cheapvega --

Any DML that uses, i.e, PVA on EPS or canvas is essentially a stress skin panel.

Thin aluminum skins make great stress skin panels.

Aluminum flashing doesn't cost much and one can work it with wood working tools.

I built my first DMLs from aluminum honeycomb core with aluminum skins. I love them.

DIYing aluminum stress skin panels with some suitable core material makes for very rigid and light panels.

They can get very light because you can make the aluminum skins very thin due to aluminums surface tensile strength (among the highest of any material).

One can also make such stress skin panels from DIYed core material:

I've made painting panels like this long before my DIY Audiophile interests developed.

Just gives one options try.

-- Andreas

........... but what is the point of the (aluminum) skins?

Any DML that uses, i.e, PVA on EPS or canvas is essentially a stress skin panel.

Thin aluminum skins make great stress skin panels.

Aluminum flashing doesn't cost much and one can work it with wood working tools.

I built my first DMLs from aluminum honeycomb core with aluminum skins. I love them.

DIYing aluminum stress skin panels with some suitable core material makes for very rigid and light panels.

They can get very light because you can make the aluminum skins very thin due to aluminums surface tensile strength (among the highest of any material).

One can also make such stress skin panels from DIYed core material:

Build a very light wooden frame, maybe 3/8" deep.

Set it on top of a piece of aluminum flashing.

Whip up PVA in a blender or with a beater (like whipping egg whites).

Pour the whipped PVA into the frame.

Set the second aluminum skin on top.

I've made painting panels like this long before my DIY Audiophile interests developed.

Just gives one options try.

-- Andreas

CheapvegaI think part of the good low end was the panel basically being on the floor. Still, the 1/16" looked a lot like my EPS panels when I measured them long ago, so I think there is something to this thing's heft. It def feels hefty... Amazon says a sheet like this is about 3kg which seems nuts but not too far off.

I will need to wait until the kids are gone and the house is quiet to get the impulse response. I saw your PDF- that is honestly beyond my ability lol. If you tell me the measurements you need I can do them and send you the data to analyze. I measured the panel on the floor with a UMIK-1 about 0.8m or so away. Based on your report it looks like I can do that again for my other measurements. I guess floor gain doesn't hit from 100Hz and up.

Your PDF has me intrigued about the canvas panels I have sitting around. Problem is they are huge and kind of flappy. Is the face of one of your canvas panels very taut? The response with and without the wall looks really good. On page 5 what is the difference between the red and green graphs? It does look like these panels need room for the low end to work based on your data. Still, ~50-400Hz is def tunable. That's pretty crazy. How do they sound with music?

Many points... Sorry for the long reply...

Generally speaking about measurement, what I do now with DML is to measure them at a close distance (proximity, let say 1 or 2 cm right on the exciter axis) and at distance somewhere from 0,7m up to 2m or more (listening position).

The proximity measure gives a good overview of the overall performance. Like for conventional cone speaker it shows the best performance the panel can have at low frequency (without room influence). As it is not a pistonic behavior, the result at medium or even high freq is almost right.

At distance, you have the combination of the front and the rear wave plus the room reflections. It is much more tricky to understand what is what. Additional tests by changing the mic position or the panel position help in the interpretation... I am sure not mastering it!

Up to now, I have seen a little influence of the panel position according to the floor (see page 14). I think this goes in the way what Spedge get with his canvas in contact with the side wall (wall perpendicular to the panel)

I see a much important effect of the rear wall distance (wall parallel to the panel) or the panel dimension (how the reflected wave can go around or not)

The weight is still a question for me. The main drawback of weight is the efficiency. As you said watts are almost free (except in tube applications). The possible problem is pushing at to high power the exciters. At the opposite the weight might be a countermeasure against possible reflected waves coming through the panel but I have no evidence about that.

About REW and the views in my pdf, everything is available quite easily when the measurement is done. If needed, you will find in the attached file some screenshots of what I use.

