also interested.

I am also wondering, would it not be feasible to use a teres motor assembly or something like that?

b

I am also wondering, would it not be feasible to use a teres motor assembly or something like that?

b

some of those bits look familiar : http://www.revolveraudio.co.uk/replay.htm

The large offset between platter hieght and arm mounting plane

could cause problems with arm mounting, looks somewhat awkward.

🙂/sreten.

The large offset between platter hieght and arm mounting plane

could cause problems with arm mounting, looks somewhat awkward.

🙂/sreten.

sreten...familar bits

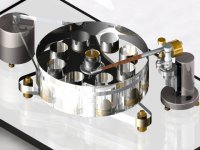

Please know that this is a unique design and not actively copied from anyone. However, there really only a few ways to skin a cat, if the design parameters are the same or similar. The bearing is unique, the platter is 315mm in diameter, the thickness is 43mm, the label area is .005" deep. Presently I have a 40mm bearing housing, using a 20mm bearing shaft, and a 1mm hardened steel thrust surface. I am thinking that a total length of the bearing/housing will need to be in excess of 60mm.

I agree the tonearm mounting has not been optimized, and that needs to be addressed. I am thinking that a rotating arm board, with a mounting collar and a height of say 1" or so should provide the required vertical offset, and provide enough room to mount a 12" arm if so desired. This could be placed in the existing mounting location or another one.

C of G calculations put it at 18mm down from the top of the platter. The distance between the bottom of the platter and top plinth (or only plinth if so desired) needs to be reduced by at least half. The prototype used an old bearing from an old discarded direct drive (after I threw out the original bearing, because it was absolutely terrible). I'd say that overall, the turntable is easily on par with my Oracle. Even with the bodged bearing the sound is very robust and very quiet. The motor has its own electronics, but I do not like the housing nor the "pillars", they simply are not required unless trying to appear like a Delphi or similar.

Greg, email me directly as cnc machine work may be required.

Thanks to all that may be interested.

stew

Please know that this is a unique design and not actively copied from anyone. However, there really only a few ways to skin a cat, if the design parameters are the same or similar. The bearing is unique, the platter is 315mm in diameter, the thickness is 43mm, the label area is .005" deep. Presently I have a 40mm bearing housing, using a 20mm bearing shaft, and a 1mm hardened steel thrust surface. I am thinking that a total length of the bearing/housing will need to be in excess of 60mm.

I agree the tonearm mounting has not been optimized, and that needs to be addressed. I am thinking that a rotating arm board, with a mounting collar and a height of say 1" or so should provide the required vertical offset, and provide enough room to mount a 12" arm if so desired. This could be placed in the existing mounting location or another one.

C of G calculations put it at 18mm down from the top of the platter. The distance between the bottom of the platter and top plinth (or only plinth if so desired) needs to be reduced by at least half. The prototype used an old bearing from an old discarded direct drive (after I threw out the original bearing, because it was absolutely terrible). I'd say that overall, the turntable is easily on par with my Oracle. Even with the bodged bearing the sound is very robust and very quiet. The motor has its own electronics, but I do not like the housing nor the "pillars", they simply are not required unless trying to appear like a Delphi or similar.

Greg, email me directly as cnc machine work may be required.

Thanks to all that may be interested.

stew

sorry all...

I've been into the States and back today--what a gong show. Blizzard there and back. Picked up some demo loudspeakers, may do a follow up on them in affordable$$audio. Mark had them on extended loan from Totem Acoustics in Montreal. Initial impressions are very good. I need to email Mark and thank him for breaking them in for me🙂.

Because sreten indicated that the turntable prototype looks a lot like the Revolver, I need to do further research to ensure there is no theft of intellectual property. I was handed the turntable in a preliminary state, and tore it apart to literally nothing---all I could find were problems (other than the appearance). mainly the drive system which appears week, and the platter bearing.I have a completely dismantled tonearm to prove that portion. The motor is what I might consider a robust tape drive motor, with a nylon pulley--not the best solution. If it turns out that this table has been in fact "knocked off" or copied directly from the Revolver, then a complete redesign will be done (unless the original source of both of the turntables turns out to be the same place, and they released it to us--if they owned the design).

Like I said I was brought in on this preproduction project to try to get the kinks out of it, and there are quite a few.

This table (the Revolver) presently sells for something like $3350 in Canada with what appears to be an old Audioquest tonearm. Even for the complete table we were aiming for a sub $1800 price, based on manufacturing costs, without tonearm. I was hoping for a turnkey price with a Rega RB250 in the neighbourhood under $2200. Once I can get the new platter price and bearing design and dimensions firmed up, we can set the price for the complete table, and for parts.

