I'm sorry, but I got those at the local electronic surplus store.

They don't get all that hot, whatever you have is likely enough.

They don't get all that hot, whatever you have is likely enough.

Last edited:

I've searched this thread to find what to use for thermistors at the AC mains inlet, no results. Additionally looking for a value for what appears to be the cap at the ground to chassis point.

Maybe not the inlet at the IEC, but those on the terminal strip in the original post.

Limiting inrush current sounds good and less work than a soft start, but not sure I understand either enough to know if the thermistors have a similar effect as a soft start or if only to prevent arcing.

I see a mystery to me part in ori0nzbelt's BOM - 3300pF ceramic disk capacitor... I'm not building the PSU the same way, but with monolithic bridge rectifiers so don't know which part it is related to.

quoted form the first post:

Maybe not the inlet at the IEC, but those on the terminal strip in the original post.

Limiting inrush current sounds good and less work than a soft start, but not sure I understand either enough to know if the thermistors have a similar effect as a soft start or if only to prevent arcing.

I see a mystery to me part in ori0nzbelt's BOM - 3300pF ceramic disk capacitor... I'm not building the PSU the same way, but with monolithic bridge rectifiers so don't know which part it is related to.

quoted form the first post:

Left to right we have post 1, 2, 3, 4

POST 1 - Transformer primary 'B 0' which will be connected to AC Neutral at post 2, through the thermistor between post 1 and 2.

POST 2 - AC Neutral in (not shown in photo), connected to Transformer primary 'A 0" , a thermistor to post 1, and a line cap to post 3

POST 3 - AC Hot in, connected to transformer primary "B 120", thermistor to post 4, and line cap to post 2

POST 4 - Transformer primary "A 120", connected to AC Hot through the thermistor to post 3

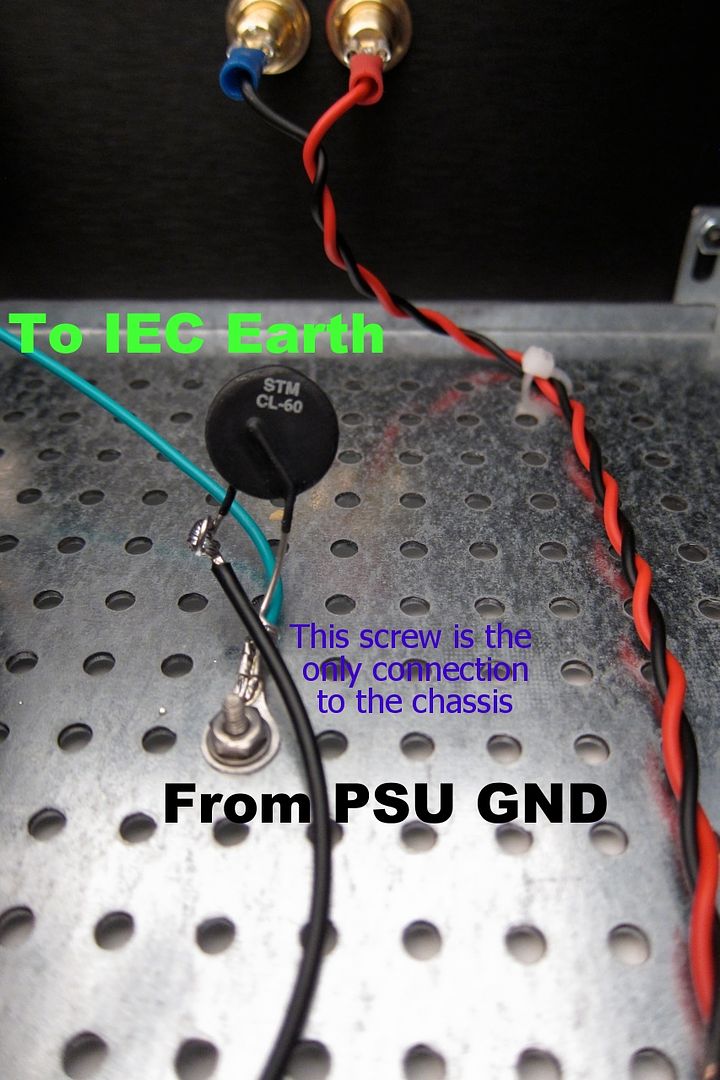

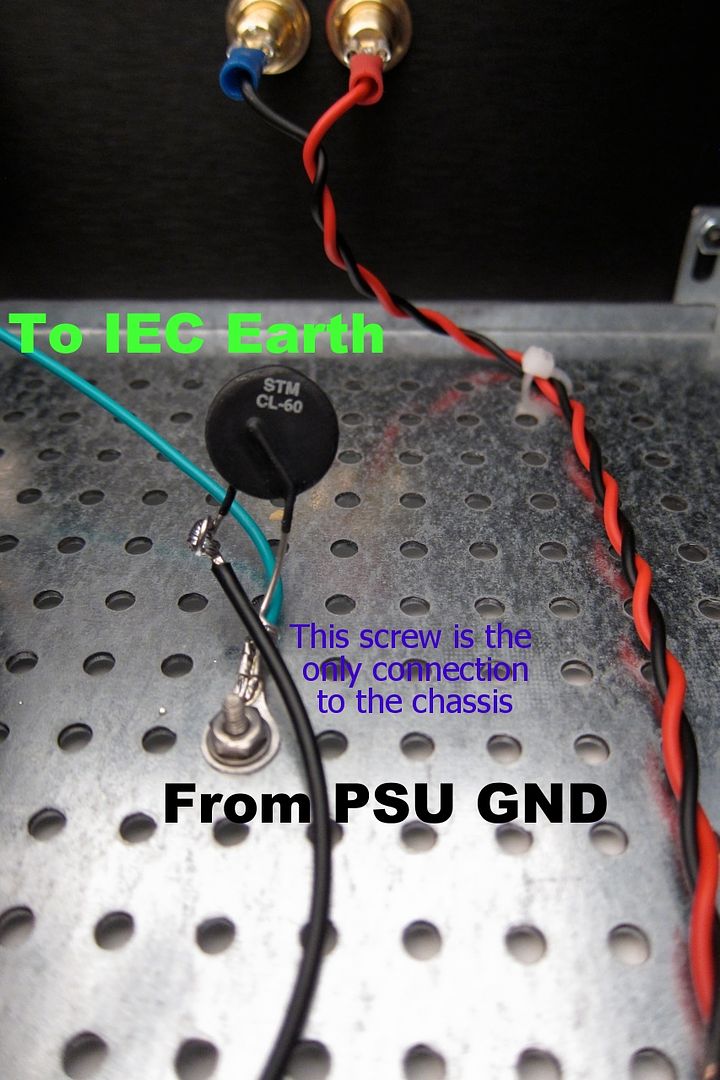

If you look at the red and black wires in the photo you will see that the Mains AC must to pass through a thermistor to connect to each of the 2 primaries. And that is the point of them, to keep inrush under control during power up.

Limiting the starting current with a Power NTC Thermistor is a "Soft Start".Limiting inrush current sounds good and less work than a soft start,

For 110/120Vac mains the CL60 is a good choice for larger transformers.

For 220/240Vac one generally needs a lot more resistance, typically 20r to 100r depending on transformer being started.

BUT !!!!!!

for all these, the performance of the transformer and the following PSU is compromised if the resistance is left permanently in the mains line.

You really should arrange some mechanism to remove the resistance for best Transformer/PSU performance.

You really should arrange some mechanism to remove the resistance for best Transformer/PSU performance.

Nelson doesn't bother in the factory-built Firstwatt amps...

I have a question as I work through my F4 build. I am using the soft start board. If I understand correctly this effectively replaces the two thermistors across the incoming AC.

Thanks for your comments.

David

Thanks for your comments.

David

Hi 6L6

My F4 boards are ready stuffed exception of power transistors.

I always in admiration about yours finished pcb showed in build guides.

What chemicals give such good clean results ?

Greetings 🙂

My F4 boards are ready stuffed exception of power transistors.

I always in admiration about yours finished pcb showed in build guides.

What chemicals give such good clean results ?

Greetings 🙂

Attachments

Many here refer to IPA as India pale ale.I use Isopropanol alcohol, IPA for short.

I use Cardas Quad Eutectic solder, which leaves very little residue.

I also use Kester "44" solder, which has lots of rosin, but I never clean it off... for me, cleaning always makes more of a mess

I also use Kester "44" solder, which has lots of rosin, but I never clean it off... for me, cleaning always makes more of a mess

Thanks @ Mcendmar , Triodethom , Marra and 6L6 for councils and links

Think i try something in between ipa ,aerosol product to see what happen

and next time higher quality solder like Cardas

if i write the letter to Santa Claus 🙂

Now components for power supply

i have four huge caps like this but is to much ?

Greetings

Think i try something in between ipa ,aerosol product to see what happen

and next time higher quality solder like Cardas

if i write the letter to Santa Claus 🙂

Now components for power supply

i have four huge caps like this but is to much ?

Greetings

Attachments

I use Cardas Quad myself and found the complete opposite, it leaves lots of flux gloop behind. curious.

I use Isopropanol alcohol, IPA for short.

Isopropanol is the way to go, together with toothbrush😀

Those are huge! You can make a much bigger amplifier than an F4...

But they will work beautifully!! Power-on inrush will be an issue, make sure you use thermistors or soft-start..

But they will work beautifully!! Power-on inrush will be an issue, make sure you use thermistors or soft-start..

- Home

- Amplifiers

- Pass Labs

- A guide to building the Pass F4 amplifier