For sure you can post what REW records (see attached file [save]). It is .mdat file extension probably to embed in a .zip for posting... but I can't guarantee you to work on it... We can give a try.

About my canvas : yes the canvas is taut (= stretched?). Very... I don't know; I would say yes (the 1st resonance is about 50Hz where Spedge mentions 40Hz if I remember). When I bought it it was already stretched. I then increased a little bit the tension by inserting the wood corners provided with canvas. After I apply several layers of watered PVA on the back side (one layer, the pad was glued, new layer on the pad and around, then a 3rd layer on the whole surface). See the attached picture. I will try to provide later a record of the panel resonance while hitting it).

On page 5 of the doc, the red curve is what I suggest at the beginning of this reply : the microphone was a few cm from the panel in the exciter axis (hand-held mic). The green curve is at 75cm according to the setup of the document.

About the sound... The panels work in full range with no EQ (I have no sub for now, neither EQ). In the first place (west of France) I tested them in december, it was correct but not exceptional (not like reported in other canvas builders posts). In the place (Paris area) they are now, it is much much better. They change from good full range to very good for me. Still not as good my 3mm plywood panels which have a better sound stage, perhaps more life and faster transients but the canvas are really promising. They are quite simple to build (less complex than the plywood version). Their cost and building time efficiency is incredible.Very low surface also (currently they are simply on the top of my previous 3 way column). Really living room friendly.

At the moment I think they could be by their dimensions more sensitive to the boundaries than bigger panels like my plywood. This is an assumption. I just ordered a batch of "magic sponges" (see Jaxboy #4133) to experiment some rear wave absoption. I will try also to understand why in the first place, they sound not so good (walls around? electronic?).

Christian

Attachments

Andreas,Build a very light wooden frame, maybe 3/8" deep.

Set it on top of a piece of aluminum flashing.Whip up PVA in a blender or with a beater (like whipping egg whites).Pour the whipped PVA into the frame.Set the second aluminum skin on top.

I have always been intrigued by the solutions you have taken. I don't have in mind other DML builder working with metal. Have you already post information or data about our aluminum honeycomb (aerial mass, bending stiffness, how it is damp enough...)? Some picture to see more detail of your material?

Your recipe is in my history file (your post #3252 p163). "Just an amazing engineered material and you can make it at home..." good teasing to keep it in notes!

Have you already built panel with that? Someone else?

I haven't seen PVA as a possible material adhering to aluminum. Seems it can. No risk of peeling off (if well cleaning with alcohol of course)?

Christian

Build a very light wooden frame, maybe 3/8" deep.

Set it on top of a piece of aluminum flashing.Whip up PVA in a blender or with a beater (like whipping egg whites).Pour the whipped PVA into the frame.Set the second aluminum skin on top.

Sorry Andreas... forget one question of translation

By aluminum flashing do you mean the thin aluminum sheet sold mainly for example for foodstuff use in roll (thickness ?). It exist for professional use in 50cm width.

Any clue about the ratio PVA/whipped PVA?

Christian

No, you've described aluminum foil.Sorry Andreas... forget one question of translation

By aluminum flashing do you mean the thin aluminum sheet sold mainly for example for foodstuff use in roll (thickness ?). It exist for professional use in 50cm width.

Christian

Aluminum flashing gets used in roofing applications such as where a chimney meets a shingled roof.

Any clue about the ratio PVA/whipped PVA?

No ratio, just whip PVA. You just beat air into it, like whipped cream.

@homeswinghome thanks for the thorough reply- the up close test is a great idea! I will test my existing EPS panels the same way. Again I also received a 400x500mm CF panel.... hoping to test all 3 again by the end of the week

OK I see... is aluminum flashing available in dimensions large enough (I haven't search for that in France, shingle is not so popular here for roof)? Idea of the thickness?No, you've described aluminum foil.

Aluminum flashing gets used in roofing applications such as where a chimney meets a shingled roof.

...

No ratio, just whip PVA. You just beat air into it, like whipped cream.

May you have a look also to #4323 ? thanks.

Fail / Resurrection

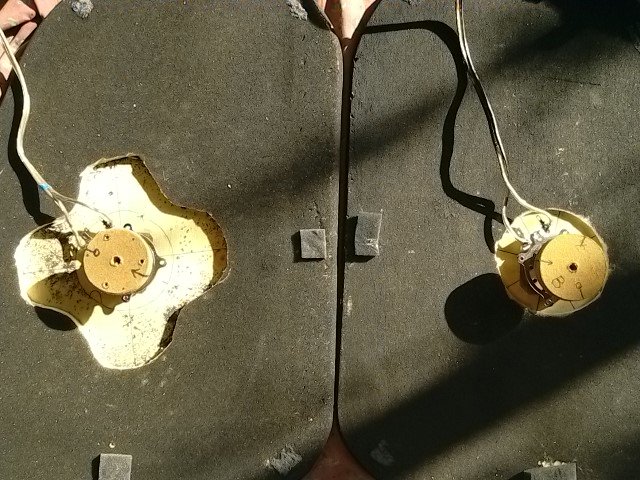

So I built the DML's in these posts: #3076 (canvas + wood) and #3207 (dense EPS + back frame/spine). While trying to extract the homemade exciter from the dense EPS I ended up with holes in the panels so I decided to combine the two build techniques to see what happens.

I finally received a pair of DAEX25FHE-4 exciters so this experiment is for real. I originally cut the EPS rough torn holes out to about a 3" diameter circle and cut the thin ply in a "freehand" t shape 7x7" and glued them to the front of the EPS at an angle which I don't think really matters but intended to black it all out anyway.

After figuring out the mounting of the exciters (dense foam and wood disc) so they can be seperated from the backframe easily I mounted them so that the exciters were holding the panel all by themselves except for the top foam strip which is super glued to frame and panel. I just see future problems without some support. The other foam strips are just attached to the panel because they were there anyway so I just left them but it is

mostly "free floating".

mostly "free floating".

Testing was a major letdown, certain things as expected stood out and sounded great, as in wooden instruments (cellos to die for) and mid range percussion and all instruments in general were pretty darn good, piano especially along with those cellos. The rub was the vocals. Willie Nelson's "The Last Thing I Needed TFTTM" has a slight "hall" thing going on anyway, but he sounded as if he were singing down a long steel pipe. Not hollow sounding but just distant and filtered.....strange.

So on with the experiment. I removed the frames and carefully cut out and removed as much EPS as I dare that's glued (50/50) to the wood. BOOM!...that was it. Night and day on the vocals and everything else came alive as well, especially the high's. These could easily be used as stand alone speakers with sub but In conjunction with my bookshelf JBL's and new Klipsch sub they just fill my small listening space wonderfully. They take away the directness of the bookshelfs allowing everything to blend.

Next project is a pair of center channel panels, mounted over and under the TV wired in series to obtain 8ohms. Have read good things here about doing that. take care

So I built the DML's in these posts: #3076 (canvas + wood) and #3207 (dense EPS + back frame/spine). While trying to extract the homemade exciter from the dense EPS I ended up with holes in the panels so I decided to combine the two build techniques to see what happens.

I finally received a pair of DAEX25FHE-4 exciters so this experiment is for real. I originally cut the EPS rough torn holes out to about a 3" diameter circle and cut the thin ply in a "freehand" t shape 7x7" and glued them to the front of the EPS at an angle which I don't think really matters but intended to black it all out anyway.

After figuring out the mounting of the exciters (dense foam and wood disc) so they can be seperated from the backframe easily I mounted them so that the exciters were holding the panel all by themselves except for the top foam strip which is super glued to frame and panel. I just see future problems without some support. The other foam strips are just attached to the panel because they were there anyway so I just left them but it is

Testing was a major letdown, certain things as expected stood out and sounded great, as in wooden instruments (cellos to die for) and mid range percussion and all instruments in general were pretty darn good, piano especially along with those cellos. The rub was the vocals. Willie Nelson's "The Last Thing I Needed TFTTM" has a slight "hall" thing going on anyway, but he sounded as if he were singing down a long steel pipe. Not hollow sounding but just distant and filtered.....strange.

So on with the experiment. I removed the frames and carefully cut out and removed as much EPS as I dare that's glued (50/50) to the wood. BOOM!...that was it. Night and day on the vocals and everything else came alive as well, especially the high's. These could easily be used as stand alone speakers with sub but In conjunction with my bookshelf JBL's and new Klipsch sub they just fill my small listening space wonderfully. They take away the directness of the bookshelfs allowing everything to blend.

Next project is a pair of center channel panels, mounted over and under the TV wired in series to obtain 8ohms. Have read good things here about doing that. take care

In the US one can readily get aluminum flashing in thicknesses of 0.42 mm or even less. Again in the US one can readily get rolls 24 inches wide by 25 feet for around $30.OK I see... is aluminum flashing available in dimensions large enough (I haven't search for that in France, shingle is not so popular here for roof)? Idea of the thickness?

May you have a look also to #4323 ? thanks.

It gets used for flashing (waterproofing) and lots of other things.

Essentially you want the thinnest aluminum sheet that isn't foil.

If you can't find it in a hardware store in France, you could likely get almost any size you'd want at a sheet metal supply.

Here is an mp3 you can hear the canvas panel while hitting with a wood spoon (mp3 in a zip)@homeswinghome thanks for the thorough reply- the up close test is a great idea! I will test my existing EPS panels the same way. Again I also received a 400x500mm CF panel.... hoping to test all 3 again by the end of the week

The spectrum

Attachments

That is just how I wish to use dml panels in the hopefully near future.Fail / Resurrection

So I built the DML's in these posts: #3076 (canvas + wood) and #3207 (dense EPS + back frame/spine). While trying to extract the homemade exciter from the dense EPS I ended up with holes in the panels so I decided to combine the two build techniques to see what happens.

I finally received a pair of DAEX25FHE-4 exciters so this experiment is for real. I originally cut the EPS rough torn holes out to about a 3" diameter circle and cut the thin ply in a "freehand" t shape 7x7" and glued them to the front of the EPS at an angle which I don't think really matters but intended to black it all out anyway.

After figuring out the mounting of the exciters (dense foam and wood disc) so they can be seperated from the backframe easily I mounted them so that the exciters were holding the panel all by themselves except for the top foam strip which is super glued to frame and panel. I just see future problems without some support. The other foam strips are just attached to the panel because they were there anyway so I just left them but it is View attachment 1014512View attachment 1014513View attachment 1014514View attachment 1014515View attachment 1014516View attachment 1014518mostly "free floating".

Testing was a major letdown, certain things as expected stood out and sounded great, as in wooden instruments (cellos to die for) and mid range percussion and all instruments in general were pretty darn good, piano especially along with those cellos. The rub was the vocals. Willie Nelson's "The Last Thing I Needed TFTTM" has a slight "hall" thing going on anyway, but he sounded as if he were singing down a long steel pipe. Not hollow sounding but just distant and filtered.....strange.

So on with the experiment. I removed the frames and carefully cut out and removed as much EPS as I dare that's glued (50/50) to the wood. BOOM!...that was it. Night and day on the vocals and everything else came alive as well, especially the high's. These could easily be used as stand alone speakers with sub but In conjunction with my bookshelf JBL's and new Klipsch sub they just fill my small listening space wonderfully. They take away the directness of the bookshelfs allowing everything to blend.

Next project is a pair of center channel panels, mounted over and under the TV wired in series to obtain 8ohms. Have read good things here about doing that. take care

How did you set up your jbl and dml? DML on the outsides of the jbl or the other way around?

Hi Pepe, I have the dml's on the outside of the jbl's, my space requires it, but you know, try them both ways if you can and go with what you prefer. This entire sound endeavor boils down to just that, find what you're happy with and that's all that matters. good luckThat is just how I wish to use dml panels in the hopefully near future.

How did you set up your jbl and dml? DML on the outsides of the jbl or the other way around?

Fail / Resurrection

So I built the DML's in these posts: #3076 (canvas + wood) and #3207 (dense EPS + back frame/spine). While trying to extract the homemade exciter from the dense EPS I ended up with holes in the panels so I decided to combine the two build techniques to see what happens.

I finally received a pair of DAEX25FHE-4 exciters so this experiment is for real. I originally cut the EPS rough torn holes out to about a 3" diameter circle and cut the thin ply in a "freehand" t shape 7x7" and glued them to the front of the EPS at an angle which I don't think really matters but intended to black it all out anyway.

After figuring out the mounting of the exciters (dense foam and wood disc) so they can be seperated from the backframe easily I mounted them so that the exciters were holding the panel all by themselves except for the top foam strip which is super glued to frame and panel. I just see future problems without some support. The other foam strips are just attached to the panel because they were there anyway so I just left them but it is View attachment 1014512View attachment 1014513View attachment 1014514View attachment 1014515View attachment 1014516View attachment 1014518mostly "free floating".

Testing was a major letdown, certain things as expected stood out and sounded great, as in wooden instruments (cellos to die for) and mid range percussion and all instruments in general were pretty darn good, piano especially along with those cellos. The rub was the vocals. Willie Nelson's "The Last Thing I Needed TFTTM" has a slight "hall" thing going on anyway, but he sounded as if he were singing down a long steel pipe. Not hollow sounding but just distant and filtered.....strange.

So on with the experiment. I removed the frames and carefully cut out and removed as much EPS as I dare that's glued (50/50) to the wood. BOOM!...that was it. Night and day on the vocals and everything else came alive as well, especially the high's. These could easily be used as stand alone speakers with sub but In conjunction with my bookshelf JBL's and new Klipsch sub they just fill my small listening space wonderfully. They take away the directness of the bookshelfs allowing everything to blend.

Next project is a pair of center channel panels, mounted over and under the TV wired in series to obtain 8ohms. Have read good things here about doing that. take care

Replying to my own post, I plan on thrift store searching for a used flat back guitar with the proper wood so I can cut out new wood sections and replace the existing ply in search for even cleaner vocals and sound. I'll post results.Fail / Resurrection

So I built the DML's in these posts: #3076 (canvas + wood) and #3207 (dense EPS + back frame/spine). While trying to extract the homemade exciter from the dense EPS I ended up with holes in the panels so I decided to combine the two build techniques to see what happens.

I finally received a pair of DAEX25FHE-4 exciters so this experiment is for real. I originally cut the EPS rough torn holes out to about a 3" diameter circle and cut the thin ply in a "freehand" t shape 7x7" and glued them to the front of the EPS at an angle which I don't think really matters but intended to black it all out anyway.

After figuring out the mounting of the exciters (dense foam and wood disc) so they can be seperated from the backframe easily I mounted them so that the exciters were holding the panel all by themselves except for the top foam strip which is super glued to frame and panel. I just see future problems without some support. The other foam strips are just attached to the panel because they were there anyway so I just left them but it is View attachment 1014512View attachment 1014513View attachment 1014514View attachment 1014515View attachment 1014516View attachment 1014518mostly "free floating".

Testing was a major letdown, certain things as expected stood out and sounded great, as in wooden instruments (cellos to die for) and mid range percussion and all instruments in general were pretty darn good, piano especially along with those cellos. The rub was the vocals. Willie Nelson's "The Last Thing I Needed TFTTM" has a slight "hall" thing going on anyway, but he sounded as if he were singing down a long steel pipe. Not hollow sounding but just distant and filtered.....strange.

So on with the experiment. I removed the frames and carefully cut out and removed as much EPS as I dare that's glued (50/50) to the wood. BOOM!...that was it. Night and day on the vocals and everything else came alive as well, especially the high's. These could easily be used as stand alone speakers with sub but In conjunction with my bookshelf JBL's and new Klipsch sub they just fill my small listening space wonderfully. They take away the directness of the bookshelfs allowing everything to blend.

Next project is a pair of center channel panels, mounted over and under the TV wired in series to obtain 8ohms. Have read good things here about doing that. take care

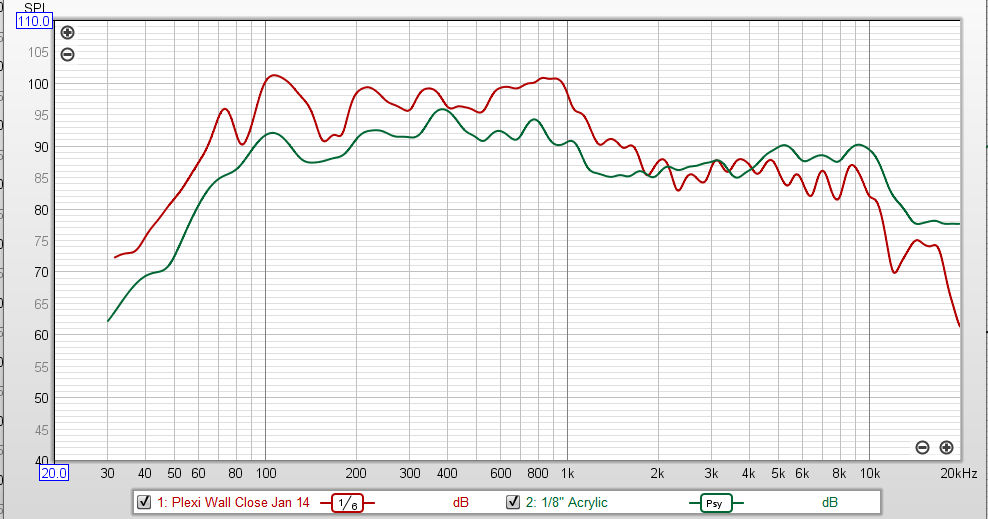

Small update.... I tested the 18x24x1/8" acrylic panel again as well as a CF panel. Results shown below are as follows:

Green: old test; 75cm on hardwood floor against desk

Red: new test; ~2cm on carpet against dresser

Surprised with the change to be honest. Same mic/amp/setup. I will have to test on the hardwood again to see if some property of the panel has changed over the last few days (???).

Also CF was a total bust. I lost the reading but it was terrible. Another bad bandpass, with a very loud resonance between 100-200Hz that repeated with harmonics. Sensitivity wasn't great either. Honestly I'm kind of glad as that will save me a lot of money. I spend that on exciters instead of panels and maybe get enough low end to #DitchTheSub.

Anyways hoping to measure and confirm the hardwood setup again. My kitchen is more similar to the hardwood setup in terms of room properties so if it works better there that's a good thing. I'm happy to lose that sub 1K hump for a flatter overall response (especially above 10k)

Green: old test; 75cm on hardwood floor against desk

Red: new test; ~2cm on carpet against dresser

Surprised with the change to be honest. Same mic/amp/setup. I will have to test on the hardwood again to see if some property of the panel has changed over the last few days (???).

Also CF was a total bust. I lost the reading but it was terrible. Another bad bandpass, with a very loud resonance between 100-200Hz that repeated with harmonics. Sensitivity wasn't great either. Honestly I'm kind of glad as that will save me a lot of money. I spend that on exciters instead of panels and maybe get enough low end to #DitchTheSub.

Anyways hoping to measure and confirm the hardwood setup again. My kitchen is more similar to the hardwood setup in terms of room properties so if it works better there that's a good thing. I'm happy to lose that sub 1K hump for a flatter overall response (especially above 10k)

Absolutly will try both ways.Hi Pepe, I have the dml's on the outside of the jbl's, my space requires it, but you know, try them both ways if you can and go with what you prefer. This entire sound endeavor boils down to just that, find what you're happy with and that's all that matters. good luck

It’s just that I was curiose of you tried both ways and what the difference was.

I heard good tvinga about having the DMLs on the outside. It’s been described as ”it takes the room away”. I wondered of the same thing applied to having the DMLs centered between the coned speakers.

I am far to have all the explanations but there are similarities with what I see in my measurements. I think the measurement at short distance gives the general character of the panel. Here a loss of level above 1kHz. At distance, the mic receive the front wave and also the rear wave reflected by the surrounding walls. It seems this has a low consequence at high frequency (the reflected wave is attenuated?). At low frequency the level is reduced by the recombination. In your test, the panel loss after 1k might be compensated by the loss in low frequency at distance. At medium frequency, reinforcements can happen. For my canvas, it is more flat at close distance so there is a lack of level at distance at low frequency. This my understanding from today... Let see with new tests, design, listening if it will remain like that.Small update.... I tested the 18x24x1/8" acrylic panel again as well as a CF panel. Results shown below are as follows:

Green: old test; 75cm on hardwood floor against desk

Red: new test; ~2cm on carpet against dresser

Surprised with the change to be honest. Same mic/amp/setup. I will have to test on the hardwood again to see if some property of the panel has changed over the last few days (???).

Also CF was a total bust. I lost the reading but it was terrible. Another bad bandpass, with a very loud resonance between View attachment 1014940100-200Hz that repeated with harmonics. Sensitivity wasn't great either. Honestly I'm kind of glad as that will save me a lot of money. I spend that on exciters instead of panels and maybe get enough low end to #DitchTheSub.

Anyways hoping to measure and confirm the hardwood setup again. My kitchen is more similar to the hardwood setup in terms of room properties so if it works better there that's a good thing. I'm happy to lose that sub 1K hump for a flatter overall response (especially above 10k)

About CF (I don't know this material) it might be one characteristic is its low damping. Is it? The frequency response of a DML is the result of the all the individual frequency response (bandpass) of each modes. If the material damping is low, holes will remain between those frequencies. I add below the example of the canvas panel. The blue curve is at close distance with no smoothing. We can think the damping of this panel is high (no real visible resonance except at very low frequency). The brown curve is at listening position 1/6 octave smoothing no windowing. At close distance we see also a slight drop of the level above 3kHz. As in a standard loudspeaker (cone) we could imagine that the voice coil mass and its inductance play a role of low pass filter.

I don't have an explanation (even idea of) for the band pass characteristic of some panels (seems the case for your CF)

Up to now I made 2 types of panels : 2 where quite big size (about 1.2m high, 50cm width) and 2 other with the height similar to the width (like 70x50cm or 41x31cm). For those latter, it seems the loss in low frequency is higher leading to a more important difference between the close distance measurement and at distance. Yesterday, I baffled the canvas panel using one big cardboard calendar on each side. The low frequency loss was significantly reduced. I had the same results testing one panel outdoor last summer. The low frequency level was much higher than in a room, close to the short distance measurement.

Beware of the rear sound wave ;-)

Christian

@homeswinghome,

I should mention- I measured the panel at listening distance in the carpeted room, and the measurements were basically identical to the up close measurement, which is part of why I didn't post them. So it looks like my original measurement in the more reflective room might have had some mid to high frequency resonances. Kind of makes sense with a sweep on a hardwood floor. In any case, having the "true" speaker measurement seems like very valuable information for general tuning- again I will have to make some confirmation measurements back in the hardwood floor room that mimics where these panels will be mounted.

And yes the CF panel has super low damping........ they basically ring like a bell on impact; I will get a measurement of that too when I have some time. The response was terrible too. Just a surprisingly bad material all around.

I should mention- I measured the panel at listening distance in the carpeted room, and the measurements were basically identical to the up close measurement, which is part of why I didn't post them. So it looks like my original measurement in the more reflective room might have had some mid to high frequency resonances. Kind of makes sense with a sweep on a hardwood floor. In any case, having the "true" speaker measurement seems like very valuable information for general tuning- again I will have to make some confirmation measurements back in the hardwood floor room that mimics where these panels will be mounted.

And yes the CF panel has super low damping........ they basically ring like a bell on impact; I will get a measurement of that too when I have some time. The response was terrible too. Just a surprisingly bad material all around.

Happy if you can find help in short distance measurement.@homeswinghome,

I should mention- I measured the panel at listening distance in the carpeted room, and the measurements were basically identical to the up close measurement, which is part of why I didn't post them. So it looks like my original measurement in the more reflective room might have had some mid to high frequency resonances. Kind of makes sense with a sweep on a hardwood floor. In any case, having the "true" speaker measurement seems like very valuable information for general tuning- again I will have to make some confirmation measurements back in the hardwood floor room that mimics where these panels will be mounted.

The difference at distance shows the interactions panel/room are different according to the room. At the top in my list is the distance to walls (let say any wall at less than 1m?). All the rooms I make test are about the same with hard floor (no carpet) so I have no measurement showing how the floor material influence the result... I have perhaps something to make a quick tests. Let's see in the next days (my list of "basic" tests is increasing a bit too fast!)

Keep us informed

Christian

PS @All does somebody know about modelling OB/room interaction

On this page you will find picture's showing the response of an old eps panel, it shows the peak in response at about 10k in front of the exciter area,caused by the oil can affect.Dmlbes.

Thanks for that post,I can't believe it was 2007 ,I remember being at the 2006 audio show and being very excited at listening to the podium demo.

I don't remember the interview being so detailed and that the layered sound idea came before the podiums,should have paid more attention!

To him sound is everything ,the problem with nxt patents and the like,is that the sound doesn't seem to get a mention,I do wonder if it's more about quantity than quality.

Anyway here are some pics I hope.

Yes hooray.

The first from left is a very old 170cmx60cm x25mm eps panel 70 grade I think ,I sanded down the panel but never got round to re-coting the sureface ,large panels are hard work! And messy .

Distance is 1ft approx,in front of exciter.

Second pic is the same panel but an inch of two to the left of exciter,also 1ft.

Third pic is same panel but now at least 10ft back into room near seating position,I have rolled off the response below 150hz on all pics to simplify the view ,sorry about quality of the pics as I had to take photos of my phone pictures ,too large for this site!

Steve

Moving the microphone a few inches to the left or right of the exciter coil area (near field),you will see the response above 10k drop like a stone.

This is measuring the pistonic pulse or primary drive area.

But the in room response picture shows a flat ledge from 10k extending to 20k at a lower level, this is the in room panel response.

This is from 2years ago and are pretty much identical to postings I made on the NXT RUBBISH site over 10years ago with various eps panels.

This is with my exciters and my panels in my room.

This response is easily improved as with my small veneer or card panels and the canvas panels.

It just takes a lot of loving care , and attention to detail.

Steve.

I should have mentioned the wonderfully flat response from 200hz to 10k, even with the 10k peak it is about plus and minus 2.5db !!

This is with no EQ !!

there was probably a dip in the room response below the 150hz point so I probably cut this off so as to make it a simpler view.

I use my TLs to fill in below 300hz anyway and would recommend the same to others for good room integration.

Steve.

This is with no EQ !!

there was probably a dip in the room response below the 150hz point so I probably cut this off so as to make it a simpler view.

I use my TLs to fill in below 300hz anyway and would recommend the same to others for good room integration.

Steve.

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker