Hi

Solhaga beat me posting,

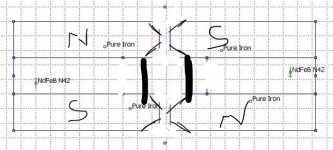

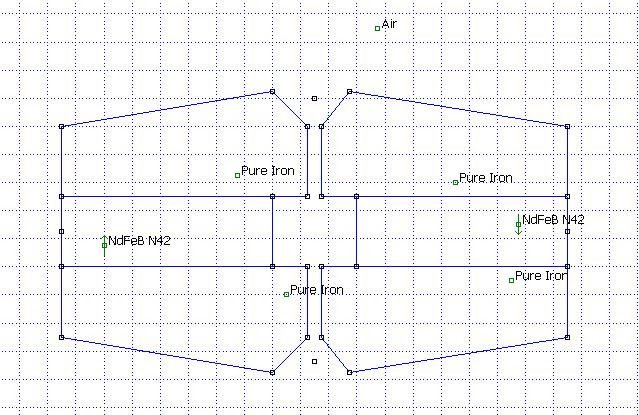

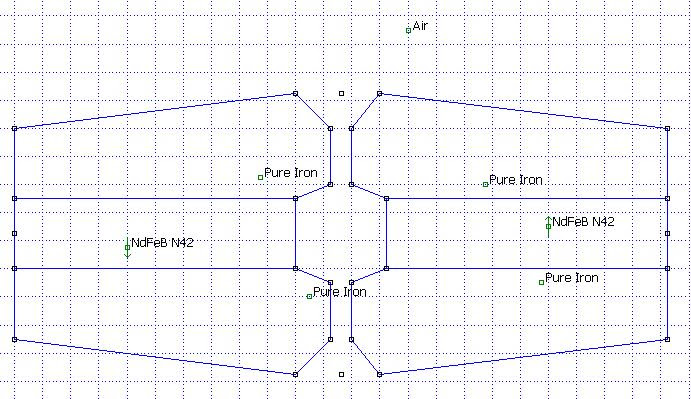

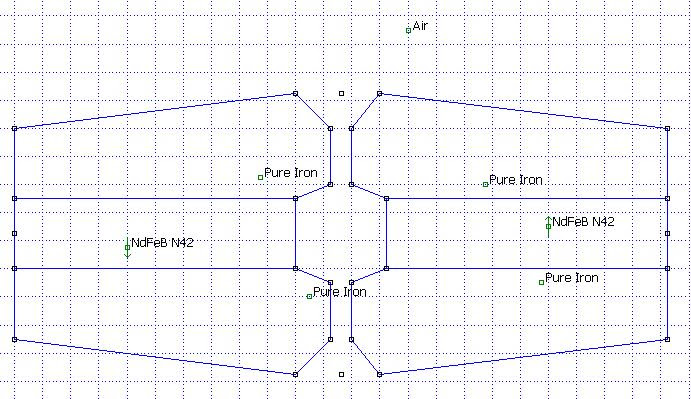

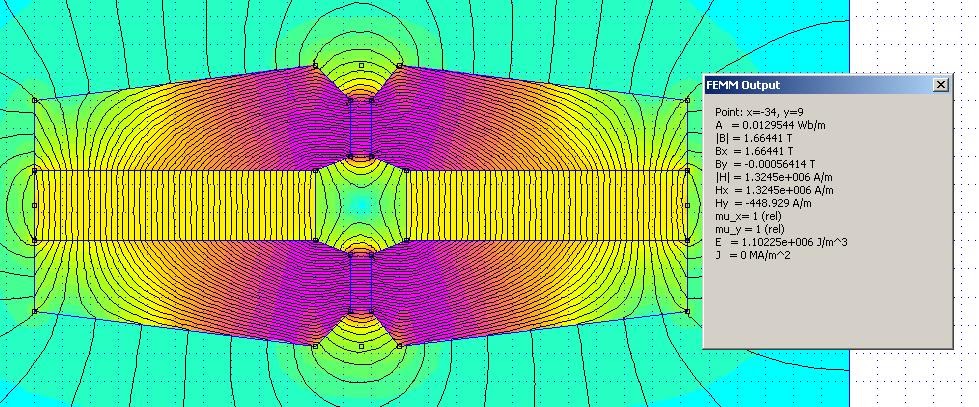

Her my simm. and drawing:

[/url][/IMG]

[/url][/IMG]

2,5 mm gap, and 10x10mm alu 20mm magnet.

App.1T. in gap ,and1,4T in iron.

Bernt

Hello dear colleagues,

Thank you really much for the simulations. I couldnt done it along.

What symulated Bernt above is what i had in mind but believe me 1T is not my target. My target is between 1.4-1.5T or above in the 3mm gap. What would you sugest to achieve these figures. The aluminium bars are therre and acts as a short ring and to help with the aligning process of the magnets but i would eliminate them if necessary. That is why i put the Al bars there my friends.

I dont have a printed coil like our friend Wrine so i want to make one from aluminium like Solhag and others did in the AMT thread or lower awg copper wire...so a 3mm gap is a must.

I want to position the magnets on the long side on the plates, with the 40*20 face facing the plates so that i obtain a 52cm row with 13pcs magnets. The rest of 3cm is for better fixing the plates (1.5 cm above and 1.5 cm bellow) with metric bar screws..

I have at my disposal only "OLC" steel not AISI in Romania. I'm looking to find an OLC carbon substitute for the AISI 1018 steel and a solution to achieve atleast 1.4T my friends.

I really apreciate your help and please help me again with your sims.

Kind regards

Sergiu

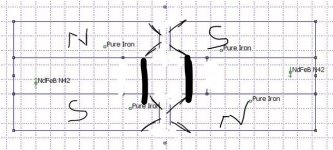

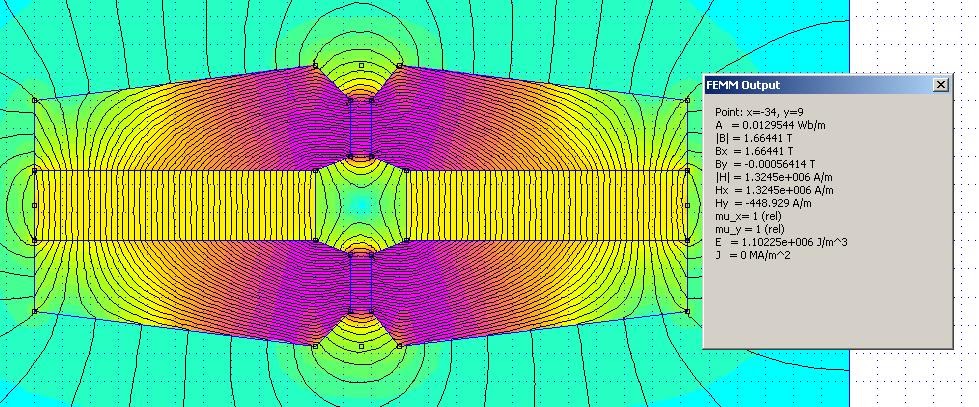

With this kind of configuration:

and with N42 and a 3 mm gap I get 1.32 T,

with N52 and a 3 mm gap I get 1.43 T,

with N42 and a 2 mm gap I get 1.64 T,

and with N52 and a 2 mm gap I get 1.76 T.

Again, easy to simulate but a hell to build:

Also, at these levels, the iron must be more or less carbon free.

and with N42 and a 3 mm gap I get 1.32 T,

with N52 and a 3 mm gap I get 1.43 T,

with N42 and a 2 mm gap I get 1.64 T,

and with N52 and a 2 mm gap I get 1.76 T.

Again, easy to simulate but a hell to build:

Also, at these levels, the iron must be more or less carbon free.

With this kind of configuration:

and with N42 and a 3 mm gap I get 1.32 T,

with N52 and a 3 mm gap I get 1.43 T,

with N42 and a 2 mm gap I get 1.64 T,

and with N52 and a 2 mm gap I get 1.76 T.

Again, easy to simulate but a hell to build:

Also, at these levels, the iron must be more or less carbon free.

Hi Solhaga,

The design is really interesting. Can you simulate it with steel AISI 1017 please?

The equivallent for this steel in OLC15X. Is steel 1017 good for this aplication?

And how about the modification that i did in the picture bellow so that the gap remains at 3mm but the plates are machined from 10 to 8 mm so that the flux gets increased. I want to try thinner 0.16mm square copper wire (it should ensure only 25w power for the speaker and keep a low mass).

Sorry for my bad talent at painting. 🙂

I will post this next week from my phone because i'm out of town on a 1week vacation and dont have acces to a pc.

Wrine, my friend, thank you for the sugestion.

Cheers

Sergiu

Attachments

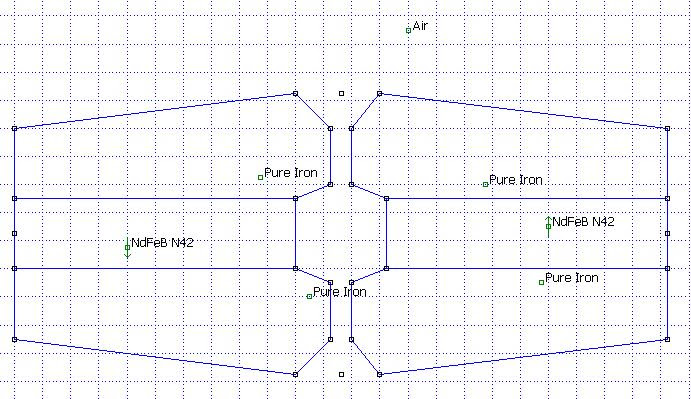

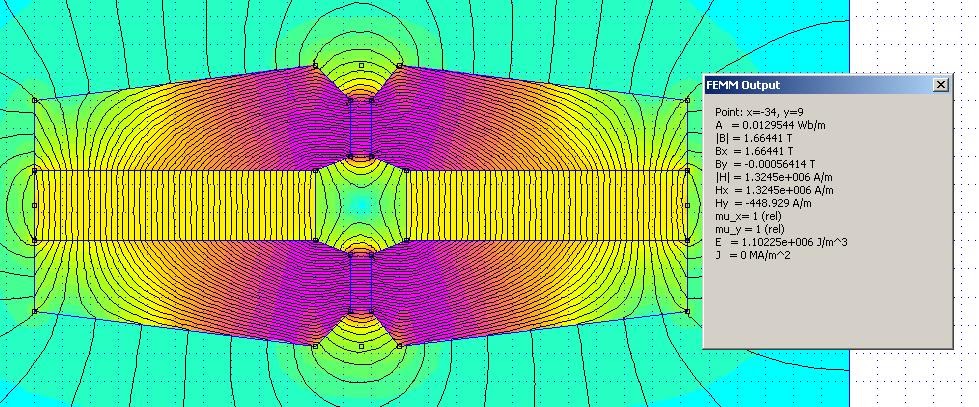

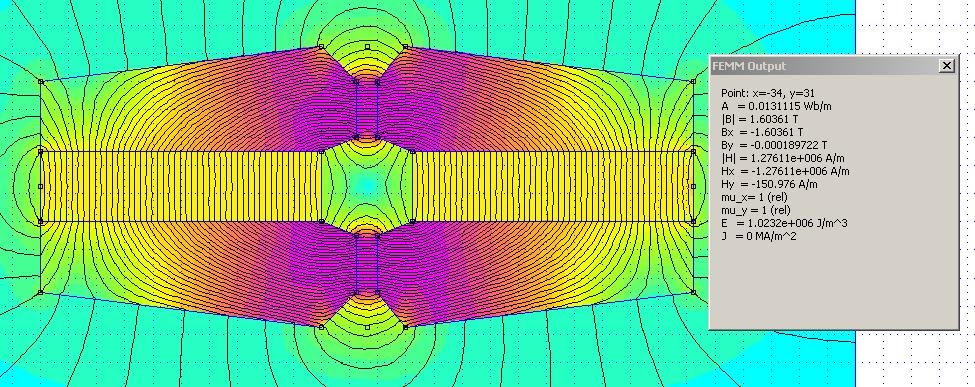

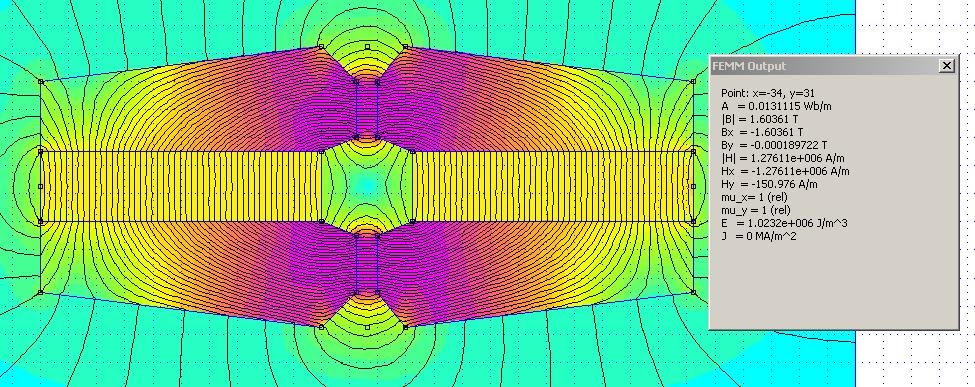

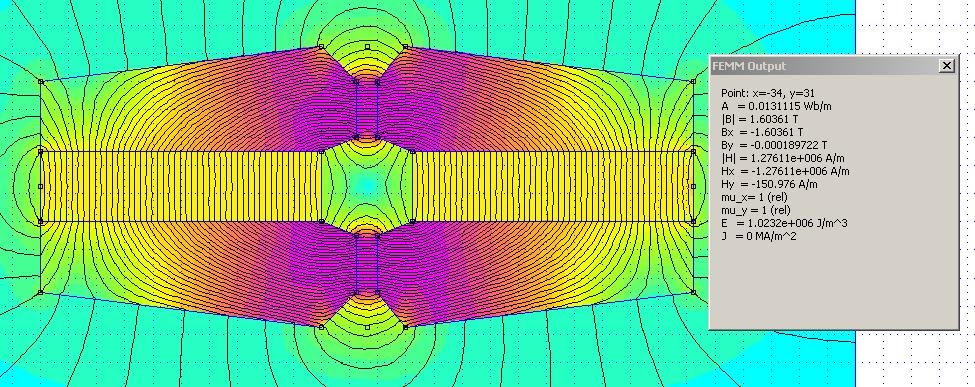

Sorry, I just realized that the Neos only were 30 mm in the simulation.

For the full long side, 40 mm, the configuration will then look like:

with Pure Iron will have a magnetic flux density of well over 1,6 T

and with 1018 Iron it'll still be over 1,6 T.

Didn't have 1017 in my materials library.

For the full long side, 40 mm, the configuration will then look like:

with Pure Iron will have a magnetic flux density of well over 1,6 T

and with 1018 Iron it'll still be over 1,6 T.

Didn't have 1017 in my materials library.

Sorry, I just realized that the Neos only were 30 mm in the simulation.

For the full long side, 40 mm, the configuration will then look like:

with Pure Iron will have a magnetic flux density of well over 1,6 T

and with 1018 Iron it'll still be over 1,6 T.

Didn't have 1017 in my materials library.

thats a nice gain. but also it gets complicated in the iron department.

is it not more easy to increase to use lower magnet flux and taller metal ? this will increase efficiency and extend the low end ?

Btw i've read somewhere that the janus dont reach the 102db but rather 94 according to messurements.

still if i look at the 2 cylinders i cant imagine the comercial version reaches 20khz or looks like shark teeth in the freq response.

i think its weird that 8000 euro speakers dont publish any measurements data, nor any THD.... the physical layout of the 2 cylinders dont allow good high feq response that looks anywhere near a flat response.......

this because its not the exclusive material that determen this but the layout of the cylinders. at least according to my measurements.

to much variables!!! insane 🙂 and fun !

Last edited:

Sorry, I just realized that the Neos only were 30 mm in the simulation.

For the full long side, 40 mm, the configuration will then look like:

with Pure Iron will have a magnetic flux density of well over 1,6 T

and with 1018 Iron it'll still be over 1,6 T.

Didn't have 1017 in my materials library.

Thats what i'm looking for.. Wrine is right, it will be hard to machine those dimesnsions. What are the limitations for the original layout from bellow?

Same dims like in the other one: 55cm long bars by 4cm wide by 1 cm widht.

3 mm gap and milled in a way so that the plates are narrowed from 10mm to 8 mm to increase furthe te flux?

Thank you very much

Sergiu

Attachments

thats a nice gain. but also it gets complicated in the iron department.

is it not more easy to increase to use lower magnet flux and taller metal ? this will increase efficiency and extend the low end ?

Btw i've read somewhere that the janus dont reach the 102db but rather 94 according to messurements.

still if i look at the 2 cylinders i cant imagine the comercial version reaches 20khz or looks like shark teeth in the freq response.

i think its weird that 8000 euro speakers dont publish any measurements data, nor any THD.... the physical layout of the 2 cylinders dont allow good high feq response that looks anywhere near a flat response.......

this because its not the exclusive material that determen this but the layout of the cylinders. at least according to my measurements.

to much variables!!! insane 🙂 and fun !

Hi Wrine,

The rubanoide had 94 dB because it had somehow a "flat" response but the Janus 50 reached 102dB with spikes, dist and resonances and with little damping...

This speaker is really hard to measure. I think you have to measure in just one portion of the frecv range, where is more flat...

Cheers

Sergiu

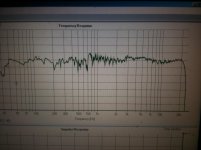

Fast measurement, at 1 meter distrance in my room. its a problem that you cant mic these speakers close since the whole response wil be weird. but its cleary that i get to 20khz 🙂

and small vid, playing with the woofer beside it crossed at 250hz

http://youtu.be/krOQmN5SY4U

as i recal the company of rubanoide said that the janus did not reach 102 dB and theres reached 100dB. all ok for me 🙂 i can live with 90 or so. wich i dont reach yet. but im close. i think i will go bigger again 🙂 so i can use an a4 size paper standing up. so isntead of 210mm 300mm. it should gain a bit efficiency and should be able to go a bit lower. now it drops at 500hz

and small vid, playing with the woofer beside it crossed at 250hz

http://youtu.be/krOQmN5SY4U

as i recal the company of rubanoide said that the janus did not reach 102 dB and theres reached 100dB. all ok for me 🙂 i can live with 90 or so. wich i dont reach yet. but im close. i think i will go bigger again 🙂 so i can use an a4 size paper standing up. so isntead of 210mm 300mm. it should gain a bit efficiency and should be able to go a bit lower. now it drops at 500hz

Attachments

Last edited:

Fast measurement, at 1 meter distrance in my room. its a problem that you cant mic these speakers close since the whole response wil be weird. but its cleary that i get to 20khz 🙂

If this frequency respons is without filtering, except for the low end, then I will congratulate you with this result!!!

According to the specs on the manufacturers websites:

Francois Deminière : 102 dB (janus 50, 70)

Audio Consulting : 103 dB (Dvaijnoy)

AudioNec : 93-96 dB (Diva, Crystal, Response, Reply and Answer)

The last two manufacturers add a supertweeter for the highest end.

Henjo

If this frequency respons is without filtering, except for the low end, then I will congratulate you with this result!!!

According to the specs on the manufacturers websites:

Francois Deminière : 102 dB (janus 50, 70)

Audio Consulting : 103 dB (Dvaijnoy)

AudioNec : 93-96 dB (Diva, Crystal, Response, Reply and Answer)

The last two manufacturers add a supertweeter for the highest end.

Henjo

Thanks, filtering is a low shelf from 350 hz to boost the low end since i had it crossed at 250.

still looking for improvements in the range around 700 and 3 khz, but what ever i do i cant see to change anything there. normally i hiunt the resonance down, but in this case im a bit clueless.

its to bad that there are no measurements of both the janus and the rubanoide. so its a guessing game

its remarkable how well a totally non flat freq response can sound decent. so i think they keep them for themself

Thanks, filtering is a low shelf from 350 hz to boost the low end since i had it crossed at 250.

still looking for improvements in the range around 700 and 3 khz, but what ever i do i cant see to change anything there. normally i hiunt the resonance down, but in this case im a bit clueless.

its to bad that there are no measurements of both the janus and the rubanoide. so its a guessing game

its remarkable how well a totally non flat freq response can sound decent. so i think they keep them for themself

As you see on page 20 of this thread I posted a heavy DSP-ed frequency response. From my experience it sounded more coherent then my unfiltered version.

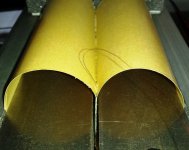

I am playing now with two models:

1- 300 mm in height with 200 gramms paper

2- 130 mm in height with 60 gramms paper

In the latest model the voice coil is sandwiched between the paper and reinforced with carbon, to keep it all straight in the gap.

The next step is to measure the speed of sound in the paper to cancel out the resonances.

Last edited:

As you see on page 20 of this thread I posted a heavy DSP-ed frequency response. From my experience it sounded more coherent then my unfiltered version.

I am playing now with two models:

1- 300 mm in height with 200 gramms paper

2- 130 mm in height with 60 gramms paper

In the latest model the voice coil is sandwiched between the paper and reinforced with carbon, to keep it all straight in the gap.

View attachment 492158

The next step is to measure the speed of sound in the paper to cancel out the resonances.

Hi Henjo,

Did you noticed the cut on the steel bars on the Janus 50 version preciselly above an bellow the magnets. I wonder if they were done to increase the flux in the gap.. Its on youtube on the presentation film with mr Francois Deminiere.What do you say, am i right or am i rong?

You work is interesting and promising. Can you post some thoughts and findings?

Sergiu

Last edited:

Hi Henjo,

Did you noticed the cut on the steel bars on the Janus 50 version preciselly above an bellow the magnets. I wonder if they were done to increase the flux in the gap.. Its on youtube on the presentation film with mr Francois Deminiere.What do you say, am i right or am i rong?

You work is interesting and promising. Can you post some thoughts and findings?

Sergiu

I'm going to look at it.

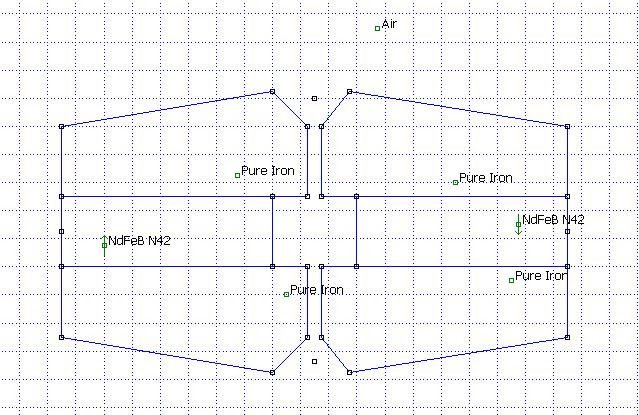

Increase the flux is not always where you looking for.

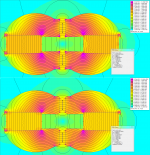

Here is a simulation of a more complex model.

The amount of iron is optimized and the magnets are sliding in a slot otherwise it is impossible to assemble the loudspeaker, without losing a few fingers.

The shape of the strip at the front (flux direction) is optimized for constant flux in the voice coil between +2/-2 mm stroke.

I don’t know if you use a underhung or overhung motor.

I am assumed to be underhung.

Henjo

Fast measurement, at 1 meter distrance in my room. its a problem that you cant mic these speakers close since the whole response wil be weird. but its cleary that i get to 20khz 🙂

and small vid, playing with the woofer beside it crossed at 250hz

http://youtu.be/krOQmN5SY4U

as i recal the company of rubanoide said that the janus did not reach 102 dB and theres reached 100dB. all ok for me 🙂 i can live with 90 or so. wich i dont reach yet. but im close. i think i will go bigger again 🙂 so i can use an a4 size paper standing up. so isntead of 210mm 300mm. it should gain a bit efficiency and should be able to go a bit lower. now it drops at 500hz

Hello my friend,

There is a comercial version of this speaker that has 94dB, i dont know wich model they are. The french guys from a forum did measure them and sayed that it really has 94dB and the Janus 50 has aprox 98dB with 4 mm gap. They also say that if you lower to 3mm the gap then you can achieve 101dB. Interesting...

Anyway for me 94-96dB is sufficient..

Again congrats for the project Wrine. It looks really good and measures really ok.

Cheers

Sergiu

As you see on page 20 of this thread I posted a heavy DSP-ed frequency response. From my experience it sounded more coherent then my unfiltered version.

I am playing now with two models:

1- 300 mm in height with 200 gramms paper

2- 130 mm in height with 60 gramms paper

In the latest model the voice coil is sandwiched between the paper and reinforced with carbon, to keep it all straight in the gap.

View attachment 492158

The next step is to measure the speed of sound in the paper to cancel out the resonances.

nice what glue did you used to sandwich ? since i want a glue that dries hard. and super glue sets a bit to fast for my taste 🙂

I'm going to look at it.

Increase the flux is not always where you looking for.

Here is a simulation of a more complex model.

The amount of iron is optimized and the magnets are sliding in a slot otherwise it is impossible to assemble the loudspeaker, without losing a few fingers.

The shape of the strip at the front (flux direction) is optimized for constant flux in the voice coil between +2/-2 mm stroke.

I don’t know if you use a underhung or overhung motor.

I am assumed to be underhung.

View attachment 492163

Henjo

Hello Henjo,

Thanks for the simulation, but i have to tell you that these special machined designs are a no go for me. I called today for a friend of mine and he sayed that he cannot mille like that or something like Solhaga symulated. I have my hands bonded to the original design. 🙁 I dont have any solutions and dont know anyone who can do this type of machining. I am very dissapointed. 🙁

Can you tell me what is the limit of the design that i attached bellow.

Yes i want to give it a try with underhung design.

I want to machine the steel on the edges like in the picture bellow so that i reduce the plate from 10 to 8 mm to increase the flux.

How close can i aproach the magnets of the egde of the plates without the aparition of saturation?

Thanks in advance.

Sergiu

Attachments

Hi Henjo,

Did you noticed the cut on the steel bars on the Janus 50 version preciselly above an bellow the magnets. I wonder if they were done to increase the flux in the gap. Its on youtube on the presentation film with mr Francois Deminiere.

Sergiu

Hi Sergui,

As expected it has hardly no influence.

Here is what I simulated.

Henjo

nice what glue did you used to sandwich ? since i want a glue that dries hard. and super glue sets a bit to fast for my taste 🙂

Carbon fiber with epoxy resin.

Hello Henjo,

Thanks for the simulation, but i have to tell you that these special machined designs are a no go for me. I called today for a friend of mine and he sayed that he cannot mille like that or something like Solhaga symulated. I have my hands bonded to the original design. 🙁 I dont have any solutions and dont know anyone who can do this type of machining. I am very dissapointed. 🙁

Can you tell me what is the limit of the design that i attached bellow.

Yes i want to give it a try with underhung design.

I want to machine the steel on the edges like in the picture bellow so that i reduce the plate from 10 to 8 mm to increase the flux.

How close can i aproach the magnets of the egde of the plates without the aparition of saturation?

Thanks in advance.

Sergiu

Related to the mechanical part it depends on your milling skills and possibilities. The slot for the magnets is a must, one way or the other.

About the magnetic part. What frequency range do you want to cover?

At the lower frequency end you need to know the maximum excursion.

The width of your voice coil + the PP excursion must be at least the width of the lineair flux area. Does it fit in 8 mm?

If not you get non lineair distortion!

I will try to make it less complex.

If there's someone who wants to fiddle with the FEMM files.

Let me know and I'll post them.

Henjo

I want to machine the steel on the edges like in the picture bellow so that i reduce the plate from 10 to 8 mm to increase the flux.

How close can i aproach the magnets of the egde of the plates without the aparition of saturation?

Thanks in advance.

Sergiu

Here's your answer:

3% benefit in flux density and 2 mm less lineair excursion.

It's up to you.

Henjo

- Home

- Loudspeakers

- Planars & Exotics

- A DIY Ribbon Speaker of a different Kind