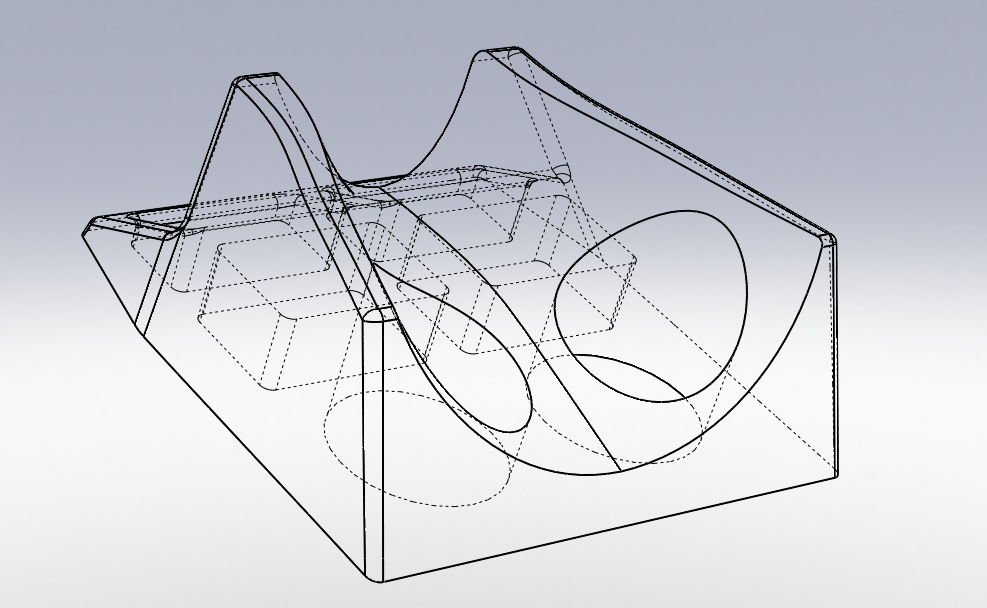

It's 5 templates at 1in spacing then approximated with 2 spline curves per template. 5 profiles are then used in lofting operation which interpolates and smooths out in between. Still, a pain to do.

With same methodology - any waveguide can be cloned and 3D printed if you had a big enough printer. However, when the commercial waveguide costs $40 to $80 it's less expensive to buy the real deal.

It looks like hollowing out won't save any time as print has to start on flat side and hollowing will require supports to be printed and that adds time. Might as well leave it solid for max strength.

With same methodology - any waveguide can be cloned and 3D printed if you had a big enough printer. However, when the commercial waveguide costs $40 to $80 it's less expensive to buy the real deal.

It looks like hollowing out won't save any time as print has to start on flat side and hollowing will require supports to be printed and that adds time. Might as well leave it solid for max strength.

Last edited:

BYRTT, are you able to establish the initial angles of those horns, for the rectangle and the round section? the datasheet is not to scale (perhaps on purpose?).

cookiemonster77, will take a look at initial angles and try to measure best i can.

For 10F/TC9 surround starts/glued on cone at diameter 58mm and inner of surround vault start at 62mm. Think about something ala below dirty drawing, don't take dimensions relationship too serious, machined in black nylon or mayby brass on a lathe.

For 10F/TC9 surround starts/glued on cone at diameter 58mm and inner of surround vault start at 62mm. Think about something ala below dirty drawing, don't take dimensions relationship too serious, machined in black nylon or mayby brass on a lathe.

Attachments

X: It seems like a great way to get a point source horn without the complex woodworking. Good work done so far! Art also seems to think the slot will mess up the hf polars. I suppose i dont really need 90 degrees horizontal, so the 4528 is a better choice. I will wait to see what BYRTT posts and if it looks promising order a pair. I suppose a 2" opening will give lots of flexibility too (print new adapters for different drivers..)

The PH2380 is a (rough) copy of the JBL 2380, which has excellent horizontal polar response, because it uses a pinched (diffraction) throat, which allows a 2" exit compression driver to have the same width profile as a 1" compression driver, which would not require the "squeeze". The treatment of the "pinch" can either be rough corners as in the PH2380, or smoothed as in the horn Bushmeister is using, which because it is not shooting for wide dispersion out to 16,000 Hz, (as the 2380 is) and starting at 1.4" rather than 2", requires less reduction, and therefore less adverse diffraction results.

Compression drivers use a phase plug to reduce the diaphragm size to a smaller exit dimension, the path length in each slit to the exit is (should be) the same, theoretically resulting in a plane wave of the exit dimension, which will theoretically expand according to the horn contour. The JBL 2380 polars prove the diffraction throat to be very effective in providing even polars using a 4" diaphragm 2" exit compression driver.

Cone drivers of the type considered in this thread do not have the magnetic strength capable of useful high end response when driving through a phase plug, so are "stuck" with the dispersion problems the width of the piston diameter imposes.

A careful match of cone diameter to throat diameter is needed to avoid transitional "pockets", but the larger the cone diameter, the lower in frequency the path length differences from the various points on the cone and relationships reflecting (rather than conforming to) the side wall are.

Therefore, although the larger 2" entrance will work OK with a driver the diameter of the TC9, without a phase plug, the path length differences on a wide dispersion, narrow throat will result in wide, but erratic polar response.Using two "full range drivers" on narrow horns, rather than one on a wide horn equaling the coverage angle will result in better better polar response, and also a bit of horn gain up high- the wide response horns actually reduce on axis sensitivity compared to the full range driver's rising on axis sensitivity.

Art

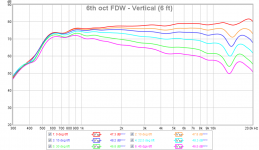

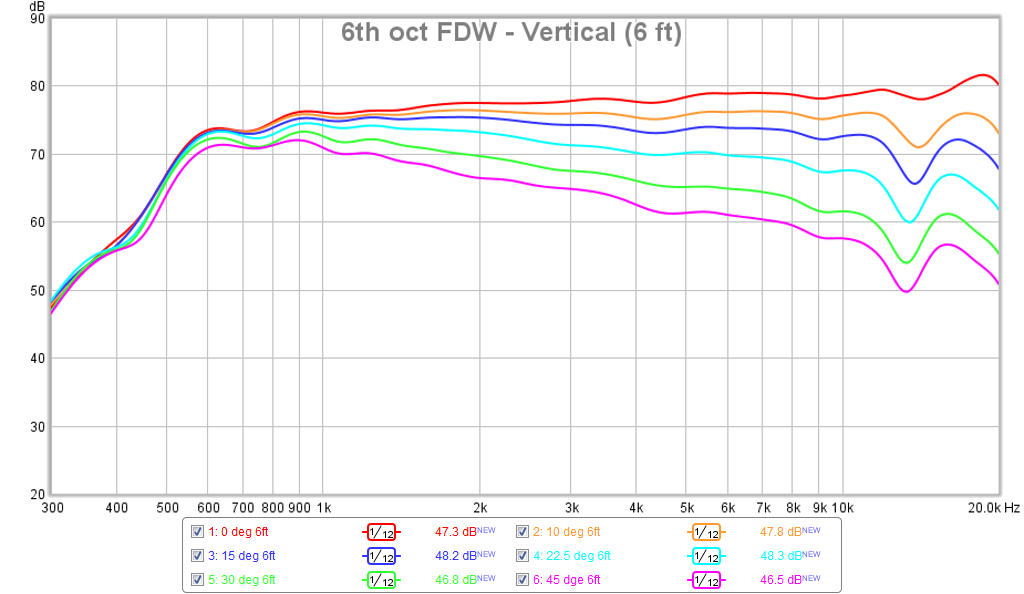

Vertical polar at 6ft LP

I repeated the polar with 90 deg rotated horn (vertical orientation) at the listening position of 6ft. Looks pretty good still. I can live with the narrow directivity - these would be monitors so I don't expect to walk around - mostly stationary listening position so 30 deg full angle seems OK.

note the 0 deg is "hot" because when I EQ'd the system it was based on 10deg offset to avoid on axis hot peaks. 10 deg is flat as expected. I will probably have to XO at 600Hz though.

I repeated the polar with 90 deg rotated horn (vertical orientation) at the listening position of 6ft. Looks pretty good still. I can live with the narrow directivity - these would be monitors so I don't expect to walk around - mostly stationary listening position so 30 deg full angle seems OK.

note the 0 deg is "hot" because when I EQ'd the system it was based on 10deg offset to avoid on axis hot peaks. 10 deg is flat as expected. I will probably have to XO at 600Hz though.

Attachments

Last edited:

The PH2380 is a (rough) copy of the JBL 2380, which has excellent horizontal polar response, because it uses a pinched (diffraction) throat, which allows a 2" exit compression driver to have the same width profile as a 1" compression driver, which would not require the "squeeze". The treatment of the "pinch" can either be rough corners as in the PH2380, or smoothed as in the horn Bushmeister is using, which because it is not shooting for wide dispersion out to 16,000 Hz, (as the 2380 is) and starting at 1.4" rather than 2", requires less reduction, and therefore less adverse diffraction results.

Compression drivers use a phase plug to reduce the diaphragm size to a smaller exit dimension, the path length in each slit to the exit is (should be) the same, theoretically resulting in a plane wave of the exit dimension, which will theoretically expand according to the horn contour. The JBL 2380 polars prove the diffraction throat to be very effective in providing even polars using a 4" diaphragm 2" exit compression driver.

Cone drivers of the type considered in this thread do not have the magnetic strength capable of useful high end response when driving through a phase plug, so are "stuck" with the dispersion problems the width of the piston diameter imposes.

A careful match of cone diameter to throat diameter is needed to avoid transitional "pockets", but the larger the cone diameter, the lower in frequency the path length differences from the various points on the cone and relationships reflecting (rather than conforming to) the side wall are.

Therefore, although the larger 2" entrance will work OK with a driver the diameter of the TC9, without a phase plug, the path length differences on a wide dispersion, narrow throat will result in wide, but erratic polar response.Using two "full range drivers" on narrow horns, rather than one on a wide horn equaling the coverage angle will result in better better polar response, and also a bit of horn gain up high- the wide response horns actually reduce on axis sensitivity compared to the full range driver's rising on axis sensitivity.

Art

So it seems to me that placing a cone driver on a 2" entry would give the opposite effect of what a compression driver accomplishes. Instead of a plane wave (or even better, a dome shaped wave conforming to the throat entry angle) you get a concave wave due to the shape of the dome?

Would a dome-type driver work better in this regard, since you can´t shape the waveform with a phase plug due to the lack of motor strength? Bigger drivers are out of the question I suppose, due to cone breakup issues?

Please forgive my ignorance here, but what´s the problem with making a synergy horn using a 2" compression driver on such a horn? The 2" driver allowing a lower crossover point, and therefore more leeway in placing the midrange/bass drivers? Does a full-range driver really offer that much lower distortion? I can probably not hear most of the top octave anyway. 🙂

EDIT: I guess I´m not really looking for a bookshelf solution.. 🙂

1) Not opposite, but different in regard to dispersion and frequency response.1)So it seems to me that placing a cone driver on a 2" entry would give the opposite effect of what a compression driver accomplishes.

2)Instead of a plane wave (or even better, a dome shaped wave conforming to the throat entry angle) you get a concave wave due to the shape of the dome?

3)Would a dome-type driver work better in this regard, since you can´t shape the waveform with a phase plug due to the lack of motor strength?

4)Bigger drivers are out of the question I suppose, due to cone breakup issues?

5)Please forgive my ignorance here, but what´s the problem with making a synergy horn using a 2" compression driver on such a horn?

6)The 2" driver allowing a lower crossover point, and therefore more leeway in placing the midrange/bass drivers?

7)Does a full-range driver really offer that much lower distortion? I can probably not hear most of the top octave anyway. 🙂

8)EDIT: I guess I´m not really looking for a bookshelf solution.. 🙂

2) Shape of the cone has little to do with the dispersion of the cone, which is determined by the piston diameter. That said, cone breakup can result in different effective diameters for different frequencies.

3) I'd expect the difference to be marginal, the difference being related primarily to how closely the cone/dome behaves like a rigid piston.

4) Bigger drivers are out of the question because of the breakup and "beaming" occurring at lower frequencies than smaller drivers, same reasons tweeters are made in very small diameters.

5) None, other than expense, and 2" exit drivers are traditionally 4" diaphragms, which must have breakup to extend high.

6) The small "full range" drivers we are considering have more than 5 times the Xmax of a HF compression driver, so have less distortion than they have. The downside is less sensitivity, and little to no HF horn gain, which means that flat response can not be achieved passively at any more sensitivity than the "full range" native front loaded response.

7) At lower crossover points (500 Hz) the full range driver has way less distortion than a 1.75" diaphragm compression driver. Compression drivers crossed high enough don't have enough distortion to worry about in domestic situations.

8) Then look at larger options, which will afford decent pattern control to below 500 Hz.

If I would stop typing, I could finish up the Maltese quad, which will do just that- at rock concert levels.

Art

Cheers X. Can't wait to see your 3D printed version.

The crazy thing is, all the epoxy, MDF, plywood, etc has made the horn incredibly inert.

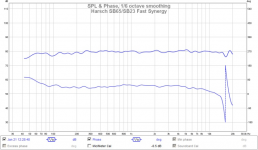

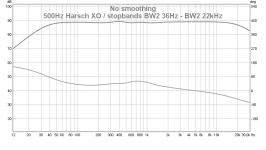

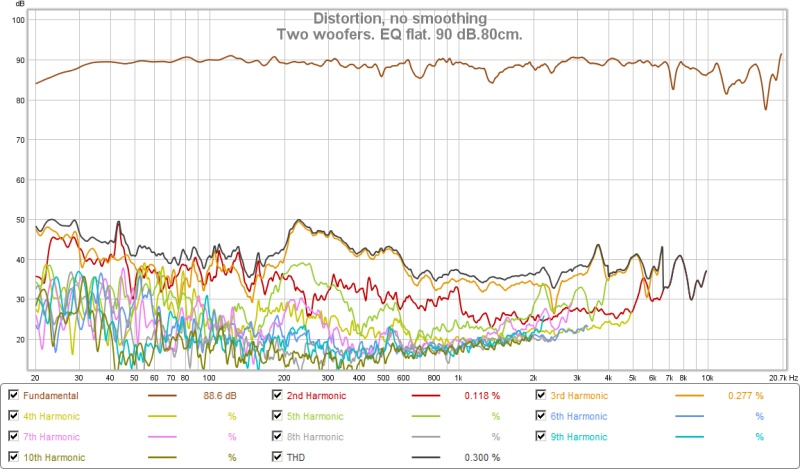

I think this is quite impressive. No sub. Just the two woofers:

The crazy thing is, all the epoxy, MDF, plywood, etc has made the horn incredibly inert.

I think this is quite impressive. No sub. Just the two woofers:

Attachments

With measurements like this, who needs a box? I guess it helps your max SPL.

That is very clean, apart from the hump at 200-500Hz. You may want to check to make sure the SB65 surround is not rubbing on the gasket foam - I noticed a hump like that on mine when it was rubbing.

Would it not be easier to model as a solid and let you slicer work out 15-30% infill automatically. Bridgeing won't be pretty in your voids and slicer might create support anyway. 5 wall + top and bottom should be very rigid.

Sent from my GT-I8200 using Tapatalk

Sent from my GT-I8200 using Tapatalk

Last edited:

Those pockets and cutouts are saving almost 2 hrs on the job. Maybe not worth the hassle though. I am using 20% infill and 3 layers, supports are being made for the two rectangular pockets. My main problem is getting good adhesion for the first support layer to the glass when it lays down the thinner supports. By the 2nd layer I could see that the supports were not sticking so I tried brushing on 50:50 PVA/water solution onto the glass where supports go and once dry, now the PLA sticks quite well there. I am going to coat the whole glass with this next time.

Brytt- I noticed that too. I might be able to optomize the xover more, as I just kept the same settings as for a single woofer.

I wonder if the original flat phase had something to do with loading the horn only on one size with a single woofer?

X, sounds like you have your hands full. To be honest I would rather play with epoxy and routers, as I know nothing about 3d printing!

I wonder if the original flat phase had something to do with loading the horn only on one size with a single woofer?

X, sounds like you have your hands full. To be honest I would rather play with epoxy and routers, as I know nothing about 3d printing!

Print job so far so good. 9 more hours to go.

Your epoxy covered horn is probanly extremely dead sounding with no rings.

Your epoxy covered horn is probanly extremely dead sounding with no rings.

Many ways to prototype

I love the different construction methods!

Would love to try the 3d printing (just soon expensive for decent machine)

That being said I am working up to buying a 4 axis cnc miller, and I suspect the construction method would be similar (working in layers)

I love the different construction methods!

Would love to try the 3d printing (just soon expensive for decent machine)

That being said I am working up to buying a 4 axis cnc miller, and I suspect the construction method would be similar (working in layers)

Brytt- I noticed that too. I might be able to optomize the xover more, as I just kept the same settings as for a single woofer.

I wonder if the original flat phase had something to do with loading the horn only on one size with a single woofer?

X, sounds like you have your hands full. To be honest I would rather play with epoxy and routers, as I know nothing about 3d printing!

Yes, the difference in phase immediately caught my eye too. Would love to see another early waterfall with the same settings as before. Just to see if there is indeed a change.

- Home

- Loudspeakers

- Multi-Way

- A Bookshelf Multi-Way Point-Source Horn