Yes, basically you are right .Hello Steve, what is your last solution for the voice coil foot area problem, especially regarding EPS panels? If I remember correctly you thinned the EPS in a dome shape and made a small hole in the center of the exciter area and filled it with sound deadening material, am I right?

But it is more complicated than that.

The cone shape was for the thicker 1inch panels that needed the sound brought more around to the front of the panel.

This gave a more forwards projection, a more intimate experience.

Although a more shallow concave size similar to a tweeter could be used on a 1cm thick eps.

I have found that a 2mm hole seems to work very well.

But to get the right amount of foam in this gap you need to be able to measure the response.

Too much and you loose the top end altogether.

Too little and you have done nothing.

The best to start with is to use a very thin slither of soft foam( I usually use old dish washer foam sponges that have become very soft over time, and lost their nasty sound) then push it in the hole to fill the depth , this must not be tight in the hole but easy to push in and to pull out.

I usually use a longer peace of foam and pull it back out a little so that it is not jammed in too tight.

But without some way of measuring and seeing the changes you make to the frequency response, you will be working blind.

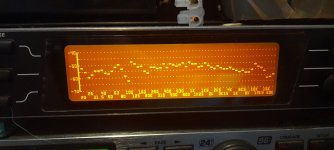

The first picture has the sharp peak the second is fixed.

The third is slightly over damped.

The fourth are some of the different thicknesses used, note how thin they are.

Steve.

Ps.

I use a tooth pick or a cocktail stick to push and pull the foam through the hole.

Steve.

Attachments

These are a few photos of how I use the cocktail sticks to insert the foam strips .

Attachments

Eucy and Eric.

As far as the paper is concerned.

There are too many problems mainly because of materials and different exciters used.

If I (which I have) tested different discs I would use the same exact exciter and use various disc materials and compare them.

The stiffening of the exciter area does not get rid of the so called resonance but merely pushes it up higher in frequency.

The disc also increases weight in the coil area and adds resonances of its own.

This as usual does not mention anything about how the disc affects the sound only the response.

He mentions the problems he has with the materials he is using , which are caused by him.

I am surprised he bothered printing the findings.

As he says it needs to be looked into more carefully at some later date.

Steve.

As far as the paper is concerned.

There are too many problems mainly because of materials and different exciters used.

If I (which I have) tested different discs I would use the same exact exciter and use various disc materials and compare them.

The stiffening of the exciter area does not get rid of the so called resonance but merely pushes it up higher in frequency.

The disc also increases weight in the coil area and adds resonances of its own.

This as usual does not mention anything about how the disc affects the sound only the response.

He mentions the problems he has with the materials he is using , which are caused by him.

I am surprised he bothered printing the findings.

As he says it needs to be looked into more carefully at some later date.

Steve.

The Link is to a Bamboo Supplier who has Compressed Bamboo as a large dimension sheet of 1.3mm thickness @ 1Kg/m2

A Cheap Plywood with a cheap adhesive and little compression between layers is at a 1.3mm thickness approx' 800g - 900g/m2.

file:///C:/Users/karen/Downloads/Spec-Sheet-Bamboo-Boards-Veneers-UK-Bamboo-Supplies-Ltd-V2.pdf

A Cheap Plywood with a cheap adhesive and little compression between layers is at a 1.3mm thickness approx' 800g - 900g/m2.

file:///C:/Users/karen/Downloads/Spec-Sheet-Bamboo-Boards-Veneers-UK-Bamboo-Supplies-Ltd-V2.pdf

https://www.ukbamboo.com/shop/bamboo-boards/1-5mm-caramel-veneer/

JohnnoG.

Is this the same link ?

The smallest size will cost nearly £60 for 5 sheets and they are 3ply and not a veneer.

Steve

JohnnoG.

Is this the same link ?

The smallest size will cost nearly £60 for 5 sheets and they are 3ply and not a veneer.

Steve

He chose to test different exciters because he derived equations that predicted the effect of different exciter foot dimensions and types (ring vs. disc), so the only way to properly test how well the equations worked was to test different exciters. So using only the one exciter would have been a poor test. And he did test the 19 mm exciter with and without a disc. Sure, it would have been great to test more disc materials, but I don't see why that is a "problem" with the paper. There is always more work that could be done. That doesn't invalidate the work that was done.As far as the paper is concerned.

There are too many problems mainly because of materials and different exciters used.

If I (which I have) tested different discs I would use the same exact exciter and use various disc materials and compare them.

Why does that constitute a "problem" with the paper? Wouldn't pushing any problems above 20 kHz be as good as eliminating them? Besides, he's not even making claims about what is better or worse, he's just helping all of us to understand better how changes in exciter geometry effect response.The stiffening of the exciter area does not get rid of the so called resonance but merely pushes it up higher in frequency.

The disc also increases weight in the coil area and adds resonances of its own.

Why does that constitute a problem with the paper?The disc also increases weight in the coil area and adds resonances of its own.

I don't think his subjective descriptions of how the disc effects the "sound" would get past the reviewers and the publishers. True scientific papers in peer reviewed technical journals are never going to include the subjective descriptions of the authors. The only way subjective descriptions are going to be included is if the authors have large numbers of tests "subjects" listen under very controlled conditions. These kind of studies are sometimes done, but it is a totally different kind of study and way beyond the scope of a paper like this one. If you want to know how something "sounds" to somebody, you are going to have to stick with advertising mumbo jumbo, or random internet posts.This as usual does not mention anything about how the disc affects the sound only the response.

And please tell us how he "causes" problems with the materials he uses?He mentions the problems he has with the materials he is using , which are caused by him.

Eric

Hi Stevehttps://www.ukbamboo.com/shop/bamboo-boards/1-5mm-caramel-veneer/

JohnnoG.

Is this the same link ?

The smallest size will cost nearly £60 for 5 sheets and they are 3ply and not a veneer.

Steve

I put the link up as the material is a similar weight to the recently discussed Plywood Sheet.

The Bamboo is Compressed and Impregnated, which leaves myself wondering if a Valuable Sonic Difference can be discovered.

As a side, has anybody done a design for a DML, which is like a DSP controlled Open Baffle.

Different Dimension Panels or Same Dimension Panels, Driven to cover a differing frequencies by different Amp's using a DSP Xover?

Your answer was as expected.He chose to test different exciters because he derived equations that predicted the effect of different exciter foot dimensions and types (ring vs. disc), so the only way to properly test how well the equations worked was to test different exciters. So using only the one exciter would have been a poor test. And he did test the 19 mm exciter with and without a disc. Sure, it would have been great to test more disc materials, but I don't see why that is a "problem" with the paper. There is always more work that could be done. That doesn't invalidate the work that was done.

Why does that constitute a "problem" with the paper? Wouldn't pushing any problems above 20 kHz be as good as eliminating them? Besides, he's not even making claims about what is better or worse, he's just helping all of us to understand better how changes in exciter geometry effect response.

Why does that constitute a problem with the paper?

I don't think his subjective descriptions of how the disc effects the "sound" would get past the reviewers and the publishers. True scientific papers in peer reviewed technical journals are never going to include the subjective descriptions of the authors. The only way subjective descriptions are going to be included is if the authors have large numbers of tests "subjects" listen under very controlled conditions. These kind of studies are sometimes done, but it is a totally different kind of study and way beyond the scope of a paper like this one. If you want to know how something "sounds" to somebody, you are going to have to stick with advertising mumbo jumbo, or random internet posts.

And please tell us how he "causes" problems with the materials he uses?

Eric

I am so happy for you ,that you were so enlightened by the paper.

I will continue to be disappointed.

Steve.

As a side, has anybody done a design for a DML, which is like a DSP controlled Open Baffle.

Different Dimension Panels or Same Dimension Panels, Driven to cover a differing frequencies by different Amp's using a DSP Xover?

Some time ago i did that because it seems to be (it is) the only logical way to the desired full range DML (although "full" will be 40Hz up and a sub below)

I`m happy with the PMMA acrylic (100 cm/50 cm) with the DAEX25FHE-4 exciters 160Hz up, so i used the excites xt-32-4 to the lows in several materials, from cello and guitar woods to honeycomb aluminum, processed via adobe audition through five amp channels.

So... if one wants to listen at loud levels (88-90 dB up) or like the hear the impact of a unconstrained drum, it`s the way to go, although it`s far behind what can be achieved with conventional bass speakers, and that`s why i use OB (4x15") 160Hz down and 15" sub.

For moderated levels or small rooms, please have a try, it will be far better than a dual panel.

If it is cost effective... it depends on the listening level, program material tastes, and neighbors.

