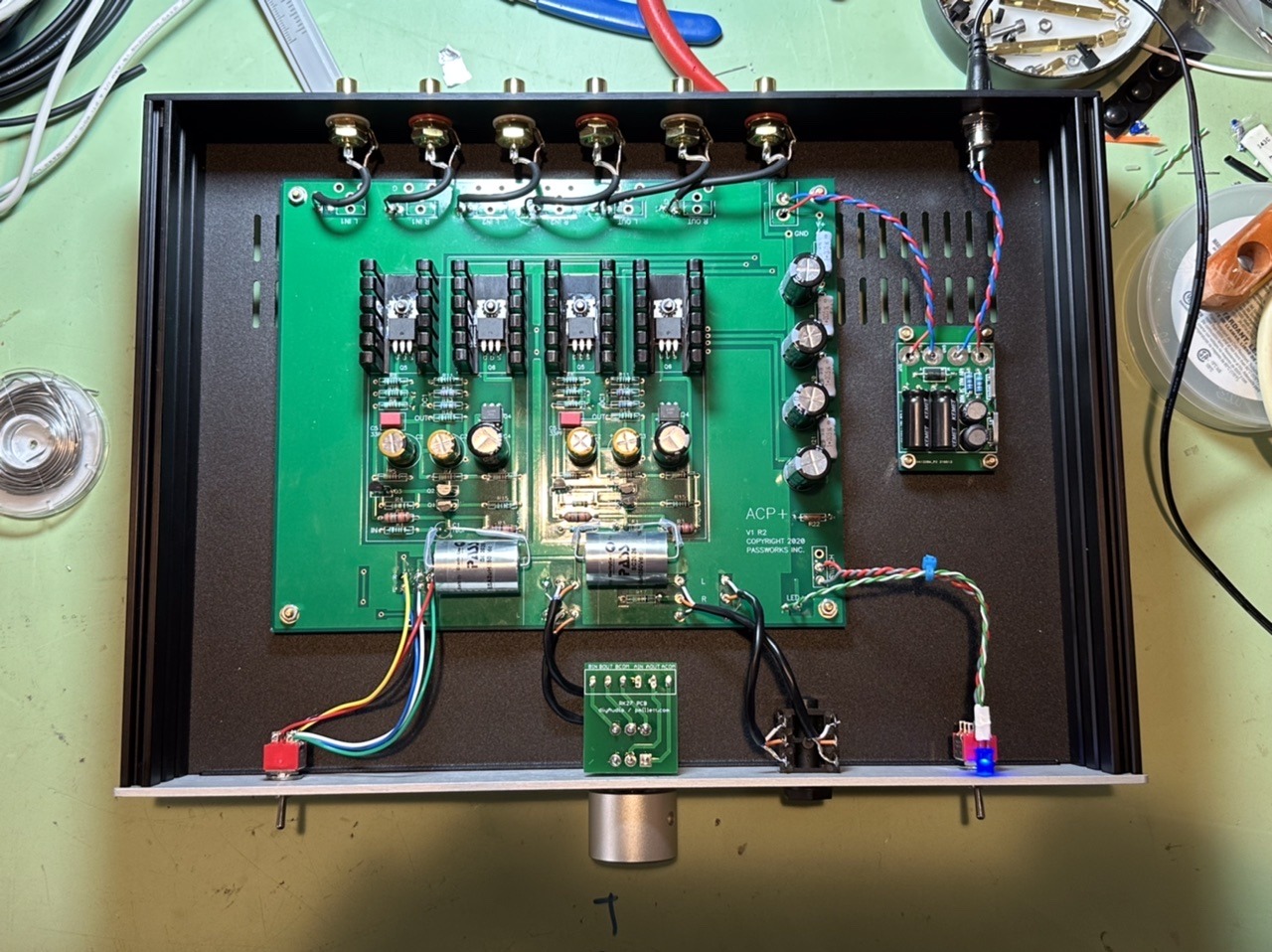

Built up an ACP+ in a chassis. HiFi2000/Modushop Galaxy 330x230 1U. This is a very nice size to work in. Yes, it will fit in smaller, but I like a little room and I quite like this form factor.

Hard-wired the P089ZB filter. Needed a couple of panel mount switches. DPDT On-On for select, and although I used the same for power, you only need SPST On-Off.

All the holes could be made with a hand drill, this is a very simple project. (Although an inexpensive pillar drill/drill press is worth every penny for this kind of work.)

Hard-wired the P089ZB filter. Needed a couple of panel mount switches. DPDT On-On for select, and although I used the same for power, you only need SPST On-Off.

All the holes could be made with a hand drill, this is a very simple project. (Although an inexpensive pillar drill/drill press is worth every penny for this kind of work.)

