Wow, this is interesting.

But for DML, lots of small and thin elements would be very time-consuming to build.

Take a look at these:

6moons audio reviews: Podium Sound Model 1

Estrada i Studio Online

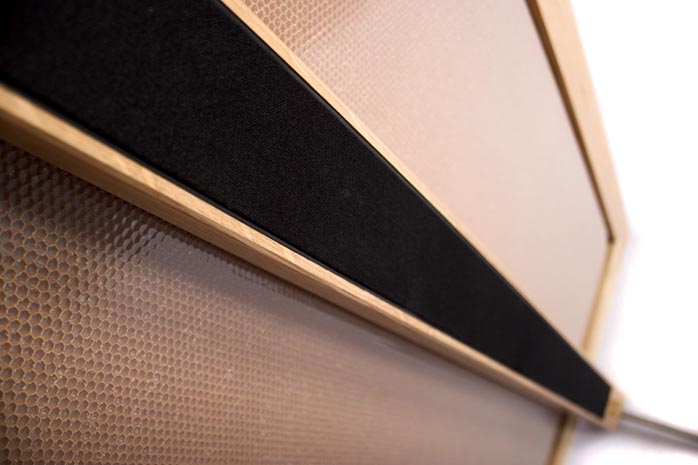

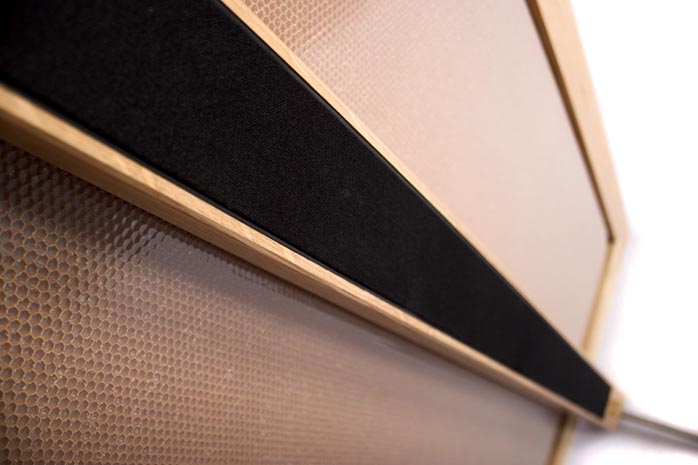

Very small cell in their boards.

But for DML, lots of small and thin elements would be very time-consuming to build.

Take a look at these:

6moons audio reviews: Podium Sound Model 1

An externally hosted image should be here but it was not working when we last tested it.

Estrada i Studio Online

Very small cell in their boards.

Yep! almost like bee hive panels with a layer of fiberglass.

I'm looking into China's wall panels...

What do you think of this?

MGO board, thickness from 3-25mm, biggest size available is 122cm x 366cm.

China Fireproof MGO Board Ceiling Panel - China Thin Mgo Boards, Mgo Waterproof Board

I'm looking into China's wall panels...

What do you think of this?

MGO board, thickness from 3-25mm, biggest size available is 122cm x 366cm.

China Fireproof MGO Board Ceiling Panel - China Thin Mgo Boards, Mgo Waterproof Board

Interesting stuff!

Some thoughts so far:

(1) Many types of panel are possible. It seems to me that we would want to avoid any that are sound-aborbing. That would seem to reduce the desirability of (say) the honeycomb fiberglass board. Since the goal of a DML is to produce resonances, don't we want a material that "rings"?

(2) While several types of exciters are available and inexpensive, if one uses conventional drivers adapted to direct connection to a panel, the main advantage is that a huge variety of drivers become possible "exciters." There are, of course, many ways to attach the voice coil to the panel. The simplest I've considered so far are variations on the "puck" idea of xrk971: a proper-sized round (does it have to be?) puck (or cat food tin 🙂 ) is glued to the cone and also to panel surface. I am still experimenting with (hardened) Gorilla Glue to substitute for the puck: first two samples did not work well, I believe due to too much glue impeding the cone's movement and/or I managed to glue the voice coil due to leakage

Batch #2 I am going to try to "fill" the cone first with a dried and smoothed/flattened layer of Gorilla Glue. I am trying to make the (new) cone surface to be flush to the panel. This may be too much effort in the wrong place. I observe that my best result so far is a variation of xrk971's diagram. I am driving the surface via a (too-tall) "puck" and my stand-offs (or spacers) are pieces of wood and (of course!) coroplast shims to get the height of the baset correct.

Of course you can dispense with the cone and basket entirely. If you have a machine shop or tools to excise those parts, by all means "go for it." But these seem to be unneeded steps which don't gain you anything except a more compact driver mounting.

(3) Rounded corners. Being lazy by nature, I am always pleased to find a recommendation that I actually "cut corners" 🙂

(4) What is ideal shape for a panel? Apparently not much consensus. All the better for wild experimentation and ego-boosting ("I invented it myself!") Adding to the chaos, is the option of tuning the panel by adding mass: so you may have a square or a circle if you must, and can still bugger the resonances with hidden mass 🙂

Some thoughts so far:

(1) Many types of panel are possible. It seems to me that we would want to avoid any that are sound-aborbing. That would seem to reduce the desirability of (say) the honeycomb fiberglass board. Since the goal of a DML is to produce resonances, don't we want a material that "rings"?

(2) While several types of exciters are available and inexpensive, if one uses conventional drivers adapted to direct connection to a panel, the main advantage is that a huge variety of drivers become possible "exciters." There are, of course, many ways to attach the voice coil to the panel. The simplest I've considered so far are variations on the "puck" idea of xrk971: a proper-sized round (does it have to be?) puck (or cat food tin 🙂 ) is glued to the cone and also to panel surface. I am still experimenting with (hardened) Gorilla Glue to substitute for the puck: first two samples did not work well, I believe due to too much glue impeding the cone's movement and/or I managed to glue the voice coil due to leakage

Batch #2 I am going to try to "fill" the cone first with a dried and smoothed/flattened layer of Gorilla Glue. I am trying to make the (new) cone surface to be flush to the panel. This may be too much effort in the wrong place. I observe that my best result so far is a variation of xrk971's diagram. I am driving the surface via a (too-tall) "puck" and my stand-offs (or spacers) are pieces of wood and (of course!) coroplast shims to get the height of the baset correct.

Of course you can dispense with the cone and basket entirely. If you have a machine shop or tools to excise those parts, by all means "go for it." But these seem to be unneeded steps which don't gain you anything except a more compact driver mounting.

(3) Rounded corners. Being lazy by nature, I am always pleased to find a recommendation that I actually "cut corners" 🙂

(4) What is ideal shape for a panel? Apparently not much consensus. All the better for wild experimentation and ego-boosting ("I invented it myself!") Adding to the chaos, is the option of tuning the panel by adding mass: so you may have a square or a circle if you must, and can still bugger the resonances with hidden mass 🙂

Last edited:

One thing to add to the mix is that 3d printing is now more and more accessible. Would a custom excited basket/spider made from printed plastic to hold the voice coil and magnet be beneficial? Maybe make a puck that combines a buttressed wide rib spreader base to effect a larger area of piston to avoid the HF peak at one point on the panel?

I know nought of 3D printing, but I am sure there are many options for how to mount the exciter or its evil twin, the modified normal driver 🙂

I have one more thought for using the normal driver + puck method: It would be helpful if the driver can be (re-)moved from the panel for whatever reason. This is possible, at least with Gorilla Glue, but at risk of damaging both the panel and the cone/driver. For my next pair of exciters, never mind what I just said about making the "puck" area flush; instead I will have a little extra depth. This will, of couse, require stand-offs or shims for the basket but the "puck' can be cut through with a long knife and (I hope) re-used.

I have one more thought for using the normal driver + puck method: It would be helpful if the driver can be (re-)moved from the panel for whatever reason. This is possible, at least with Gorilla Glue, but at risk of damaging both the panel and the cone/driver. For my next pair of exciters, never mind what I just said about making the "puck" area flush; instead I will have a little extra depth. This will, of couse, require stand-offs or shims for the basket but the "puck' can be cut through with a long knife and (I hope) re-used.

Additional resources

X and others,

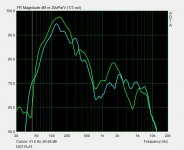

Thanks for a very interesting thread. This technology looks like it might be a good match to my SE tube amps... very benign impedance curve. Use of multiple exciters may be needed to get SPL up to useful levels. Spurred by this thread, I looked for and found some interesting information on the web. Excuse me if this has been discussed in some of the linked threads mentioned earlier.

Henry Azima, one of NXT's engineers/designers has an explanation of NXT panels (also something of a marketing brochure) available at 21st-NXT/Azima. Dayton Audio has a Tech Note: Understanding Exciters - Principles and Applications available as a PDF at either the Dayton Audio or the Parts Express websites. The tech note has good descriptions of the various types of exciters, materials for panels (and yes, paper-backed foam-core is listed as excellent), exciter placement, edge termination and damping, among other things. Last, the Azima article and some of the Dayton product information sheets mention NXT Designer software. Apparently, the software is available for free download at NXT System Designer 1.1 Download - PanSys.exe. It appears to be compatible with Windows 7/8/Vista/XP/2000/NT, and it was last updated May 27, 2013. I haven't tried to download it yet.

X and others,

Thanks for a very interesting thread. This technology looks like it might be a good match to my SE tube amps... very benign impedance curve. Use of multiple exciters may be needed to get SPL up to useful levels. Spurred by this thread, I looked for and found some interesting information on the web. Excuse me if this has been discussed in some of the linked threads mentioned earlier.

Henry Azima, one of NXT's engineers/designers has an explanation of NXT panels (also something of a marketing brochure) available at 21st-NXT/Azima. Dayton Audio has a Tech Note: Understanding Exciters - Principles and Applications available as a PDF at either the Dayton Audio or the Parts Express websites. The tech note has good descriptions of the various types of exciters, materials for panels (and yes, paper-backed foam-core is listed as excellent), exciter placement, edge termination and damping, among other things. Last, the Azima article and some of the Dayton product information sheets mention NXT Designer software. Apparently, the software is available for free download at NXT System Designer 1.1 Download - PanSys.exe. It appears to be compatible with Windows 7/8/Vista/XP/2000/NT, and it was last updated May 27, 2013. I haven't tried to download it yet.

In theory, the goal should be an expanding wave with an origin at the motor that matches the expansion of a spherical wave formed in the air. Essentially, you want a mechanical Quad ESL. Assuming a large flat panel forming a hemispherical radiation, the sound should travel through the panel at the same speed as the air at 'normal' temp and pressure. The wave speed should constant at all frequencies -- which as a requirement is a doozy.

Hi,

In practise distributed mode loudspeakers don't work like that at all.

The operation is entirely different, and your missing the point entirely.

rgds, sreten.

I'm a bit late in replying to this one, but I'm rehashing it because it's relevant to the current discussion. Of course sreten is right, DML don't work like that. I'll maintain however, that they should. It seems to me that there is more than a little rationalizing going on, and what is really happening in DML is a randomly shifting set of chladni patterns, with modes and multiple acoustic centers shifting around as well.

I think there's a limited level of high fidelity inherent in this concept. Regardless, it's an interesting proposition to see how far the idea can be taken. We are on the full range forum after all, and those have inherent limitations as well.

Has anyone tried this on a really thin membrane, something like a big drum head? I guess Manger does something like this, but I'm thinking bigger, or possibly a small foam core center diaphragm, with a really huge mylar film surround.

Soldermizer be trippin...

hmmm....if I can find a (relatively) reversible way to adhere my drivers to panel...

Why not stick a big panel on each of my Marimba "line array" speakers? That will probably truly be a 1st: a distributed mode, psuedo-bipolar, line-array, 8 driver ("exciter"), each with its own (mis-)tuned quarter wave resonator 🙂

Does anyone know an easy way to add electrostatic, planar magnetic, and ionic into the Mix?

Notify the men in the white jackets.... 🙂

hmmm....if I can find a (relatively) reversible way to adhere my drivers to panel...

Why not stick a big panel on each of my Marimba "line array" speakers? That will probably truly be a 1st: a distributed mode, psuedo-bipolar, line-array, 8 driver ("exciter"), each with its own (mis-)tuned quarter wave resonator 🙂

Does anyone know an easy way to add electrostatic, planar magnetic, and ionic into the Mix?

Notify the men in the white jackets.... 🙂

.....

I think there's a limited level of high fidelity inherent in this concept. Regardless, it's an interesting proposition to see how far the idea can be taken. We are on the full range forum after all, and those have inherent limitations as well.

...

Give it more time and efforts. Compared to the development history of cone drivers, the progressing pace of DML is like a rocket already.

On the contrary, actually we've been listening to DML for countless years without knowing it. We are just re-discovering it and doing it electronically now.

It's far more than just cheap and fun. (I believe you don't look at Stradivari's in this way... )

In addition, for the researches of room acoustics and psychoacoustics, DML is also a very good entrance to those fields. Eventually, 'how we hear' matters much more than 'how they make sound'. Sadly it's largely ignored.

I hope there is a way to get some bass out of these things. My current panel is approx 4x4' with a (formerly) 3-way car speaker (4 ohm) and I barely get anything < 200 Hz w/o EQ.

You should buy some cheap $5 exciters from PE and put them on a piece of cardboard or foam core. I get 50Hz easily - sounds quite rich.

I hope there is a way to get some bass out of these things.

Can you show us how you mount the driver to the panel, and the assembly of the whole thing?

Divergent opinions on exciter placement

PartsExpress says

http://www.parts-express.com/pedocs/buyer-guides/Tech_Note_Understanding_Exciters.pdf

But here is what purports to be a scholary paper that says way differently:

http://publications.lib.chalmers.se/records/fulltext/154618.pdf

This 2nd source claims a rectangle panel should be of ratio just < 1:1 (about 0.95:1); the PE doc suggests < 0.80:1.

Also they don't agree on exciter placements.

Somebody is wrong! The only thing that I'm certain about is you put some electricity through this thing, and the thing it's attached to makes noise .... 🙂

"Two men say they're Jesus; one of them must be wrong..."

-- Dire Straits, "Industrial Disease"

PartsExpress says

http://www.parts-express.com/pedocs/buyer-guides/Tech_Note_Understanding_Exciters.pdf

But here is what purports to be a scholary paper that says way differently:

http://publications.lib.chalmers.se/records/fulltext/154618.pdf

This 2nd source claims a rectangle panel should be of ratio just < 1:1 (about 0.95:1); the PE doc suggests < 0.80:1.

Also they don't agree on exciter placements.

Somebody is wrong! The only thing that I'm certain about is you put some electricity through this thing, and the thing it's attached to makes noise .... 🙂

"Two men say they're Jesus; one of them must be wrong..."

-- Dire Straits, "Industrial Disease"

Eventually...

I am still working on my (p)rototypes ["roto" is Spanish for "broken" which pretty well describes my stuff...] I guess the pun doesn't work so well in Ingles.

At the least I could run some frequency sweeps for each panel before I change it around yet again. While I use active EQ almost always, I know what low (or even mid) bass sounds like and I hardly hear any, even with EQ!

Meanwhile, I have attached the 12" sub to a 4x8' sheet of "R-Matte Plus-3" foam board but not yet hooked up to test.

Can you show us how you mount the driver to the panel, and the assembly of the whole thing?

I am still working on my (p)rototypes ["roto" is Spanish for "broken" which pretty well describes my stuff...] I guess the pun doesn't work so well in Ingles.

At the least I could run some frequency sweeps for each panel before I change it around yet again. While I use active EQ almost always, I know what low (or even mid) bass sounds like and I hardly hear any, even with EQ!

Meanwhile, I have attached the 12" sub to a 4x8' sheet of "R-Matte Plus-3" foam board but not yet hooked up to test.

Soldermiser,

The Master's Thesis from Kuonan Li that you've referenced also indicates that the 0.95:1 aspect ratio is a "golden ratio." I believe that would be a 0.618:1 ratio, which would be closer to the ratio suggested in the PE tech note. The thesis by Li does have some interesting theory and equations. For instance, I used his equation 3.9 to predict that a 24.75-inch by 40-inch panel of 0.5-inch thick "gator board" foam-core should have useable bass to 60 Hz. I think it may be worth a try for building. Still have to work out exciter placement as you've noted.

The Master's Thesis from Kuonan Li that you've referenced also indicates that the 0.95:1 aspect ratio is a "golden ratio." I believe that would be a 0.618:1 ratio, which would be closer to the ratio suggested in the PE tech note. The thesis by Li does have some interesting theory and equations. For instance, I used his equation 3.9 to predict that a 24.75-inch by 40-inch panel of 0.5-inch thick "gator board" foam-core should have useable bass to 60 Hz. I think it may be worth a try for building. Still have to work out exciter placement as you've noted.

Another contradiction...

It's possible Mr. Li only concerns himself with NXT DML tech, and also a rectangle panel.

I think he also claims a DML (NXT version) is more efficient than a standard box. Exactly opposite what other sources (Parts Express?) say. Agree that "his" golden ratio is not the classical one, but which one to use? I'll try his 0.95:1 since I'm close to square (4'x4'). Then I can round off the corners, change dimensions, etc. until the foam board is the size of a postage stamp. Then I start all over

For my current "full range" on wall experiments ("campaign sign" is offline now, current build has different "exciters" each is a Scosche HD5253A "car" driver, they are 5 1/4 3-ways from Wal-Mart. Well they are "one-way" after I remove the dreadful mid and tweeter. About $25/pair.). Also am doubling # of drivers per panel and putting a NU3000 in service instead of tiny class D amp 🙂

Meanwhile, I get bass out of my 4x8' with 12" sub but not impressive. I will admit I am doing many things "wrong", (1) not using proper exciters; (2) very possibly my mounting: I have voice coil (piston) in center and four points of contact where basket's screws would connect in a normal panel. This no doubt damps resonances more than if my "basket" were connected far away from driving force.

It's possible Mr. Li only concerns himself with NXT DML tech, and also a rectangle panel.

I think he also claims a DML (NXT version) is more efficient than a standard box. Exactly opposite what other sources (Parts Express?) say. Agree that "his" golden ratio is not the classical one, but which one to use? I'll try his 0.95:1 since I'm close to square (4'x4'). Then I can round off the corners, change dimensions, etc. until the foam board is the size of a postage stamp. Then I start all over

For my current "full range" on wall experiments ("campaign sign" is offline now, current build has different "exciters" each is a Scosche HD5253A "car" driver, they are 5 1/4 3-ways from Wal-Mart. Well they are "one-way" after I remove the dreadful mid and tweeter. About $25/pair.). Also am doubling # of drivers per panel and putting a NU3000 in service instead of tiny class D amp 🙂

Meanwhile, I get bass out of my 4x8' with 12" sub but not impressive. I will admit I am doing many things "wrong", (1) not using proper exciters; (2) very possibly my mounting: I have voice coil (piston) in center and four points of contact where basket's screws would connect in a normal panel. This no doubt damps resonances more than if my "basket" were connected far away from driving force.

Last edited:

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker