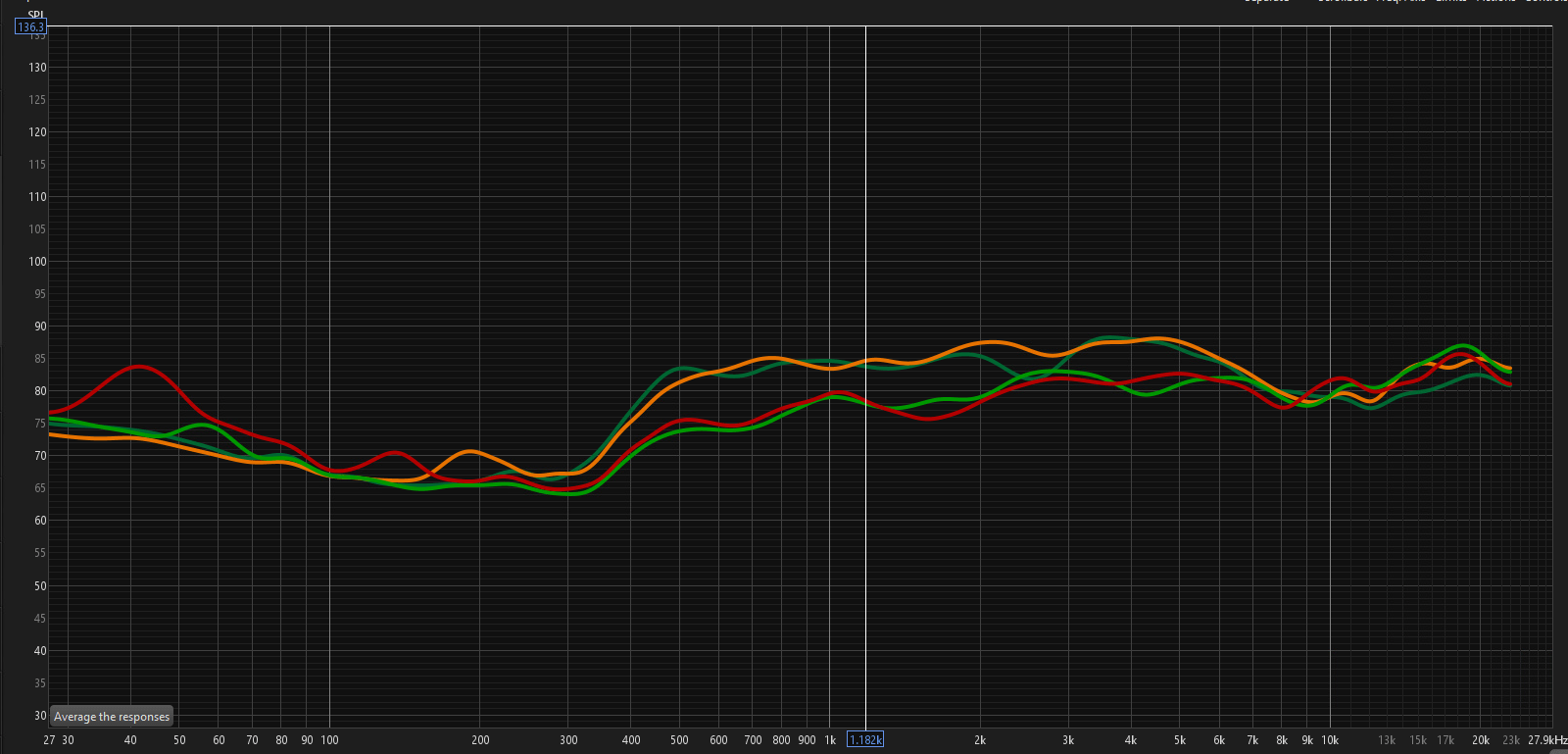

Great result on orange curve adapter. Maybe stuffing got rid of 3.5kHz notch?

