You seem to have omitted the time gating in your considerations. If there was only the main mode radiated, it would uniformly reach the top cover, then reflect back into the throat, and back again - but this reflection (its arrival back to the top) will be gated out. All that would be measured, would be a frequency response independent of off-axis angle. Any deviation from uniform wavefront across the top cover must be due to a HOM, IMHO.

What we still don't know, though, is what part is due to the driver and what due to the non-1P geometry of the waveguide...

What we still don't know, though, is what part is due to the driver and what due to the non-1P geometry of the waveguide...

Last edited:

looking forward to it! I am busy with my baby as he got sick but is getting better. I will start building once he is back on his feet and I would love to try yours too (if you choose to share)I think I have found a decent waveguide to build a 3 way MEH from.

It is not conical, just pure R-OSSE. Now I need to test if I can fit all the woofers and if the curvature is not too much different to build on my CNC.

View attachment 1275980

@kodomo I started a separate project thread here https://www.diyaudio.com/community/...sse-free-standing-round-octagonal-meh.409454/ not to occupy the space here. All will be shared there.

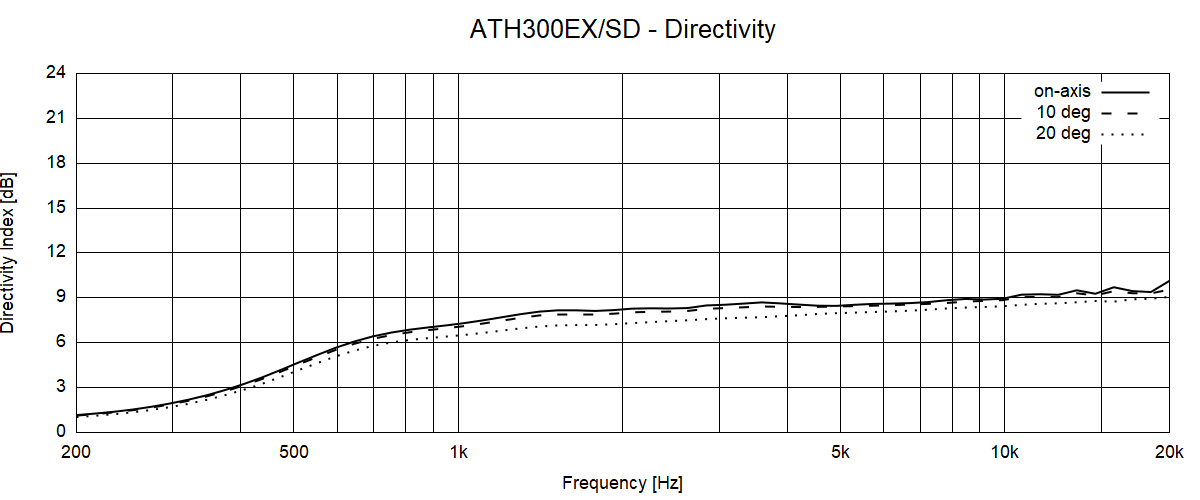

I've added a free (experimental) design on my web: http://www.at-horns.eu/ath300ex.html#CDW

There was a time when this would be an immediate NO GO, but as we've seen, it's not always so simple...

There was a time when this would be an immediate NO GO, but as we've seen, it's not always so simple...

Hello Marcel, printing the ATH300EX/S, I have the ATH280EX-MK2 to print, but I am trying this one, on Monday I finished the adapter, I have given 5 layers to the walls and a 5% fill without botton layers to be able to pour some type of epoxy resin with charge of some low density filler (microballoon) I will update.

Gracias

Gracias

Attachments

That's an interesting option, worth a try.I have given 5 layers to the walls and a 5% fill without botton layers ...

You all seem to be reliably printing big parts. I do have issues with my prints curling up further on in the printing process, which ends up with lots and lots of printing fails. Starting to get tired of it. Already burned through almost 100€ worth of filament for almost no result. Do you use different parameters beyond a certain z-height? Slower printing speeds to make it cool down faster? Less fan to have more even heat in the print during cooling?

My printer is a semi-industrial Zaxe X3, which is pretty precise, fast and reliable otherwise...

I am open for any suggetions.

My printer is a semi-industrial Zaxe X3, which is pretty precise, fast and reliable otherwise...

I am open for any suggetions.

Check if your filament is wet or old. Also some cheapish filament caused problems once at my printing.

I already have all the current models printed, some assembled. Can't wait for taking measurements, maybe on weekend...

In the meantime I'm working on the new EXARs (finally found something that is at least as good as the original ones)...

Those will have six discrete segments - may be actually easier to print if warping is an issue.

In the meantime I'm working on the new EXARs (finally found something that is at least as good as the original ones)...

Those will have six discrete segments - may be actually easier to print if warping is an issue.

Last edited:

For stiffening fill, it seems a mixture of hybrid-polymer construction adhesive (e.g. PVC Trim construction adhesive) mixed with vermiculite would fit the bill. Relatively strong, relatively easy to work with, very durable, and not significantly shrinking or expanding.

Last edited:

I am currently using Sunluu PLA+, which is a big improvement to Amazon Basic PLA. My last failed print i used a fresh roll, straight out of the vaccum bag.

Print surface is a PEI sheet i have no problems with. Adhesion is great, overhangs are problematic even though i use supports everywhere.

Because this is always happening above 100mm z-height, i think one reason might be the temperature differential between fresh filament and the already printed part. I could decrease fan speed above 100mm to alleviate this, does anyone of you play with such parameters?

Print surface is a PEI sheet i have no problems with. Adhesion is great, overhangs are problematic even though i use supports everywhere.

Because this is always happening above 100mm z-height, i think one reason might be the temperature differential between fresh filament and the already printed part. I could decrease fan speed above 100mm to alleviate this, does anyone of you play with such parameters?

I have no experience with PLA+, but this sounds more a like a printer issue to me. Anyway, you can always split the model in two (lower) parts in a slicer.

Corners always lift when I'm printing. Setup is important, but not enough for large stuff in my case.

Therefor I always use a brim. Even though the corners of the part still lift a bit, the brim keeps the part attached to the printing surface.

Therefor I always use a brim. Even though the corners of the part still lift a bit, the brim keeps the part attached to the printing surface.

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)