walterwalter: "However, for DIY-ers here, those who thinks of electronically guided one, I would suggest to consider CD-LD-DVD tracking solutions, those there seems to be using constant and smooth transition of laser pick up head, instead of sporadic movement with most of tangential tone arms..."

Digital disks do not have eccentric spiral like many vinyl records which sometimes drift off several millimeters, which can knock ANY tonearm out of tangency. So perhaps using CD like tracking might be too sensitive for vinyl tracking. Besides, groove to groove distance is different on each record--I don't believe that's standardized. I think the Rabco style servo tracking system is adequate and simply let the arm wriggle when encountering eccentric records and on perfectly centered records it will tracking smoothly, if adjusted precisely.

----------------------------------------------------------------------

By the way, most motorized servo linear arms move only one direction (Rabco, Yamaha PX2, Golmund, etc) and the only one I can think of that moves both directions is the Pioneer PL-L1000 that works like a mag-lev train but the sporadic movement seems unnecessary.

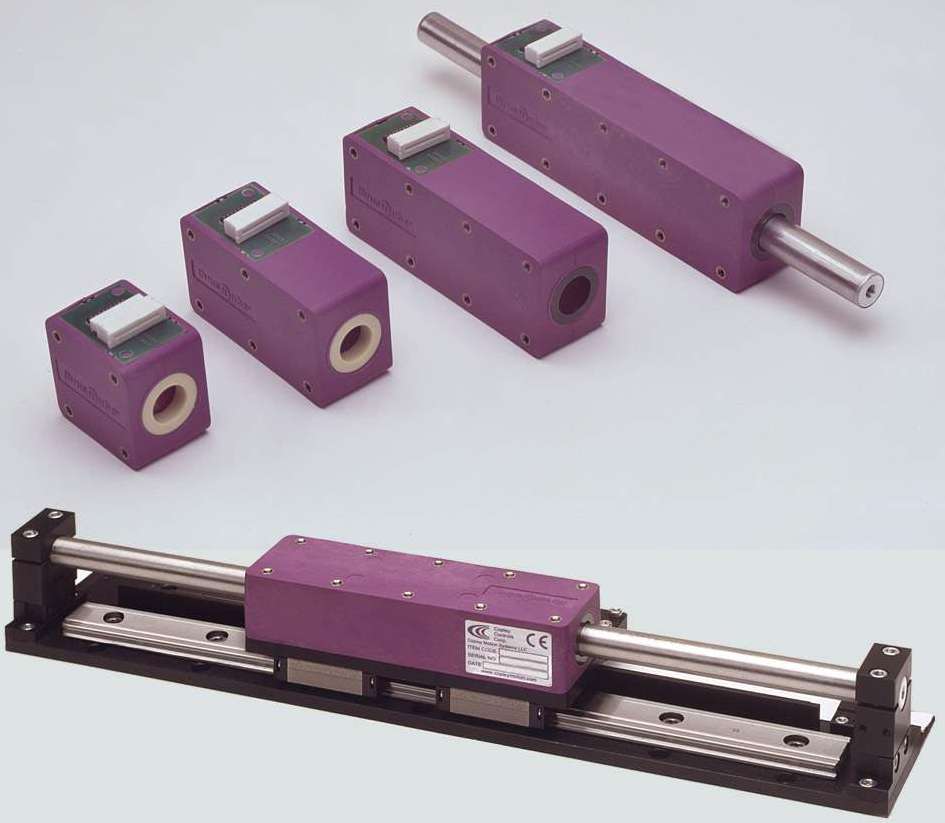

Speaking of motors. I found this linear motor online from the biomedical industry. Looks fascinating and might be useful on a linear tonearm. No cheap, price from $235 each (Forcer +Thrust Road). Check it out:

.

walterwalter, I don't believe there's an anti-skating solution for cantilever forces in the hz to ten hz region, which is where I believe the real problem lies. If you've got one, it would certainly be interesting!

I don't want to track eccentric records with the servo, be it mechanical or electronic, at least not the normal minor ones. Tangency to that level is not the problem. IMO, that's what people fail to grasp. 0.1 degrees is fine; you should just let the nice pivoted arm do its job. Do not design the servo system to wander back and forth at a 0.555 Hz rate, but keep the response much slower. That doesn't mean increased error if the thing is implemented properly.

I don't want to track eccentric records with the servo, be it mechanical or electronic, at least not the normal minor ones. Tangency to that level is not the problem. IMO, that's what people fail to grasp. 0.1 degrees is fine; you should just let the nice pivoted arm do its job. Do not design the servo system to wander back and forth at a 0.555 Hz rate, but keep the response much slower. That doesn't mean increased error if the thing is implemented properly.

Conrad Hoffman: "IMO, that's what people fail to grasp. 0.1 degrees is fine; you should just let the nice pivoted arm do its job. Do not design the servo system to wander back and forth at a 0.555 Hz rate, but keep the response much slower."

I agree! Over obsessing tangency on eccentric record is a lost cause.

The weakness in many servo tonearm is not even the servo system but the poor quality of the pivot arm section. Just imagine having a base with a well designed servo system with high quality gliding mechanism, mounted with the best pivot arm that the market has to offer.... That'll be something to listen to!

.

walterwalter, I don't believe there's an anti-skating solution for cantilever forces in the hz to ten hz region, which is where I believe the real problem lies. If you've got one, it would certainly be interesting!

I don't want to track eccentric records with the servo, be it mechanical or electronic, at least not the normal minor ones.

Thank you Conrad. I didn't think of the whole arm with it's base and counterweight, waving with the record eccentricity, -it is really a bad solution for tangential arm. But it seems to be not a case with semi-tangential, as Thales etc.?.And they will still need an anti-skating, which is better to be following the curve of skating force, increasing and decreasing on it's path according to track radius ( this is what we are really able to pursue, apart from the completely irregular issues). Rather than just apply constant antiskating force, or a such one which decreases-increases on it's own path (that is how most of existing anti-skating compensator operate)...

Last edited:

Hi,

The problem with creating the "perfect" skating force compensation device is that skating force depends on a multitude of parameters(i.e. vinyl formula, modulation level, stylus profile and quality of polishing,etc...), resulting in a compensation varying from 4-18% of the VTF. ALL antiskating mechanisms are a compromise with about 8% of VTF being a reasonable compromise.

<snip> Frank

Hi Frank, what is a practical method to set the anti-skating force in the string of a DIY Thales-circle arm similar to the one you developed? Or do you just set it to 8% VTF on principle? Arg

tonearm porn

More pictures of Thales Simplicity tonearm from a Taiwanese website

.

.

More pictures of Thales Simplicity tonearm from a Taiwanese website

.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

.

More tonearm porn. Here's a picture that shows the Thales tonearm on a Monaco Grand Prix direct drive turntable. Looks like they had to machine a mounting platform for the Thales arm.

I have to wonder why can't the designer make the mounting scheme a little more user friendly, instead of all these oddly shaped custom made parts. It's an unconventional arm to begin with and to make it even more unconventional to mount is really unnecessary...

.

I have to wonder why can't the designer make the mounting scheme a little more user friendly, instead of all these oddly shaped custom made parts. It's an unconventional arm to begin with and to make it even more unconventional to mount is really unnecessary...

.

Nice to see we are back on topic after all that Goldmund LT diversion.

If that variation in skating force with groove modulation is only 2-4% (post 134), that seems like a small concern?

If that variation in skating force with groove modulation is only 2-4% (post 134), that seems like a small concern?

I have seen and heard that arm in krefeld but I could not access it´s virtues because of the show ambient.... It seems way to complicated and with too many pivots .... Do you believe it is a singer ?

I think of all the pivot headshell designs the simplest one still is the mysterious string tonearm, check post #84 for bigger detailed pictures.

I want to make it even simpler by taking out one string on the left and replace the right string with a rigid light mass rod but the bearings will still be string tied.

.

I want to make it even simpler by taking out one string on the left and replace the right string with a rigid light mass rod but the bearings will still be string tied.

.

Last edited:

the bearings will still be string tied.

How do you push string? what am I missing?

Cheers

Steve

stevieg:"How do you push string? what am I missing?"

Think of it as a linkage or an extremely short string between two rigid parts or think of the Schroder arm with a very very short string. Or think of the beads strung together on a necklace. Kinda like a unipivot bearing. I hope it makes sense...

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

.

Last edited:

Sounds like a smart way to get rid of the unnecessary precision bearings. And it will be possible to make a simple inexpensive conversion of existing arm into semi-tangent one.

walterwalter: "it will be possible to make a simple inexpensive conversion of existing arm into semi-tangent one."

That's the whole idea. For someone without extensive machining tools, the design has to be simple enough for the DIY community.

The reason I chose to eliminate the string on the left instead of the right is because the tonearm in the picture has a rather wide bearing that gets in the way of the left string and the maker used a spring to get around it when arm is in back in the rest position and that's rather awkward. The guiding rod needs to be very rigid and light weight. Another way is to string tied the headshell side and the on the bearing side make it a unipivot style bearing and add a small counterweight to offset the mass.

If you have an existing tonearm that has a more narrow bearing housing such as the reasonably priced Jelco straight arm, it would be a good candidate for conversion AND you can have the guiding rod on the left side so it would not get in the way of the arm-lift and arm-holder. (A Rega arm might not work as well as the Jelco but since it's the most common budget arm you can still make it work.)

Even better is the now discontinued Graham Robin tonearm (made by Jelco) with detachable headshell so you don't even have to butcher the headshell, just use a replaceable conventional headshell without offset angle and install a ball bearing there. Everything can be reversible.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

.

Gosh idk. I think the idea of a pivoting headshell is a good one, but you still have the issue of skating, and of reduced stiffness, and increased mechanical complexity.

When you factor all of that in, I keep coming back to the idea of having a unipivot on a driven sled, being the best compromise between increased complexity (electromechanical componenets) and the mechanical simplicity (rigidity and overall performance).

If I had the impetus to start building this design I would first try it out by manually sliding the arm base over to the middle of the track I wanted to listen to. If it were a nine inch arm it wouldn't be any worse than any other unipivot nine inch arm, and for that track would be much better.

A painfully simple and effective way to implement a sliding base might be to use a gear with a flat bottom as the unipivot base. The gear would mesh towards the record against a straight gear affixed to the base, and the rear of the gear would be driven by a worm screw. As the base moves it would rotate, but since it is a unipivot, that wouldn't matter. The flat bottom of the gear could be set in oil or greased, which would provide a very rigid coupling to the plinth, and still allow slow translation.

When you factor all of that in, I keep coming back to the idea of having a unipivot on a driven sled, being the best compromise between increased complexity (electromechanical componenets) and the mechanical simplicity (rigidity and overall performance).

If I had the impetus to start building this design I would first try it out by manually sliding the arm base over to the middle of the track I wanted to listen to. If it were a nine inch arm it wouldn't be any worse than any other unipivot nine inch arm, and for that track would be much better.

A painfully simple and effective way to implement a sliding base might be to use a gear with a flat bottom as the unipivot base. The gear would mesh towards the record against a straight gear affixed to the base, and the rear of the gear would be driven by a worm screw. As the base moves it would rotate, but since it is a unipivot, that wouldn't matter. The flat bottom of the gear could be set in oil or greased, which would provide a very rigid coupling to the plinth, and still allow slow translation.

tade: "you still have the issue of skating, and of reduced stiffness, and increased mechanical complexity... When you factor all of that in, I keep coming back to the idea of having a unipivot on a driven sled, being the best compromise between increased complexity (electromechanical componenets) and the mechanical simplicity (rigidity and overall performance)."

I am not against a sliding track but it is still just as or more complicated than pivoting headshell. Since this thread is focused on achieving tangency via pivoting means, I am only staying true to the topic.

The pivoting headshell idea actually can be implemented or converted on a unipivot arm. Think of the Van Eps arm or Thales Simplicity using TWO unipivot bearings, just have to make sure the pivot heights are equal to not affect azimuth. Let's say the guiding arm is on the left, so the cartridge and main arm will tend to lean on the left so not only the guiding arm acting as "articulation" but also acting as azimuth stabilizing, almost like the Graham Phantom's secondary bearing. This way, we don't have to worry about the azimuth instability of typical unipivot designs. And at the arm base area, there are only TWO contact points - low friction! Kills two birds with one stone.

Of course, the headshell pivot still requires a ball racing bearing.... or the RS Labs type of headshell.

.

My apologies, I didn't realize that a pivoting headshell was a goal for the thread.

I think that instead of ball bearings, or string tying, using small diameter plain bearings; a smooth rod in a greased hole, should be plenty low enough friction and plenty smooth.

Let me ponder for a bit...

I think that instead of ball bearings, or string tying, using small diameter plain bearings; a smooth rod in a greased hole, should be plenty low enough friction and plenty smooth.

Let me ponder for a bit...

If I had the impetus to start building this design I would first try it out by manually sliding the arm base over to the middle of the track I wanted to listen to. If it were a nine inch arm it wouldn't be any worse than any other unipivot nine inch arm, and for that track would be much better.

Now this is a very cool idea.

I would use a 12inch arm with a sliding armboard.

tade: "My apologies, I didn't realize that a pivoting headshell was a goal for the thread."

No apologies needed. All ideas are welcome. I have intruded on other threads and sidetracked enough topics to understand the urge to chime in. Feel free to contribute.

tade: "a smooth rod in a greased hole, should be plenty low enough friction and plenty smooth.... Let me ponder for a bit..."

I look forward to your further pondering.

.

- Home

- Source & Line

- Analogue Source

- Angling for 90° - tangential pivot tonearms