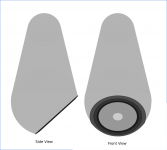

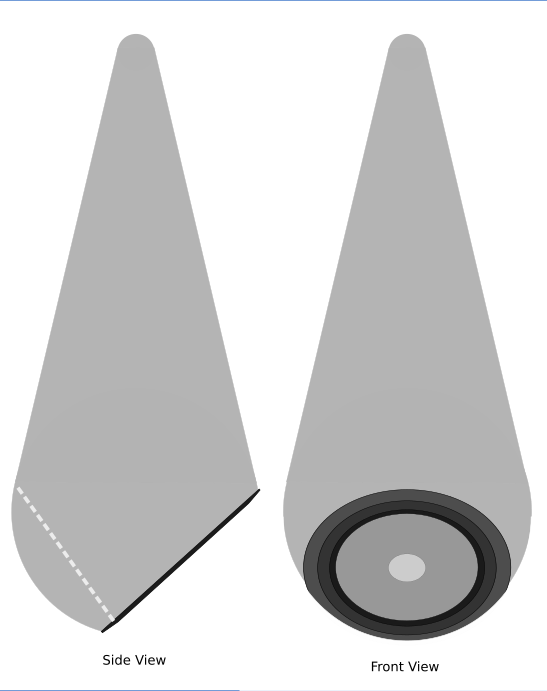

The round shape of my proposed pods isn't ideal for width and depth being the same, but for enclosures that will be rotated during positioning I like them being symmetrical around the vertical axis. However, on reflection there is no reason why they need to also be symmetrical top-to-bottom, so i could change that. Probably not a great benefit, but also no real penalty aside from being a tiny bit taller and (arguably) a bit more elegant as a result so seems like a reasonable thing to do.

For example: Rather than:

Rather than:

For example:

Rather than:

Rather than:

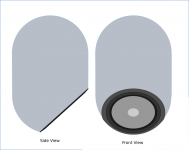

Thanks, zman01. Yes, i think you're right. Maybe it would be harder for standing waves to become established, and also the longer cone might offer slightly more opportunity to damp things.

Though the cone isn't up to the standards of the B&W nautilus (or similar), I guess every little helps.

Perhaps mine could be elongated a little more than in my image, and there could be an angled plane put behind the driver to reflect more internal sound upwards into the vertical cone, and less of it directly back through the driver.

e.g.

Though the cone isn't up to the standards of the B&W nautilus (or similar), I guess every little helps.

Perhaps mine could be elongated a little more than in my image, and there could be an angled plane put behind the driver to reflect more internal sound upwards into the vertical cone, and less of it directly back through the driver.

e.g.

Last edited:

Kev06,

If I am not wrong you will be using a sealed enclosure?

You will also need to put in some lining material like felt inside the cone, those will help absorb some of the reflections coming off the rear of the cone.

Some poly-fill behind the drivers also helps. Some members have used melamine foam (like Magic Eraser sponges) inside cabinets to good effect to absorb the reflections.

If I am not wrong you will be using a sealed enclosure?

You will also need to put in some lining material like felt inside the cone, those will help absorb some of the reflections coming off the rear of the cone.

Some poly-fill behind the drivers also helps. Some members have used melamine foam (like Magic Eraser sponges) inside cabinets to good effect to absorb the reflections.

Thanks again. Yes I'm intending to use a sealed enclosure; partly for the smaller volume, and partly because a port might reduce some of the benefits of having a single source (considering how close these are intended to be). The EBP of the Alpair 11ms is (unfortunately) around 110 by my calculations, which might suggest sealed isn't ideal, though of course I'll be using DSP and low SPLs so hopefully that won't matter too much.Kev06,

If I am not wrong you will be using a sealed enclosure?

You will also need to put in some lining material like felt inside the cone, those will help absorb some of the reflections coming off the rear of the cone.

Some poly-fill behind the drivers also helps. Some members have used melamine foam (like Magic Eraser sponges) inside cabinets to good effect to absorb the reflections.

I'm not completely averse to allowing things to breathe in some way, but I don't think an actual bass reflex is necessary and this design doesn't suit the more interesting but bigger cabinets one sees full-range drivers used with. Maybe in a future project, if I get bitten by the full-range bug.

The felt is a good call, thanks. I was expecting to fill the cone with poly-fill or wool insulation, but hadn't yet considered covering the walls with anything. At this stage I haven't even decided how I shall construct the cabinet, either. Though as the shape becomes more elaborate it is looking increasingly like fiberglass will be the strongest contender.

Have you got any dimensions of the enclosure as of yet?

From the visuals, the elongated shape means they might end up being quite deep?

From the visuals, the elongated shape means they might end up being quite deep?

That much isn't clear. You seem to be basing this on not being able to manage what is in the box. If that is so, couldn't this be making things worse?I guess every little helps.

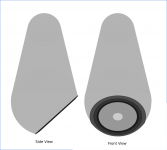

Nothing is really set in stone as yet, but I don't want them to be larger in girth than necessary (since larger cabinets quickly become intrusive given how close up they are). So in order to house the drivers, which have quite a large diameter for their modest sd, the bottom/spherical end of the cabinet will need to be around 200mm or 8inches in diameter, and ideally not much more.Have you got any dimensions of the enclosure as of yet?

From the visuals, the elongated shape means they might end up being quite deep?

This probably isn't large enough to bring the optimum diffraction benefits of a small driver in a big sphere, as in that classic work by Olson that gets pictured frequently, and the cone stuck on top also changes it of course. However, it is at least quite a rounded shape with few sharp edges in most aspects so I hope it should be reasonable.

The height is more arbitrary; I'd imagine the pods as being maybe 300mm 12" tall, but the new cone shape can go longer without seeming big, as such. So maybe a couple of feet tall or so wouldn't be out of the question.

Yes that is a possibility; a small nod towards the conical idea might be so half-hearted that any real result is pointless, and in some ways worse. For instance, the 2xhemisphere+tube shape is inherently quite strong, used both for pressure and vacuum vessels for instance, so diverging from it might be throwing something good away. I don't suppose a gentle taper would lose much, but a tall thin one might and could even create some undesirable pipe-like behaviour.That much isn't clear. You seem to be basing this on not being able to manage what is in the box. If that is so, couldn't this be making things worse?

Though aesthetically I do quite like the cone or teardrop shape for a hanging speaker, so it is something I'll want to read up on before deciding very much; to see what sonic benefits such a cone might be able to offer (if any) and how far one might need to go for effectiveness. Rightly or wrongly, I've got the impression that the more elongated ones involve a different way of managing things, rather than not being able to, but I could well be misguided about that at this stage.

Thanks, as always, for the grounded thoughts; very valuable!

Kev06,

From eye-balling the illustrations it looks like you have 2.5x - 3x depth vs baffle diameter; so if the front baffle is 8" in diameter (including the round-overs), you will have a pretty deep (and big) speaker at 20"-24" deep.

Attached is a pic of a commercial offering which looks like a smaller and more rotund version of what you are trying to make?

From eye-balling the illustrations it looks like you have 2.5x - 3x depth vs baffle diameter; so if the front baffle is 8" in diameter (including the round-overs), you will have a pretty deep (and big) speaker at 20"-24" deep.

Attached is a pic of a commercial offering which looks like a smaller and more rotund version of what you are trying to make?

Attachments

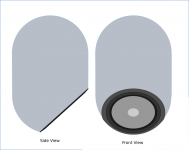

Yes, height is less of an issue than girth but it is still not exactly desirable; shapes closer to spherical are indeed more space-efficient.

It may be that I decide to back off again and go back to my original pod shape, but possibly just slightly tapered - simply to avoid exactly parallel walls. Which is not far from your picture there really. Sort of like an egg or stylised beehive, perhaps

It may be that I decide to back off again and go back to my original pod shape, but possibly just slightly tapered - simply to avoid exactly parallel walls. Which is not far from your picture there really. Sort of like an egg or stylised beehive, perhaps

Okay, I believe that interesting ideas are leading me astray from the main aims here. So I've decided to go back to the essence of what i wanted and test the drivers in a simple sphere, to see if they'll work for me or not. If not then fine, that would have answered the question and something bigger and/or more elaborate would at least be justified.

Having done a few more tests and simulations, I suspect it may not be necessary to go bigger though. A Qtc of 1.0 or less could probably be achieved with an 8" sphere even allowing for some wall thickness and volume occupied by the driver, so it isn't an excessive amount to correct with DSP at the low SPLs in question.

If so, then about the only thing I'd want to do to the sphere, i think, is to break up the internal space in some way, so that all internal dimensions aren't the same. Hopefully stuffing might offset the volume taken up with internal baffles etc. Though perhaps thin stiff materials might be used, at this small scale.

Having done a few more tests and simulations, I suspect it may not be necessary to go bigger though. A Qtc of 1.0 or less could probably be achieved with an 8" sphere even allowing for some wall thickness and volume occupied by the driver, so it isn't an excessive amount to correct with DSP at the low SPLs in question.

If so, then about the only thing I'd want to do to the sphere, i think, is to break up the internal space in some way, so that all internal dimensions aren't the same. Hopefully stuffing might offset the volume taken up with internal baffles etc. Though perhaps thin stiff materials might be used, at this small scale.

Now that volume is more restricted, I've decided to try the metal ikea (Blanda) bowls rather than the bamboo. Their outside dimensions are the same (maybe a few mm lower, so not quite a perfect sphere). But being thinner-walled, a spherical pair offer roughly 0.8L extra internal volume, which may not sound like much but at these scales it is meaningful; around 25% more than the bamboo bowls.

It may be that some of this gain is lost, should extra wall-damping be needed. However, they don't particularly ring even when open, and less so when closed to a sphere. They are light (due to thinness) and reasonably stiff (due to the material and shape) so I expect any wall/cabinet resonances to be quite high frequency and so easier to damp; certainly there isn't a lot of mass for sound waves to get wobbling about.

Possibly construction might be less easy. I could silver-solder them but stainless is a fairly poor conductor of heat and so large areas have a tendency to buckle rather than expand smoothly. I'll very likely just glue them instead - simply using adhesive suited to stainless rather than to wood.

It may be that some of this gain is lost, should extra wall-damping be needed. However, they don't particularly ring even when open, and less so when closed to a sphere. They are light (due to thinness) and reasonably stiff (due to the material and shape) so I expect any wall/cabinet resonances to be quite high frequency and so easier to damp; certainly there isn't a lot of mass for sound waves to get wobbling about.

Possibly construction might be less easy. I could silver-solder them but stainless is a fairly poor conductor of heat and so large areas have a tendency to buckle rather than expand smoothly. I'll very likely just glue them instead - simply using adhesive suited to stainless rather than to wood.

I'd been wondering what might need to be done to improve the acoustic performance of the metal bowls, but am starting to think perhaps not as much as i had expected. Mostly because their shape makes them already very rigid, even though thin. (except perhaps around the mouth, which will be closed anyway, when made into a sphere).

They don't ring very much either really, even 'as is'. I tried sticking some bitumen self-adhesive flashing on one, and now it doesn't ring perceptually at all: just makes a 'tick' noise when struck. The bitumen has lowered the pitch a bit which isn't perfect, but not by very much. It is only a couple of mm thick or so, and not heavy in the way that (eg) lead would be; I'm not expecting these to be bass monsters but i think they could cope quite well - stiff due to the shape and what weight could be set oscillating is mostly very lossy bitumen, which refuses to resonate audibly.

Of course, I'll want to reinforce the hole that would need to be made for the driver; probably with a thicker stainless ring that'd double as a surface to mount the driver to. I'll also want to brace where the two bowls join, to ensure it doesn't allow a weakness or flexing in the otherwise spherical shape. And possibly I might add an internal aluminium divider or two, to break up the rather uniform internal dimensions.

All in all, it doesn't seem that lots of internal space need be sacrificed. I will add felt lining and of course stuffing to reduce reflections and standing waves respectively, but if anything those should increase apparent volume.

They don't ring very much either really, even 'as is'. I tried sticking some bitumen self-adhesive flashing on one, and now it doesn't ring perceptually at all: just makes a 'tick' noise when struck. The bitumen has lowered the pitch a bit which isn't perfect, but not by very much. It is only a couple of mm thick or so, and not heavy in the way that (eg) lead would be; I'm not expecting these to be bass monsters but i think they could cope quite well - stiff due to the shape and what weight could be set oscillating is mostly very lossy bitumen, which refuses to resonate audibly.

Of course, I'll want to reinforce the hole that would need to be made for the driver; probably with a thicker stainless ring that'd double as a surface to mount the driver to. I'll also want to brace where the two bowls join, to ensure it doesn't allow a weakness or flexing in the otherwise spherical shape. And possibly I might add an internal aluminium divider or two, to break up the rather uniform internal dimensions.

All in all, it doesn't seem that lots of internal space need be sacrificed. I will add felt lining and of course stuffing to reduce reflections and standing waves respectively, but if anything those should increase apparent volume.

I'm sure we'd all want to damp like you have with the bitumen, just for good measure.. however tapping the bowl with a spoon is not something that a speaker itself will do when placed in it. I'd perhaps check whether the structure buckles around the flat surface/driver mounting area.

Yes I haven't tried with a driver as yet; really just my impression of the bowl's characteristics and intentions of how to first try using them, which may or may not stand the test of reality. Especially with my limited experience, I'm expecting some trial and error; at least the metal bowls are much cheaper than the bamboo ones if a plan B (C, D etc) is needed. .

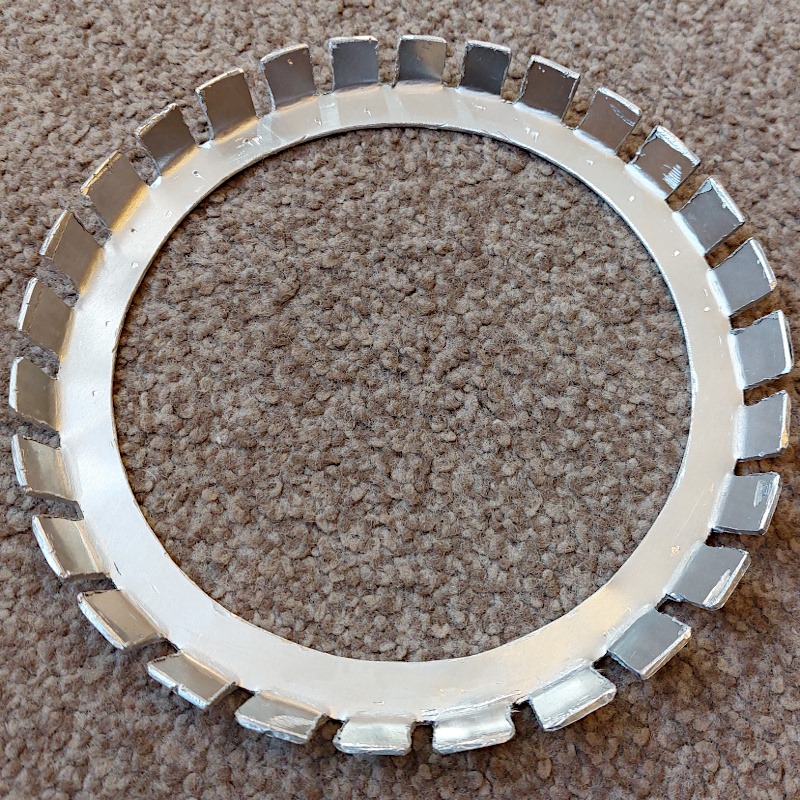

I'm sure that you're also right about the hole and mounting area being a potential weak point. I've got some 3mm thick stainless sheet somewhere, the initial plan is to make a big washer-shape from that partly as a fixing plane for the driver and partly to strengthen the hole. 3mm doesn't sound a lot, although it is pretty stiff stuff and won't be large (as speakers go) so won't see buckling. It could still vibrate, but the plan is to fix it solidly to the bowl walls, so the two parts (which will be almost at right-angles) will then be stiff in both directions. I'll most likely add a fillet behind to strengthen the joint and also brace the washer further.

Whether that works as envisaged might be another matter, but it seems like a reasonable possibility. The temptation is to fill the thing with heavy ply supports and braces, but instead I'm going to try using the shape and material for stiffness instead, as a hopefully more elegant and volume-saving measure given how small these are.

I'm sure that you're also right about the hole and mounting area being a potential weak point. I've got some 3mm thick stainless sheet somewhere, the initial plan is to make a big washer-shape from that partly as a fixing plane for the driver and partly to strengthen the hole. 3mm doesn't sound a lot, although it is pretty stiff stuff and won't be large (as speakers go) so won't see buckling. It could still vibrate, but the plan is to fix it solidly to the bowl walls, so the two parts (which will be almost at right-angles) will then be stiff in both directions. I'll most likely add a fillet behind to strengthen the joint and also brace the washer further.

Whether that works as envisaged might be another matter, but it seems like a reasonable possibility. The temptation is to fill the thing with heavy ply supports and braces, but instead I'm going to try using the shape and material for stiffness instead, as a hopefully more elegant and volume-saving measure given how small these are.

Ah yes, that is the general kind of approach I was envisaging; looks encouraging! I shall be very interested to see how the thin bowls progress actually; my previous cabinets have all been timber board with thick walls. But as far as I can tell, it is mainly stiffness that is being targeted (plus adequate wall damping), and there should be ways of achieving that which don't involve much thickness or weight, especially in a small cabinet.

I shall have to arrange a visit to relatives and make a start next week. The small apartment that has lead to this project is also not ideal for cutting metal in, especially if wishing to use an angle grinder.

I shall have to arrange a visit to relatives and make a start next week. The small apartment that has lead to this project is also not ideal for cutting metal in, especially if wishing to use an angle grinder.

Well i couldn't find the stainless sheet so ordered some... which was never sent. So i'm now going to make the minimal-baffle/mounting-ring for the driver with thinner stainless sheet laminated to a slightly thicker aluminium one. Mixing material layers can have merit of course, though in this situation it probably offers small benefit compared to the extra complication. However I actually have the materials to hand so it will avoid more delays and not cost anything more, except perhaps a small amount of extra adhesive.

Anyway, I mostly wanted to mention my surprise at how the 11ms drivers are bedding in. Generally speaking I expect drive units to change a little bit as they're first run in; they are of course mechanical things and for once this is a real effect rather than myth or (purely) psychology. But the 11ms drivers have changed quite significantly even to the ear; very obvious because I did one driver before the other so almost by accident could compare them side by side.

TBH I was not initially as impressed with them as I'd hoped, as my first experience of (high quality) full-range drivers, but am becoming happier with them now. Combined with DSP they can sound pretty good, and so I'm quite content with their choice for this project. Probably for bookshelf or floor-stander use I'd personally want to use them in an assisted or multi-way configuration, but for this compact and low-SPL project they are probably going to be sufficient used alone.

Anyway, I mostly wanted to mention my surprise at how the 11ms drivers are bedding in. Generally speaking I expect drive units to change a little bit as they're first run in; they are of course mechanical things and for once this is a real effect rather than myth or (purely) psychology. But the 11ms drivers have changed quite significantly even to the ear; very obvious because I did one driver before the other so almost by accident could compare them side by side.

TBH I was not initially as impressed with them as I'd hoped, as my first experience of (high quality) full-range drivers, but am becoming happier with them now. Combined with DSP they can sound pretty good, and so I'm quite content with their choice for this project. Probably for bookshelf or floor-stander use I'd personally want to use them in an assisted or multi-way configuration, but for this compact and low-SPL project they are probably going to be sufficient used alone.

At last, I had a bit of time to start working on this. First the bottom of an ikea 20cm Blanda bowl was cut off, at a diameter of just over that of the 11ms. Then a stainless steel ring was glued in, using JB-Weld epoxy adhesive, to provide a minimal baffle or mounting for the driver.

The ring is quite thin but the width of it is sufficient to return a surprising amount of rigidity to the cut bowl.

However, such a thin baffle is quite flexible in one direction, and only offers a tiny edge to glue. So a thicker aluminium bracing ring was made, partly to prevent flexing of the baffle and partly to transfer forces between the baffle and bowl over a much larger contact area.

The bracing ring wasn't a particularly close fit, so I decided to bond it in using something cheaper than JB-weld. Specifically, some 'Big Boy' ultra-tough metal filler (there might be better options, but I already had it), which can accommodate a little flexing and can bond to aluminium and steel. The surfaces are fairly large and were thoroughly roughed up and cleaned with acetone just before-hand, so hopefully the bond will be good enough.

It looks a bit crude (because it is), however the result is pleasingly rigid. It is also very dead-sounding when tapped, which may not in any way simulate what a driver will do when playing music, but I still find it reassuring that it doesn't want to ring.

This will be repeated for the second of the two speakers, and then in some way a second bowl will be glued to these, in order to make a sphere (albeit truncated where the driver sits).

By my calculations, the internal volume will be a little under 3L (after the truncation) but the 11MS will take up some space; i can't see this specified anywhere but I estimate maybe 0.35L - leaving me with about 2.55L. Some more may be lost if I add bracing and wall-damping but some effectively gained when stuffing is added, so it may roughly even out.

If so, then the Qtc should be about 1.0, which doesn't seem unreasonable to be adjusted by EQ. That is especially so at the low SPLs intended - keeping a cap on the power needed (which would otherwise be the limiting factor), and perhaps even benefiting from more of a lower-frequency lift as indicated by fletcher-munson curves.

The ring is quite thin but the width of it is sufficient to return a surprising amount of rigidity to the cut bowl.

However, such a thin baffle is quite flexible in one direction, and only offers a tiny edge to glue. So a thicker aluminium bracing ring was made, partly to prevent flexing of the baffle and partly to transfer forces between the baffle and bowl over a much larger contact area.

The bracing ring wasn't a particularly close fit, so I decided to bond it in using something cheaper than JB-weld. Specifically, some 'Big Boy' ultra-tough metal filler (there might be better options, but I already had it), which can accommodate a little flexing and can bond to aluminium and steel. The surfaces are fairly large and were thoroughly roughed up and cleaned with acetone just before-hand, so hopefully the bond will be good enough.

It looks a bit crude (because it is), however the result is pleasingly rigid. It is also very dead-sounding when tapped, which may not in any way simulate what a driver will do when playing music, but I still find it reassuring that it doesn't want to ring.

This will be repeated for the second of the two speakers, and then in some way a second bowl will be glued to these, in order to make a sphere (albeit truncated where the driver sits).

By my calculations, the internal volume will be a little under 3L (after the truncation) but the 11MS will take up some space; i can't see this specified anywhere but I estimate maybe 0.35L - leaving me with about 2.55L. Some more may be lost if I add bracing and wall-damping but some effectively gained when stuffing is added, so it may roughly even out.

If so, then the Qtc should be about 1.0, which doesn't seem unreasonable to be adjusted by EQ. That is especially so at the low SPLs intended - keeping a cap on the power needed (which would otherwise be the limiting factor), and perhaps even benefiting from more of a lower-frequency lift as indicated by fletcher-munson curves.

- Home

- Loudspeakers

- Full Range

- Alpair 11MS close-listening (nearfield) project