Sorry Direct Driver, your post beat me by about 30 seconds - but I'll post mine anyways :

I appreciate any contributions to the the subject at hand. I don't care whether it is theoretical, practical application or actual examples. I of course have my preferences to see a certain type of contribution to the forum - such as example prototypes of designs, more theoretical info relating to designs with attempts of no skating, but it is not my place to tell others what they should contribute. If I don't like a post I can pass it by. Some of the most prolific or authoritative posters ( 2wice, Frank Schroeder, etc. ) have or may want to have commercial interests. They have provided excellent, often important and authoritative input into the discussion. They contribute whatever they feel like contributing. Fine with me. What bothers me is when exaggerations or manipulations of language - "but obsessing over ", "are merely a form of free advertising", "Wonder if most of the people do listen music" as seen in the last few posts enter the picture to attempt to control or sway the forum discussion in a dishonest way. I know which posts I prefer to read or skip.

I appreciate any contributions to the the subject at hand. I don't care whether it is theoretical, practical application or actual examples. I of course have my preferences to see a certain type of contribution to the forum - such as example prototypes of designs, more theoretical info relating to designs with attempts of no skating, but it is not my place to tell others what they should contribute. If I don't like a post I can pass it by. Some of the most prolific or authoritative posters ( 2wice, Frank Schroeder, etc. ) have or may want to have commercial interests. They have provided excellent, often important and authoritative input into the discussion. They contribute whatever they feel like contributing. Fine with me. What bothers me is when exaggerations or manipulations of language - "but obsessing over ", "are merely a form of free advertising", "Wonder if most of the people do listen music" as seen in the last few posts enter the picture to attempt to control or sway the forum discussion in a dishonest way. I know which posts I prefer to read or skip.

HI Bugbob,

If you take a look at my post and small contribution to the forum I don to think you can say or write I am not honest, on the contrary I think I am quite honest indeed..

Kindly note that I am not dishonest and not trying to deviate any technical discussion.

Kind regards

Adelmo

If you take a look at my post and small contribution to the forum I don to think you can say or write I am not honest, on the contrary I think I am quite honest indeed..

Kindly note that I am not dishonest and not trying to deviate any technical discussion.

Kind regards

Adelmo

People have the right to show or not show their invention. I have no problem with that and I understand their concern about intellectual property. I firmly believe some commercial entities took ideas from this thread without crediting us but so what we posted this in a public forum and that's the risk we took. That's why people file a patent. The members who withhold information at least contributed into the discussion and they could have simply not post anything at all and that would be boring! This thread has been around for 11 years now and I never felt the need to pressure people to post anything they don't want to reveal. Moving on. People are welcome to post whatever pertinent to the topic and people are welcome not to post but are enjoying the reading and gleaming ideas from the posts. Just enjoy the ride.

Hi direct Driver,

I agree with you about the intellectual property and I rather comply pretty well with such rule.

Also I do not think I am pressing anyone to post their project as I believe to be a pretty discreet guy and respectful, I do not think anyone here can say I was pressing for informations. You may check my post in this forum, the questions and my answers technically speaking or what so ever.

But allow me to say that I am a bit surprised that my comment raised such concern, sorry if I touched such sensitive area..........., but sorry I also cannot recall the small laugh I had.

Above if your post was referring precisely to myself, if not accept my apology.

Rgards

Adelmo

And all above is quoted as a proposal in a forum for Audio DIYers. Sounds like a proposal to who? Mmmmm........yourself ?

Please be aware of the context of the "proposal" Jim (super10018) was referring to is actually posted in another thread. Before we accuse people of withholding information, we need to respect their choices and the context of the discussion. This is a long thread and Jim has been a long time participant who posted many interesting ideas before so he has done his contribution and we appreciate him (or 2wice, Carlo, Frank, Ray, Ralf, Doug, etc...), even at times we might disagree with each other.

Let us just get back to discussing ideas, scratching potentials, enjoying pictures, and sparking creativity. Just enjoy it as entertainment.

Hi Directdriver,

i am not keeping this discussion any longer despite I am not in agreement with your thinking and writing in the last post to the main accusation concept.

I shall give if possible my contribution to the forum on the technical side with my limited technical skills....

Enjoy you too the entertainment.

Adelmo

i am not keeping this discussion any longer despite I am not in agreement with your thinking and writing in the last post to the main accusation concept.

I shall give if possible my contribution to the forum on the technical side with my limited technical skills....

Enjoy you too the entertainment.

Adelmo

Last edited by a moderator:

Well, I decided to reveal my proposal so everyone gets entertained.

An externally hosted image should be here but it was not working when we last tested it.

And now something completely different.

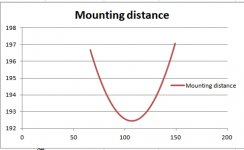

A shown elsewhere, tonearms following the Thales circle struggle with greater skating force than traditional pivoting tonearms.

Distortion caused by skating is not better that distortion caused by tracking error.

Can the traditional tonearm be improved to have zero tracking error?

Yes! The idea is to vary the mounting distance during playing so that the null point moves with the tonearm.

I made a little spreadsheet with the shown result. Effective length is 220 mm, offset 22 degrees.

I don't know whether this has any practical significance since a precise cam is needed and a linear bearing or a pivoting arm long enough on which the tonearm is mounted.

On the other side, ANY existing tonearm can be modified.

A shown elsewhere, tonearms following the Thales circle struggle with greater skating force than traditional pivoting tonearms.

Distortion caused by skating is not better that distortion caused by tracking error.

Can the traditional tonearm be improved to have zero tracking error?

Yes! The idea is to vary the mounting distance during playing so that the null point moves with the tonearm.

I made a little spreadsheet with the shown result. Effective length is 220 mm, offset 22 degrees.

I don't know whether this has any practical significance since a precise cam is needed and a linear bearing or a pivoting arm long enough on which the tonearm is mounted.

On the other side, ANY existing tonearm can be modified.

Attachments

Last edited:

A regular pivot arm will always have larger tracking errors than a tangential pivot arm no matter it is 9" or 12". The tangential pivot arm I proposed here has zero tracking error.

I believe that generally speaking, a tangential arm has a weaker skating force than a regular pivot arm. But it is just a guess. Need evidence for that.

I believe that generally speaking, a tangential arm has a weaker skating force than a regular pivot arm. But it is just a guess. Need evidence for that.

super10018,

Your proposal does not reveal on my Mac.

Here you go.

Attachments

I believe that generally speaking, a tangential arm has a weaker skating force than a regular pivot arm. But it is just a guess. Need evidence for that.

Until the radius of the Thales circle is smaller than the effective length of the traditional tonearm the skating force is greater.

String Test Primer

The string test by Ray is useful so I want to transplant his post from another thread onto this thread for future reference, since it recalls this thread multiple times.

The string test by Ray is useful so I want to transplant his post from another thread onto this thread for future reference, since it recalls this thread multiple times.

The string test was originally conceived to be applied to offset arms and tangential pivot arms, both of which had/have the goal of maintaining tangency across the playing area of the disc. . . . As clarified in subsequent posts by myself and others, you have to pull the string tangentially to the stylus contact point, which is not necessarily in line with the headshell. I have outlined pertinent historical mileposts to clarify this and present them below.

Post #11 4-28-10, Conrad Hoffman’s original criterion: “If you draw a line, or at least a vertical plane, through the stylus/cartridge and it doesn't intersect the arm pivot, you've got forces you don't want.”

Post #949 04-07-15, diyrayk’s original String Test challenge: “Take a string 12 or longer, it doesn’t really matter, and tie it to the headshell or the cartridge body so that it stretches straight out from the cartridge and in line with the stylus.”

post #1149 03-22-17 alighiszem proposes his ‘yarn’ test: “if you bind a piece of cotton yarn on the tonearm and pull it in the direction the friction force would pull” Note he states more clearly than I originally did that you have to pull in the direction of the friction force which means, in other words, tangentially.

post #1156 03-22-17 “Yes, the simulated 'friction force' is tangential, but if the tangential string force vector is offset or not in line with the pivot, be it fixed or virtual, the tangential friction force will resolve itself into some rotary component about the pivot point, and this manifests itself as skating.” At this point I still referred to being in line with the headshell, but also began to emphasize that we are simulating friction force and for that the string has to be pulled ‘tangentially’, which is a clearer way of stating the groove friction force direction.

post #120 06-19-21 Point of clarification: The discussion has veered off course and I have to clarify the frame of reference for tangency. 2wice proposes reframing the test as “String Test 2.0”, which I did.

post #36 07-14-21 Straight Tracker further clarifies that the frame of reference for “tangential” should be more precisely defined as the tangential location of the stylus on a “concentric circle”. Excellent! With that we are now up to “String Test 2.1”.

Summary:

If we take Straight Tracker’s precise definition of “tangential” and substitute that precise definition in my “String Test 2.1”, alighiszem’s ‘yarn’ test, Conrad Hoffman’s criterion, and Klaus Rampelmann’s explanation of skating, then there is no conflict or incompatibility among these test criteria for skating, and by all these methods, the DJ arm (a straight arm with no offset headshell) FAILS the test. All four methods work as advertised if you use the correct frame of reference for tangency, and the physics of the universe is happy. The nice thing about String Test 2.1 is that with a simple piece of string you can walk up to a tonearm and determine if it will skate even if you don’t know where exactly the pivot is, which is sometimes not clear on a complex mechanism such as a KLAUDIO arm.

Ray K

Last edited:

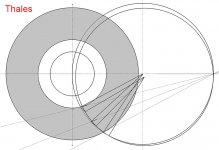

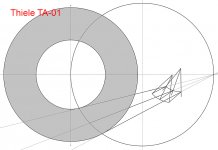

Thiele TA01

More pictures and test of the very interesting tangential tracker from the German website HifiStatement net-magazine.

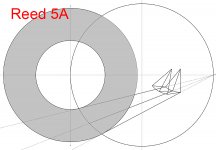

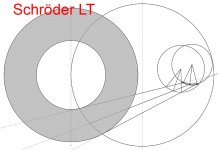

Along with Thales Simplicity, Schröder LT, & Reed 5A, the Thiele TA-01 provides another option as a ready made commercial product in the genre of passive pivoting tangential tonearms. And the Big Four all exceed the $10,000USD price tag!

Early prototype.

More pictures and test of the very interesting tangential tracker from the German website HifiStatement net-magazine.

Along with Thales Simplicity, Schröder LT, & Reed 5A, the Thiele TA-01 provides another option as a ready made commercial product in the genre of passive pivoting tangential tonearms. And the Big Four all exceed the $10,000USD price tag!

Early prototype.

super10018,

Thanks for the Thiele arm geometry drawing. Thiele's own drawing was difficult for me to understand.

DD - or anyone else - was there ever a commercial tonearm based directly on the Birch/Thales geometry?

Thanks for the Thiele arm geometry drawing. Thiele's own drawing was difficult for me to understand.

DD - or anyone else - was there ever a commercial tonearm based directly on the Birch/Thales geometry?

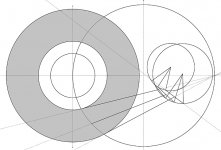

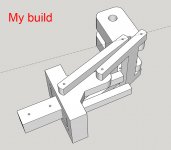

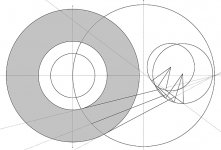

Here are some geometries of commercial tangential pivot arms. You may see that all tonearms use double Birch and Thales theorem except Thales tonearm since I am not sure if I can say that they use double Birch geometry. I also include a drawing of my ongoing build. The reason I tried to find an alternative other than Reed 5A was because I thought Reed 5A has room to improve. Although I found the geometry for my build independently, I have to admit that Frank did it before I did. My idea collides with his LT design. This is why I reveal it here. But I don’t intend to use a guiding slot as Frank did. In my opinion, a jewel bearing may be better than a guiding slot. I also thought of using a magnet as a guiding mechanism, but I gave it up since I think it introduces unnecessarily complex. I think my build will skate but it may not be as significant as regular pivot arms. I do not intend to add any anti-skating device but a pre-loaded bearing may work nicely. However, my build is not intended to play records so I am not going to add any pre-loaded bearing though I do have a couple of ideas for pre-loaded bearing. This build is purely for fun.

I also included an idea I published here before. Both geometries, in my opinion, are very interesting, simple, and practical. This is why I published it here. I found many alternatives. Some of them are nice, too. However, I don't think I need to publish them here. Again, I do think both my ideas are better than Reed 5A structurally. My ideas are simpler and they integrate the main bearing with the construction of the tonearms beautifully.

I also included an idea I published here before. Both geometries, in my opinion, are very interesting, simple, and practical. This is why I published it here. I found many alternatives. Some of them are nice, too. However, I don't think I need to publish them here. Again, I do think both my ideas are better than Reed 5A structurally. My ideas are simpler and they integrate the main bearing with the construction of the tonearms beautifully.

Attachments

Last edited:

Hello gentlemen,

Thanks for putting those drawings side by side, as the show that Reed, Thiele, some of the DIY efforts are principally the same. Just as one can built an LT following that schematic.

The difference is the lack of need to adhere to a strict radius/circle segment, due to the magnet following any(straight, ellipse-segment, circle segment, parabolic...) guide rail.

If one is to substitute the guide magnet with a marker/pencil, then follow the path of the stylus tangentially, the marking/line by the pencil left will describe the required curve segment, - and it obviously will not automatically be a circle segment.

Due to the changing angle of the attracting force (magnet- rail), the proximity changes under load(friction: stylus - record groove)from beginning to end an so, needs to be compensated for. That may appear difficult to achieve/execute, but the absence of all the linkages, additional bearings and indifference regarding structural integrity/resonance behaviour comes to what I see as less complex.

All the best,

Frank

Thanks for putting those drawings side by side, as the show that Reed, Thiele, some of the DIY efforts are principally the same. Just as one can built an LT following that schematic.

The difference is the lack of need to adhere to a strict radius/circle segment, due to the magnet following any(straight, ellipse-segment, circle segment, parabolic...) guide rail.

If one is to substitute the guide magnet with a marker/pencil, then follow the path of the stylus tangentially, the marking/line by the pencil left will describe the required curve segment, - and it obviously will not automatically be a circle segment.

Due to the changing angle of the attracting force (magnet- rail), the proximity changes under load(friction: stylus - record groove)from beginning to end an so, needs to be compensated for. That may appear difficult to achieve/execute, but the absence of all the linkages, additional bearings and indifference regarding structural integrity/resonance behaviour comes to what I see as less complex.

All the best,

Frank

Frank,

Thanks for correcting my drawing!

I used a circle segment for the rear guiding mechanism just because it is easy to deal with a circle segment. In reality, there is no huge difference for different guiding rails at all. Tracking errors are almost inevitable for different types of guide rails. I adjusted the parameters of the arm so the tracking errors were minimized. According to LP standard, the minimum center ungrooved area is 4.75" in diameter. My build has zero tracking errors in about 2/3 grooved areas. In the rest of 1/3 areas, the maximum tracking error is less than 0.1 degrees. Even for these tracking errors, I purposely constructed the arm so that all the tracking errors are on the most outer groove only. In my build, I am going to use magnetic counter weight. This is another reason why I tried to avoid magnetic guide.

Jim

Thanks for correcting my drawing!

I used a circle segment for the rear guiding mechanism just because it is easy to deal with a circle segment. In reality, there is no huge difference for different guiding rails at all. Tracking errors are almost inevitable for different types of guide rails. I adjusted the parameters of the arm so the tracking errors were minimized. According to LP standard, the minimum center ungrooved area is 4.75" in diameter. My build has zero tracking errors in about 2/3 grooved areas. In the rest of 1/3 areas, the maximum tracking error is less than 0.1 degrees. Even for these tracking errors, I purposely constructed the arm so that all the tracking errors are on the most outer groove only. In my build, I am going to use magnetic counter weight. This is another reason why I tried to avoid magnetic guide.

Jim

Last edited:

- Home

- Source & Line

- Analogue Source

- Angling for 90° - tangential pivot tonearms