Disregard my panel response measurements posted here.

Based on some measurements I made on a completely different speaker system, with and without sound panels, I think that there may be significant response alteration from those panels. I'll get better measurements outside later on but it will have to wait. We have bad weather forecast for about a week.

Based on some measurements I made on a completely different speaker system, with and without sound panels, I think that there may be significant response alteration from those panels. I'll get better measurements outside later on but it will have to wait. We have bad weather forecast for about a week.

Hi EarbourneThankyou . thats a good bit of hunting.

I didnt see those new posts , but i have picked up 3mm Poplar ply and 1.8 mm Sassafras to do some testing with and also a sheet of Bunnings sourced 10 mm thick / 20 kg3m EPS.

Do you have a clear assembly strategy with the 28 kg3M EPS or still in the stage of manual evaluation so you can map out the design around the initial performance ?

My anticipated framing method for the EPS to get a reasonable visual aesthetic as per sectional drawing below , 6 mm foam glued to the EPS and the quarter round pine trim , quarter round glued and nailed to the 65 x 19 framing.

View attachment 1167179

I visited ACT Foam and Rubber. They buy in the 10mm sheets so no chance of different thicknesses to trial. Also evident was the fragility of the 1200 lg sheet with several sheets snapped in half on the shelf.

I bought 2 full sheets and 6 of the snapped ones to trial.

Will have to wait until I'm back in Brisbane... Won't be long now. Just have to successfully get it there without finding I have ended up with 10 snapped pieces 🤭😵💫

Observation... The compressive strength of both XPS and EPS sheets seems to me to rely a lot on the skins formed when cutting. XPS reportedly has above 2x the compressive strength of VH grade EPS with both having about the same SG, but doing a highly technical fingernail test on edges of both (no skin), the XPS actually felt softer than the VH...Interesting.

Speaking about the frame....I know it's common and popular to do deep frames, as attested by the comments already received. However, when I was building my Viridian speakers, I tested and listened to many partial stages of completion, and one lasting impression was that when I tried the 60mm dia half cylinder sides attached to the front panel but with no back panel, (ie: like a 60mm deep side frame) there was a definite degradation/boxiness in the sound compared to the bare front panel. Overcoming that effect was a major part of the overall detailing of those speakers.

I realise Viridian is a different concept to the norm, and I have not constructed a framed system apart from very early experiments with XPS, for which I have no tests or memory of performance, but a deep frame intuitively must have a significant disturbing effect on rearward transmission... You can of course test that and draw your own conclusions.. So this is just a heads up on what I noticed.

Fwiw, I would do the following in my design process:

1/ test and measure the panel by itself with minimal support;

2/ test with side rails only and compare with 1/ above;

3/ try acoustic foam or equivalent in the inside of the frame and compare

3/ do the same with all sides framed, no foam;

4/ do the same with all sides framed plus foam;

5/ Try a ventilated (slotted) frame with and without fibre backing.

Tedious I know, but instructive, and I'll bet the differences will surprise you.

Cheers

Eucy

Last edited:

PS to the above

To do this effectively, you need to have 2 panels at different stages, and do rapid A/B switching for listening tests, as well as, and apart from frequency sweeps, which may not expose the tonal differences brought on by the differing supports

Eucy

To do this effectively, you need to have 2 panels at different stages, and do rapid A/B switching for listening tests, as well as, and apart from frequency sweeps, which may not expose the tonal differences brought on by the differing supports

Eucy

To @Eucyblues99 comments above, I agree that a listening test is a good idea instead of relying completely on test data. However that begs the question... For DML designs in particular, what REW tests will help separate the great, the good, the mediocre, and the bad?

I know this is a HUGE topic, full of simple and complex pitfalls, but hopefully we can keep it relatively simple?

But, off the top of my head, based on discussions here... Feel free to add, subtract, and comment

1. Sine sweep test (usual 20 Hz-20kHz)

2. Random periodic pink noise test

3. Impulse response test

4. Phase test (?)

5. Impedance test (?) - I do not think I have the equipment for this since speaker coil voltage/current needs to be measured and synchronized correct? I need to read up on this.

6. In room test to compare to 1-3 above to see how much (or little) the room changes the response, one of the DML benefits. This could also cast light on panel size relative to room size and/or listening position, something I have wondered about.

Also, ideally, all the tests above would be done with best practices to the extent practically possible for that individual.

I know this is a HUGE topic, full of simple and complex pitfalls, but hopefully we can keep it relatively simple?

But, off the top of my head, based on discussions here... Feel free to add, subtract, and comment

1. Sine sweep test (usual 20 Hz-20kHz)

2. Random periodic pink noise test

3. Impulse response test

4. Phase test (?)

5. Impedance test (?) - I do not think I have the equipment for this since speaker coil voltage/current needs to be measured and synchronized correct? I need to read up on this.

6. In room test to compare to 1-3 above to see how much (or little) the room changes the response, one of the DML benefits. This could also cast light on panel size relative to room size and/or listening position, something I have wondered about.

Also, ideally, all the tests above would be done with best practices to the extent practically possible for that individual.

REW impedance measurements article

https://www.roomeqwizard.com/help/help_en-GB/html/impedancemeasurement.html

https://www.roomeqwizard.com/help/help_en-GB/html/impedancemeasurement.html

I was going to avoid using speaker cloth due to having zero knowledge on how it may mute down the sound with this type of panel , i was going to test this week with using diluted PVA brushed on to a surface with some colouring stains sprinkled and brushed through the PVA to create a fake timber look. I have some light brown and dark brown concrete pigment powder to play with first up and compare the sound to the untreated panel.That framing should work well and will look nicer than setting it on the top edge. And if you decide to clamp both sides of the EPS later on (some do) you can still do it. Be sure there is a nice gap between the edge of the EPS and the inside face of the pine. I'd want something like 3-5mm. I would also make a couple of minor tweaks to the wood, like rounding the edges in red (see below). It is not necessary, just a hedge against edge rubbing and splintering/flaking.

I would also recess the EPS well below the top edge of the pine so the pine frame can be wrapped with speaker cloth later on without the risk of the cloth interfering with the EPS.

View attachment 1167230

The foam type is 6mm window sealing strip , i have a couple of self adhesive foams to test and honestly have no idea which will perform better with my panel and framing yet.

Last edited:

was going to avoid using speaker cloth due to having zero knowledge on how it may mute down the sound with this type of panel

If you try it instead of avoiding it you'll know for certain what, if any, the effect is, and if it works, it'll remove the need for cosmetic treatment of the panel which conceivably may have more effect on the sound than the cloth.

Very fine, light material like interfacing from Spotlight et al can be lightly sprayed or dyed without deleterious effects and is acoustically transparent in my testing. It will not be as tough as traditional speaker cloth, but tough enough.

https://www.spotlightstores.com/sew...RaFNqHRoCeSfKBTAz9OUGfR7_Krl-Lh8aAhBgEALw_wcB

I used the non-woven type...

Cheers

Eucy

Cement pigments are generally not ground fine enough to make a paint except for use on masonry surfaces... You may end up with a somewhat gritty finish... You'll obviously do a trial first so that will tell the tale 👍I have some light brown and dark brown concrete pigment powder to play with first

Alternatively, you could try ink jet dye based ink, acrylic artists paint and even food colouring mixed in with the PVA

agreeTo do this effectively, you need to have 2 panels at different stages, and do rapid A/B switching for listening tests

I've used (and currently) cloth to knock down a bit of brightness on certain panels to take the edge off as I prefer them warmer but still want to enjoy that high hat.

wow , Bookshelf speakers that look like . . . a bookshelf. 🤣View attachment 1129695

Bollocks!!! Just dragged this old project up from the hifi dungeon ( bottom of the tool shed) while I add another layer to my cardboard panels, I thought what the hell I've not tried my 32mm exciters on these bookshelf speakers ( get it!)

So attached exciter to the front as this sounds better I found in the past with these panels, slotted in the ribbon tweeter's hooked them up and sat there open-mouthed. Having spent the last hour gluing up my cardboard jobs, which I was very happy with, I can tell you that's where the bollocks moment happened.

To make things worse these are just lent up against the wall no frame, no wire nothing. Now what do I do?

I'll post a video using the same song at the same volume so you can compare and let me know which you prefer.

That reminds me of my weekend where i drove over a pothole that was shaped like a pot . boom goes $ 4000 suspension damage.

Back to topic , thats a beautiful clean and rich sound , is it XPS foam ? and looks like it might be around 12 - 16 mm thickness ?

May i ask what adhesive was used and what type of canvas ?

I have these canvas art panels in mind below if i ever find a way to effectively refine the structural assembly , i have no doubt the canvas and adhesive types chosen could create 300 % variation in sound quality ranging from abject failure to excellence.

They are Ebay specials , identified only as using "waterproof canvas and latex inks"

The outermost pair of panels could house the DML's

TBH I am not sure that really figures in this area. Music is often mixed to a pink noise frequency profile so if a panel gives a good pink noise response it may pink the music even more. 😉 Can't think of a better way of putting it. In terms of excitation and looking for a broad frequency response as some have white noise makes more sense.2. Random periodic pink noise test

I would go with one exciter apiece for the four outside panels so you get more varied sound and can series two of them to 8ohm.The outermost pair of panels could house the DML's

Hello,I'm not sure if I agree with the white noise preference (over pink) for DMLs.

2 tests can be made with REW, independently of the nature of the source : pink noise with the spectrum analyzer with the possibility to average over different positions (MMM, moving microphone measurement) or the reconstruction of the IR from a log sweep which is a technique that improve the signal to noise ratio of the measurement (the basis is a bit technique, see M Farina work). Then more information can be extracted : frequency response with different possible windowing or smoothing, the IR itself, spectrogram (level according frequency and time).

There is debate about the number of points of measure to get for a DML. By nature the MMM allows it easily while the log sweep is from one point. With the pink noise, the time information is lost. So the best is to be able to run both which is easy with REW.

The white noise has not the right properties to get the FR across a spectrum analyzer.

The impedance measurement is from an other kind of measurement; For DML, it can inform about the frequency of the modes.

My tool box by order of use : logsweep (IR), pink noise, impedance measurement.

I have some modest information on how many points to measure for a DML...

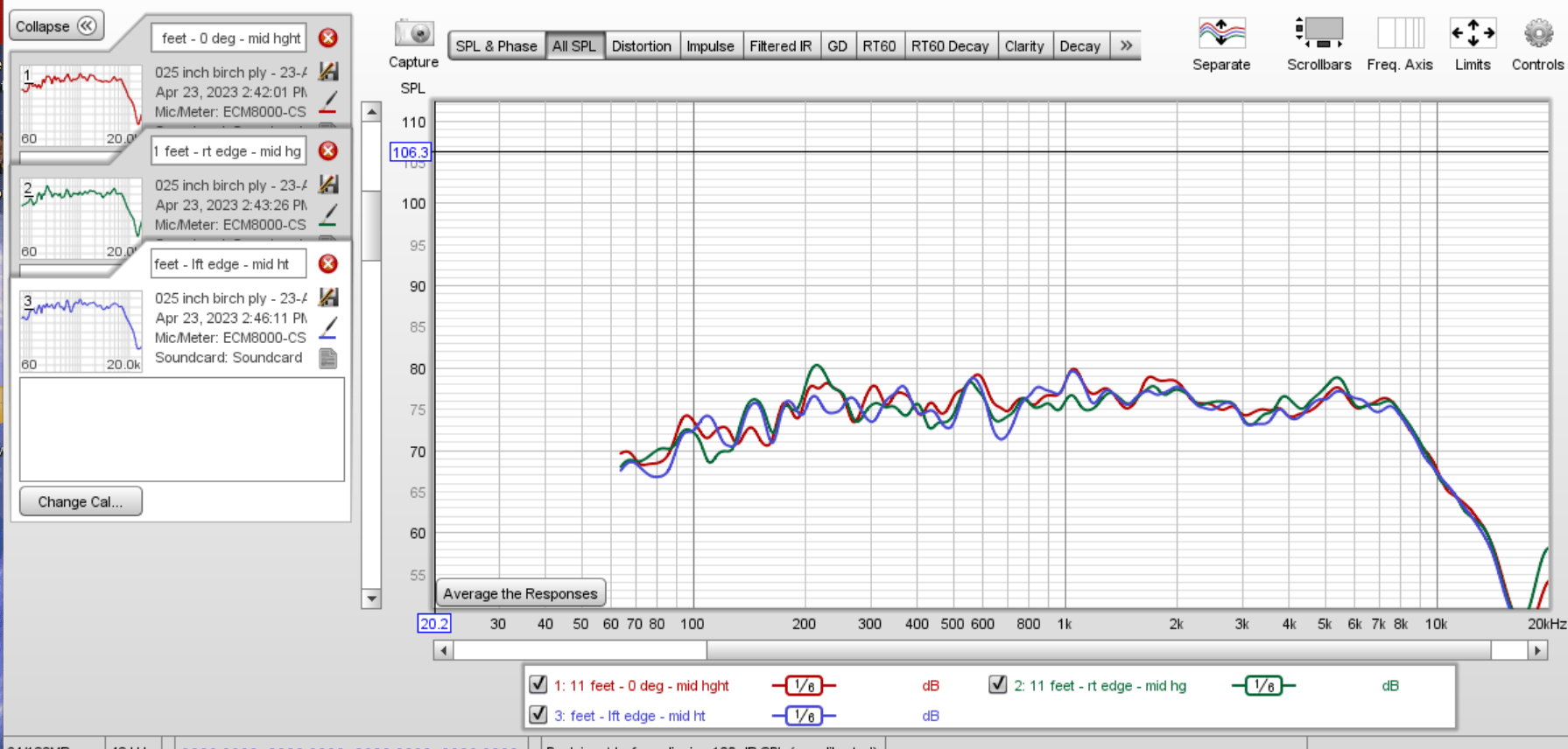

So yesterday on a whim I bought a panel of 1/4" birch ply and had it cut to size to fit in my car (and on my panel). Compared to the 3mm hardwood ply, and the 1/2" Foamular panel, this birch sounds great. I think I finally found a winner. It is not cheap at $44 US for a 4'x8' panel but it was worth it.

So I measured the response in my shop with REW and a ECM8000 with two exciters at and next to the 2/5 position (length and width). I ran three sine sweeps with the mic at the mid panel level (vertically): measured at the center, at the left edge of the panel, and the right edge of the panel. This amounts to 4 feet each side of center. The response for all three positions is remarkably close considering; measurement to measurement it is only +/- 1.5 dB at the widest deviations and most of it is better than that.

Red is in the middle, green is at the right side, blue is at the left side. I swept from 60 Hz - 20 kHz.

Also notice that the response from 60 Hz to 200 Hz has a nice slope at about 6 dB/octave. That is MUCH better (shallower) than the much steeper dropoffs I have seen on other DML measurements including mine (more like 20-25 dB/octave). I attribute that to the large size of the panel (24" x 93") and minimal edge damping.

I then played some music and walked around the room in front of the panel and noticed very little if any change in frequency response; SPL dropoff with distance was low. Sitting in front of the panel listening to a few songs it sounded really good; nice extension in the upper frequencies (with some 14 kHz boost) and bass response was easily good enough to cross with a sub at 100 Hz. It needs a little EQ here and there but otherwise I think this is the way to go for me. It gets plenty loud enough with two exciters in the 30x40 space I will be using it in. And that was only one panel; two panels (left and right) will be even louder of course.

I'll make more measurements later especially after the weather calms down and I can take it outside. For now, I think I finally found something that is close to the performance I was looking for.

So yesterday on a whim I bought a panel of 1/4" birch ply and had it cut to size to fit in my car (and on my panel). Compared to the 3mm hardwood ply, and the 1/2" Foamular panel, this birch sounds great. I think I finally found a winner. It is not cheap at $44 US for a 4'x8' panel but it was worth it.

So I measured the response in my shop with REW and a ECM8000 with two exciters at and next to the 2/5 position (length and width). I ran three sine sweeps with the mic at the mid panel level (vertically): measured at the center, at the left edge of the panel, and the right edge of the panel. This amounts to 4 feet each side of center. The response for all three positions is remarkably close considering; measurement to measurement it is only +/- 1.5 dB at the widest deviations and most of it is better than that.

Red is in the middle, green is at the right side, blue is at the left side. I swept from 60 Hz - 20 kHz.

Also notice that the response from 60 Hz to 200 Hz has a nice slope at about 6 dB/octave. That is MUCH better (shallower) than the much steeper dropoffs I have seen on other DML measurements including mine (more like 20-25 dB/octave). I attribute that to the large size of the panel (24" x 93") and minimal edge damping.

I then played some music and walked around the room in front of the panel and noticed very little if any change in frequency response; SPL dropoff with distance was low. Sitting in front of the panel listening to a few songs it sounded really good; nice extension in the upper frequencies (with some 14 kHz boost) and bass response was easily good enough to cross with a sub at 100 Hz. It needs a little EQ here and there but otherwise I think this is the way to go for me. It gets plenty loud enough with two exciters in the 30x40 space I will be using it in. And that was only one panel; two panels (left and right) will be even louder of course.