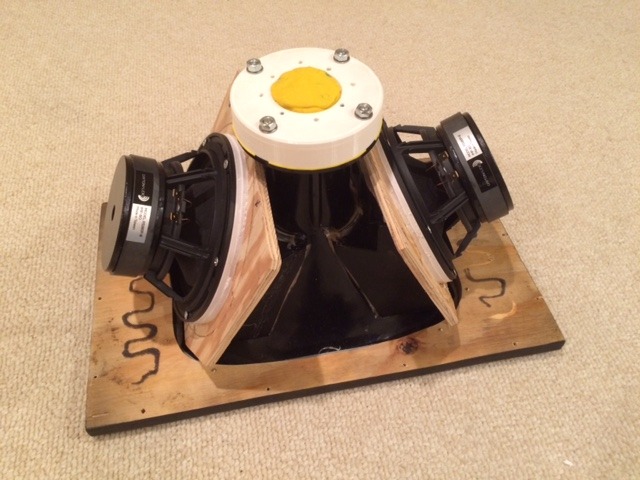

You can fit an 8in woofer by mounting that to a larger piece of plywood then mount that to horn wall. The holes for woofer injection are quite small so you have plenty of room. I would aim for hole area of about 20% to 30% of cone Sd. It can be smaller if you have less need for deeper bass. Make two racetrack shaped oval apertures angled along corner of the horn wall.

Sort of like this but you won’t need such a long adapter plate.

Go ahead and post here if you wish it’s the same spirit and idea as original thread.

You can fit an 8in woofer by mounting that to a larger piece of plywood then mount that to horn wall. The holes for woofer injection are quite small so you have plenty of room. I would aim for hole area of about 20% to 30% of cone Sd. It can be smaller if you have less need for deeper bass. Make two racetrack shaped oval apertures angled along corner of the horn wall.

Sort of like this but you won’t need such a long adapter plate.

Go ahead and post here if you wish it’s the same spirit and idea as original thread.

The Top and bottom wall is straight... inside of the horn ;(

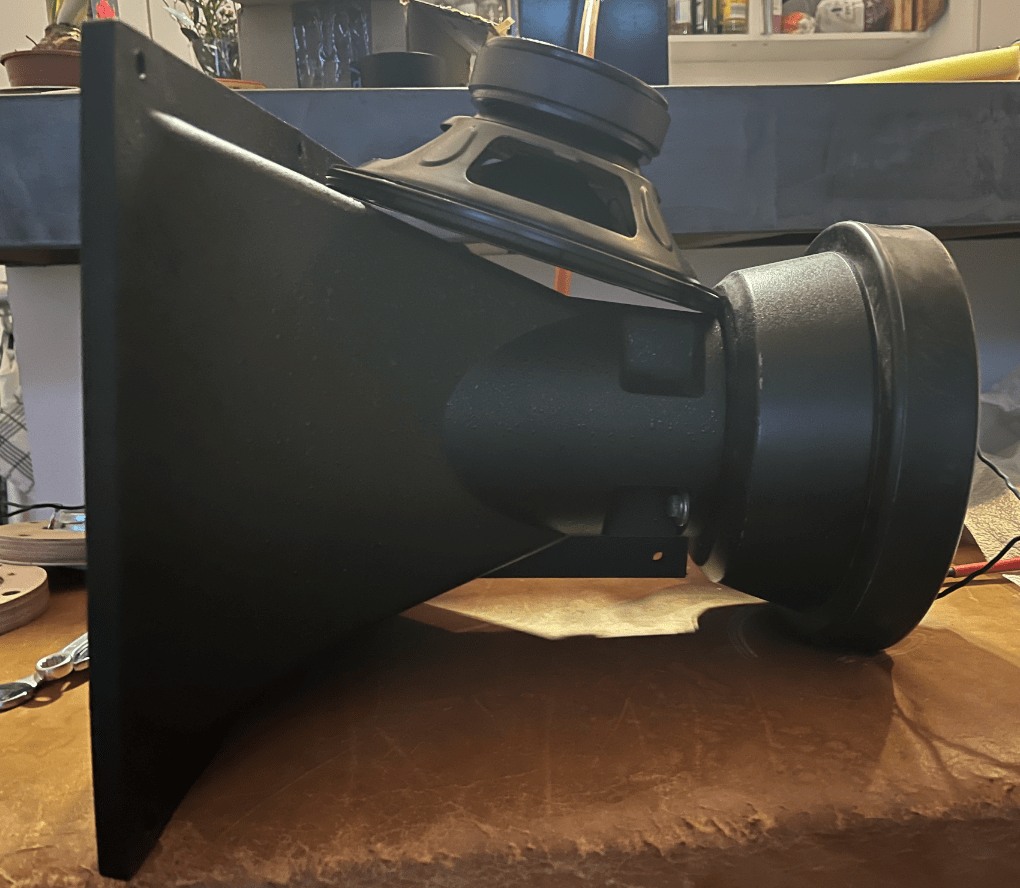

Outside the throat has a diameter of 120mm. Now i need to decide: modify/ cut the throat or using thick plywood and cut this out 😉

Outside the throat has a diameter of 120mm. Now i need to decide: modify/ cut the throat or using thick plywood and cut this out 😉

That’s what I meant with thicker plywood and cut out 😉Maybe thicker wood to elevate bezel to fit?

There is not much space to move to the mouth like the driver in your sketch… the perspective shows it wrong 😉

Now you made it worse 😕 I had couple of questions, but now have many many more. I enjoy reading your projects, they are very well documented, if I can use that word, maybe too much for my acoustics knowledge, but still huge contribution for community for which (I am) grateful

Ok... Which starting point to chose...

Lets start

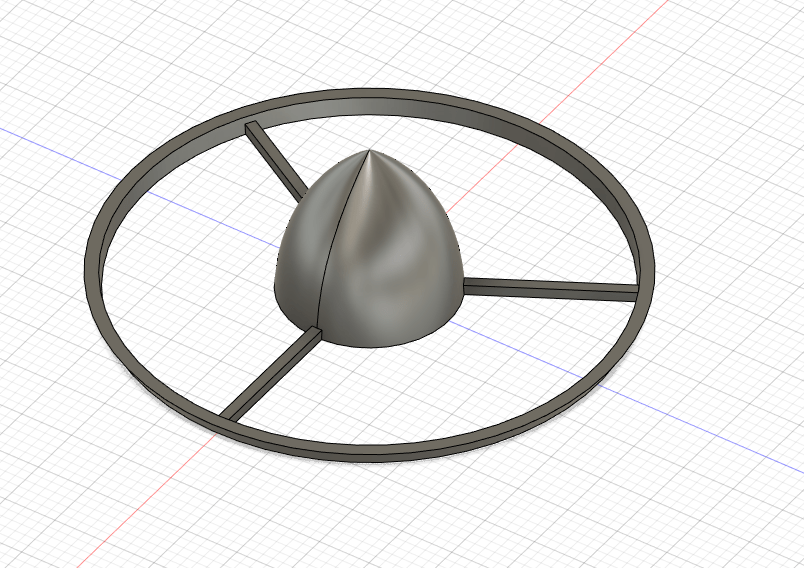

Another option is to cut the front face and add 3d printed attachment to it, making smth like

This is from manufacturing perspective. Have no idea how that will affect acoustics

Ok... Which starting point to chose...

Lets start

The Top and bottom wall is straight... inside of the horn ;(

Outside the throat has a diameter of 120mm. Now i need to decide: modify/ cut the throat or using thick plywood and cut this out 😉

View attachment 1251392

Another option is to cut the front face and add 3d printed attachment to it, making smth like

This is from manufacturing perspective. Have no idea how that will affect acoustics

That is an interesting thought to make the Smith horn into a point source horn. You might look at Joseph Crowe's website. He sells a lot of 3D hoirn/waveguide models so you can CNC mill in wood or plastic or 3D print. He does beautiful wooden horns. See for example.

Here is a bi-radial (scalable plans):

So we could use the large flats on top and bottom for mounting a woofer - but it would have a longer channel/duct to reach out. You could also mount on the flat sides with an adapter plate but the holes may mess with the far horizontal pattern. Might work.

https://josephcrowe.com/collections/see-all-3d-cad-files

Here is a bi-radial (scalable plans):

So we could use the large flats on top and bottom for mounting a woofer - but it would have a longer channel/duct to reach out. You could also mount on the flat sides with an adapter plate but the holes may mess with the far horizontal pattern. Might work.

https://josephcrowe.com/collections/see-all-3d-cad-files

What I would like to know:

The TangBand has a fixed PhasePlug… is this more good or more bad in a horn… or does it depend on what ever?

Joseph Crowe:

I like his speakers!

And maybe the sabourine is a good basis for a synergy horn 😉

The TangBand has a fixed PhasePlug… is this more good or more bad in a horn… or does it depend on what ever?

Joseph Crowe:

I like his speakers!

And maybe the sabourine is a good basis for a synergy horn 😉

Last edited:

Regarding phase plug on TB cone. It’s all very dependent on geometry. It may be helping you. Only way to know is to try driver without it. In general, throats of horns benefit from phase plug if designed correctly. All compression drivers use a phase plug. Purpose is to equalize the path from edges to the middle.

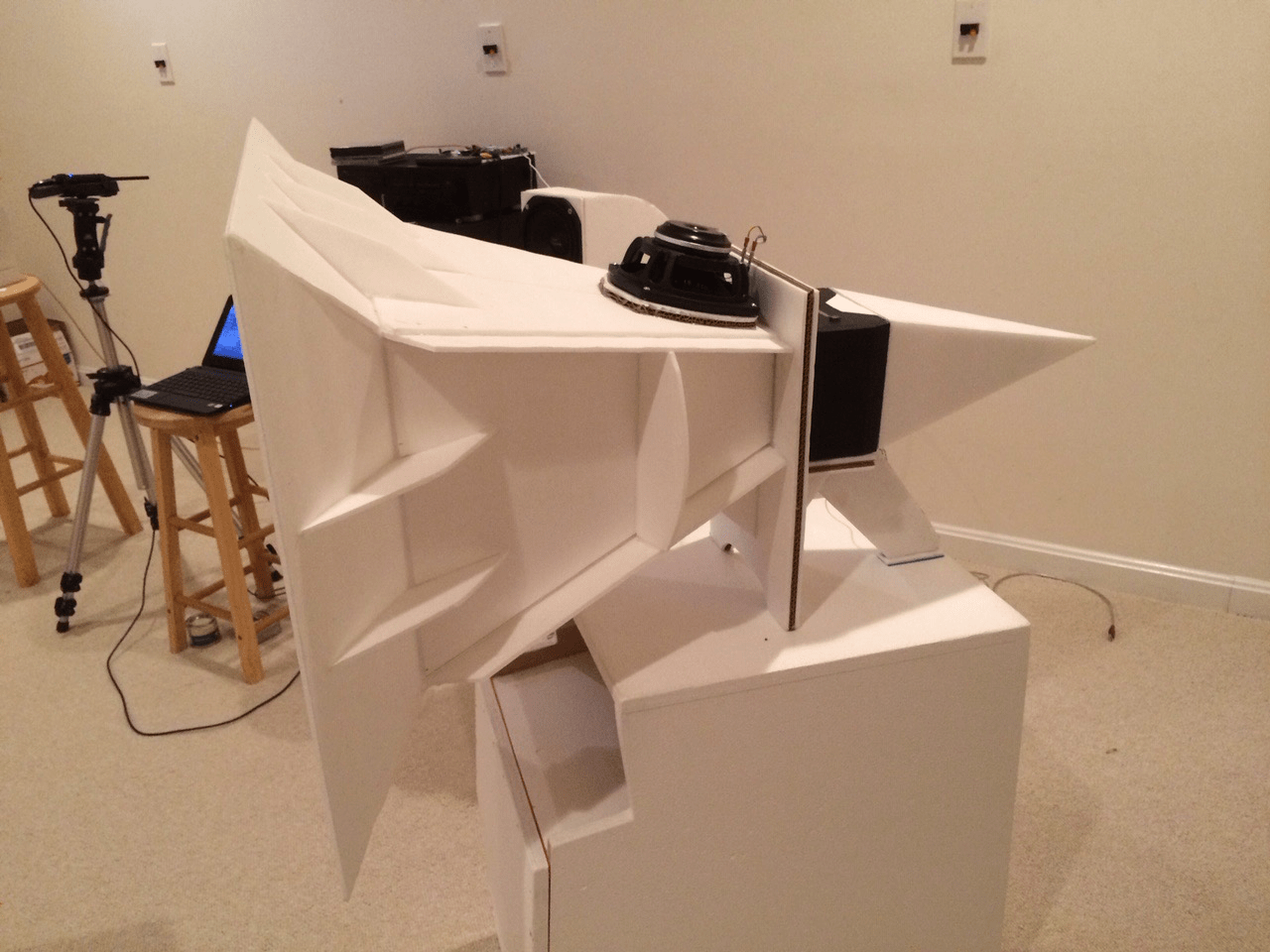

Reminds me of my AMT synergy:

The box it sits on is my own horn loaded sub woofer with a new topology as described here.

Vs Sanbourine:

Reminds me of my AMT synergy:

The box it sits on is my own horn loaded sub woofer with a new topology as described here.

Vs Sanbourine:

Last edited:

Hi

I think at the end i definitely need 3 way because i don't think, that i can bring them down to <40Hz.

To keep the budget for testing small:

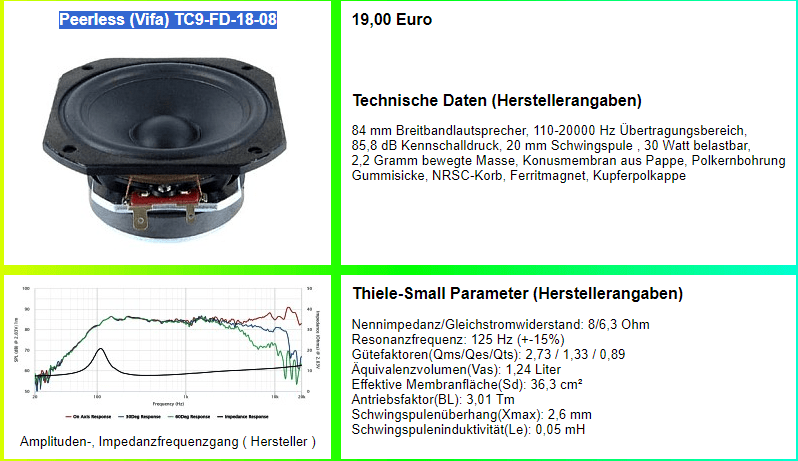

I have a bunch of Peerless (Vifa) TC9-FD-18-08. Do you think using 4 (or more) of them from 150Hz up could work? They don't have the strongest motor ;(

In my big EV6040 i have 4 5" FaitalPro wich work pretty well down to 90Hz

I think at the end i definitely need 3 way because i don't think, that i can bring them down to <40Hz.

To keep the budget for testing small:

I have a bunch of Peerless (Vifa) TC9-FD-18-08. Do you think using 4 (or more) of them from 150Hz up could work? They don't have the strongest motor ;(

In my big EV6040 i have 4 5" FaitalPro wich work pretty well down to 90Hz

I have used TC9FD in many prototype synergy horns. Good choice.

@diyuser2010 - what horn is that shown above?

@diyuser2010 - what horn is that shown above?

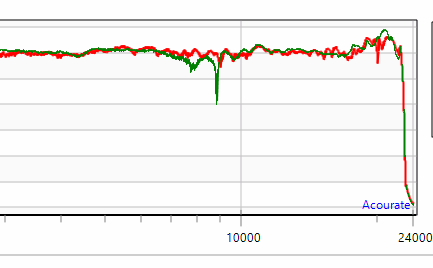

SB has arrived.

Upper: TangBand

Lower: SB

both with 4.7uF in series. SB looks pretty nice to me 😉

Upper: TangBand

Lower: SB

both with 4.7uF in series. SB looks pretty nice to me 😉

That looks pretty smooth. Seems your driver to horn throat adapter is working well as I do not see the typical sharp cancellation dips.

A little bit of smoothness is because of smoothing the Signal... but over all, i am happy with the measurement.

It seems to be a good idea to cover the whole surrounding!

AND: i have a 2" Throat... so by covering the surrounding, my adapter always gets wider never smaller.

I have attached my latest stl-file. If you like, i can send the Fusion file.

It seems to be a good idea to cover the whole surrounding!

AND: i have a 2" Throat... so by covering the surrounding, my adapter always gets wider never smaller.

I have attached my latest stl-file. If you like, i can send the Fusion file.

Attachments

Some news.

I noticed, that i have a big problem in the frequency response when measuring exactly on axis with the sb- acoustic, so i tried printing a phaseplug, without any success. Next i tried two pieces of wood, which covers the horn on top and buttom by ~2cm. THIS makes a huge difference:

I noticed, that i have a big problem in the frequency response when measuring exactly on axis with the sb- acoustic, so i tried printing a phaseplug, without any success. Next i tried two pieces of wood, which covers the horn on top and buttom by ~2cm. THIS makes a huge difference:

- Home

- Loudspeakers

- Multi-Way

- A Bookshelf Multi-Way Point-Source Horn