One could also 3D print the inner mold in pieces, glue together with construction glue and maybe a few nuts and bolts. It could be even printed as a relatively thin shell and be filled with something. It would not make that much sense where bent plates can be used, but for a general shaped horn, that would be an easy option.

For loudspeakers, I think Aircrete method might work well. Or using Styrofoam as aggregate.

Light Agrigate

What I used:

https://www.specialistaggregates.com/pumice-gravel-p-1540.html

I would look for lightweight angular agrigate if I did it again. My experience of casting steps and such outdoors is It will allow a stronger cast when parts get thin, intricate or when making sharp steps.

Just hit the mesh button to solve for the mesh only in ABEC that will tell you how many elements on the log calc page.

Result:

Code:

Frequency Term solving (number of threads used = 4)

Out of memory

Out of memoryjzagaja: try to reduce max number of cores used. I am nut sure but I had the impression the max number of cpu cores correllate with the "expected" ram.

Another question: the 2-profile method works nice so far. But is this somehow possible to combine with the superformula? At the moment I can choose between rectangular horn with 2 seperate defined profiles or superformula attempt with h/v aspect ratio without the possibility to define the 2 profiles seperately. Not sure if it makes sense.... just wonder if a smooth h/v transition might be overall better?

Another question: the 2-profile method works nice so far. But is this somehow possible to combine with the superformula? At the moment I can choose between rectangular horn with 2 seperate defined profiles or superformula attempt with h/v aspect ratio without the possibility to define the 2 profiles seperately. Not sure if it makes sense.... just wonder if a smooth h/v transition might be overall better?

No, the 2-profile geometry is a special case solely for using flat or bended boards, not possible to combine with anything else.Another question: the 2-profile method works nice so far. But is this somehow possible to combine with the superformula?

- As the new features are added the configuration options become a mess but that's just the way it is. I wanted to write a separate application note for each possible approach (there are now at least three completely different ways to specify a horn geometry) but I can't find the time... A suitable GUI would make it all clear and simple (for the user) but that's impossible for the time being.

Last edited:

Hi

Totally understand. Tons of options lead to complexity. So is there any usable approach I could use to simulate a (bi-)radial horn with seperate definition of vertical and horizontal curves?

Totally understand. Tons of options lead to complexity. So is there any usable approach I could use to simulate a (bi-)radial horn with seperate definition of vertical and horizontal curves?

Not with the fast and nice workflow of ath ;-)

No problem doong it in CAD/gmsh/abec but as the ath workflow is very good I wanted to know if possible with it. Basically I am interested what this outstanding lips contribute in the end (if something at all…)

No problem doong it in CAD/gmsh/abec but as the ath workflow is very good I wanted to know if possible with it. Basically I am interested what this outstanding lips contribute in the end (if something at all…)

Nope, you'll need to put in more effort 😉. But I guess ATH specializes in ideal shapes, not shapes of the past...

I am now only playing wirh it some days and it is amazing how easy you can alter different aspects. Mighty tool…

Wouldn't such protracting vertical walls enable better pattern control in this direction without the necessity of bigger / wider overall dimensions? I always thought this was the idea behind this designs.What should be the point doing so?

So this might be a little bit of repetition compared to my previous post about the ST260 KVAR horn on this thread. But still posting it here in case someone finds it useful.I tried to do the best I could do w.r.t measurements but there could be some minor errors due to my setup and the environment in which I measured. Please excuse me for that.

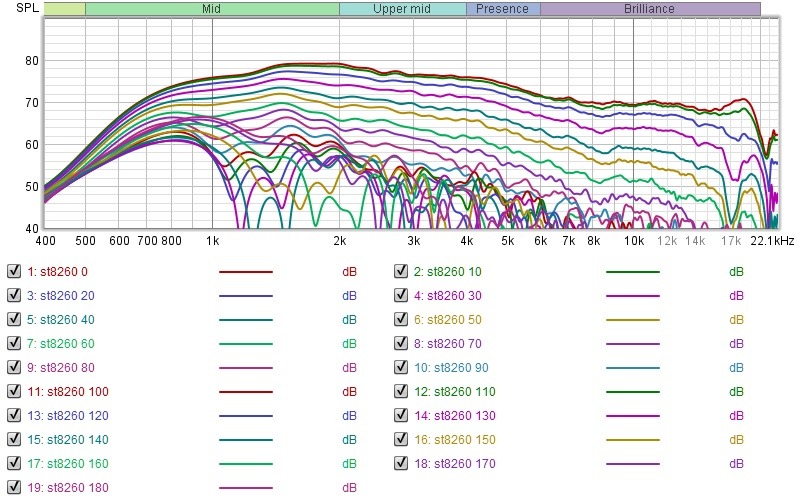

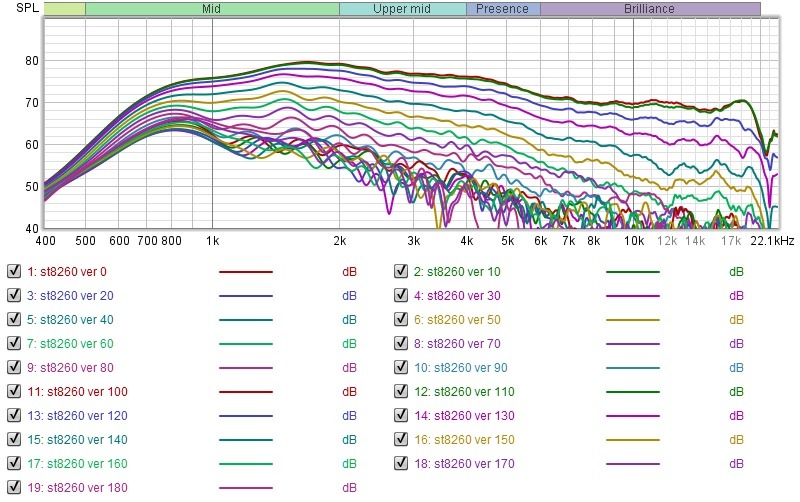

These are raw horizontal and vertical polar (4ms gated, mic 1m away from horn outer surface) measurements of the ST260 KVAR on Peerless DFM 2544R00 compression driver.

Pic of the measurement set up (This is what I thought is the vertical polar measuring configuration of the horn)

Horizontal polars

Vertical polars

My temporary system set up

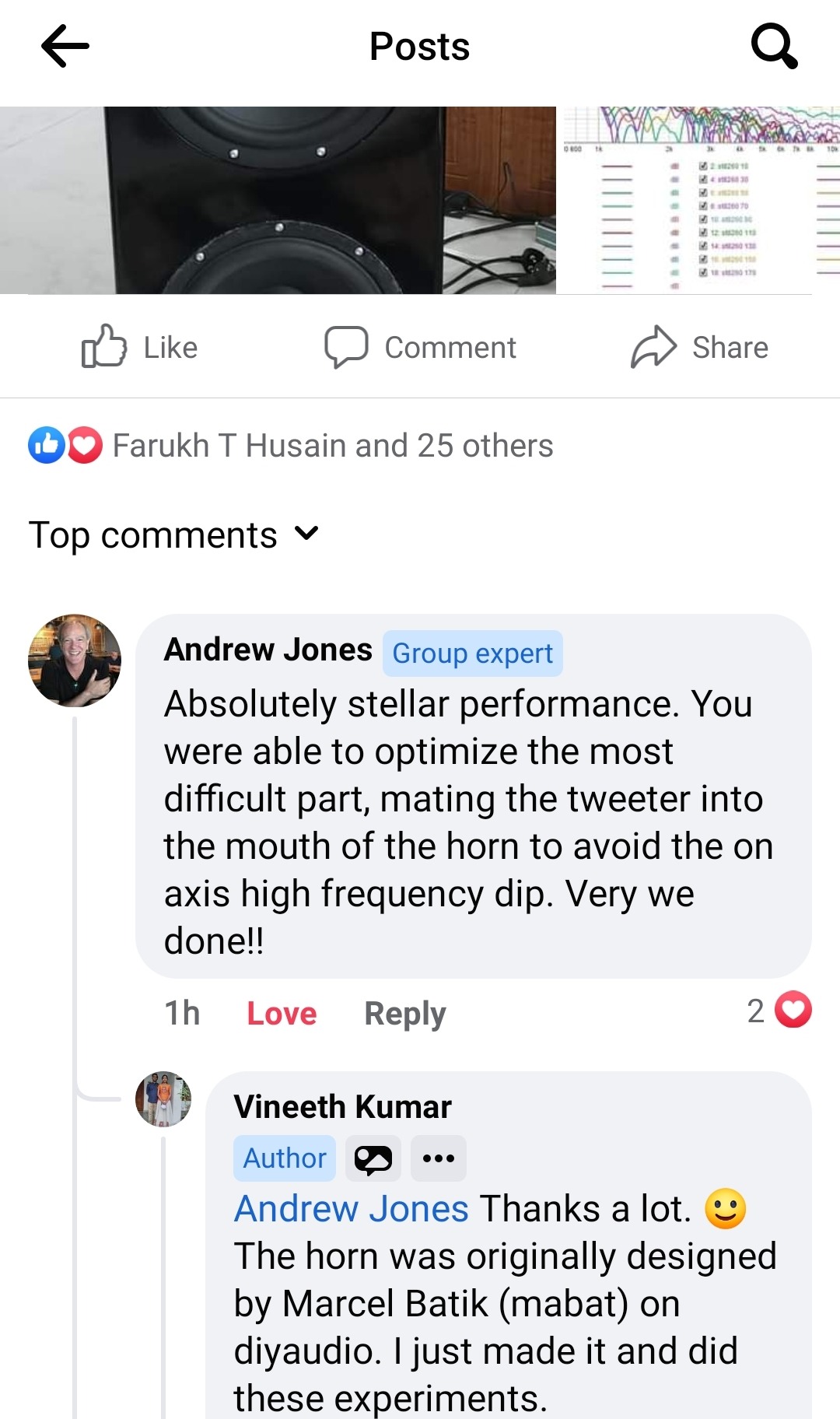

And I thought mabat should get the credit for his work on this horn. So here is what Andrew jones said about this horn (in a facebook group that I am a part of). Please excuse me if I have misspelt the name.

Thanks

Vineeth

These are raw horizontal and vertical polar (4ms gated, mic 1m away from horn outer surface) measurements of the ST260 KVAR on Peerless DFM 2544R00 compression driver.

Pic of the measurement set up (This is what I thought is the vertical polar measuring configuration of the horn)

Horizontal polars

Vertical polars

My temporary system set up

And I thought mabat should get the credit for his work on this horn. So here is what Andrew jones said about this horn (in a facebook group that I am a part of). Please excuse me if I have misspelt the name.

Thanks

Vineeth

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)