It will take some time to complete this project, but, for what its worth i will give my judgement on the 20/80 balance and the cost involved as well, at the end.

My family like the sound from my 3 ways, and that will also be a factor............

I don't have loads of experience of alternatives, but that can be an advantage as well!

M

My family like the sound from my 3 ways, and that will also be a factor............

I don't have loads of experience of alternatives, but that can be an advantage as well!

M

The cabinet build will be relatively easy if you don‘t pursue a trans lam approach…..the wiring though?….that‘s going to be some work!…….150 connection points at least! 😛

I think your baffle will be the greatest concern…..long and narrow with so many holes is going to make it weak. The easiest build would be surface mounting but using a thick material will congest the back wave of the driver. I think Wesayso used an aluminum baffle maybe for the reasons above?….best to ask him……if you have to have something like that made, you’ll want to factor in that cost

The TC9 isn‘t a ‘bad’ driver…..not at all. There’s just better drivers for the same money these days. IVO makes a good point…..I’m of the strong opinion that the array doesn’t need to be floor to ceiling either…..it just needs to be long enough to cover your desired vertical listening window and be dynamic enough to suit your listening levels…….i think most folks who’ve built these come to the reality at some point that no matter how many, a subwoofer is still required. Sixteen drivers would be a suitable array IMO with an overall line length of 60” or so……..offset 18” from the floor and ceiling gives you balance in the common 8ft US ceiling height……not sure what yours are over in the UK.

I think your baffle will be the greatest concern…..long and narrow with so many holes is going to make it weak. The easiest build would be surface mounting but using a thick material will congest the back wave of the driver. I think Wesayso used an aluminum baffle maybe for the reasons above?….best to ask him……if you have to have something like that made, you’ll want to factor in that cost

The TC9 isn‘t a ‘bad’ driver…..not at all. There’s just better drivers for the same money these days. IVO makes a good point…..I’m of the strong opinion that the array doesn’t need to be floor to ceiling either…..it just needs to be long enough to cover your desired vertical listening window and be dynamic enough to suit your listening levels…….i think most folks who’ve built these come to the reality at some point that no matter how many, a subwoofer is still required. Sixteen drivers would be a suitable array IMO with an overall line length of 60” or so……..offset 18” from the floor and ceiling gives you balance in the common 8ft US ceiling height……not sure what yours are over in the UK.

Cabinets and baffles.

Looking forward to inputs please! 10 thoughts to start with.........

1. I am most likely to use wood, could be ply wood, could be MDF, maybe veneered

2. I know Halair documented that his improved cabinets were worthwhile, with stiffness and filling, i am not likely to go so far but imagine to have more than a simple rectangle shape

3. We have discussed having a rounded section cabinet, rather than building it into the corner, so that baffle aim can be varied without the unit looking strange in the corner.

4. I would quite like a grille (or sock) as i prefer that in the domestic environment

5. I imagine a rounded and/or irregular internal volume might stop some strange resonances

6. I made a hexagonal section (#82) recently thinking i might use that, probably with rounded external corners and veneer or sock cover the outside. this was at a 1 litre internal volume per driver, could easily be 1.65 litres. i liked my walnut veneer 3 ways.

7. I see the baffle shapes vary, some with a rounded ridge running vertically either side of the drivers, some as narrow as possible at the driver

This is probably the start point, the rest can follow

8. I could make a construction using shaped side panels and a front baffle and back

9. I assume i will face mount the drivers

10. I assume its best to separate each drivers volume.

Looking forward to inputs please! 10 thoughts to start with.........

1. I am most likely to use wood, could be ply wood, could be MDF, maybe veneered

2. I know Halair documented that his improved cabinets were worthwhile, with stiffness and filling, i am not likely to go so far but imagine to have more than a simple rectangle shape

3. We have discussed having a rounded section cabinet, rather than building it into the corner, so that baffle aim can be varied without the unit looking strange in the corner.

4. I would quite like a grille (or sock) as i prefer that in the domestic environment

5. I imagine a rounded and/or irregular internal volume might stop some strange resonances

6. I made a hexagonal section (#82) recently thinking i might use that, probably with rounded external corners and veneer or sock cover the outside. this was at a 1 litre internal volume per driver, could easily be 1.65 litres. i liked my walnut veneer 3 ways.

7. I see the baffle shapes vary, some with a rounded ridge running vertically either side of the drivers, some as narrow as possible at the driver

This is probably the start point, the rest can follow

8. I could make a construction using shaped side panels and a front baffle and back

9. I assume i will face mount the drivers

10. I assume its best to separate each drivers volume.

For simplicity put the drivers on a long board and fit it just into the corner letting on top and low being open a bit and damping the complete line.

Easy construction TML like with corner horn effect?

Easy construction TML like with corner horn effect?

I have come to believe in the benefit of being able to change the aim of the speakers in relation to the listening positions, hence it will be a complete box, even though it will stand in the corners.

I understand the work involved, i like making things, so am comfortable with that.

But it will take some time!

Depending on the answer concerning baffle shape and side ridges i could consider a walnut cabinet detail somewhat related to the section like this i did previously or go with the simple approach of the "sock" that wesayso copied in.

I understand the work involved, i like making things, so am comfortable with that.

But it will take some time!

Depending on the answer concerning baffle shape and side ridges i could consider a walnut cabinet detail somewhat related to the section like this i did previously or go with the simple approach of the "sock" that wesayso copied in.

Attachments

I am most comfortable working with wood, so hope to stay with that, but can rout an angle on the back of the baffle holes, if there is room to do so, like i have done before.I think your baffle will be the greatest concern…..long and narrow with so many holes is going to make it weak. The easiest build would be surface mounting but using a thick material will congest the back wave of the driver. I think Wesayso used an aluminum baffle maybe for the reasons above?….best to ask him……if you have to have something like that made, you’ll want to factor in that cost

You won’t be able to effectively chamfer the rear of the baffle due to the close proximity of the flange mounting screws….they’re won’t be enough wood to bite into.

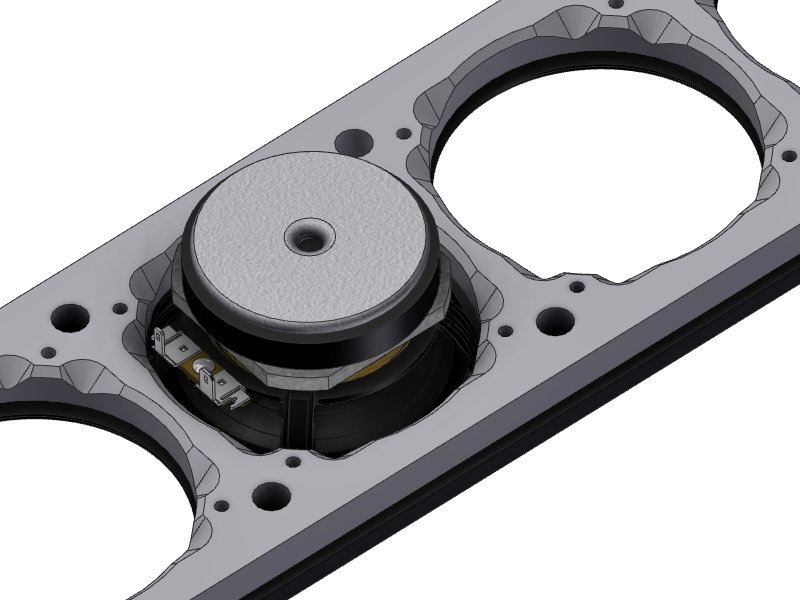

I had a couple of reasons for the aluminum baffle. I wanted a serviceable construction that would hold up fine, even after several rebuilds. I couldn't see that happening with an MDF or even ply construction. @koldby had shown that aluminum could look the part and be firm enough.

I didn't regret making it serviceable. I've had it apart for several different reasons. Most of them just aimed at improving the results, only one out of necessity due to driver failure after moisture damage. (had them stored open in a very damp garage for just about a complete year.

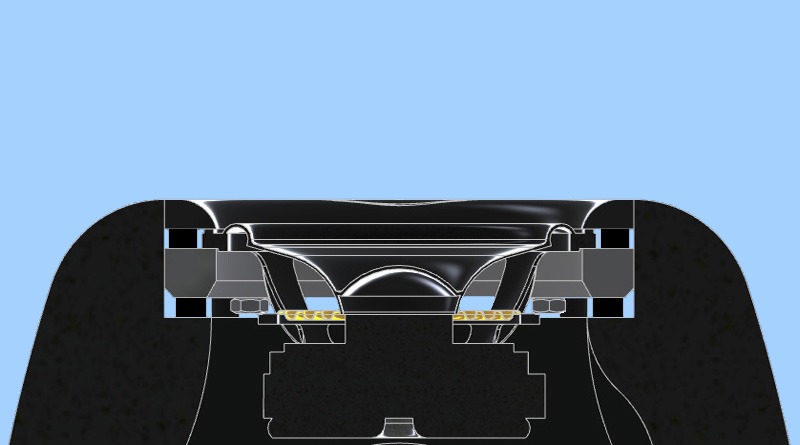

I found evidence online that the back mounted 3.5" driver had advantages over a flush mounted construction as far as off axis results. That evidence isn't available online anymore but the sims we ran years later basically confirmed that line of thought.

I used an inner baffle to hold the drivers and a "beauty baffle" to be able to have that beneficial round-over in front of the drivers. I treated it like a CLD construction with butyl rope damping in-between.

As designed

As fabricated

It has seen several cycles of assembly and still is as fresh as it ever was.

About the bass part, this quote might be a fun read:

https://www.stereophile.com/rmaf2006/102106ids/index.html

A couple of quotes from the IDS site:

https://www.ids25.com/reviews.htm

And having ran the arrays for multiple years without sub-woofers, I know the above quotes aren't bull. When I announced my plans to add subs some of the folks that had visited asked me: why? For music, there wasn't a need, simple and true. As long as the room isn't too large, the position of the arrays is helping out by being reasonably close to the back wall or even one in a corner, it can be made to work satisfactory. That's the honest truth. Don't try that with the Scan Speak 10F though, but the Vifa/Peerless TC9 FD18-08 can do it in the right room, with EQ. It has been a surprise for many to hear what they are capable of.

I didn't regret making it serviceable. I've had it apart for several different reasons. Most of them just aimed at improving the results, only one out of necessity due to driver failure after moisture damage. (had them stored open in a very damp garage for just about a complete year.

I found evidence online that the back mounted 3.5" driver had advantages over a flush mounted construction as far as off axis results. That evidence isn't available online anymore but the sims we ran years later basically confirmed that line of thought.

I used an inner baffle to hold the drivers and a "beauty baffle" to be able to have that beneficial round-over in front of the drivers. I treated it like a CLD construction with butyl rope damping in-between.

As designed

As fabricated

It has seen several cycles of assembly and still is as fresh as it ever was.

About the bass part, this quote might be a fun read:

In the amazing bass department, Roger Russell’s towering IDS-25 took today’s cake. With 25 drivers per side, and designed to sit very close to the rear wall with speakers and sweet-spot seat arranged in an isosceles triangle, the $18,900/pair speakers eliminate crossovers, woofers, midranges, tweeters, subwoofers...well, everything but the sound itself. With a sensitivity of 92dB, and capable of sounding their best with far less power than that offered by the room’s beefy McIntosh electronics, the IDS-25 includes a fixed active equalizer that creates purported dead flat response between 20Hz and 18kHz. Designed by McIntosh’s former chief designer, and distributed by Ken Haig (pictured) via the www.ids25.com website, the speakers are brand new; the first pair sold arrived at their happy purchaser’s home today.

https://www.stereophile.com/rmaf2006/102106ids/index.html

A couple of quotes from the IDS site:

I was shocked at the extension, power and weight of the low frequencies. Also pitch, dynamics, tonal balance and transients were superb. The fact that they're meant to be positioned against the wall makes them even more appealing for small rooms where it's often difficult to move speakers out into the room. Even against the wall they produced good imaging and soundstage depth.

In short, it sounds superb. The bass is well extended in frequency response and quite deep. If anyone has heard a well designed 15 inch woofer, then that is the frequency response that one gets. The frequency response is such that great one keeps looking for the sub woofer, which, of course isn’t there. But your eyes and previous experiences still lie to you. It is difficult to relearn or adjust to something after years of life experience.

https://www.ids25.com/reviews.htm

And having ran the arrays for multiple years without sub-woofers, I know the above quotes aren't bull. When I announced my plans to add subs some of the folks that had visited asked me: why? For music, there wasn't a need, simple and true. As long as the room isn't too large, the position of the arrays is helping out by being reasonably close to the back wall or even one in a corner, it can be made to work satisfactory. That's the honest truth. Don't try that with the Scan Speak 10F though, but the Vifa/Peerless TC9 FD18-08 can do it in the right room, with EQ. It has been a surprise for many to hear what they are capable of.

https://www.diyaudio.com/community/...range-line-array.242171/page-207#post-5360439And I can testify that, you do NOT miss any bass extention or level @ wesayso!

https://www.diyaudio.com/community/...range-line-array.242171/page-206#post-5353272koldby said:And now I know , why the subwoofer project has been delayed for such a long time😛😀

The level and quality in the bass-sub bass region leaves very little to desire, only this nagging feeling "if I haven´t tried it, what will I miss?"

