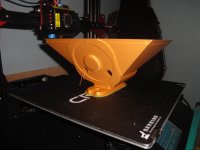

The gap at the throat (if I'm seeing what you mean) should pull together when you tighten the bolts that hold the two halves together there. At least it did on mine.2nd half horn done.....yeah 3days.

Are those guides to align piece together?

I wouldn't use "wood" type PLA -- it is very brittle stuff, breaks and cracks easily.

Thanks for the heads up

My new printer should be in by the 27th and I’m going to do all of the test prints and get it right. I got the one with a 300x300x400mm build size

The wood PLA looks nice, but just isn't much good for structural things (at least not the type I used). A better way to do a wood color is just to use spray paint - works well on PLA plastic.

that is I am planning to do.should pull together when you tighten the bolts that hold the two halves together there. At least it did on mine.

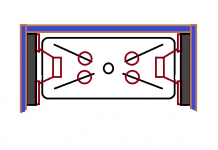

V6 printing is in progress. Could the ports place on the size doable? I kinda prefer the V6 because they are smaller.

Attachments

that is I am planning to do.

V6 printing is in progress. Could the ports place on the size doable? I kinda prefer the V6 because they are smaller.

That arrangement what I had in mind for the fully printed waveguide.

The V6 isn't intended to be smaller -- it's meant to be larger, as it's only a horn 'stub', to have plywood walls added to the size desired. I was going to make one 5ft (1.5 m) wide, but never did, as I have no place to put such things!

Last edited:

What’s the size for a full print and a have print? And does anyone have the files for these? Message me please. I have one from the very first ones that where done and I’m sure there’s been a few updates to the file

Could you please point me to the STL for the stub? The large waveguide is quite hard to print, but the V6 stub should be possible for me. Thanks!

Could you please point me to the STL for the stub? The large waveguide is quite hard to print, but the V6 stub should be possible for me. Thanks!

It should be here --- http://libinst.com/SynergyDIY/StubV6/V6%20stub%20with%20airvolume%20plugs.stl

Please correct if it's wrong!

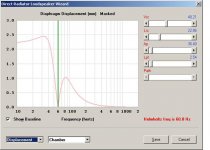

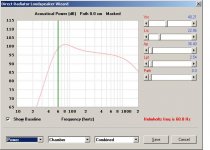

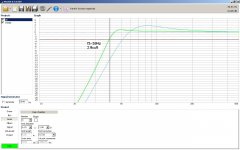

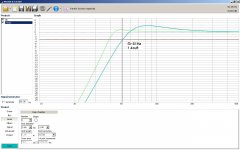

Box is net volume.

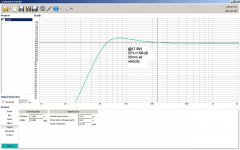

What are we looking at?? Can't tell what these plots are, can't expand enough to read the text...

What’s the size for a full print and a have print? And does anyone have the files for these? Message me please. I have one from the very first ones that where done and I’m sure there’s been a few updates to the file

Here's the latest file, a version without the woofer mounts or ports. I think the woofers might work better (directivity meet up with the mids better) if they exited a littler further out horizontally. Right about just past the edges of the horn. Idea is to mount the woofs inside, facing toward the outside, exiting through vents on the baffle just to the sides of the horn. Never tried, btw, so just an idea. And should be lots easier to print, too.

http://libinst.com/3DP/Half%20WG%20No%20Woofs.stl

Size: the picture is shown on a 300mm x 300mm print surface grid. Count the squares, should allow for a good estimate of dimensions, I don't have the info anymore (I think it's something like 19"x15")

You should bring them to my house when they're done! We could A/B them with Bill's Cosynes.

(Just realized we're both in San Diego.)

(Just realized we're both in San Diego.)

I could not edit for some reason, sorry!

Trying to squeeze to about half size.

Internal dimension 20X17X9=3060cuin

Speakers, X-over, 2 braces~600cuin

Net volume=2460cuin=1.42cuft

1 round port 2.68" diameter 1" length, I might put it at the rear.

Box tunning=60Hz, 1st port resonance ~6.7KHz (should I be worried?)

F3= 51Hz vs your of 39Hz base on my calculation.

Thanks,

Trying to squeeze to about half size.

Internal dimension 20X17X9=3060cuin

Speakers, X-over, 2 braces~600cuin

Net volume=2460cuin=1.42cuft

1 round port 2.68" diameter 1" length, I might put it at the rear.

Box tunning=60Hz, 1st port resonance ~6.7KHz (should I be worried?)

F3= 51Hz vs your of 39Hz base on my calculation.

Thanks,

Attachments

...better yet VS MetlakoYou should bring them to my house when they're done! We could A/B them with Bill's Cosynes.

(Just realized we're both in San Diego.)

...better yet VS Metlako

Oh I never actually *finish* anything lol

In the span of 27 years doing this hobby, I think the longest I've actually had one of my projects as my "main" speakers has been about six weeks.

I like building things more than finishing things.

But Bill's speakers are great!

I am building the Metlako, will see how each differ in sound. I think Bill's built is like PA "sound" while your are for "HiFi"Oh I never actually *finish* anything lol

I am for smaller horn that behave like big horn.I like building things more than finishing things.

Wait, what?I think Bill's built is like PA "sound" while your are for "HiFi"

- Home

- Loudspeakers

- Multi-Way

- 3D printing 1/2 of a waveguide