Personally I'd prefer to buy all parts and construct the "complete" tables myself so that I know when they go to their final destinations, they have been completely function tested, and speed checked, then dismantled and shipped. Obviously parts is parts, so the bearings and platters would be trial fitted and OK'd. I am seeking local manufacture of the bearing so that QC can be maintained.

so thanks to all for the interest. I'm gonna completely vacate and ignore all things internet for a few days so that I can sort out what's what, double check my bearing design ( which has not been presented to anyone outside of this forum, or my direct business aquaintances.

I will check my email, and respond to all who have posted me, but will ignore all else until at least Monday so that I can actually get some work done.

stew

I've been into the States and back today--what a gong show. Blizzard there and back. Picked up some demo loudspeakers, may do a follow up on them in affordable$$audio. Mark had them on extended loan from Totem Acoustics in Montreal. Initial impressions are very good. I need to email Mark and thank him for breaking them in for me🙂.

Because sreten indicated that the turntable prototype looks a lot like the Revolver, I need to do further research to ensure there is no theft of intellectual property. I was handed the turntable in a preliminary state, and tore it apart to literally nothing---all I could find were problems (other than the appearance). mainly the drive system which appears week, and the platter bearing.I have a completely dismantled tonearm to prove that portion. The motor is what I might consider a robust tape drive motor, with a nylon pulley--not the best solution. If it turns out that this table has been in fact "knocked off" or copied directly from the Revolver, then a complete redesign will be done (unless the original source of both of the turntables turns out to be the same place, and they released it to us--if they owned the design).

Like I said I was brought in on this preproduction project to try to get the kinks out of it, and there are quite a few.

This table (the Revolver) presently sells for something like $3350 in Canada with what appears to be an old Audioquest tonearm. Even for the complete table we were aiming for a sub $1800 price, based on manufacturing costs, without tonearm. I was hoping for a turnkey price with a Rega RB250 in the neighbourhood under $2200. Once I can get the new platter price and bearing design and dimensions firmed up, we can set the price for the complete table, and for parts.

Personally I'd prefer to buy all parts and construct the "complete" tables myself so that I know when they go to their final destinations, they have been completely function tested, and speed checked, then dismantled and shipped. Obviously parts is parts, so the bearings and platters would be trial fitted and OK'd. I am seeking local manufacture of the bearing so that QC can be maintained.

so thanks to all for the interest. I'm gonna completely vacate and ignore all things internet for a few days so that I can sort out what's what, double check my bearing design ( which has not been presented to anyone outside of this forum, or my direct business aquaintances.

I will check my email, and respond to all who have posted me, but will ignore all else until at least Monday so that I can actually get some work done.

stew

I am interested. Since this will be a low mass design will there be suspension parts for sale beyond simple cones? Maybe fluid damping or something?

Interested as well...

Platter & bearing definitely interest me. Looking forward to more details (& pricing of course). 😉

Pekka

Platter & bearing definitely interest me. Looking forward to more details (& pricing of course). 😉

Pekka

dampening.

well the main plinth is Granite, so "mass dampened". Also I would use a compliant block between the upper and lower plinths. The upper "plinth" or sub-chassis or whatever one would call it is made of MDF (ugh!). I'd make one from wood, Baltic Birch, Ikea maple cutting board, or a very light weight, non-energy storing material or torsion box. It may even be possible to get it in a coloured Acrylic, but at additional cost over the standard. Sorbothane feet or half squash balls or similar could be used between the two. The towers serve no purpose, except the rear left hand side one which is where the factory installed the cheap and cheesy toy motor, which should be completely modified or removed any ways (particularly if the Maxon Group Buy folks are to use the sub-chassis parts).

As far as cosmetics go, I really like the clean classic lines of the Xerses10 and 20. And my mag SME309 or improved Nanook's $2.19 tonearm would look pretty stunning.

to all...seems like somehow I've managed to cause someone to complain to the moderators that I am designing and product developing here (which hasn't been the case./ I have not changed the design of the TT or any parts, except on my own ), so this thread may be moved to the vendor's forum. Also all need to know that the availability of all of the parts (or any) is directly out of my control, I am relying on the maker of the table to allow me to get the parts, and mod them accordingly or have them do it. That is why all the ambiguity concerning pricing ---the availability and the costs of re-designing/engineering/custom machining that may need to be done.

I am in the process of contacting the moderators directly. It doesn't matter to me where they end up wanting to put the thread, but know this---I am working independently of the existing designs for bearings, although there are only so many ways one can do it. I like the JA Michell oil pump type (did they rip it off from Garrard?), and the Teres type (they admit to "ripping off" certain features from JC Verdier --the balanced mass approach)

I have the bearing and platter drawn ion sketchup using my modified dimensions. I need to redesign the upper "plinth" or sub-chassis and redraw it to reflect my current taste for aesthetics.

stew

well the main plinth is Granite, so "mass dampened". Also I would use a compliant block between the upper and lower plinths. The upper "plinth" or sub-chassis or whatever one would call it is made of MDF (ugh!). I'd make one from wood, Baltic Birch, Ikea maple cutting board, or a very light weight, non-energy storing material or torsion box. It may even be possible to get it in a coloured Acrylic, but at additional cost over the standard. Sorbothane feet or half squash balls or similar could be used between the two. The towers serve no purpose, except the rear left hand side one which is where the factory installed the cheap and cheesy toy motor, which should be completely modified or removed any ways (particularly if the Maxon Group Buy folks are to use the sub-chassis parts).

As far as cosmetics go, I really like the clean classic lines of the Xerses10 and 20. And my mag SME309 or improved Nanook's $2.19 tonearm would look pretty stunning.

to all...seems like somehow I've managed to cause someone to complain to the moderators that I am designing and product developing here (which hasn't been the case./ I have not changed the design of the TT or any parts, except on my own ), so this thread may be moved to the vendor's forum. Also all need to know that the availability of all of the parts (or any) is directly out of my control, I am relying on the maker of the table to allow me to get the parts, and mod them accordingly or have them do it. That is why all the ambiguity concerning pricing ---the availability and the costs of re-designing/engineering/custom machining that may need to be done.

I am in the process of contacting the moderators directly. It doesn't matter to me where they end up wanting to put the thread, but know this---I am working independently of the existing designs for bearings, although there are only so many ways one can do it. I like the JA Michell oil pump type (did they rip it off from Garrard?), and the Teres type (they admit to "ripping off" certain features from JC Verdier --the balanced mass approach)

I have the bearing and platter drawn ion sketchup using my modified dimensions. I need to redesign the upper "plinth" or sub-chassis and redraw it to reflect my current taste for aesthetics.

stew

sketchup of two turntables

all,

please have a look at the image "two turntables". Only meant as an idea of finishing a table.

the bearing drawing is completed as are the two "plinth styles" and the platter

Obviously not everyone's taste, but typical of many tables out there.

enjoy. Now that the drawing is done, I'll work at getting the quotes together, or if existing parts are available for the bearing, a list of what might be needed (from McMaster & Carr or similar).

I haven't settled on materials for the bearing, but most probably a sintered bronze bushing, ceramic or hardened steel ball, a thrust plate (teflon or hardened steel or polished unobtainium), with a brass body.

So folks please stay tuned. Once I get in touch with those that can quote me, I'll post the results as soon as possible.

As I suggested earlier, this may be moved to the vendor's forum.

stew

all,

please have a look at the image "two turntables". Only meant as an idea of finishing a table.

the bearing drawing is completed as are the two "plinth styles" and the platter

Obviously not everyone's taste, but typical of many tables out there.

enjoy. Now that the drawing is done, I'll work at getting the quotes together, or if existing parts are available for the bearing, a list of what might be needed (from McMaster & Carr or similar).

I haven't settled on materials for the bearing, but most probably a sintered bronze bushing, ceramic or hardened steel ball, a thrust plate (teflon or hardened steel or polished unobtainium), with a brass body.

So folks please stay tuned. Once I get in touch with those that can quote me, I'll post the results as soon as possible.

As I suggested earlier, this may be moved to the vendor's forum.

stew

Attachments

I would not use McMaster Carr for a source for the Acrylic. I just bought a 13" x 13" piece of cast acrylic for $175 from a distributor. McMaster is easily double that.

McMaster-Carr is a great "I need it tomorrow" supplier but the premium is usually doubling the price. If this is a group buy then 4x8 sheets can be purchased and waterjet cut for the blanks.

Oddly, I am most often of that opinion, but there have been a number of times that I have been unable to find cheaper anywhere else. I think this was mostly with hardware, but I was surprised that their prices are sometimes very competitive. The exception is when it comes to material. Almost universally, their material is more expensive.

- Status

- Not open for further replies.

- Home

- Group Buys

- Any interest in an acrylic platter group buy, and a bearing?