Last edited:

I shall take a look when i have some drivers!You won’t be able to effectively chamfer the rear of the baffle due to the close proximity of the flange mounting screws….they’re won’t be enough wood to bite into.

Seeing also the vertical half round either side of the drivers on a couple of examples, it is useful for grille spacing, can be made with the baffle for stiffness, which is the sound answer, flat, ridges, or different compromises?

2 days delivery at £12.75 each I have 55 drivers ready to go, 5 spares as someone advised.

I cut some 11mm grey MDF with a 75mm hole saw and 45 degree routed back angle. i would use black on the real version.

That means the fastening holes are just in the chamfer, more than enough material to take a screw or bolt with backnut. The remaining part seems adequately stiff for handling during build.

If the baffle is minimum width i might make it in two parts to ease handling an 8 foot length.

So, at first look that seems adequate to front face mount the drivers. I have some mass loaded vinyl sheet which would fill the gaps between driver plates nicely if they are face fitted as pictured.

I am not looking to add this complexity but i could make a jig and recess each driver, lots of work for how much benefit?

What is the preferred edge treatment for the baffle, the vertical half round on some makes an easy grille/sock fit?

In fact i could just copy the front shape of OPC, why not, his thread reads like he knows what he is doing!

He uses 5 drivers per enclosure, is this preferable to sealed individual ones?

M

I cut some 11mm grey MDF with a 75mm hole saw and 45 degree routed back angle. i would use black on the real version.

That means the fastening holes are just in the chamfer, more than enough material to take a screw or bolt with backnut. The remaining part seems adequately stiff for handling during build.

If the baffle is minimum width i might make it in two parts to ease handling an 8 foot length.

So, at first look that seems adequate to front face mount the drivers. I have some mass loaded vinyl sheet which would fill the gaps between driver plates nicely if they are face fitted as pictured.

I am not looking to add this complexity but i could make a jig and recess each driver, lots of work for how much benefit?

What is the preferred edge treatment for the baffle, the vertical half round on some makes an easy grille/sock fit?

In fact i could just copy the front shape of OPC, why not, his thread reads like he knows what he is doing!

He uses 5 drivers per enclosure, is this preferable to sealed individual ones?

M

Attachments

The gasket was damaged on arrival, is this just normal.

I only opened one, assuming i use a grille like OPC is of no consequence.

So here is a baffle with half rounds and a fill piece bottom left, would appear flush in sonic terms?

Paint white like OPC and a white sock overall, or much more complicated a front grille and veneered curved sides.......

M

I only opened one, assuming i use a grille like OPC is of no consequence.

So here is a baffle with half rounds and a fill piece bottom left, would appear flush in sonic terms?

Paint white like OPC and a white sock overall, or much more complicated a front grille and veneered curved sides.......

M

Attachments

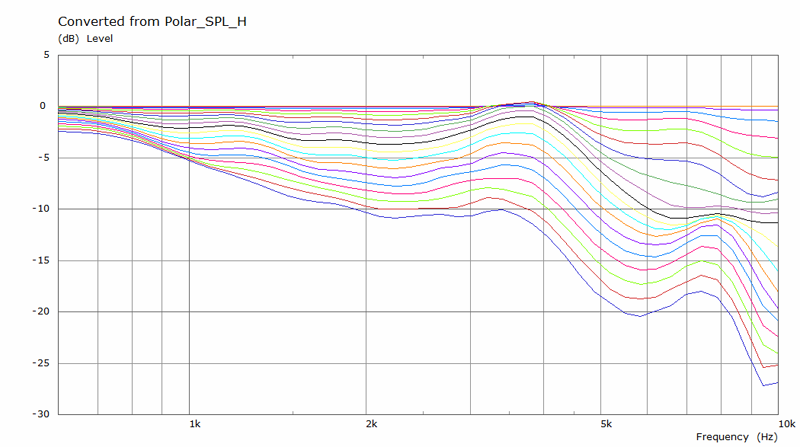

I've put my trust in creating a smooth transition, from the cone out to the enclosure, obviously with a surround that get's in the way somewhat, but think how that cone moves and that surround changes accordingly.

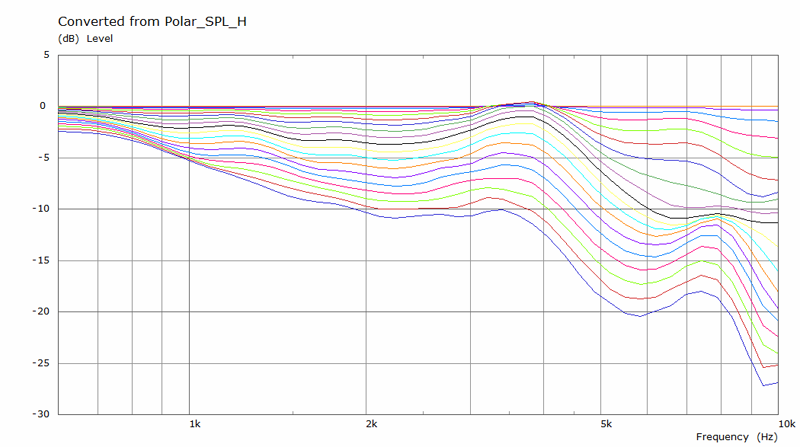

The simulations have shown that it is working: https://www.vandermill-audio.nl/smooth-curves-to-avoid-diffraction/

So if I were you, I'd either put an extra shape in front of the drivers, with a rounded over cut-out like I did, or make sure that the driver "sees" as less of a ridge as possible when you construct those protruding sides. Because if it acts as a ridge, and is just about the same for every driver in that array, it will influence the frequency outcome through diffraction. I wanted to minimise the diffraction footprint. As that would aid in the "speakers disappearing act, while listening to music". That part was very important to me, a set goal if you will. I believe the more gradual change of output as seen moving from on-axis to off-axis frequency curves in the simulations as presented in that link do show it makes a difference.

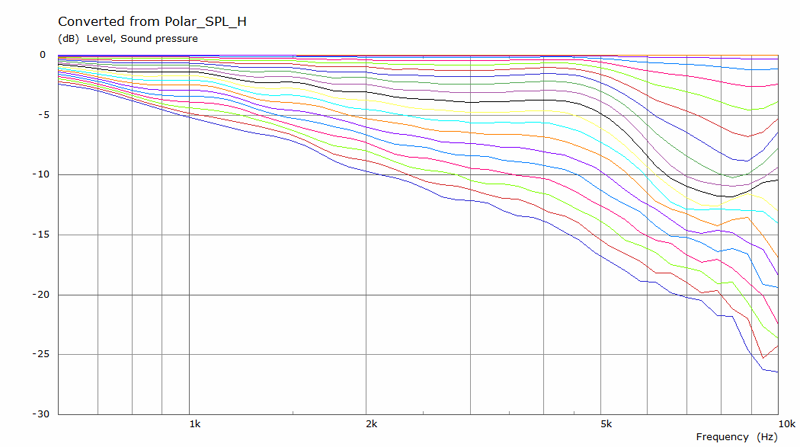

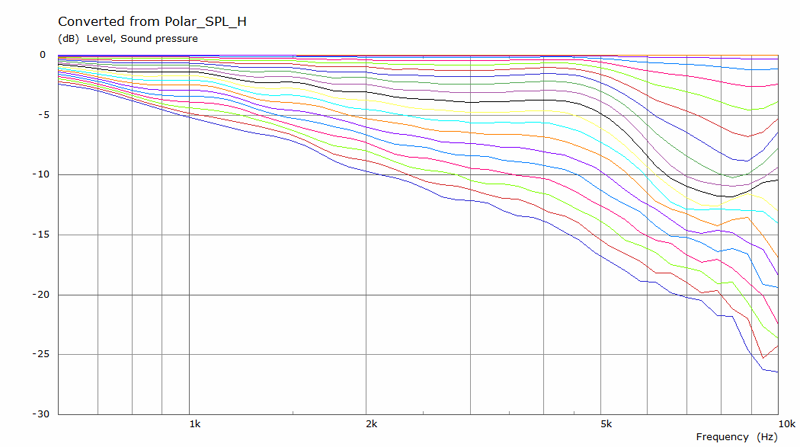

From flush mount in a rectangle:

To the curved enclosure with that small waveguide in front:

So I would try and make sure that whatever is used to hold off that sock from the cone does not reduce my rounded enclosure to look like a rectangle again to the acoustic output 😉.