Last edited:

Sweet!Built up an ACP+ in a chassis. HiFi2000/Modushop Galaxy 330x230 1U. This is a very nice size to work in. Yes, it will fit in smaller, but I like a little room and i really like this form factor.

Hard-wired the P089ZB filter. Needed a couple of panel mount switches. DPDT On-On for select, and although I used the same for power, you only need SPST On-Off.

All the holes could be made with a hand drill, this is a very simple project. (Although an inexpensive pillar drill/drill press Is worth every penny for this kind of work.)

View attachment 1096363View attachment 1096364View attachment 1096365

Great job of banishing SMPS noise and high frequency crud. LCLC filter on outrigger board, followed by RCRC filter on ACP+ main board, is extremely powerful medicine. A pleasant way to achieve Noise Be Gone.

Hi - new here. Considering building the ACP+ or the WHAMMY as my first diy headamp. I couldn't help but notice you have the ACP sitting next to the Arcam rHead in this photo. As that's an amp that I own and know pretty well, I was wondering if you have any thoughts on how they compare?One of us has let their ACP+ out in public without a knob on.

Hi - new here. Considering building the ACP+ or the WHAMMY as my first diy headamp.

Honestly you can't go wrong with either, they both sound fantastic, and you'll likely end up building both because it's a lot of fun. I'd start with ACP+ if you've never built anything before.

+1 on building the ACP+ for a newbie project. The simple fact that there is no AC or chassis fabrication involved means you will get to the finish line in about half the time and you can build on that success with modifications, measurements, etc... of a fully functional preamp that YOU built. Bonus, down the road if something breaks/fails you'll know exactly how to fix it! 🙂Honestly you can't go wrong with either, they both sound fantastic, and you'll likely end up building both because it's a lot of fun. I'd start with ACP+ if you've never built anything before.

This answers the very question I came here to ask when I saw ACP+ was back in stock - namely whether the build would fit in a 1u case (height-wise). Nice.Built up an ACP+ in a chassis. HiFi2000/Modushop Galaxy 330x230 1U. This is a very nice size to work in. Yes, it will fit in smaller, but I like a little room and i really like this form factor.

Hard-wired the P089ZB filter. Needed a couple of panel mount switches. DPDT On-On for select, and although I used the same for power, you only need SPST On-Off.

All the holes could be made with a hand drill, this is a very simple project. (Although an inexpensive pillar drill/drill press Is worth every penny for this kind of work.)

View attachment 1096363View attachment 1096364View attachment 1096365

I'm assuming the big chonkers are just 10uf film caps to sub for the stock electrolytics?

I recently acquired a hobbyist Bosch bench drill, and so I was considering this in the little 230x170 Galaxy, although looking at yours I'm seeing the benefit of going big (i.e. getting the sockets and pot off the boards means I don't have to be 100% accurate with my drilling, and also means there's no stress on the board, AND I can fit filtering in).

I built the ACP+ similar to 6L6 and used the SMPS filter board from the store. This is currently my favorite headphone amp and works really really well for my desktop audio system feeding the ACA. I have a WAMMY also which is more portable, I can take it to work with me in a backpack. But I like the ACP+ just a little bit better for headphone listening.

@twofires The input film caps are actually 2.2uF, that's more than enough to get the cap time constant low enough. The stock 10uF was chosen because Nelson had a bajillion Silmic caps available to use, and they have a very compact footprint.

Looking forward to seeing photos of your progress!

Looking forward to seeing photos of your progress!

@twofires The input film caps are actually 2.2uF, that's more than enough to get the cap time constant low enough. The stock 10uF was chosen because Nelson had a bajillion Silmic caps available to use, and they have a very compact footprint.

Looking forward to seeing photos of your progress!

Ah, nice. Are the film caps any particular kind of fancy? I like fancy but I'm on more of a Dayton sort of budget.

Might be a little while yet before progress shots - I still have 3 other projects in progress! I'm just looking to jump on the kit before it goes out of stock again. 😅

I'm thinking I might go for the 1U 230x230 Galaxy - should sit nicely with the Whammy (which is one of the three other projects)

you can start with claritycaps 250v good and cheap ,Pa use too if I'm not wrong....looking at 6L6 caps 🙂

I suppose the film capacitor choice will depend on the rest of your system and your personal taste. When I played with DIY DACs, my favourites were Mundorf silver in oil (a bit of a body/touch of warmth, and a lot of high/low extension... but not really 100% natural... but very nice), and Auricap XO (more like a meaning of separating DC from AC; not colouring the sound in any way... maybe just a touch on the lean side - also very nice). I started with the Mundorf... but as the rest of my system improved... I leaned towards the Auricap XO... and eventually, I removed all sound coupling capacitors from my signal chain (apart from the speakers' crossover capacitors). The Blackgate C type 4.7uF/50V was also outstanding (!)... If you can still find them.

Apologies for the beginner questions - this is my first time building anything like this, previously only ever done simple repairs.

I received my ACP+ kit today and count 37 resistors, while there seem to be 39 in the photo in the build guide. Am I missing a couple, or is the pic outdated?

Also, as far as matching the J113s, from what I'm seeing I will need a transistor tester and a breadboard - is that right, or is there some simpler way to do it? Apologies if I missed this in the thread somewhere. Right now I have a soldering iron, some 60/40 solder, and a dmm - any other tools I will need? Lead bender?

Thanks for any advice!

I received my ACP+ kit today and count 37 resistors, while there seem to be 39 in the photo in the build guide. Am I missing a couple, or is the pic outdated?

Also, as far as matching the J113s, from what I'm seeing I will need a transistor tester and a breadboard - is that right, or is there some simpler way to do it? Apologies if I missed this in the thread somewhere. Right now I have a soldering iron, some 60/40 solder, and a dmm - any other tools I will need? Lead bender?

Thanks for any advice!

Resistors... which pic? I count 37 in one and 39 in another. 😀 Either way, 37 is correct. Always check the schematic.

You don’t need to match anything if you got the full kit. Just assemble.

Lead forming tool is completely optional. You have all the necessary tools.

Have fun!

You don’t need to match anything if you got the full kit. Just assemble.

Lead forming tool is completely optional. You have all the necessary tools.

Have fun!

Ah I see - makes sense! Thanks for clearing that upResistors... which pic? I count 37 in one and 39 in another. 😀 Either way, 37 is correct. Always check the schematic.

You don’t need to match anything if you got the full kit. Just assemble.

Lead forming tool is completely optional. You have all the necessary tools.

Have fun!

Maybe, but I'd suggest you start with the caps specified in the article (or those that come with the kit) and give it a listen for yourself before you run out and spend a ton of cash on any caps. If you've not listened to the affects that input coupling caps can (or cannot) have, then this is your chance to find the particular combo that works for your ears in this design. You will also find out that in many cases, you won't find much difference if any. As 6L6 says, the design/kit come with 10uFs but its worth trying out lower values, higher voltage ratings and brands to see what effects if any, these have on the character of the sound. The simple answer is that there is no "right" answer here, just "different" and hopefully eventually you will find the ones most suitable for your ears in this design through some trial/error measuring and listening. Thats really one of the cool parts of the whole DIY Audio situation if you ask me! 🙂you can start with claritycaps 250v good and cheap ,Pa use too if I'm not wrong....looking at 6L6 caps 🙂

I help that user ...I'm old diy's I do not need suggestion about caps I know very wellMaybe, but I'd suggest you start with the caps specified in the article (or those that come with the kit) and give it a listen for yourself before you run out and spend a ton of cash on any caps. If you've not listened to the affects that input coupling caps can (or cannot) have, then this is your chance to find the particular combo that works for your ears in this design. You will also find out that in many cases, you won't find much difference if any. As 6L6 says, the design/kit come with 10uFs but its worth trying out lower values, higher voltage ratings and brands to see what effects if any, these have on the character of the sound. The simple answer is that there is no "right" answer here, just "different" and hopefully eventually you will find the ones most suitable for your ears in this design through some trial/error measuring and listening. Thats really one of the cool parts of the whole DIY Audio situation if you ask me! 🙂

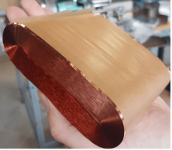

PS copper foil isnt metallized

😉

Attachments

Last edited:

A more general inquiry: has anyone thought about using, or actually used, PCB test points so that test caps and resistors can easily be installed and removed to permit easy exchange? Same thought for connecting input and output leads.

These Kobiconn test points can be ordered with different glass beads for polarity/channel ID, etc. https://www.mouser.com/datasheet/2/439/KC-300780-1211686.pdf

These Kobiconn test points can be ordered with different glass beads for polarity/channel ID, etc. https://www.mouser.com/datasheet/2/439/KC-300780-1211686.pdf

I just solder one side only the outer of R1 C1 on pbc the inner direct pin to pin ,in this manner you can test using the same pin too

You can solder in a small euro block with screw connector leads so you can roll the input caps. I've done this in the past with another project. Keep in mind that YMMV depending on the spo,t but if you build the ACP+ as @6L6 and @airborne11b did above, you should have enough room up front as the pot will be mounted off board.A more general inquiry: has anyone thought about using, or actually used, PCB test points so that test caps and resistors can easily be installed and removed to permit easy exchange? Same thought for connecting input and output leads.

These Kobiconn test points can be ordered with different glass beads for polarity/channel ID, etc. https://www.mouser.com/datasheet/2/439/KC-300780-1211686.pdf

- Home

- Amplifiers

- Pass Labs

- Amp Camp Pre+Headphone Amp - ACP+