I finally put all the pieces together to make some FR measurements on DML (and other) speakers. I'm using a Behringer ECM8000 microphone w/o their generic calibration curve. The FR plot shown below was done inside, in a room that is about 9 x 10 meters. It's a bit less than 3M high (8 feet). The measurement was taken on-axis, about 3.7 meters away from the panel (11 feet). The panel is 22w x 24h inches and is attached on all 4 sides to a wood frame using soft butyl rubber weatherstripping. I smoothed the plot, the raw plot looked like grass in the upper frequencies.

The FR actually looks a lot better than I thought it would. I think I'm mainly seeing panel resonances at 110, 240, 370 and 600 Hz. The dip at about 150Hz could be the floor reflection interfering with the direct path -- the path-length difference is about right.

I also am encouraged by the HF response. Definitely better than what I expected. Given my age (73) it probably isn't worth working very hard to extend its FR, beyond a little equalization.

The FR actually looks a lot better than I thought it would. I think I'm mainly seeing panel resonances at 110, 240, 370 and 600 Hz. The dip at about 150Hz could be the floor reflection interfering with the direct path -- the path-length difference is about right.

I also am encouraged by the HF response. Definitely better than what I expected. Given my age (73) it probably isn't worth working very hard to extend its FR, beyond a little equalization.

Hi RMAMSome time ago i did that because it seems to be (it is) the only logical way to the desired full range DML (although "full" will be 40Hz up and a sub below)

I`m happy with the PMMA acrylic (100 cm/50 cm) with the DAEX25FHE-4 exciters 160Hz up, so i used the excites xt-32-4 to the lows in several materials, from cello and guitar woods to honeycomb aluminum, processed via adobe audition through five amp channels.

So... if one wants to listen at loud levels (88-90 dB up) or like the hear the impact of a unconstrained drum, it`s the way to go, although it`s far behind what can be achieved with conventional bass speakers, and that`s why i use OB (4x15") 160Hz down and 15" sub.

For moderated levels or small rooms, please have a try, it will be far better than a dual panel.

If it is cost effective... it depends on the listening level, program material tastes, and neighbors.

Thank you for your reply, I have a Valve Amp's that can be hooked up to different Panel Dimensions / Exciters.

I also have a selection of 5 x Eminence Beta 15's that can be Plate Amp driven as an OB Subwoofer.

JohnnoG, hands to the task.

I presume that you will not use a computer and a muitiway DAC, so join a crossover (if you want to spend very low money try the no dsp car audio ones, Alpine`s are ok) and you have the flexibility to tailor the midbass to the exciters but also the bass to the midbass (note that the Beta 15 (A?) is a woofer, the fs is to high for sub duties).

You can use the plate amps to cross the bass to the midbass, but i don`t know any with a passband filter for the later. If you don`t have the plate amps, consider class D ones at a cost of peanuts and a EQ.

Again, you cope with the flexibility to understand the interaction between your multiple speakers and, more important, those in your room.

Meanwhile, with that sound reference, don`t give up from the quest for a full range DML and compare the results with the 4 plates/different materials/exciters/frequencies approach.

Good auditions

I presume that you will not use a computer and a muitiway DAC, so join a crossover (if you want to spend very low money try the no dsp car audio ones, Alpine`s are ok) and you have the flexibility to tailor the midbass to the exciters but also the bass to the midbass (note that the Beta 15 (A?) is a woofer, the fs is to high for sub duties).

You can use the plate amps to cross the bass to the midbass, but i don`t know any with a passband filter for the later. If you don`t have the plate amps, consider class D ones at a cost of peanuts and a EQ.

Again, you cope with the flexibility to understand the interaction between your multiple speakers and, more important, those in your room.

Meanwhile, with that sound reference, don`t give up from the quest for a full range DML and compare the results with the 4 plates/different materials/exciters/frequencies approach.

Good auditions

My friends OB panels work very well with his dml panels with a simple electronic XO.Hi RMAM

Thank you for your reply, I have a Valve Amp's that can be hooked up to different Panel Dimensions / Exciters.

I also have a selection of 5 x Eminence Beta 15's that can be Plate Amp driven as an OB Subwoofer.

These are his panels in the youtube video.

I listened with a good headphone amp and Status OB-1 headphones. It does sound amazing - the bass is quite incredible and overall experience of a bell in a clocktower is real. Thanks for posting.This is the recording of a recording I sent to Christian.

I had deleted it from my phone gallery but managed to retrieve it from WhatsApp.

Steve.

I recall buying 2x4 wood for this project years ago but it got stalled and the wood is still in the garage. I have some thin wood panels somewhere.

What’s the ideal size of your panel ?

This one sounds fantastic on headphones as well. A great idea to hybridize them for bass with conventional drivers and DML’s for mids and highs. A DML FAST essentially. Nice!My friends OB panels work very well with his dml panels with a simple electronic XO.

These are his panels in the youtube video.

The amazing part for me was that the recording still sounded as good as the small card panels that I recorded the bells playing on.I listened with a good headphone amp and Status OB-1 headphones. It does sound amazing - the bass is quite incredible and overall experience of a bell in a clocktower is real. Thanks for posting.

I recall buying 2x4 wood for this project years ago but it got stalled and the wood is still in the garage. I have some thin wood panels somewhere.

What’s the ideal size of your panel ?

The small card panels did have a cleaner sound though.

Once you start a heavy 6 foot panel in motion it is difficult to stop it moving, so it is best to keep the low frequencies away from the panel, this cleans up the sound a lot more.

I now prefer to use very thin flexible wood or ply at 1mm or so.

This is after playing around with my crate ply and off cuts of 1mm ply.

Steve.

are you saying that you prefer the small one mm thick wood or ply small panels to your small card stock panels? Thanks.I now prefer to use very thin flexible wood or ply at 1mm or so.

Hi Steve

After seeing your 1mm Preference, I have had a search on FBM and not found anything.

The link is for a UK Supplier of 0.6mm Bamboo at a more reasonable cost, to the last supplier posted.

If the samples found on 'bay are selected for the larger dimension, 4 x 600mm x 400mm pieces can be produced and bonded together if an increased thickness/rigidity is desired.

A Mesh sandwiched when bonding together will also produce a strengthened panel.

https://www.ebay.co.uk/itm/15555127...ogLn49V2oZ7Eta76thM4yS4Q==|tkp:Bk9SR_rnuIrOZQ

I would be happy to contribute towards a raw material cost if this material type was to be assessed.

Another off the cuff idea, being a Bamboo Rear Panel > Mesh > Veneer of choice Fascia, used to produce a Sandwich Panel may allow for tuning the sound, by trying different Wood Types as a Fascia Panel.

Obviously even more ideal if required materials are not costing and time is freely available.

After seeing your 1mm Preference, I have had a search on FBM and not found anything.

The link is for a UK Supplier of 0.6mm Bamboo at a more reasonable cost, to the last supplier posted.

If the samples found on 'bay are selected for the larger dimension, 4 x 600mm x 400mm pieces can be produced and bonded together if an increased thickness/rigidity is desired.

A Mesh sandwiched when bonding together will also produce a strengthened panel.

https://www.ebay.co.uk/itm/15555127...ogLn49V2oZ7Eta76thM4yS4Q==|tkp:Bk9SR_rnuIrOZQ

I would be happy to contribute towards a raw material cost if this material type was to be assessed.

Another off the cuff idea, being a Bamboo Rear Panel > Mesh > Veneer of choice Fascia, used to produce a Sandwich Panel may allow for tuning the sound, by trying different Wood Types as a Fascia Panel.

Obviously even more ideal if required materials are not costing and time is freely available.

Xrk971.

Did you also listen to my large 1.5mm dml panel on YouTube.

I was very surprised at the performance of this material.

I have had this material for over a year now , and on the spur of the moment because I had some free time, I just stuck a brand new exciter onto the panel , it has the sticky tape type mounting, so it was up and running in a matter of minutes.

What do you think of the sound of this panel.

Steve.

Did you also listen to my large 1.5mm dml panel on YouTube.

I was very surprised at the performance of this material.

I have had this material for over a year now , and on the spur of the moment because I had some free time, I just stuck a brand new exciter onto the panel , it has the sticky tape type mounting, so it was up and running in a matter of minutes.

What do you think of the sound of this panel.

Steve.

I found some Finnish birch aircraft plywood that is thin as .4mm. It comes in .4, .8, 1.0, 1.5, 2.0, 2.5 and 3.0mm (and on up, but I think this is the range that DML-makers might want to experiment with). The thinner versions might be useful as a skin for a honeycomb core of some kind.After seeing your 1mm Preference, I have had a search on FBM and not found anything.

Before I found this stuff I wouldn't have thought that 400 micron-thick plywood was even possible. And just to put the icing on the cake, that stuff is THREE PLYS thick. Wow!

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker