I really like this iteration but it is probably impossible to make one that looks like this here.. 😀

I will probably try to flatten out the back and sides and go with that......

Why not? People here really love industrial precision, which I find is relatable, but you could easily create this at home if you combine a number of MDF sections and remove the edges by hand:

Diffraction wont care if the geometry is slightly off here and there and when working carefully after some filler, a very nice looking result should be possible.

I have to admit that the variant with a coaxial driver is quite attractive, mainly for its simplicity. I'd be content even with a simple box in that case. With say 12" drivers this could make a very well performing loudspeaker.

Last edited:

@mabat: Is it possible to simulate a normal cuboidal kind of box in ATH (with the slot) instead of the current top & bottom rounded enclosure (with the box shape looking like an oval from the front)?

Also how does the top &bottom rounding of the enclosure play a role in the overall diffraction reduction? Was it primarily meant of reducing the woofer cabinet impact on the waveguide kept above it?

Also how does the top &bottom rounding of the enclosure play a role in the overall diffraction reduction? Was it primarily meant of reducing the woofer cabinet impact on the waveguide kept above it?

At wavelengths where the open midrange structure was supposed to be used, i.e. up to ~1 kHz, I would expect the effect of a different shape to be only mild. Maybe the biggest effect will be on the coaxial tweeter's response, after all, but that's just my guess.

I'm working on that, as I want to try it myself. The round top was simply what occurred to me first (and I believe it does reduce an interference with a waveguide above it).Is it possible to simulate a normal cuboidal kind of box in ATH (with the slot) instead of the current top & bottom rounded enclosure (with the box shape looking like an oval from the front)?

Last edited:

In the meanwhile, I am trying to read up and understand Kimmosto's experiments with cardioid 🙂

https://web.archive.org/web/2017050...t/CardSub/CARDSUB.html#Cardioid_constructions

https://web.archive.org/web/2017050...t/CardSub/CARDSUB.html#Cardioid_constructions

I really like one for the cardioid speaker. I may go with this one if manufacturing is possible 😀

Try and put a mock driver or two in the renders to soften some of toilet design language 😉I really like one for the cardioid speaker. I may go with this one if manufacturing is possible

Purifi and Scanspeak have ready made 3D model files you could scale and insert.

The porcelain look is just in the rendering. Color it

, even black, and that goes away.

I hate to say it but I think morphing the curved sides into a rectangular back is a mistake. Keep the side curvature constant and you've got a simple cnc glue lam construction. Round over the back panel like you do the front and you are done.

, even black, and that goes away.

I hate to say it but I think morphing the curved sides into a rectangular back is a mistake. Keep the side curvature constant and you've got a simple cnc glue lam construction. Round over the back panel like you do the front and you are done.

Yes, with CNC you could then easily produce few layers and glue them together. Then some sanding and sealing and voila!

If you are enough persistent (and we can see that you are) you could actually cut MDF layers with small handheld jig saw...

Would you get any changes in directivity if you make back of the coax also rounded and not so rectangular? Also box would appear smaller on desktop...

If you are enough persistent (and we can see that you are) you could actually cut MDF layers with small handheld jig saw...

Would you get any changes in directivity if you make back of the coax also rounded and not so rectangular? Also box would appear smaller on desktop...

Attachments

Iterated it once more trying to get rid of that rectangular morph & having a sloping down top.. 😀

I don't think that those shapes affect directivity much because of the slot port which mostly controls directivity down to the region where the coax operates.. But I like the looks.. 😀

I don't think that those shapes affect directivity much because of the slot port which mostly controls directivity down to the region where the coax operates.. But I like the looks.. 😀

Overdesigned anf gives off stale "early 2000s hi-end" vibes IMO. I think Gaya-like white iteration looks the best. Maybe needs more organic, curvilinear baffle.

This was a fun technique to suggest but quicker, easier progress will be made with an electric palm sander and coarse grit sandpaper. I no longer have pictures but back in the day I hand sculpted curves/rounds on solid oak that way. Unfortunately, a couple of years later, the solid oak had drying cracks.Why not? People here really love industrial precision, which I find is relatable, but you could easily create this at home if you combine a number of MDF sections and remove the edges by hand:

View attachment 1172948

Diffraction wont care if the geometry is slightly off here and there and when working carefully after some filler, a very nice looking result should be possible.

Being lazy , I wonder if the desire curves as in the latest images can be achieved with a step-wise approximation using MDF layers parallel to the baffle. Glue the layers together, smooth the steps flat with bondo, then palm sand it to a smooth curve?

Even though I do not like the looks, I created a sort of 'poor man's' version of the speaker for easier manufacturability. 😀 I am just slowly trying to accept reality through the simplification process in sketches.. The last bit to go now is that top slant down.. 😀

Last edited:

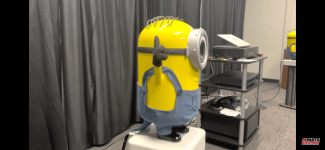

I just couldn't keep myself from not doing this.. 🤓

Latest iteration which I like a lot

I need to use something like hornresp to see if the 8ish cm long tunnel at the backside of the bass driver forms a transmission line and does something unwanted to that driver's response I think..🤔 But other than that I like the looks. Speaker has probably gone out of "desktop placement" category I think.. 😀 But I have dedicated bookshelf speaker stands lying unused so I can even use that.. 🙂

I know it has that one eyed minion looks.. 😛

But still I like it.. 😀

Manufacturability is also easier for this one I think, due the constant curvature bodies everywhere... CNC cut and atcked MDF can be used probably.. in 3 parts. One for the main box. Two separate pieces for the top and bottom rings that hold the drivers..

Latest iteration which I like a lot

I need to use something like hornresp to see if the 8ish cm long tunnel at the backside of the bass driver forms a transmission line and does something unwanted to that driver's response I think..🤔 But other than that I like the looks. Speaker has probably gone out of "desktop placement" category I think.. 😀 But I have dedicated bookshelf speaker stands lying unused so I can even use that.. 🙂

I know it has that one eyed minion looks.. 😛

But still I like it.. 😀

Manufacturability is also easier for this one I think, due the constant curvature bodies everywhere... CNC cut and atcked MDF can be used probably.. in 3 parts. One for the main box. Two separate pieces for the top and bottom rings that hold the drivers..

Go hard or go home.

all hail

Nick Santorineos

all hail

Nick Santorineos

Attachments

Last edited:

I was thinking more B&W meets LX MiniI know it has that one eyed minion looks.. 😛

- Home

- Loudspeakers

- Multi-Way

- A 3 way design study