@aagas ...just a thought in case the prices or spec are better https://signtradesupplies.co.uk/col...luminium-composite-sign-blanks-standard-sizesA possiblability?

AlumaComp Aluminum, 30"x36" Archival Painting & Mounting Panel

Not cheap.

Polyethylene core 1/8"

Size : 30" x 36" x 3/16"

Seems heavy, but perhaps not much heavier than 6mm Proplex.

I've got some from having mounted a painting.

You can cut it with a good razor knife.

On my list to try.

This company produces signage blanks as an Aluminium/EPS/Aluminium composite material. There are many stock sizes and the price looks reasonable. The Aluminium Skin is very thin at 0.21 but the blanks are described as very rigid. I am tempted to test a small sample

Last edited:

I used the panels just as I found them.Thanks for the info. So, you used the panel as you found it (as a cupboard door) - no cutting done? I was wondering if this panel could be easily cut with a table daw and the correct blade?

One an easily cut the panel, but I'd likely you a track saw rather than a table saw. Less chance of delaminating I think.

Doing so would leave the edging absent and I've come to suspect that the edging matters.

Looks like a great find. I haven't seen anything like this as available in the US. Let us know how it works.@aagas ...just a thought in case the prices or spec are better https://signtradesupplies.co.uk/col...luminium-composite-sign-blanks-standard-sizes

This company produces signage blanks as an Aluminium/EPS/Aluminium composite material. There are many stock sizes and the price looks reasonable. The Aluminium Skin is very thin at 0.21 but the blanks are described as very rigid. I am tempted to test a small sample

@ Andre Bellwood

Further to my post #8,616

It might be interesting to transfer the 'pistonic' motion to the panel front through a slit in the panel by some sort of a stiff material from the transducer, maybe as shown in this Paddock patent. Red arrow.

The panel doesn't have to be curved as in that patent. By keeping the transducer away from the panel, the panel would not get any distortions from the transducer, or at least be minimalised. The transducer is a piezo in this patent, but it can be any motor. In this patent and in Arcophon, the all sides/edges are held tight, maybe with a soft foam underneath, except the edge(s) that gets the vibrations from the transducer. When we have a flat panel, and with all edges held tight, we can make a slit in the panel to transfer the 'pistonic' motion vibrations to the front. We may not divide the divide the panel in half as in Joppe's video. But we can prepare that area around the joint vertically to get more HF. Just a thought. 🙂

Further to my post #8,616

It might be interesting to transfer the 'pistonic' motion to the panel front through a slit in the panel by some sort of a stiff material from the transducer, maybe as shown in this Paddock patent. Red arrow.

The panel doesn't have to be curved as in that patent. By keeping the transducer away from the panel, the panel would not get any distortions from the transducer, or at least be minimalised. The transducer is a piezo in this patent, but it can be any motor. In this patent and in Arcophon, the all sides/edges are held tight, maybe with a soft foam underneath, except the edge(s) that gets the vibrations from the transducer. When we have a flat panel, and with all edges held tight, we can make a slit in the panel to transfer the 'pistonic' motion vibrations to the front. We may not divide the divide the panel in half as in Joppe's video. But we can prepare that area around the joint vertically to get more HF. Just a thought. 🙂

Will do. If it does work out I am happy to ship to you if that helps? I have ordered a couple of A3 test samples.Looks like a great find. I haven't seen anything like this as available in the US. Let us know how it works.

Is this the Rubanoide tweeter?@ Andre Bellwood

Further to my post #8,616

It might be interesting to transfer the 'pistonic' motion to the panel front through a slit in the panel by some sort of a stiff material from the transducer, maybe as shown in this Paddock patent. Red arrow.

View attachment 1131141

The panel doesn't have to be curved as in that patent. By keeping the transducer away from the panel, the panel would not get any distortions from the transducer, or at least be minimalised. The transducer is a piezo in this patent, but it can be any motor. In this patent and in Arcophon, the all sides/edges are held tight, maybe with a soft foam underneath, except the edge(s) that gets the vibrations from the transducer. When we have a flat panel, and with all edges held tight, we can make a slit in the panel to transfer the 'pistonic' motion vibrations to the front. We may not divide the divide the panel in half as in Joppe's video. But we can prepare that area around the joint vertically to get more HF. Just a thought. 🙂

Yes, I've been tempted to build something like this with an exciter behind it. But if I did go that far then I think I wouldn't even bother with a panel around it, and just make it long enough to hit at least 150hz on the bottom end, and have space for 4 or 8 exciters on the back... I'd also try to make it open-back and dipolar...

I'm undecided.

Just taking an idea off that patent. 🙂Is this the Rubanoide tweeter?

Yes, I've been tempted to build something like this with an exciter behind it. But if I did go that far then I think I wouldn't even bother with a panel around it, and just make it long enough to hit at least 150hz on the bottom end, and have space for 4 or 8 exciters on the back... I'd also try to make it open-back and dipolar...

I'm undecided.

That's more like a modern looking Arcophon.

Link 1,

Link2

Further to my post #8,624

@Andre Bellwood

As @Sandasnickaren made here, #8,102 and here, #8,112, but keep the transducer away from the panel itself. The transducer/exciter held tightly far away, say, on the back of that box, but with only the connector attached to it and to the front of the panel through a slit on the panel. Of course, later the panel can be covered with a nice covering.

@Andre Bellwood

As @Sandasnickaren made here, #8,102 and here, #8,112, but keep the transducer away from the panel itself. The transducer/exciter held tightly far away, say, on the back of that box, but with only the connector attached to it and to the front of the panel through a slit on the panel. Of course, later the panel can be covered with a nice covering.

Great!Hi Thomas,

Ok, so I've tested this...

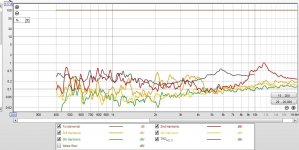

There's a difference! Red trace is the front side of the panel. Blue is the driver side on the back...

View attachment 1131081

It’s confirms my thought.

It supports that the panel needs a core that is light and does not compress easily.

Thomas

I've been experimenting with smaller panels to use in a 2-way setup. I've settled on a 350mm H by 150mm W panel made of a 3.5mm Nomex honeycomb core sandwiched with CF (purchased panel). I will probably crossover around 400Hz because the woofer I'm using has lower distortion below 500Hz. I'm using a MiniDSP 2x4HD for EQ along with REW for measurement. After measurement REW provides a file export of the EQ filter coefficients that load directly into the MiniDSP. The attached response was accomplished in less than 15 minutes (blue is prior to EQ and red is after). I was kind of amazed at how well the panel responded to EQ. I'm still working on the woofer integration. The current panel mounting is a bit crude. I have 3/8" foam strips along the edges and the white duct tape provides a quasi "medial clamp". This is a work in progress but pleased with the results so far. The exciter is a PUI Audio ASX0504-HD-R.

Thanks, Dave

Thanks, Dave

Attachments

What is the exciter placement?I've been experimenting with smaller panels to use in a 2-way setup. I've settled on a 350mm H by 150mm W panel made of a 3.5mm Nomex honeycomb core sandwiched with CF (purchased panel). I will probably crossover around 400Hz because the woofer I'm using has lower distortion below 500Hz. I'm using a MiniDSP 2x4HD for EQ along with REW for measurement. After measurement REW provides a file export of the EQ filter coefficients that load directly into the MiniDSP. The attached response was accomplished in less than 15 minutes (blue is prior to EQ and red is after). I was kind of amazed at how well the panel responded to EQ. I'm still working on the woofer integration. The current panel mounting is a bit crude. I have 3/8" foam strips along the edges and the white duct tape provides a quasi "medial clamp". This is a work in progress but pleased with the results so far. The exciter is a PUI Audio ASX0504-HD-R.

Thanks, Dave

ExcellentI've been experimenting with smaller panels to use in a 2-way setup. I've settled on a 350mm H by 150mm W panel made of a 3.5mm Nomex honeycomb core sandwiched with CF (purchased panel). I will probably crossover around 400Hz because the woofer I'm using has lower distortion below 500Hz. I'm using a MiniDSP 2x4HD for EQ along with REW for measurement. After measurement REW provides a file export of the EQ filter coefficients that load directly into the MiniDSP. The attached response was accomplished in less than 15 minutes (blue is prior to EQ and red is after). I was kind of amazed at how well the panel responded to EQ. I'm still working on the woofer integration. The current panel mounting is a bit crude. I have 3/8" foam strips along the edges and the white duct tape provides a quasi "medial clamp". This is a work in progress but pleased with the results so far. The exciter is a PUI Audio ASX0504-HD-R.

Thanks, Dave

It was already pointed here that the DML by their resonant nature would be suitable for an EQ correction.

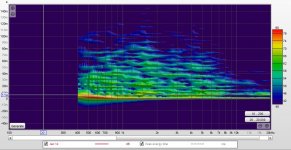

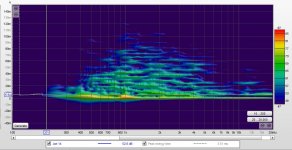

Is it possible to see the spectrogram in the wavelet mode 1/6 oct of REW before and after EQ?

Christian

My question exactly!Excellent

It was already pointed here that the DML by their resonant nature would be suitable for an EQ correction.

Is it possible to see the spectrogram in the wavelet mode 1/6 oct of REW before and after EQ?

Christian

Eric

Dave,I've been experimenting with smaller panels to use in a 2-way setup. I've settled on a 350mm H by 150mm W panel made of a 3.5mm Nomex honeycomb core sandwiched with CF (purchased panel). I will probably crossover around 400Hz because the woofer I'm using has lower distortion below 500Hz. I'm using a MiniDSP 2x4HD for EQ along with REW for measurement. After measurement REW provides a file export of the EQ filter coefficients that load directly into the MiniDSP. The attached response was accomplished in less than 15 minutes (blue is prior to EQ and red is after). I was kind of amazed at how well the panel responded to EQ. I'm still working on the woofer integration. The current panel mounting is a bit crude. I have 3/8" foam strips along the edges and the white duct tape provides a quasi "medial clamp". This is a work in progress but pleased with the results so far. The exciter is a PUI Audio ASX0504-HD-R.

Thanks, Dave

Did the distortion impove after EQ? I assume the posted distortion results (very good!) are after EQ, is that correct?

Thanks,

Eric

Very kind of you. Thanks.Will do. If it does work out I am happy to ship to you if that helps? I have ordered a couple of A3 test samples.

(Frankly - I'd rather you just brought it to NY so we could listen to some panels together. Keep me in mind if you find yourself in my part of the world ;-)

I will do that 👍Very kind of you. Thanks.

(Frankly - I'd rather you just brought it to NY so we could listen to some panels together. Keep me in mind if you find yourself in my part of the world ;-)

T

The distortion did improve some after EQ in the 1kHz area (see attached). The exciter is mounted essentially in the center of the panel. Attached are the before and after EQ REW spectrograms.

Thanks, Dave

Dave,

Did the distortion impove after EQ? I assume the posted distortion results (very good!) are after EQ, is that correct?

Thanks,

Eric

The distortion did improve some after EQ in the 1kHz area (see attached). The exciter is mounted essentially in the center of the panel. Attached are the before and after EQ REW spectrograms.

Thanks, Dave

Attachments

This is amazing indeed!I've been experimenting with smaller panels to use in a 2-way setup. I've settled on a 350mm H by 150mm W panel made of a 3.5mm Nomex honeycomb core sandwiched with CF (purchased panel). I will probably crossover around 400Hz because the woofer I'm using has lower distortion below 500Hz. I'm using a MiniDSP 2x4HD for EQ along with REW for measurement. After measurement REW provides a file export of the EQ filter coefficients that load directly into the MiniDSP. The attached response was accomplished in less than 15 minutes (blue is prior to EQ and red is after). I was kind of amazed at how well the panel responded to EQ. I'm still working on the woofer integration. The current panel mounting is a bit crude. I have 3/8" foam strips along the edges and the white duct tape provides a quasi "medial clamp". This is a work in progress but pleased with the results so far. The exciter is a PUI Audio ASX0504-HD-R.

Thanks, Dave

I find it very interesting indeed that the DSP Eq reduces distortion to such a degree. Is this because of undamped panel resonances that are addressed or controlled by Eq?

I've been very very tempted to use a DSP-based EQ, with a pre-programmed curve embedded in an integrated chip in a pre-amp. And your results make me do a double-take and force me to consider this option very seriously.

I too found that the centre placing of the exciter works well, when the height is near or more than double the width. This places the NXT patents (and others following/copying them) somewhat on its head. Sure, EQ works quite well with thin panels, just like with 'normal' speakers.The distortion did improve some after EQ in the 1kHz area (see attached). The exciter is mounted essentially in the center of the panel. Attached are the before and after EQ REW spectrograms.

Thanks, Dave

I went on a bit of a pub crawl yesterday in London, so am feeling a little delicate today.Yep Steve... I realise that your 6 mm sheet differs from the 'norm' (presuming there is one)

Using a dome on the corflute lifted the mids/highs and brightened the slightly 'soft' tone...I can't seem to get anyone to try it though 😔..oh well...que sera..(I know you've tried lots of domes.. (but not the coke can one I believe?))

Eucy

But tonight I will force a can of beer down me tonight(hair of the dog) and make one of your domes.

I will attach it to the square fluted ,I think the square flute is called biplex ,not proplex?

I will measure the response and listen, and get back to you.

The domes I used for my thin 1mm panels was to prevent distortions in in the about 3k and 10k areas caused by the exciter problems mentioned in my posts.

I did not design them as a tweeter as such, but they do act as such depending on panel efficiency.

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker