Tweeter spacers

Ok, I've made some spacers to make my APT-50s sit in the right place in the waveguide (1cm or so further back).

There's not a massive difference in perceived sonics but it does seem a touch smoother.

Ok, I've made some spacers to make my APT-50s sit in the right place in the waveguide (1cm or so further back).

There's not a massive difference in perceived sonics but it does seem a touch smoother.

Attachments

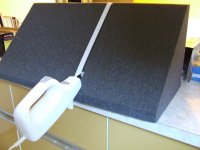

I cut one of my corner absorbers up with an electric carving knife, scissors and a bread knife to make my mids semi-open instead of fully open. I've attached these foam blocks to the speaker backs using velcro so the sound can easily be switched between open (clear and spacious) or foam-backed (more focussed but shut-in).

I'm really, really happy with these speakers now. The sound is, in most respects, what I dreamed of two years ago when I started: dynamic, rich, warm, detailed and full-bodied.

I'm really, really happy with these speakers now. The sound is, in most respects, what I dreamed of two years ago when I started: dynamic, rich, warm, detailed and full-bodied.

Attachments

Hi

The waveguide ( if that's what it is ) looks astonishing - never mind how it's

going to sound.

How do you make the waveguide like that ?

Have you got some technical wood working machinery in your workshop?

Andrew

The waveguide ( if that's what it is ) looks astonishing - never mind how it's

going to sound.

How do you make the waveguide like that ?

Have you got some technical wood working machinery in your workshop?

Andrew

Hi Andrew,

The 'guide was initially 3 discs of ply glued together, which I then cut into with the router to get the rough shape. I then took it to a friend's Dad who has a lathe.

He spent AGES sorting the final shape out because his lathe is for metal-work and couldn't fit the whole thing in. He had to break the 'guides in two and work on each separately and then reattach them. I was stunned by his work but he's retired so had the time and loves this kind of challenge.

I then just had to sand them and make up some spacers to make these Eminence drivers fit in the appropriate way.

The 'guide was initially 3 discs of ply glued together, which I then cut into with the router to get the rough shape. I then took it to a friend's Dad who has a lathe.

He spent AGES sorting the final shape out because his lathe is for metal-work and couldn't fit the whole thing in. He had to break the 'guides in two and work on each separately and then reattach them. I was stunned by his work but he's retired so had the time and loves this kind of challenge.

I then just had to sand them and make up some spacers to make these Eminence drivers fit in the appropriate way.

Last edited:

Those look awesome Ricardo! Are those 12" mids?

The shape of the waveguide came from reading the thread Geddes on Waveguides, where Dr Earl Geddes discusses what shape a waveguide should be to control directivity and have a minimum of horn colouration. Some other kind soul made a spreadsheet to assist design of such a waveguide, which I made a template from to give to my lathe-owning friend.

The guide is very shallow and straight, only changing in profile at the mouth and throat. These are the two areas that determine how it will sound.

The next step with it (other than some EnABL pattern rings) is to install some open-cell foam in the throat in front of the driver. This will absorb some early reflections and reduce what Geddes refers to as HOMs (High Order Modes). These are thought to cause "bad horn sound" and by absorbing reflections early on the ratio of direct to "HOM" sound is improved, making the top end cleaner and easier to enjoy. He used EQ on his own designs to overcome the loss of top end treble. Given my already-OTT top end treble I might not even need the EQ so it could be a very nice move.

...but I've no idea where to buy the foam 🙁

The shape of the waveguide came from reading the thread Geddes on Waveguides, where Dr Earl Geddes discusses what shape a waveguide should be to control directivity and have a minimum of horn colouration. Some other kind soul made a spreadsheet to assist design of such a waveguide, which I made a template from to give to my lathe-owning friend.

The guide is very shallow and straight, only changing in profile at the mouth and throat. These are the two areas that determine how it will sound.

The next step with it (other than some EnABL pattern rings) is to install some open-cell foam in the throat in front of the driver. This will absorb some early reflections and reduce what Geddes refers to as HOMs (High Order Modes). These are thought to cause "bad horn sound" and by absorbing reflections early on the ratio of direct to "HOM" sound is improved, making the top end cleaner and easier to enjoy. He used EQ on his own designs to overcome the loss of top end treble. Given my already-OTT top end treble I might not even need the EQ so it could be a very nice move.

...but I've no idea where to buy the foam 🙁

These are Robert Bastani 12´´ speakers : Unbenanntes Dokument

I found this site about foams: sound proofing and deadening foam products, acoustic insulation, home studio soundproofing,

I found this site about foams: sound proofing and deadening foam products, acoustic insulation, home studio soundproofing,

Thanks for the links. I've seen many places selling acoustic foam but that stuff is very dense. What this application calls for is very large pores. I've no idea where to buy it from.

Hi Simon.

This is a great thread. I have a couple of Beta-8a and some different hf drivers laying around. I also have some waveguides from other projects both in wood and fibreglass, so I´ll try a OB using these drivers.

Looking at the Eminence APT-50 driver, I noticed one thing, do you use the APT-3 adapter ?

If not I think you will have a cavity between the mouting plate and the driver causing strange reflections.

I also need to read up on the EnABL thread, as it seems quite interesting.

Did the 2 way glue come with the EnABL kit, or where did you get that from ?

This is a great thread. I have a couple of Beta-8a and some different hf drivers laying around. I also have some waveguides from other projects both in wood and fibreglass, so I´ll try a OB using these drivers.

Looking at the Eminence APT-50 driver, I noticed one thing, do you use the APT-3 adapter ?

If not I think you will have a cavity between the mouting plate and the driver causing strange reflections.

I also need to read up on the EnABL thread, as it seems quite interesting.

Did the 2 way glue come with the EnABL kit, or where did you get that from ?

Last edited:

The APT-3 adaptor fit well at the driver side, however it's straight sided.

So, at the other end meeting horn (WG) throat, the transition is not so good. An abrupt angle at the connection is usually unavoidable🙁 Some mods to the adaptor and the horn throat are needed to make them perfectly smooth.

I don't know why they make APT-50 that way. It's odd and nothing else can directly fit. Perfect adaptor doesn't exist, and it often need more than one! Argh~

A good sounding tweeter, though.

So, at the other end meeting horn (WG) throat, the transition is not so good. An abrupt angle at the connection is usually unavoidable🙁 Some mods to the adaptor and the horn throat are needed to make them perfectly smooth.

I don't know why they make APT-50 that way. It's odd and nothing else can directly fit. Perfect adaptor doesn't exist, and it often need more than one! Argh~

A good sounding tweeter, though.

Hi Kim,

I don't use an Eminence adaptor, but a piece of extra wood at the throat end of the waveguide. I just set the driver back enough to make the exit of the phase plug roughly parallel with the waveguide throat. I hope to upgrade to more expensive tweeters (B&C) later, but with some further tweaking perhaps these could be really good (quite good so far)! I've found a place to buy 30PPI foam to plug the waveguide (reduce high order modes) and I will change my series cap to Mundorf Supreme - my favourite cap.

Do read up on EnABL, it's really interesting and useful in getting the most from a driver.

The 2-way glue doesn't come with the kits, but the man who sells the kits can source it for you if you can't find it. I bought mine from a chain store here in the UK called WH Smith - they mainly sell stationary, books and magazines etc. but have a craft section with the 2-way glue made by Zig Memory Systems.

Simon

I don't use an Eminence adaptor, but a piece of extra wood at the throat end of the waveguide. I just set the driver back enough to make the exit of the phase plug roughly parallel with the waveguide throat. I hope to upgrade to more expensive tweeters (B&C) later, but with some further tweaking perhaps these could be really good (quite good so far)! I've found a place to buy 30PPI foam to plug the waveguide (reduce high order modes) and I will change my series cap to Mundorf Supreme - my favourite cap.

Do read up on EnABL, it's really interesting and useful in getting the most from a driver.

The 2-way glue doesn't come with the kits, but the man who sells the kits can source it for you if you can't find it. I bought mine from a chain store here in the UK called WH Smith - they mainly sell stationary, books and magazines etc. but have a craft section with the 2-way glue made by Zig Memory Systems.

Simon

Attachments

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Hi Simon.

Does your drivers look like the first or second picture, my APT-50 (actually a APT-80 with the horn screwed off) looks like the second picture.

So the throat of the WG is smaller than the exit of the driver, I hope this makes sense.

At the start of the APT-80 horn, it is straight for the part that screws down in the driver, and the actual horn contour does not start before the edge of the thread on the driver.

Hi,

Mine are the 2nd type shown. Mine were also APT-80, which I turned into APT-50 (name of the compression driver alone) by unscrewing the tiny horn it came with.

Mine are the 2nd type shown. Mine were also APT-80, which I turned into APT-50 (name of the compression driver alone) by unscrewing the tiny horn it came with.

Ok, then I think you should either cut off the first 15mm of your APT-80 horns and use that in the driver to get a 1" throat.

Or make a small tube protruding out from the mouting plate to fit into the driver.

As you can see in the horn pictures the part of the horn with the thread (about 15mm) is straight down, and if you don´t have that you will have a larger than 1" diameter going to the mounting plate with a 1" hole, and therefore create a small cavity between the hole in the driver and the mounting plate.

I might try to make a small tube like adapter later today, and make some measurements with and without it on my WG, then we´ll see if it matters much.

Or make a small tube protruding out from the mouting plate to fit into the driver.

As you can see in the horn pictures the part of the horn with the thread (about 15mm) is straight down, and if you don´t have that you will have a larger than 1" diameter going to the mounting plate with a 1" hole, and therefore create a small cavity between the hole in the driver and the mounting plate.

I might try to make a small tube like adapter later today, and make some measurements with and without it on my WG, then we´ll see if it matters much.

Attachments

Indeed, you can see from my pictures I have a small gap. I'd really like to know if you can measure a difference. Another thing I could try here would be to put clay or blu-tac in that gap between throat edge and phase plug edge and measure before/after.

I think this will be a small tweak though - the biggie will be the 30ppi reticulated foam that Dr Geddes has now patented!

I think this will be a small tweak though - the biggie will be the 30ppi reticulated foam that Dr Geddes has now patented!

I think it will make a difference to make the transistion from driver to waveguide as smooth as possible.

But I would be carefull with clay or bluetac, as you don't want that stuff getting in the outer slits of the driver.

Regarding the foam trick, is sure does work well, but I have'nt found anywhere to buy the foam at reasonable prices. I did try with some acoustafill damping material stuffed in the throat and it worked too, but looked ugly.

But I would be carefull with clay or bluetac, as you don't want that stuff getting in the outer slits of the driver.

Regarding the foam trick, is sure does work well, but I have'nt found anywhere to buy the foam at reasonable prices. I did try with some acoustafill damping material stuffed in the throat and it worked too, but looked ugly.

I noticed the easiest place to buy it is from suppliers of aquarium and pond products, as its primary use is in pond/tank filters, often as the 2nd stage of filtering. Have you tried such sources?

I found a UK-based website that sells huge 25mm thick sheets of the "correct" 30PPI foam for about £30UKP - free delivery.

(Just as soon as I have £30 available I'll buy it!)

I found a UK-based website that sells huge 25mm thick sheets of the "correct" 30PPI foam for about £30UKP - free delivery.

(Just as soon as I have £30 available I'll buy it!)

Perhaps, if of interest, I could share the cost with you and send you some when I buy a big sheet. It looks like there'll be enough for loads of waveguides/horns.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- 3 way open baffle with Eminence and Skytronic