Who's Gonna Be First?

Quote.. bradleypnw

I'm not sure enclosures increase bass.

I can agree.. but an enclosure (be it ever so subtle) that can help "Focus" or direct sound towards an intended direction does help. Not an enclosed type but a calculated surface to reflect from, beyond items in a room.. (Think slightly concave surface behind the unit) Frequency reflections can be adjusted with sound absorbing materials, like adding scrub pads around the baffle of a tweeter..

You made another magical statement that I agree with..

"Longer panel length, even despite narrow width, increases bass."

This thought is the basis of my next experiment. Most everyone constructs panels with one surface being the primary emitter of sound when both surfaces can emit equally without cancelation. The nulls are at the edge of both surfaces on both sides, top and bottom..

What "IF" a long, somewhat narrow panel was used with one side edge facing the back, or towards the wall and the other edge facing away, or towards the listening area? Emitting left and right! A totally different approach! One side edge null will be towards the wall so a surround of some type could be used to support the panel without much loss. Same for the side edge facing the desired listening area. Not much ceiling or floor reflections to worry about from the driven element on top and bottom. Width change could be used for different frequency response along the length. Chambers, elements, cavities or whatever could be designed to control or enhance different frequency reactions being created by the driven element along its length.. 😎

OK, fellas.. You just heard a big 'ol Hillbilly Brain Fart. You can bet I'm gonna be building one! Mine will be crude but you guys with that fancy equipment could refine one just fine! Let's git on it! 😉

Quote.. bradleypnw

I'm not sure enclosures increase bass.

I can agree.. but an enclosure (be it ever so subtle) that can help "Focus" or direct sound towards an intended direction does help. Not an enclosed type but a calculated surface to reflect from, beyond items in a room.. (Think slightly concave surface behind the unit) Frequency reflections can be adjusted with sound absorbing materials, like adding scrub pads around the baffle of a tweeter..

You made another magical statement that I agree with..

"Longer panel length, even despite narrow width, increases bass."

This thought is the basis of my next experiment. Most everyone constructs panels with one surface being the primary emitter of sound when both surfaces can emit equally without cancelation. The nulls are at the edge of both surfaces on both sides, top and bottom..

What "IF" a long, somewhat narrow panel was used with one side edge facing the back, or towards the wall and the other edge facing away, or towards the listening area? Emitting left and right! A totally different approach! One side edge null will be towards the wall so a surround of some type could be used to support the panel without much loss. Same for the side edge facing the desired listening area. Not much ceiling or floor reflections to worry about from the driven element on top and bottom. Width change could be used for different frequency response along the length. Chambers, elements, cavities or whatever could be designed to control or enhance different frequency reactions being created by the driven element along its length.. 😎

OK, fellas.. You just heard a big 'ol Hillbilly Brain Fart. You can bet I'm gonna be building one! Mine will be crude but you guys with that fancy equipment could refine one just fine! Let's git on it! 😉

Now this pic basically shows you one way of how to mount said panel material to a frame.

If he had added a spline/brace to hold the exciter in place then it would be more similar to a BMR design like Ive mentioned before.

OGKG

Did you ever try the same panels just hanging from strings or similar? And if so, how did their performance differ?

DMBLES,

How would being more like a BMR design be advantageous?

Thanks,

Eric

I've been reading through the old patents and patent applications, and many show the transducer and panel both mounted to the same frame. My assumption is that the primary reason for that is that the exciters at that time were much larger and massive than what we have now, and that simply gluing them to the panel was not really feasible. But now that we have relatively lightweight exciters, simply attaching them to the panel without external support can be just as good as supporting them with a frame. Is this correct, or am I missing something?

Eric

Eric

Last edited:

As I mentioned, I've been reading the patents. Overall, I'm really disappointed in how much they actually teach, but perhaps I should not be surprised at that...

But the Warnaka patent filed in 1962 was interesting. It contends that the main condition for efficient reproduction of low frequency music is having a panel with a sufficiently high ratio of stiffness to mass. Panel size is not indicated as critical.

Until now, I've been assuming that producing low frequencies would require a large panel whose fundamental natural vibration was at least as low as the target low for the speaker. Or even that say the fundamental natural frequency of the panel had to be some fraction (1/2? 1/10?) of the minimum frequency you hoped to achieve.

Is the Warnake "critical frequency" calculation still considered valid for DML speakers?

But the Warnaka patent filed in 1962 was interesting. It contends that the main condition for efficient reproduction of low frequency music is having a panel with a sufficiently high ratio of stiffness to mass. Panel size is not indicated as critical.

Until now, I've been assuming that producing low frequencies would require a large panel whose fundamental natural vibration was at least as low as the target low for the speaker. Or even that say the fundamental natural frequency of the panel had to be some fraction (1/2? 1/10?) of the minimum frequency you hoped to achieve.

Is the Warnake "critical frequency" calculation still considered valid for DML speakers?

DMBLES,

How would being more like a BMR design be advantageous?

But now that we have relatively lightweight exciters, simply attaching them to the panel without external support can be just as good as supporting them with a frame. Is this correct, or am I missing something?

Thanks,

Eric

The voice coil is the weakest part of the speaker its not meant to hold much weight. In a conventional cone driver the diaphragm and magnet is held by the plastic or metal basket which acts as the frame and spline to add support so that the voice coil wont have to bare much weight.

With free floating exciters it has to bear the weight of not only the diaphragm material/panel but the weight of there own magnet.

By adding a surround to the panel material attached to a frame will take the weight off of the panel material and a spline/brace will take the weight off the exciters magnet. Basically like a BMR driver. Another reason for the spline/brace is that the exciter needs something to push off of so that all the energy is transferred to the coil into the panel material. Without a spline or brace the magnet itself moves and this results in a loss of energy transfer to the panel diaphragm. With a spline/brace the magnet does not move therefore all the energy is transferred to the panel. Those are the advantages of a BMR driver as its basically the design.

As I mentioned, I've been reading the patents. Overall, I'm really disappointed in how much they actually teach, but perhaps I should not be surprised at that...

But the Warnaka patent filed in 1962 was interesting. It contends that the main condition for efficient reproduction of low frequency music is having a panel with a sufficiently high ratio of stiffness to mass. Panel size is not indicated as critical.

Until now, I've been assuming that producing low frequencies would require a large panel whose fundamental natural vibration was at least as low as the target low for the speaker. Or even that say the fundamental natural frequency of the panel had to be some fraction (1/2? 1/10?) of the minimum frequency you hoped to achieve.

Is the Warnake "critical frequency" calculation still considered valid for DML speakers?

A panel should be very stiff but at the same time very LIGHT. Hence why the higher grades of XPS and EPS and Honey comb composites make for a good sounding panel because they are stiff but at the same time light. When choosing a panel material make sure these two qualities come into play.

To produce low frequencies there is a limit to how small a panel can be before low frequencies are effected. There is also a limit as to how large a panel can be before lows as well as high frequencies are affected.

It seems some are over thinking things instead of using the KISS method.

Physics involved with low frequencies are the same with conventional cone drivers as well as DML/BMR drivers/panels. A single 3inch conventional cone driver cannot physically produce as much bass as a single 12inch conventional cone driver and same goes for a 3inch DML panel cannot produce as much lows as a 12inch DML panel its just plain ole physics.

Conventional cone line arrays on the other hand are slightly different as you can use many multiple small drivers to increase the bass out put. Also the larger the cone area the more lower frequencies it can generate. Its no different in a DML line array where more exciters used even on a narrower panel will result in more bass output. When DML panel size is increased in a line array the lower they will play.

OffGrid thats a very sound proposal! I used to mount my old electrostatics side on to the wall and it did indeed boost the bass. I might give that a try with DML's and see what happens.

P.S. Out of interest what is a poor honest Hillbilly doing in Ohio?

P.S. Out of interest what is a poor honest Hillbilly doing in Ohio?

OffGridKindaGuy you got me thinking.

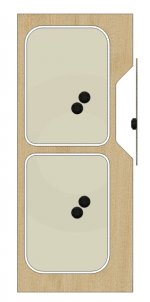

I was planning a pair of small DML's for the TV with a subwoofer but maybe something like this would work? I have a couple of bass panels with two exciters per panel cut from a single sheet of ply with a mid/high panel on the front. That way as DMLBES suggested you can choose materials and exciter numbers to suit the task. All run full range letting the panels sort out the frequency response. Just a riff on your excellent idea.

I was planning a pair of small DML's for the TV with a subwoofer but maybe something like this would work? I have a couple of bass panels with two exciters per panel cut from a single sheet of ply with a mid/high panel on the front. That way as DMLBES suggested you can choose materials and exciter numbers to suit the task. All run full range letting the panels sort out the frequency response. Just a riff on your excellent idea.

Attachments

It seems some are over thinking things instead of using the KISS method.

You couldn't mean ME! Haha, actually overthinking is what I do best!

But to be fair (to me), I need something to do while I'm waiting for my exciters to arrive, and thinking (and overthinking) doesn't seem like a bad thing to do in the meantime.

By adding a surround to the panel material attached to a frame will take the weight off of the panel material and a spline/brace will take the weight off the exciters magnet. Basically like a BMR driver. Another reason for the spline/brace is that the exciter needs something to push off of so that all the energy is transferred to the coil into the panel material. Without a spline or brace the magnet itself moves and this results in a loss of energy transfer to the panel diaphragm. With a spline/brace the magnet does not move therefore all the energy is transferred to the panel. Those are the advantages of a BMR driver as its basically the design.

That all makes sense to me.

Wouldn't the KISS principle say hang the panels from a pair of strings, glue the exciter to your favorite spot and your done, right?

But I gather instead that you think supporting the panel and exciter(s) on a common frame is worth the extra complication that it adds. Is that correct?

Thanks,

Eric

Yes through out the years I have built many prototype DML panels.

My favorite designs are ones that use a Frame to support the panel material and a brace/spline to support the exciter in place. They are basically Floor standing DML panels, instead of the hanging from the ceiling by a string.

My question already answered!

The voice coil is the weakest part of the speaker its not meant to hold much weight. In a conventional cone driver the diaphragm and magnet is held by the plastic or metal basket which acts as the frame and spline to add support so that the voice coil wont have to bare much weight.

With free floating exciters it has to bear the weight of not only the diaphragm material/panel but the weight of there own magnet.

By adding a surround to the panel material attached to a frame will take the weight off of the panel material and a spline/brace will take the weight off the exciters magnet. Basically like a BMR driver. Another reason for the spline/brace is that the exciter needs something to push off of so that all the energy is transferred to the coil into the panel material. Without a spline or brace the magnet itself moves and this results in a loss of energy transfer to the panel diaphragm. With a spline/brace the magnet does not move therefore all the energy is transferred to the panel. Those are the advantages of a BMR driver as its basically the design.

Hmm, sounds a lot like this patent:

https://patentimages.storage.googleapis.com/51/48/36/1ddccf0a605929/US6144746.pdf

Width change could be used for different frequency response along the length.

Size in one dimension influences frequency (longer = lower.) Size in two dimensions influences sound pressure level (wider = louder.) But that's a simplified explanation. You can impact frequency and SPL in other ways such as adding more exciters to put more energy into a given panel. You can also design panel mass and actuator geometry to create pistonic movement rather than modal.

At one time there was a web site that had an interactive DML dimension calculator. I think the guys at Tech Ingredients ran it but I can't find it now.

The elephant in the room, however, is the room itself. If you're building live sound reinforcement panels (pro audio for live concerts) then you'd want to pursue low frequencies in your design. For example, Tectonic DMLs are primarily designed for pro audio. They need low frequency reproduction in their panels.

In your home, mid and high frequency speaker placement and characteristics are different from bass frequency speaker placement and characteristics.

You can design bass DMLs, but why are you doing it? One answer might be that you want to hide your bass speakers in the wall. In that case you're taking advantage of the thin geometry of a DML, you're getting rid of a subwoofer box. On the other hand, you might want a traditional sub woofer box for whatever reason. In small rooms, bass frequencies are modal. Your speaker type won't change how physically long bass frequencies behave and won't change how your brain processes those frequencies.

At mids and highs, DMLs are analogous to wave guides in a certain respect. Wave guides try to physically direct sound waves to prevent the influence of reflections. DMLs take advantage of your brain processing (psychoacoustics) to prevent the influence of reflections. Wave guides try to physically prevent early reflections from hitting your ear. DMLs overwhelm your ear and your brain filters it out. But just like waveguides can't help you with bass frequencies, neither can DMLs. Of course, as mentioned above, you might prefer the visual characteristics of a bass frequency DML.

You couldn't mean ME! Haha, actually overthinking is what I do best!

But to be fair (to me), I need something to do while I'm waiting for my exciters to arrive, and thinking (and overthinking) doesn't seem like a bad thing to do in the meantime.

That all makes sense to me.

Wouldn't the KISS principle say hang the panels from a pair of strings, glue the exciter to your favorite spot and your done, right?

But I gather instead that you think supporting the panel and exciter(s) on a common frame is worth the extra complication that it adds. Is that correct?

Hmm, sounds a lot like this patent:

https://patentimages.storage.googlea.../US6144746.pdf

Thanks,

Eric

I mean in general not just to you. The reason I mentioned the KISS method is because exciters are not really that different then conventional cone drivers when it comes to certain physical aspects like I mentioned before. There is a simple foundation to conventional cone drivers which utilize a plastic or metal basket that supports the cone diaphragm and magnet in place as one single unit. This same foundation is applied to DML's panels utilizing what is known as a BMR design which basically uses the design of a conventional cone driver.

Yes that patent basically uses a BMR design as its foundation. Although that patent is nothing new as BMR design has been utilized since the 60's or earlier.

I forgot to mention that I have never heard of any commercialized DML type of loudspeaker that hangs there panels by a string.

Last edited:

I forgot to mention that I have never heard of any commercialized DML type of loudspeaker that hangs there panels by a string.

Yes, I noticed that too. And I wonder if that is because there is a good technical reason for that, or if it is more about marketing. That is, is it because there is a real performance advantage to having a frame to support the panel and/or exciter, or is it simply because people expect to be able to set the speakers they purchase on the floor (or table, or bookcase), and don't expect to have to hang them from wires?

Are you sure it's the former (technical advantage) and not the latter (marketing motivation), that is the reason for the lack of commercial designs with strings?

Eric

Yes, I noticed that too. And I wonder if that is because there is a good technical reason for that, or if it is more about marketing. That is, is it because there is a real performance advantage to having a frame to support the panel and/or exciter, or is it simply because people expect to be able to set the speakers they purchase on the floor (or table, or bookcase), and don't expect to have to hang them from wires?

Are you sure it's the former (technical advantage) and not the latter (marketing motivation), that is the reason for the lack of commercial designs with strings?

Eric

I've already explained the technical advantages of utilizing a frame and a spline by preventing voice coil sag and the transfer of energy from stabilizing the magnet. These are real world mechanical advantages that actually matter and work, they are not marketing schemes.

Placement convenience is only a secondary advantage to the mechanical advantages of using a frame and spline mentioned above.

Yes I am sure its the former (technical) and not the latter (marketing) as the reason for the lack (if any at all) of commercial designs with strings.

Even the link you posted of the patent uses a frame and a spline.

What I want to know is what is the reason for your doubts about using a frame and a spline? (Besides the influence of Tech Ingredients videos.) LOL

I've already explained the technical advantages of utilizing a frame and a spline by preventing voice coil sag and the transfer of energy from stabilizing the magnet. These are real world mechanical advantages that actually matter and work, they are not marketing schemes.

Placement convenience is only a secondary advantage to the mechanical advantages of using a frame and spline mentioned above.

Yes I am sure its the former (technical) and not the latter (marketing) as the reason for the lack (if any at all) of commercial designs with strings.

Even the link you posted of the patent uses a frame and a spline.

What I want to know is what is the reason for your doubts about using a frame and a spline? (Besides the influence of Tech Ingredients videos.) LOL

I think that the frame and spine approach makes perfect sense and I intend to build one soon. If you can get away with it hanging the panels it is a very fast way of getting going which is what I did as an experiment, but carefully absorption of the vibration at the edges of the panel and increasing energy input into the panels has to make sense.

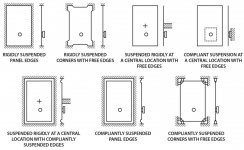

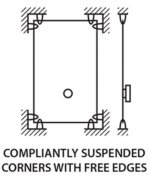

Frames, edge dampening, and panel suspension are all different things. Frames are mostly protection for shipping and handling as well as cosmetic. Edge dampening, in contrast, influences panel modulation. The goal of dampening is to encourage the panel to vibrate as randomly as possible by controlling edge reflections. However, edge dampening isn't the only way to encourage random modal behavior. For example, one common alternative is to round the corners of the panel.

Finally, the panel can be suspended in various ways, too. Even from the center as you can see in the image attachment. (source: Dayton Audio Exciters Buyers Guide)

Suspending a panel with strings is one option among many. If you think it looks nice to suspend your speakers in the air, do it. If you like how suspending your panel in a frame looks, do it. Then, choose a dampening strategy that works with your choice.

Once you understand the various methods and what they accomplish you'll have a lot more flexibility in your design. The Dayton Audio site is an excellent source of good DML information. When you see Dayton's notes about bass in their reference just remind yourself that you might not need bass in your DML.

Finally, the panel can be suspended in various ways, too. Even from the center as you can see in the image attachment. (source: Dayton Audio Exciters Buyers Guide)

Suspending a panel with strings is one option among many. If you think it looks nice to suspend your speakers in the air, do it. If you like how suspending your panel in a frame looks, do it. Then, choose a dampening strategy that works with your choice.

Once you understand the various methods and what they accomplish you'll have a lot more flexibility in your design. The Dayton Audio site is an excellent source of good DML information. When you see Dayton's notes about bass in their reference just remind yourself that you might not need bass in your DML.

Attachments

DMLBES,

Probably you are getting tired of me making you repeat yourself. Please understand that I very much appreciate and respect your input. Thank you. Please don't think otherwise!

Got it. I will definitely try the frame/spline version.

And that was actually the reason I posted it. I was sharing a source that seemed consistent with your strategy.

Fair question. Notwithstanding your good arguments for the frame/spline, and that patents that appear to support the frame/spline, there seem to be a lot of people that are very happy with their own results without using a frame/spline (yes, I admit including the Tech ingredients videos). Another is the Parts Express DML Flat Panel project. And on top of that, as far as I can tell, the exciters I'm seeing (at least on the Parts Express catalog) don't really appear to be made with a means of attaching them to the spline. Some of them have do have 3 or 4 arms extending out, and if I'm not mistaken you (or someone else maybe) said those were for attaching to a support (i.e. frame/spline) and not the panel. But the more I looked at them and what Parts Express seems to be showing, it looks more like they intend those as extra points to attach to the panel. (If I'm wrong about this please show me an exciter that is clearly meant to be mounted to a frame!)

So, while your arguments for the frame/spline approach make very good sense to me, there's all this other evidence that many people, including the people selling the exciters, don't seem to think the frame/spline is needed. So I'm left wondering how to square this in my mind. Are people simply unaware of the benefits of the frame/spline? Or did they try it and find the difference wasn't significant? Or have the exciters changed some way since the patents were written, and hence somehow made the frame/spline less important?

In any event, I plan to try both approaches (you've convinced me that the frame/spline is worth trying). Plus I plan to be trying different exciters, different panels (maybe making or modifying my own fiberglass or CF foam core panels), moving exciters around, stiffening edges, damping edges, clamping edges, adding masses, modeling modes shapes and playing with every version I can think of until my wife says I have to stop!

Thanks,

Eric

Probably you are getting tired of me making you repeat yourself. Please understand that I very much appreciate and respect your input. Thank you. Please don't think otherwise!

I've already explained the technical advantages of utilizing a frame and a spline by preventing voice coil sag and the transfer of energy from stabilizing the magnet. These are real world mechanical advantages that actually matter and work, they are not marketing schemes.

Got it. I will definitely try the frame/spline version.

Even the link you posted of the patent uses a frame and a spline.

And that was actually the reason I posted it. I was sharing a source that seemed consistent with your strategy.

What I want to know is what is the reason for your doubts about using a frame and a spline? (Besides the influence of Tech Ingredients videos.) LOL

Fair question. Notwithstanding your good arguments for the frame/spline, and that patents that appear to support the frame/spline, there seem to be a lot of people that are very happy with their own results without using a frame/spline (yes, I admit including the Tech ingredients videos). Another is the Parts Express DML Flat Panel project. And on top of that, as far as I can tell, the exciters I'm seeing (at least on the Parts Express catalog) don't really appear to be made with a means of attaching them to the spline. Some of them have do have 3 or 4 arms extending out, and if I'm not mistaken you (or someone else maybe) said those were for attaching to a support (i.e. frame/spline) and not the panel. But the more I looked at them and what Parts Express seems to be showing, it looks more like they intend those as extra points to attach to the panel. (If I'm wrong about this please show me an exciter that is clearly meant to be mounted to a frame!)

So, while your arguments for the frame/spline approach make very good sense to me, there's all this other evidence that many people, including the people selling the exciters, don't seem to think the frame/spline is needed. So I'm left wondering how to square this in my mind. Are people simply unaware of the benefits of the frame/spline? Or did they try it and find the difference wasn't significant? Or have the exciters changed some way since the patents were written, and hence somehow made the frame/spline less important?

In any event, I plan to try both approaches (you've convinced me that the frame/spline is worth trying). Plus I plan to be trying different exciters, different panels (maybe making or modifying my own fiberglass or CF foam core panels), moving exciters around, stiffening edges, damping edges, clamping edges, adding masses, modeling modes shapes and playing with every version I can think of until my wife says I have to stop!

Thanks,

Eric

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker