Andre.

Sorry, You are misunderstanding my point.

When the exciters are at rest and the wires are positioned correctly there is no problem.

But as soon as you send positive and negative signals to the exciter everything changes.

The wires try to hold the exciter terminals in that exact position, causing the exciter to tilt ,the opposite side of the exciter continues to move.

Causing the exciter to wobbly badly at higher volumes and lower frequencies.

If this was not bad enough, the wires can also start to wobble and vibrate out of control depending on their length.

This will also feed back to the exciter terminal causing more wobbling and vibrations.

This can and probably would cause coil damage if over driven with low frequencies.

This is another reasone I XO higher up when using no back brace.

Wires are a big problem if the exciters are not braced into a fixed position.

Steve.

Sorry, You are misunderstanding my point.

When the exciters are at rest and the wires are positioned correctly there is no problem.

But as soon as you send positive and negative signals to the exciter everything changes.

The wires try to hold the exciter terminals in that exact position, causing the exciter to tilt ,the opposite side of the exciter continues to move.

Causing the exciter to wobbly badly at higher volumes and lower frequencies.

If this was not bad enough, the wires can also start to wobble and vibrate out of control depending on their length.

This will also feed back to the exciter terminal causing more wobbling and vibrations.

This can and probably would cause coil damage if over driven with low frequencies.

This is another reasone I XO higher up when using no back brace.

Wires are a big problem if the exciters are not braced into a fixed position.

Steve.

Lordtarquin.

That sounds like a good price.

I wanted larger panels which were expensive, delivery doubles the price 😫

Where did you get those panels from?

It would be interesting to see how very high grades perform.

I do have one 5mm 40x40cm HD eps sample left from years ago but I do not think it is anywhere near your density.

Steve.

That sounds like a good price.

I wanted larger panels which were expensive, delivery doubles the price 😫

Where did you get those panels from?

It would be interesting to see how very high grades perform.

I do have one 5mm 40x40cm HD eps sample left from years ago but I do not think it is anywhere near your density.

Steve.

Thanks for that great background information, Spedge. So all these years later, where have you landed on the ideal build? From your last few comments, it sounds like you prefer EPS to XPS, is that right? What is an example of high grade EPS - R-Tech from HD? It also sounds like you no longer treat the surface? Is that right?

I didn't understand that statement, how is it that you're increasing the hf output from the centre?

Also, it seems like there are two schools of though on DML -- spines and spineless. Have you built panels with frames and spines?

I'm not going to be able to try epoxy on xps for a while, I'm already in trouble for the epoxy I used a couple days ago to mount an exciter to a spine. So I'm game for trying a less intensively treated route on EPS...

Hi.

I have only ever used 5mm XPS, which suffers early hf roll off.

XPS seems to have a lot of internal damping causing this problem.

Pva doesn't help much.

Epoxy on the other hand worked wonders for the XPS.

EPS is my favourite material but if it has a hard EPS surface, I always remove it, as it sounds pretty awful.

The pva has a much better sound to it, and improves the performance.

It is very difficult to generalise about different panel types and properties.

Some panels have problems and others do not.

Every different panel must be treated differently or at least separately.

You cannot presume all panels will react the same.

That is why I can only guarantee what I do to my panels.

If others do not follow closely to what I do, this could change everything and they would sound and perform differently.

On some panels that have large peaks in the 10k area (above and below) these can easily be reduced ,with the added benefit of bringing up the response either side of the peak.

But this is generally only the response in the exciter area not of the whole panel.

But it can reduce a lot of noise and distortions causing a harsh sound in this area.

Steve.

The most interesting matter in using a honeycomb sheet, you just don't need the back facing, if the honeycomb sheet with one facing would hold its structure stiff. And, if you cannot do without the Chinese made, Chinese technology exciters -- the US, UK, or EU firms don't have their own technology exciters -- all you have to do is fix the exciter to the open honeycomb at the back, so at least 50% of the coil former/bobbin touches the honeycomb structure. It is interesting how the vibration travel along the honeycomb structure to the front facing. The front facing should have enough stiffness so it can ripple. (I'm waiting for the magnets from China to make the other motor.)

We have been playing with this kind of stuff at a friendly recording studio, just to see how they'd like the sound that a flat surface might emit. Ah, by the way, there I noticed this funny looking orange screen equaliser, sound mastering tool and asked about it. It is used for frequency curve corrections and to eliminate room modes among other uses, such as making any kind of a frequency graph. Well, about that sometime later. 🙂

We have been playing with this kind of stuff at a friendly recording studio, just to see how they'd like the sound that a flat surface might emit. Ah, by the way, there I noticed this funny looking orange screen equaliser, sound mastering tool and asked about it. It is used for frequency curve corrections and to eliminate room modes among other uses, such as making any kind of a frequency graph. Well, about that sometime later. 🙂

Last edited:

Mr Polystyrene on ebay. Just checked and the price for 10 60x40cm 10mm thick 30g/litre is now £27 delivered. The price has gone down! High density 20g/l is £20 for the same size.Lordtarquin.

That sounds like a good price.

I wanted larger panels which were expensive, delivery doubles the price 😫

Where did you get those panels from?

It would be interesting to see how very high grades perform.

I do have one 5mm 40x40cm HD eps sample left from years ago but I do not think it is anywhere near your density.

Steve.

This is partly why I XO relatively high @ somewhere between 320 & 400hz. My exciters are unbraced and have short 23awg wires running from the exciter to a connector block which is attached to the outer frame of the panel. This means that there's no drag on the exciter and the wires don't join in with the music.Andre.

Sorry, You are misunderstanding my point.

When the exciters are at rest and the wires are positioned correctly there is no problem.

But as soon as you send positive and negative signals to the exciter everything changes.

The wires try to hold the exciter terminals in that exact position, causing the exciter to tilt ,the opposite side of the exciter continues to move.

Causing the exciter to wobbly badly at higher volumes and lower frequencies.

If this was not bad enough, the wires can also start to wobble and vibrate out of control depending on their length.

This will also feed back to the exciter terminal causing more wobbling and vibrations.

This can and probably would cause coil damage if over driven with low frequencies.

This is another reasone I XO higher up when using no back brace.

Wires are a big problem if the exciters are not braced into a fixed position.

Steve.

Besides which, what matters is how it sounds. I've just listened to Miles Davis Kind of Blue in preparation for a music session with some friends this evening and it sounds excellent. Imaging is good in all planes and the instruments sound pretty realistic to me.

Attachments

Some pictures and plots of the low density EPS panel.

The first picture is the response at 12inches showing the hf roll off above about 9k.

You can also see a dip in the response at 200hz.

In the second picture you can see that I removed this dip by placing a small button battery in the position showed in picture three.

Picture four just shows the small 3watt exciter and scrap peace or low grade(density)EPS.

Picture five shows the position of the phone on the rug for the recording I have made, which I will post later on when I get time.

You can also see the other low density panel on the right,with the upside-down 14g ,which is the panel weight.

Steve.

The first picture is the response at 12inches showing the hf roll off above about 9k.

You can also see a dip in the response at 200hz.

In the second picture you can see that I removed this dip by placing a small button battery in the position showed in picture three.

Picture four just shows the small 3watt exciter and scrap peace or low grade(density)EPS.

Picture five shows the position of the phone on the rug for the recording I have made, which I will post later on when I get time.

You can also see the other low density panel on the right,with the upside-down 14g ,which is the panel weight.

Steve.

Attachments

By the way the peaks in the response in the 1 to 2 k area, i believe is to do with exciter noise.

But that is another matter.

Steve.

But that is another matter.

Steve.

Last week I was playing at an outdoor venue, with my big 4x20w's crossed over at 100hz, the sub barely ticking over.This is partly why I XO relatively high @ somewhere between 320 & 400hz

Yes, the panel did start rattling a bit when the party started degrading 😁. So, mid-performance, mic in-hand, I changed the x-over freq until the rattling stopped. 200Hz was the magic number.

I've seen several mentions by several punters of the phrase 'exciter noise.'do with exciter noise.

What exactly is exciter noise?? Is it

the voice coil rubbing on the magnet?

VC adhesive coming adrift and flapping against the panel?

loose suspension rattling against the magnet?

Wires flapping against the panel?

The panel flapping against... something?

Interesting. Your 200hz dip is in the same place as on my plywood panel.Some pictures and plots of the low density EPS panel.

The first picture is the response at 12inches showing the hf roll off above about 9k.

You can also see a dip in the response at 200hz.

In the second picture you can see that I removed this dip by placing a small button battery in the position showed in picture three.

Picture four just shows the small 3watt exciter and scrap peace or low grade(density)EPS.

Picture five shows the position of the phone on the rug for the recording I have made, which I will post later on when I get time.

You can also see the other low density panel on the right,with the upside-down 14g ,which is the panel weight.

Steve.

I will give this a go in the next few weeks. A frequency sweep from 20hz upwards in REW may also help to determine where the rattling stops. The hifi is going to be out of action for a while as we are having a new floor laid in another room, so the hifi room will be a bit of a dumping ground for a while. No excuse for not getting those H frames built now.Last week I was playing at an outdoor venue, with my big 4x20w's crossed over at 100hz, the sub barely ticking over.

Yes, the panel did start rattling a bit when the party started degrading 😁. So, mid-performance, mic in-hand, I changed the x-over freq until the rattling stopped. 200Hz was the magic number.

Sometimes the LF peaks and dips are to do with panel dimensions, modal sparsity, fundamental resonances and room resonances.Interesting. Your 200hz dip is in the same place as on my plywood panel.

As far as DML goes, one-size rarely fits all.

Pretty much always this.Sometimes the LF peaks and dips are to do with panel dimensions, modal sparsity

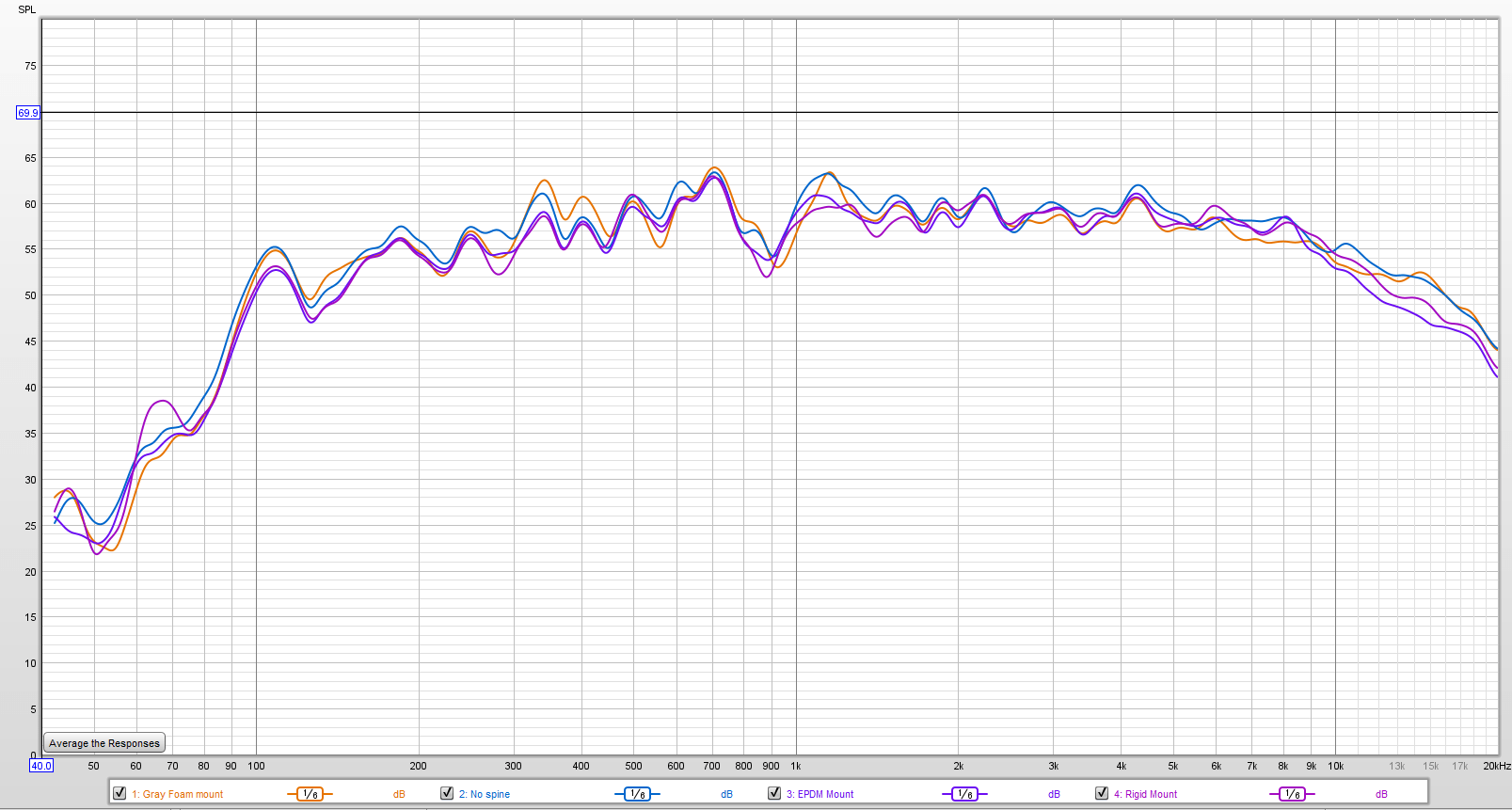

There's been some discussion lately about various mounting methods for exciters, so I thought I'd share some recent comparisons. Below are the results I got for four different mountings of the same exciter (DAEX25FHE-4) on a 4 mm plywood panel in a sturdy frame. In three of the four mountings, I used a brace/spine as shown in the image below, and in a final case I completely removed the spine.

For the mountings with the spine, between the spine and the exciter I included one of either:

That said, for final builds, I always use a spine, mainly because most exciters do need support to prevent the weight of the magnet from causing voice coil to become misaligned, or preven exciter from simply falling off the panel, or from damage by contact or rough handling. And I also typically add some foam in between, but only to give the mounting a bit of compliance so that if the panel or spine warps a bit, not all that deflection has to be taken up the voice coil and surround, as some of it is taken in the foam. But for prototypes I virtually always run tests without the spine, knowing that when I eventually add the spine for the final build the result will be virtually identical.

Eric

For the mountings with the spine, between the spine and the exciter I included one of either:

- Gray soft closed cell PVC foam (window gasket), as shown in the image

- Black EPDM foam (slightly more rigid than the PVC foam)

- Solid wood block (rigid mounting), no foam.

That said, for final builds, I always use a spine, mainly because most exciters do need support to prevent the weight of the magnet from causing voice coil to become misaligned, or preven exciter from simply falling off the panel, or from damage by contact or rough handling. And I also typically add some foam in between, but only to give the mounting a bit of compliance so that if the panel or spine warps a bit, not all that deflection has to be taken up the voice coil and surround, as some of it is taken in the foam. But for prototypes I virtually always run tests without the spine, knowing that when I eventually add the spine for the final build the result will be virtually identical.

Eric

Is this a variation on the OB H-frame woofers?the bass drivers are in asymmetrical topless U frames,

I battle to visualise it.

That is a VERY acceptable response! There's definitely something to be said for a high density, heavy panel with a high efficiency driver.four different mountings of the same exciter (DAEX25FHE-4) on a 4 mm plywood panel in a sturdy frame

the low density EPS recording.

the volume level was at my usual listening level, so this exciter can play loud with the EPS panels.

there is some noise on the strumming guitar but that is to do with my subs being too close and other problems below 200hz..

i should record the panels only in future and save all these problems,but i had to XO the little exciters at 200hz'

not bad for a tatty piece of EPS.

it still needs some work to the central area but, i would have to cut off the exciter and start again.

steve.

the volume level was at my usual listening level, so this exciter can play loud with the EPS panels.

there is some noise on the strumming guitar but that is to do with my subs being too close and other problems below 200hz..

i should record the panels only in future and save all these problems,but i had to XO the little exciters at 200hz'

not bad for a tatty piece of EPS.

it still needs some work to the central area but, i would have to cut off the exciter and start again.

steve.

Attachments

Please Steve, let us know about the HF extension in the different density you can test and the trick to increase it please.25kg/m3 and 30kg/m3 seem quite hi densities to me .

I have never tried anything this high.

70 grade is about 14kg/m3, this is the material used for the 5ftx2ft x 25mm measurements I just posted.

This is the same type of material leob used for his pa speakers, except his were carbon impregnated .

150 grade in the UK, is about 22kg/m3 .

It is very expensive to get hold of EPS with a higher grade than 70 in the UK, you have to bulk buy plus delivery.

I would never spend this sort of money on an untested material.

I am at the moment testing an EPS panel which is possibly in the 40 grade area, 9kg/m3 using a 3watt exciter to see what sort of performance can be expected.

This is for home use ,not PA work.

Steve.

Christian

This fits with my "material chart paper". For a given material reducing the thickness lowers the impedance and so the HF extension.I have only ever used 5mm XPS, which suffers early hf roll off.

XPS seems to have a lot of internal damping causing this problem.

Pva doesn't help much.

Epoxy on the other hand worked wonders for the XPS.

Adding PVA adds mass and stiffness so increase the impedance so the bandwidth but reduce the efficiency.

In the case of XPS 5mm, PVA is probably not strong neither heavy enough where epoxy is.

Some measurements of bending stiffness and areal mass might help to understand along with the material chart scales.

Christian

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker