Post a drawing of the magnetsystem and I simulate it with FEMM.

Bernt "Båndsei"

this is directed to sergiu2009 i guess 🙂

well got my nomex today... made a new one and results are weird.

High frequencys is worse. does not extend as far as i would like.

but with some damping the low end improved allot, 0.230% distortion from 200 to 20Khz acording to REW.

but a ragged feq response. i even cutted holes in between the coil according to the patent. this results in nothing! i did notice that when you make the cylinders smaller so it does not look like a cylinder it flatten some of the weird dips in the high freq. i might need to make a new version with the normal cheap 120grams paper or 80 grams paper and make the clambs further appart.

what a werid project 🙂 i starting to believe that the comercial versions dont have measurements for a reason 🙂

heee am i the only one playing with this? you got anything going sergiu2009 ? i am still waiting on my nomex 410 5 mill or around 120 micron, witch weighs less then my 120 grams paper but is far more stable!. looking forward to my first try.

i wont change my coil yet. since i got one left and i cant print a new one on the left over copper, its to small for my printer to handle 🙁

nice to see the king of the AMT's following the thread ! 🙂 love ur work! (also the work from bernt ofc)

Hi Wrine,

I finished my modyfied Hiraga super class A amp but i'm waiting for the new radiators to come. I have a temp issue (80degree celsius on the output transistors and 64 on the radiators) with the amp so i just doubled the dissipation area and eliminate the mica washers, and i will use just some thermal grease.

For the speakers:

I'm struglling to simulate with femm our case here but its abit hard. I have the money for the steel but dont know what to buy...

I was thinking about some washy paper for the membranes, so i searched this monday for a recepy but i found that this washy paper its a very laborious thing to do.. The process is done in the winter so its a no go way...

Wrine have you tried rice paper? The rice fiber is diferent from normal paper..

Cheers

Sergiu

Last edited:

Post a drawing of the magnetsystem and I simulate it with FEMM.

Bernt "Båndsei"

Hi Bernt,

I really appreciate you help.

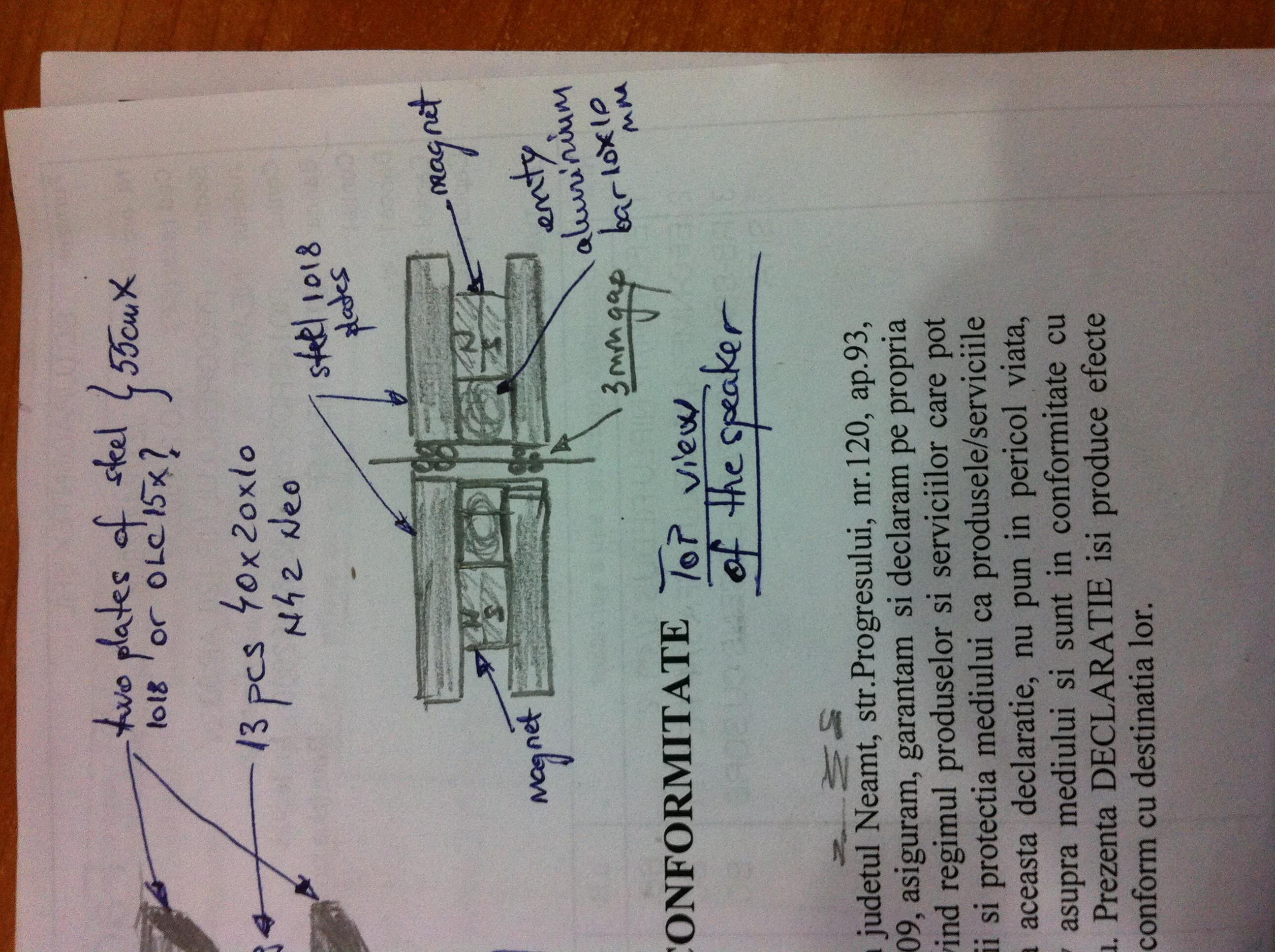

Here you have a first picture.

Here is the assembly in a top view. I want to try a 3 mm gap. I am also curious wich steel is best ( and findable in Romania) for this aplication. In Romania i can only source carbon stell with "OLC" name, not AISI Steel 1018 like in America or A37 steel like in France.

I'll upload one by one because of the old phone from i'm typing right now.

Attachments

Last edited:

Post a drawing of the magnetsystem and I simulate it with FEMM.

Bernt "Båndsei"

Here is the second picture.

The carbon steel plates have 55x4x1 cm

Attachments

Last edited:

this is directed to sergiu2009 i guess 🙂

well got my nomex today... made a new one and results are weird.

High frequencys is worse. does not extend as far as i would like.

but with some damping the low end improved allot, 0.230% distortion from 200 to 20Khz acording to REW.

but a ragged feq response. i even cutted holes in between the coil according to the patent. this results in nothing! i did notice that when you make the cylinders smaller so it does not look like a cylinder it flatten some of the weird dips in the high freq. i might need to make a new version with the normal cheap 120grams paper or 80 grams paper and make the clambs further appart.

what a werid project 🙂 i starting to believe that the comercial versions dont have measurements for a reason 🙂

Hello Wrine my friend,

Congrats for results. Your findings are very interesting. I'm starting to think that the cuts from the patent will make some improvements for a bigger version of this speaker, your membrane is allready light because of the low dimensions.

What happends when you put the elastic as close as possible to the coil? What is limited in this situation? And what happends when you tighten the elastic harder?

0.23% is allready a very good figure my friend compared to traditional speakers congratulations. How would you describe the sound? Can you post some pictures of how is the speaker looking now?

🙂 now we know why... 😉 the only ones that had at a moment some measurements where the Lineum speakers wich where really something to relly on.

Someone said on the french Janus 50 site that i finished reading that you have to listen to this speaker and not measure.

Another question i have here for you Wrine, do you hear these resonances badly or is just something that you measured and can move on and live on with this?

Cheers

Sergiu

Last edited:

Hee in your drawing why is the alumnium bar ? ive seen it in the Janus design but i wondered why its there since its not doing anything ? or am i missing something. i rather occupy that space with magnet or use less iron. (if possible with your magnets, wich could be some saturation problems)

ok next thing.

could be indeed, but i recon its not a big deal.

ok next thing.

Hello Wrine my friend,

Congrats for results. Your findings are very interesting. I'm starting to think that the cuts from the patent will make some improvements for a bigger version of this speaker, your membrane is allready light because of the low dimensions.

could be indeed, but i recon its not a big deal.

What happends when you put the elastic as close as possible to the coil? What is limited in this situation? And what happends when you tighten the elastic harder?

[QUOTE/]

adding tension does not do anything to the frequency response, weird enough. since i retension them every now and then since one elastic slipped or something (or all) and when i measure the curve is exactly the same. it will do something to high excursion , it will then limit that at the cost of dirstortion when you reach the limit.

0.23% is allready a very good figure my friend compared to traditional speakers congratulations. How would you describe the sound? Can you post some pictures of how is the speaker looking now?

🙂 now we know why... 😉 the only ones that had at a moment some measurements where the Lineum speakers wich where really something to relly on.

Someone said on the french Janus 50 site that i finished reading that you have to listen to this speaker and not measure.

[QUOTE/]

well i do find it sounding pretty Ok most of the times, BUT i cant stand not measuring, i think that is a bad way of making a speaker. only listen and be done with it. its ofcourse the easy way out. for most people after spending so much money on magnets.

But i made a new membrame this evening with 80 grams paper, a new coil wich i kind of ****** up, its only 3.5 ohms... and made the coil a bit smaller so max 8 mm width instead of the full 1 cm of the magnet gap. i added my favourite foam for windows 🙂 5 pieces, 1 top 1 bot and thre rest equally spaced. i must say this one sounded way beter then the nomex version, and does not drop as quick either. BUT there is still an enormous swing in the high frequencys, im pretty sure its phase issues from the 2 cylinderds .... again. i will trye to add more foam tomorow to make the portion that does the high frequencys narower. and i can try to make the cylinders smaller to the front looks flatter (like 2 but sheeks) instead of 2 cylinders. since both cylinders in the midle emmit high frequencys, they then phase and create a sort of sinewave frequency response in the upper frequencys. 🙂

Another question i have here for you Wrine, do you hear these resonances badly or is just something that you measured and can move on and live on with this?

Cheers

Sergiu

You can sometimes cleary hear them ,and the measurement software not even giving a huge hump, sometimes you dont hear them but when you measure theres huge distortion. think it has to do with 2e harmonics or 3th.

when i hear one i corrected it clearly, and when i see one in the measurement i then play a sinewave at this frequency with a scope(or rew) you can then see the ditortion on screen, just fidl around untill it drops.

as it is now you can live with the resonances since they are hardly there(anymore). it does depend on loudness. if i really put it super loud i bet distortion goes way way up. but ofc my setup does not have 105db efficiency so i really give them hell when i want to play loud.

its by far a flat frequency response, but getting closer and closer.

Pictures are from the nomex membrame, i already removed it since i somhow did not like it. i did ask the seller if he got any 2 and 3 mill nomex instead of the 5mill. and he had 🙂 the 2 mill is like 45 grams m2, and should still be pretty durable.

Attachments

Last edited:

nd a video for funs sake 🙂

https://youtu.be/rRSrCIKSyeA

oh and i will look into the rise paper thing !, but this could be to crinkly.

https://youtu.be/rRSrCIKSyeA

oh and i will look into the rise paper thing !, but this could be to crinkly.

oh i measured the current coil in rew and impedance is around 4.2 Ohm to 5.2 at the top.

thats good 🙂

thats good 🙂

Hi Sergiu.Hi Bernt,

I really appreciate you help.

Here you have a first picture.

Here is the assembly in a top view. I want to try a 3 mm gap. I am also curious wich steel is best ( and findable in Romania) for this aplication. In Romania i can only source carbon stell with "OLC" name, not AISI Steel 1018 like in America or A37 steel like in France.

I'll upload one by one because of the old phone from i'm typing right now.

Forgive me of any ignorance, but this configuration seems more like the one you might want to have for an AMT?

Again, I have probably misinterpreted your drawing, but with this configuration you´ll get no flux density where you intended to.

If I'm wrong, I'd be happy to stand corrected!

Hi,

Sorry for the intervention but the flux of one of the magnets has to be turned 180°.

Regards,

Henjo

Sorry for the intervention but the flux of one of the magnets has to be turned 180°.

Regards,

Henjo

Correct me if I'm wrong!

Although the aluminum prob act as a magnet short ring is demolishes you flus density. You gain only 0,2 -0,3 tesla compared. To my setup. Wich uses magnet 3 times less strong. I use 20x 10 mm steel using 40 is only usefull when you use magnets that are 40x40x10 or something , in my opinion drop the aluminum get thicker metal if needed to not go over 1,6 tesla. Since you gain hardly anything compared to my way cheaper magnets. ?

Try model steel that has the same width as the magnet and you will see. Making the gap hight smaller also gains way les flux then making the gap smaller. Benefit is you can get higher excursion as well.

I tested allot of crao today my 80 grams membrane finally got to 20khz by flaten the cylinders. But the thinner the paper the more resonances in the lower octaves . Then I cutted the menmbrane of the coil and left 20 mm or so of the 80 grams paper an glued 2,replacing membranes from the 5 mill nOmex, since it has a bit better damping, result is that at least the high freq flatens,

There is still allot of crap going on around 860 hz , peak an dips , my gues it has to do with the length or height of the cylinder or paper . Next try I'll try to maken a membrane that has either more height and or width.

See if these peaks shift. Might be able to find an older measurement of a smaller version to see if this theorie holds,

Another theorie is making the cold and the first 2 cm of light paper, then glue thicker paper or nomes on the edge, but using small pieces for instance

Total height decided by 3 (beter would be uneven pieces) glue them on the light papers edge (5 mm or so)

Then use the foam stuf to damp and tape the separate thicker pieces together without them toutching each other.

This way it should be possible to get the resonance out if the region of what this more heavy paPer is capable of of putting out ? Sound plousible 🙂

Although the aluminum prob act as a magnet short ring is demolishes you flus density. You gain only 0,2 -0,3 tesla compared. To my setup. Wich uses magnet 3 times less strong. I use 20x 10 mm steel using 40 is only usefull when you use magnets that are 40x40x10 or something , in my opinion drop the aluminum get thicker metal if needed to not go over 1,6 tesla. Since you gain hardly anything compared to my way cheaper magnets. ?

Try model steel that has the same width as the magnet and you will see. Making the gap hight smaller also gains way les flux then making the gap smaller. Benefit is you can get higher excursion as well.

I tested allot of crao today my 80 grams membrane finally got to 20khz by flaten the cylinders. But the thinner the paper the more resonances in the lower octaves . Then I cutted the menmbrane of the coil and left 20 mm or so of the 80 grams paper an glued 2,replacing membranes from the 5 mill nOmex, since it has a bit better damping, result is that at least the high freq flatens,

There is still allot of crap going on around 860 hz , peak an dips , my gues it has to do with the length or height of the cylinder or paper . Next try I'll try to maken a membrane that has either more height and or width.

See if these peaks shift. Might be able to find an older measurement of a smaller version to see if this theorie holds,

Another theorie is making the cold and the first 2 cm of light paper, then glue thicker paper or nomes on the edge, but using small pieces for instance

Total height decided by 3 (beter would be uneven pieces) glue them on the light papers edge (5 mm or so)

Then use the foam stuf to damp and tape the separate thicker pieces together without them toutching each other.

This way it should be possible to get the resonance out if the region of what this more heavy paPer is capable of of putting out ? Sound plousible 🙂

2,0 T for pure iron.Hi Solhaga,

What is the maximum flux in the iron?

I get the idea that it is far above 1,6 T.

Henjo

Yes, there are for sure some optimizations to be done.Hi Solhaga,

That's why I modified the form of the metal strip.

Otherwise it is not neccesary the buy expensive magnets.

Here is a picture for comparison:

View attachment 491737

Henjo

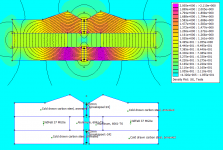

In your configuration the magnets are rotated 90 degrees so that the flux has 40 mm to build instead of 20 mm in sergiu's configuration.

Also, the gap is only 10 mm away from the magnets.

With N42 and no optimized pole pieces:

I get 1,2 T in the gap:

Perhaps some optimizations would give another tenth or two of flux density, but at these flux levels I suspect it is very hard (and unsafe!) to build DIY wise.

Also the iron pole pieces would probably need some machining to get the desired and optimized shape.

Hi

Solhaga beat me posting,

Her my simm. and drawing:

[/url][/IMG]

[/url][/IMG]

[/url][/IMG]

[/url][/IMG]

2,5 mm gap, and 10x10mm alu 20mm magnet.

App.1T. in gap ,and1,4T in iron.

Bernt

Solhaga beat me posting,

Her my simm. and drawing:

2,5 mm gap, and 10x10mm alu 20mm magnet.

App.1T. in gap ,and1,4T in iron.

Bernt

I am sorry, Bernt. But I couldn't wait any longer  .

.

Having aluminium rods on each side of the magnets is a great idea; it should be relatively easy and safe to "load" the tunnel with magnets.

.

.Having aluminium rods on each side of the magnets is a great idea; it should be relatively easy and safe to "load" the tunnel with magnets.

Last edited:

- Home

- Loudspeakers

- Planars & Exotics

- A DIY Ribbon Speaker of a different Kind