatever specification done on an individual basis by the machinist of your choice.

stew

Have you contacted Vinyl Addict about machining the main bearing?I understand he is a Top Notch Master Machinist and he just happens to be a turntable guru. I would rather see him make some money out of this and pay a top price to make sure it is done right. Even if it were to take a while it would be worth the wait. I don't know if he would be interested but it would be worth asking him.

vinyl addict and machining...

I have no problems contacting Vinyl Addict, and getting a qoute. I have solidified a local machinist, but yet to receive a quote.

I think I have what I believe to be an original design for the bearing, so no thoughts of intellectual property" issues. I also have another design in the wings that may proove to be at least as quiet and able to carry a "loaded" platter (if anyone wants to do that), and a bonus is theat it may be less expensive to have made.

stew

I have no problems contacting Vinyl Addict, and getting a qoute. I have solidified a local machinist, but yet to receive a quote.

I think I have what I believe to be an original design for the bearing, so no thoughts of intellectual property" issues. I also have another design in the wings that may proove to be at least as quiet and able to carry a "loaded" platter (if anyone wants to do that), and a bonus is theat it may be less expensive to have made.

stew

Hi,

I have been following this thread with great interest and intend on taking part in the buy.

This post is by no means a criticism of the work done so far and i greatly appreciate the commitment and work put into this product to date. The comments i have revolve around industrial design and i have been wondering if we can push the plinth design a little harder. In Nanook's own words the design is pretty typical of what is out there but since we are going to all this effort of a custom design perhaps we could question some of those assumptions.

It strikes me that the more interesting and beautiful turn tables reduce the plinth to the bear minimum. This helps the platter and arm read as the essential objects. For instance the Simon York design http://stereophile.com/turntables/1207sim/

attempts to remove the plinth all together whilst the Audio monaco table integrates the plinth and platter into a "seamless" single object.

http://stereophile.com/turntables/1107gp/

There is something about the platter and the plinth being of the same massing that i think makes the entire turntable far more elegant.

See the wilson bench turntable

http://stereophile.com/turntables/1198wilson/

My thoughts anyway... thanks

I have been following this thread with great interest and intend on taking part in the buy.

This post is by no means a criticism of the work done so far and i greatly appreciate the commitment and work put into this product to date. The comments i have revolve around industrial design and i have been wondering if we can push the plinth design a little harder. In Nanook's own words the design is pretty typical of what is out there but since we are going to all this effort of a custom design perhaps we could question some of those assumptions.

It strikes me that the more interesting and beautiful turn tables reduce the plinth to the bear minimum. This helps the platter and arm read as the essential objects. For instance the Simon York design http://stereophile.com/turntables/1207sim/

attempts to remove the plinth all together whilst the Audio monaco table integrates the plinth and platter into a "seamless" single object.

http://stereophile.com/turntables/1107gp/

There is something about the platter and the plinth being of the same massing that i think makes the entire turntable far more elegant.

See the wilson bench turntable

http://stereophile.com/turntables/1198wilson/

My thoughts anyway... thanks

pushing the plinth design....

well, this is where individuality may come in.

I've drawn up a "Constructor" plinth, I beam IRON, allowed to rust in an appropriate manner welded into an "X", with the intersection of the "X" the strongest point and where I would put the main bearing if I were to build it. lots of clear acrylic so it would mimic many of the materials in "skyscrapers".I also like particularly "traditional" appearing turn tables, like the Roksan Xerses .

The turntables linked to are absolutely stunning. But it is almost like the more skeletal, the more common (consider how uncommon the original Oracle Delphi, Ja Michell, and the Transcriptors original looked when first intoduced) today.

If a Garrard style or Thorens style plinth similar to the Shindo Labs or Loricraft is desired, that's easy enough.

In no way am I thinking that there is a "universal plinth design" out there for everyone to make, or buy.

Maybe I'll power mine with a small block Chevy (a 302 is preferable) and call it the "Z28" or "COPO" or something similar. Hmmm , 4.00" bore X 3.00" stroke = 7200 rpm + of fun.

and of course it would have to be "hugger orange" as all good '69 zeds were.

By the way Neil, if those PAWOs are your's with Jordan drivers, I'm jealous---really jealous

well, this is where individuality may come in.

I've drawn up a "Constructor" plinth, I beam IRON, allowed to rust in an appropriate manner welded into an "X", with the intersection of the "X" the strongest point and where I would put the main bearing if I were to build it. lots of clear acrylic so it would mimic many of the materials in "skyscrapers".I also like particularly "traditional" appearing turn tables, like the Roksan Xerses .

The turntables linked to are absolutely stunning. But it is almost like the more skeletal, the more common (consider how uncommon the original Oracle Delphi, Ja Michell, and the Transcriptors original looked when first intoduced) today.

If a Garrard style or Thorens style plinth similar to the Shindo Labs or Loricraft is desired, that's easy enough.

In no way am I thinking that there is a "universal plinth design" out there for everyone to make, or buy.

Maybe I'll power mine with a small block Chevy (a 302 is preferable) and call it the "Z28" or "COPO" or something similar. Hmmm , 4.00" bore X 3.00" stroke = 7200 rpm + of fun.

and of course it would have to be "hugger orange" as all good '69 zeds were.

By the way Neil, if those PAWOs are your's with Jordan drivers, I'm jealous---really jealous

neil_kaye said:Hi,

I have been following this thread with great interest and intend on taking part in the buy.

This post is by no means a criticism of the work done so far and i greatly appreciate the commitment and work put into this product to date. The comments i have revolve around industrial design and i have been wondering if we can push the plinth design a little harder. In Nanook's own words the design is pretty typical of what is out there but since we are going to all this effort of a custom design perhaps we could question some of those assumptions.

It strikes me that the more interesting and beautiful turn tables reduce the plinth to the bear minimum. This helps the platter and arm read as the essential objects. For instance the Simon York design http://stereophile.com/turntables/1207sim/

attempts to remove the plinth all together whilst the Audio monaco table integrates the plinth and platter into a "seamless" single object.

http://stereophile.com/turntables/1107gp/

There is something about the platter and the plinth being of the same massing that i think makes the entire turntable far more elegant.

See the wilson bench turntable

http://stereophile.com/turntables/1198wilson/

My thoughts anyway... thanks

This is DIY Audio. The price on the first table is $19,500. I would say that this design is a little beyond the scope of this group buy. The target price of this group buy turntable as Nanook stated, is $1500 to $1900. The idea here is to design for the best sound, not the most eye pleasing. If you want something like turntables you outlined, fire up your computer, load in Autocad and start designing. Make a prototype and why not start your own group buy.

thanks for your response Nanook, as i previously said, regardless of the plinth design i am excited about your product and look forward to seeing it realized.

hey everyone, relax....

Ideas of design are just that. All I'm trying to do here is check the interest, and to check to see if I actually get the stuff.

As far as design goes (as industrial design), that's really up to everyone else to look at individually. I know my table will end up being hacked together, 'cause I can use sketchup but have two left thumbs (one on each hand). My sketches look better than anything I've built.

kilowattski, I know the complete turntable can be had for that, because the commercial version would sell in thet range complete (less cart).

Ideas of design are just that. All I'm trying to do here is check the interest, and to check to see if I actually get the stuff.

As far as design goes (as industrial design), that's really up to everyone else to look at individually. I know my table will end up being hacked together, 'cause I can use sketchup but have two left thumbs (one on each hand). My sketches look better than anything I've built.

kilowattski, I know the complete turntable can be had for that, because the commercial version would sell in thet range complete (less cart).

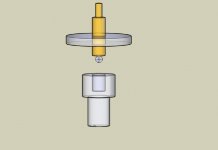

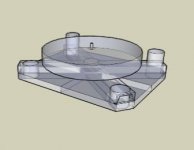

Attachments

my thinking is to go with as much mass as possible using wood. in the end, I will probably go with something like the teres. The use of wood makes for a nice look and sound.

Of course, I will try to come up with something original as well 🙂

B

Of course, I will try to come up with something original as well 🙂

B

Re: here's "the constructor"

The Constructor.

I am interested too🙂

If these are usefull as a TT motor, I dont know, but I can get these Maxon motors for approx 15usd a piece (surplus)

DC-motor

6V-24V / 1A

Omdrejningstal: v/12V - 3000VPM

Fabrikat: Maxon

Model: 2140.935-00

Mål:

Motor: LxØ: 44 x 40 mm

Aksel: LxØ: 7 x 2,5 mm

🙂

Nanook said:have a look, definitely "industrial" in design.

stew

The Constructor.

I am interested too🙂

If these are usefull as a TT motor, I dont know, but I can get these Maxon motors for approx 15usd a piece (surplus)

DC-motor

6V-24V / 1A

Omdrejningstal: v/12V - 3000VPM

Fabrikat: Maxon

Model: 2140.935-00

Mål:

Motor: LxØ: 44 x 40 mm

Aksel: LxØ: 7 x 2,5 mm

🙂

Re: pushing the plinth design....

Hey Stew, you can have the 350 that's in my old truck. Just don't try to spin it up to 7200.

I remember looking at an orange one on a lot here around the late 70's. If it had of been blue or green, I probably would have bought it.

Oh, and it was showroom too.

Jeff

Originally posted by Nanook Maybe I'll power mine with a small block Chevy (a 302 is preferable) and call it the "Z28" or "COPO" or something similar. Hmmm , 4.00" bore X 3.00" stroke = 7200 rpm + of fun.

Hey Stew, you can have the 350 that's in my old truck. Just don't try to spin it up to 7200.

Originally posted by Nanook

and of course it would have to be "hugger orange" as all good '69 zeds were.