The simulations have shown that it is working: https://www.vandermill-audio.nl/smooth-curves-to-avoid-diffraction/

So if I were you, I'd either put an extra shape in front of the drivers, with a rounded over cut-out like I did, or make sure that the driver "sees" as less of a ridge as possible when you construct those protruding sides. Because if it acts as a ridge, and is just about the same for every driver in that array, it will influence the frequency outcome through diffraction. I wanted to minimise the diffraction footprint. As that would aid in the "speakers disappearing act, while listening to music". That part was very important to me, a set goal if you will. I believe the more gradual change of output as seen moving from on-axis to off-axis frequency curves in the simulations as presented in that link do show it makes a difference.

From flush mount in a rectangle:

To the curved enclosure with that small waveguide in front:

So I would try and make sure that whatever is used to hold off that sock from the cone does not reduce my rounded enclosure to look like a rectangle again to the acoustic output 😉.

Hightech machining gives best results.

Damping the front can help minimize diffraction, too.

If corner placed damping the first reflections at the sides is worth a try.

Damping the front can help minimize diffraction, too.

If corner placed damping the first reflections at the sides is worth a try.

I had good results just covering front surface of boxes with felt.

Imaging gets better, mids are tamed, bass is a bit better coming out.

The 3/5a had some thick damping stripes around the tweeter.

This is only a low tech alternative to the sophisticated aluminum design wesayso choose to machine.

Imaging gets better, mids are tamed, bass is a bit better coming out.

The 3/5a had some thick damping stripes around the tweeter.

This is only a low tech alternative to the sophisticated aluminum design wesayso choose to machine.

Its brilliant to use felt rather than a solid surface to hold the grill cloth off the surround!

So the baffle "design" is currently a mock-up like this picture.

11mm MDF 132mm wide, with 75mm holes for each speaker so that the speaker chassis fit edge to edge at ~85mm centres

Back of holes 45 degree router relieved as shown in #112

Felt edge 25mm wide and uncompressed at 10mm deep which when wrapped in its sock will give some equivalent to the half round shown in the pic on the right but be absorptive as well.

The felt is Jantzen audio speaker cabinet felt and will go inside the boxes as well.

Little infill pieces to make the front flush at chassis front line.

Obviously the baffle is not yet trimmed to width as i would like to get the back cabinet right first and trim at the correct angles.

I have made the cabinet sides of two pieces so the outside can be rounded and the inner is not a box, then the sock should look reasonable on the outside as well.

Is it beneficial that the back is not parallel to the front? - if so that could be a two piece as well? - it would add marginally to the volume.

I can rout a cable slot in the back, either way, top to bottom.

Then back to volume, with 8mm dividers, this is 1.1 litres per chamber, i can extend the sides readily to get say 1.5 litres. its very neat at this size and would be fine also with the side legs 40% longer

All advice welcome!

M

11mm MDF 132mm wide, with 75mm holes for each speaker so that the speaker chassis fit edge to edge at ~85mm centres

Back of holes 45 degree router relieved as shown in #112

Felt edge 25mm wide and uncompressed at 10mm deep which when wrapped in its sock will give some equivalent to the half round shown in the pic on the right but be absorptive as well.

The felt is Jantzen audio speaker cabinet felt and will go inside the boxes as well.

Little infill pieces to make the front flush at chassis front line.

Obviously the baffle is not yet trimmed to width as i would like to get the back cabinet right first and trim at the correct angles.

I have made the cabinet sides of two pieces so the outside can be rounded and the inner is not a box, then the sock should look reasonable on the outside as well.

Is it beneficial that the back is not parallel to the front? - if so that could be a two piece as well? - it would add marginally to the volume.

I can rout a cable slot in the back, either way, top to bottom.

Then back to volume, with 8mm dividers, this is 1.1 litres per chamber, i can extend the sides readily to get say 1.5 litres. its very neat at this size and would be fine also with the side legs 40% longer

All advice welcome!

M

Attachments

I cut the baffle to "height" for a one unit sample at the speaker driver edge and it seems plenty strong enough, alone particularly as the material for the next driver adds to this. it seems to me that with the felt edge this gives a quite good edge shape for diffraction and the back angle relief is reasonable?

Thoughts on the box shape also welcome

Thoughts on the box shape also welcome

Attachments

- Home

- Loudspeakers

- Full Range

- Another corner array project