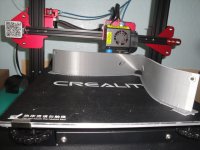

It's took about 3 days to print mine but am not in a hurry.CR10 should be capable, but with its stock hotend and nozzle (0.4mm dia) it would take days to print each half of one.

I notice the woofer ports look different from the original.

Attachments

Last edited:

CR10SproVery nice! What setup? Never get loosy strips?

PLA by Hatchbox

Nozzle: 200C

Bed:60C

Speed:90mm/s

Fill:30%

Nozzle size 0.4mm

Time print: about 3days

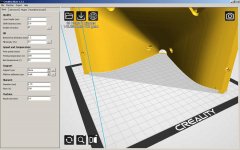

I was surprised that I have no issue with the printer very much set-and-forget. I have Raft support turn on waste little more PLA. It think it's worth it, make the print stick to the bed better. The 2nd 1/2 piece is printing at the moment. Let's see if it's turn out OK.

Attachments

It's better than Zortrax M200plus. 3 days is too long for me - I want 10 hours max. Should be possible with 1mm nozzle and volcano type hotend.

How both parts fit togather, how strong is deformation at joints?

How both parts fit togather, how strong is deformation at joints?

It's took about 3 days to print mine but am not in a hurry.

I notice the woofer ports look different from the original.

Right, the original ones caused some reflection problems so it was redesigned.

Don't know how true is the tile but it's looked flat, will see!How both parts fit togather, how strong is deformation at joints?

Attachments

Nope, But I get thisNever get loosy strips?

Attachments

more pics

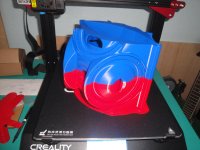

2nd half horn done.....yeah 3days.

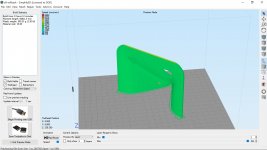

Are those guides to align piece together?

Look nice overall thank Bill.

I probable built ~2.3cuft enclosure , simple vent alignment, different shape than Bill's.

And will use different CDs as I have those already.

2nd half horn done.....yeah 3days.

Are those guides to align piece together?

Look nice overall thank Bill.

I probable built ~2.3cuft enclosure , simple vent alignment, different shape than Bill's.

And will use different CDs as I have those already.

Attachments

Those aren't guides really, just an artifact of when I was doing the clamping seams or crossover board mounts. Also those tabs at the horn mouth edges facing forward are just to give more bed contact when printing, snip them off. Nice looking print. Any reason you went with such small layer heights? I used 1mm. 1/4 wavelength at 20kHz is 4.3mm.

Yes 0.2mm.Layer is 0.2mm? I print 0.5mm usually. Throat is nice round or ellipse?

Should be round, I have not glue it yet just want to show the gap at the throat.

I probably could nail it down to 39hrs 6mins + ~45mins for the raft layer but don't want to risk the print.

Attachments

I am new to 3D, just got the printer about 2.5 weeks. I did print a number of it most came out good so I left as is.Any reason you went with such small layer heights? I used 1mm. 1/4 wavelength at 20kHz is 4.3mm.

Attachments

-

DSC03213.JPG280.5 KB · Views: 139

DSC03213.JPG280.5 KB · Views: 139 -

DSC03212.JPG299.6 KB · Views: 126

DSC03212.JPG299.6 KB · Views: 126 -

DSC03211.JPG288.9 KB · Views: 122

DSC03211.JPG288.9 KB · Views: 122 -

DSC03209.JPG274.5 KB · Views: 138

DSC03209.JPG274.5 KB · Views: 138 -

DSC03207.JPG275.2 KB · Views: 142

DSC03207.JPG275.2 KB · Views: 142 -

DSC03206.JPG272.3 KB · Views: 291

DSC03206.JPG272.3 KB · Views: 291 -

DSC03205.JPG279.1 KB · Views: 302

DSC03205.JPG279.1 KB · Views: 302 -

DSC03204.JPG262.1 KB · Views: 309

DSC03204.JPG262.1 KB · Views: 309 -

DSC03181.JPG399 KB · Views: 309

DSC03181.JPG399 KB · Views: 309

Last edited:

Thanks, I download from the link in September, but am not too sure if Bill update since.Quality is superb. Can you recall 3D model? Will check on mine.

3D printed 3-way Unity waveguide home audio speaker

How large of a printer would I need to make it in one print. Or two prints. I’m looking at printers now

I can get one that I can afford and does 500mmX500mmX500mm

I can get one that I can afford and does 500mmX500mmX500mm

I just ordered a printer that can do

300*300*400mm super large print size; 0.4mm nozzle with ±0.1mm high printing accuracy

What size print nozzles should I use? .04mm work ? I ordered a roll of

WYZworks PLA 1.75mm [ WOOD ] Premium Thermoplastic Polylactic Acid 3D Printer Filament - Dimensional Accuracy +/- 0.05mm 1kg/2.2lb

And for test just regular black PLA for setting it up. I here wood wares out the nozzles pretty fast

And guidance would be greatly appreciated

300*300*400mm super large print size; 0.4mm nozzle with ±0.1mm high printing accuracy

What size print nozzles should I use? .04mm work ? I ordered a roll of

WYZworks PLA 1.75mm [ WOOD ] Premium Thermoplastic Polylactic Acid 3D Printer Filament - Dimensional Accuracy +/- 0.05mm 1kg/2.2lb

And for test just regular black PLA for setting it up. I here wood wares out the nozzles pretty fast

And guidance would be greatly appreciated

These are glued together with five minute epoxy from home depot. Gets the job done.

Due to curling, the gap between parts can be large, so you want something thick. I also try to put the seam somewhere where it won't be a problem.

When the design model, to include measures to prevent warping, can be very effective to prevent warping.

There is a later version that removes the woofer ports and channels from the horn body. It seems that the woofers should ideally be further out (for better directivity extension), and would probably be better fed out through slots just outside the horn. Mount the woofers inside the cabinet facing toward the sides and feeding out though 'shelf port' type structure toward the front. Much easier and faster to print, too. I don't remember where the file is at the moment, I can look for it when I get back.

- Home

- Loudspeakers

- Multi-Way

- 3D printing 1/2 of a waveguide