I remember looking at an orange one on a lot here around the late 70's. If it had of been blue or green, I probably would have bought it.

Oh, and it was showroom too.

Jeff

Maxon motors...

don't read or speak any language but English (and not that well)

40mm diameter body

graphite brush-less

4-6 watts (depends on the motor, there should be some additional number on it)

For USD $15 I'd get one and experiment with it.

I prefer wood tables...too many have proven their performance in the past. Teres, Redpoint, Linn, and on and on and on. (and I still want a Xerses when I can afford one.)

302 or death.... 280 hp at 3200 rpm (or something stupid like that), =560 hp maxxed out (never believe the lies some told about how wimpy that little mouse was).

don't read or speak any language but English (and not that well)

40mm diameter body

graphite brush-less

4-6 watts (depends on the motor, there should be some additional number on it)

For USD $15 I'd get one and experiment with it.

I prefer wood tables...too many have proven their performance in the past. Teres, Redpoint, Linn, and on and on and on. (and I still want a Xerses when I can afford one.)

302 or death.... 280 hp at 3200 rpm (or something stupid like that), =560 hp maxxed out (never believe the lies some told about how wimpy that little mouse was).

Maxon motor...

Ok Here is the precise model number, gleaned from the pic's:

2140.935-00, 111-012

And it says Swiss made😉

🙂

Ok Here is the precise model number, gleaned from the pic's:

2140.935-00, 111-012

And it says Swiss made😉

🙂

Re: sketchup of two turntables

Sounds like a recipe for an inverted bearing with no oil bath.

Jeff

Nanook said:I haven't settled on materials for the bearing, but most probably a sintered bronze bushing, ceramic or hardened steel ball, a thrust plate (teflon or hardened steel or polished unobtainium), with a brass body.

Sounds like a recipe for an inverted bearing with no oil bath.

Jeff

Big block Olds 455 with W30 designation bluepriniting worked for me, horsepower is cool but torque rules the street race, if you can get it to the rear wheels and get them to stick.

Real wood is great, just need to be careful as to where it comes from and where it is going. That humidity/warping thing.

Real wood is great, just need to be careful as to where it comes from and where it is going. That humidity/warping thing.

would that be a RB or B Mopar (I like the Bs)

and the W31 olds Rockets were incredible performers, lighter engine than a SBC, and equally good if tweeked right (ala, Warren Johnson--Ian, you should remember him).

B and RB (as well as pretty much all Mopars) are big bore /small stroke. An example: 383 "B" block. 4.125" bore, 3.38 stroke (and long rods 6.675? if memory serves me correctly),. 350 SBC: 4"bore, 3.48 stroke, 5.700 rods.. wonder which one has the most "buzz" potential? hey, hey...

steenoe, I'll look a little further into THAT motor for you. The only real differences are watts and available torque ...

and the W31 olds Rockets were incredible performers, lighter engine than a SBC, and equally good if tweeked right (ala, Warren Johnson--Ian, you should remember him).

B and RB (as well as pretty much all Mopars) are big bore /small stroke. An example: 383 "B" block. 4.125" bore, 3.38 stroke (and long rods 6.675? if memory serves me correctly),. 350 SBC: 4"bore, 3.48 stroke, 5.700 rods.. wonder which one has the most "buzz" potential? hey, hey...

steenoe, I'll look a little further into THAT motor for you. The only real differences are watts and available torque ...

steenoe...

news flash: steenoe --- The complete number is no longer listed by Maxon, however, I'd guess that it is an OEM version of the 22.112 ...

so specs would be very similar to what I previously posted. it seems nominal voltage is 15VDC, although it also has rpm/V = 275. with a 12 V DC supply, you'd end up with 3300rpm. assuming the platter is 315 mm in diameter, you'd need a pulley with 3.18 (approx) mm diameter.

Go lower in Voltage and you can use a larger pulley.

stew

news flash: steenoe --- The complete number is no longer listed by Maxon, however, I'd guess that it is an OEM version of the 22.112 ...

so specs would be very similar to what I previously posted. it seems nominal voltage is 15VDC, although it also has rpm/V = 275. with a 12 V DC supply, you'd end up with 3300rpm. assuming the platter is 315 mm in diameter, you'd need a pulley with 3.18 (approx) mm diameter.

Go lower in Voltage and you can use a larger pulley.

stew

I'm starting to think we might be building the camel of turntables (designed by committee)😀

It will be hard to satisfy so many people with one design specially since this is a do it yourself group. I think the best way to handle this is to offer what you have designed for yourself. If others want it then you get enough to make your group buy financially viable.

It will be hard to satisfy so many people with one design specially since this is a do it yourself group. I think the best way to handle this is to offer what you have designed for yourself. If others want it then you get enough to make your group buy financially viable.

- Status

- Not open for further replies.

- Home

- Group Buys

- Any interest in an acrylic platter group buy, and a bearing?