I'll make more measurements later especially after the weather calms down and I can take it outside. For now, I think I finally found something that is close to the performance I was looking for.

Last edited:

Hi Deude... Good to see progress in your search 👍..I have some modest information on how many points to measure for a DML...

So yesterday on a whim I bought a panel of 1/4" birch ply and had it cut to size to fit in my car (and on my panel). Compared to the 3mm hardwood ply, and the 1/2" Foamular panel, this birch sounds great. I think I finally found a winner. It is not cheap at $44 US for a 4'x8' panel but it was worth it.

So I measured the response in my shop with REW and a ECM8000 with two exciters at and next to the 2/5 position (length and width). I ran three sine sweeps with the mic at the mid panel level (vertically): measured at the center, at the left edge of the panel, and the right edge of the panel. This amounts to 4 feet each side of center. The response for all three positions is remarkably close considering; measurement to measurement it is only +/- 1.5 dB at the widest deviations and most of it is better than that.

Red is in the middle, green is at the right side, blue is at the left side. I swept from 60 Hz - 20 kHz.

View attachment 1167641

Also notice that the response from 60 Hz to 200 Hz has a nice slope at about 6 dB/octave. That is MUCH better (shallower) than the much steeper dropoffs I have seen on other DML measurements including mine (more like 20-25 dB/octave). I attribute that to the large size of the panel (24" x 93") and minimal edge damping.

I then played some music and walked around the room in front of the panel and noticed very little if any change in frequency response; SPL dropoff with distance was low. Sitting in front of the panel listening to a few songs it sounded really good; nice extension in the upper frequencies (with some 14 kHz boost) and bass response was easily good enough to cross with a sub at 100 Hz. It needs a little EQ here and there but otherwise I think this is the way to go for me. It gets plenty loud enough with two exciters in the 30x40 space I will be using it in. And that was only one panel; two panels (left and right) will be even louder of course.

I'll make more measurements later especially after the weather calms down and I can take it outside. For now, I think I finally found something that is close to the performance I was looking for.

How heavy is the Birch ply..ie: what is the density?

My other comment is that 1/4 inch (6.4 mm) is thick for a DML panel and you may get even better results from 3/16 inch (4.7mn) if available. It may extend the hf somewhat.

4mm would be even better but you guys are stuck with that old fashioned measurement system 🤭😜

And ..If you can get Poplar ply, you should try it... It's an excellent panel ply

Cheers

Eucy

Last edited:

The ply did not come with material certifications so I do not have that information. But I got a better idea than going straight to to 4.7mm... I'm going to rig up my Bridgeport milling machine so I can shave the plies in 0.01mm increments and test each one for response until I find the best thickness. After all what are the odds that 4.7mm is optimum?

If that does not get an acceptable result then I'll lay my own plies and try out different grain orientations in 10 deg increments. Hybrid plies, like poplar mixed with birch and balsa, are also worth a try. Then I'll play around with PVA, poly, and epoxy bonding agents in at least ten different shear moduli for each one. Then I'll start the 0.01mm incremental shave test again. It should not be more than 1.5E^20 permutations and thus testing will only take... well... I'll be dead by then. Hmmm...

If that does not get an acceptable result then I'll lay my own plies and try out different grain orientations in 10 deg increments. Hybrid plies, like poplar mixed with birch and balsa, are also worth a try. Then I'll play around with PVA, poly, and epoxy bonding agents in at least ten different shear moduli for each one. Then I'll start the 0.01mm incremental shave test again. It should not be more than 1.5E^20 permutations and thus testing will only take... well... I'll be dead by then. Hmmm...

Last edited:

Yes , And the 80 x 40 panels could have 3 mm Poplar glued to the canvas , while the 60 x 40 panels could have 10 mm EPS glued to them.I would go with one exciter apiece for the four outside panels so you get more varied sound and can series two of them to 8ohm.

If we work out one day how to produce Subs from a DML then that can go in the center panel.

What contrast and balance that gives without EQ ? I dont have the experience to predict it yet , I am 10 - 15 years behind the wisdom of some people on this page.

Being Chinese made "canvas" it could be closer to plastic than any traditional art canvas so the construction aspects would need alot of experimentation

Last edited:

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker