I'm slowly working on a MEH project that uses direct radiating woofers and midrange drivers. The midrange drivers cover 300 - 1800 Hz, the problem with using a compression driver for this range is that at the bottom of the range there is not much gain from the horn as this is below cutoff and so drivers with more surface area and excursion capability are required. I have to use direct radiating woofers as they physically won't fit onto the horn.

Otherwise, I think that people would build Synergy like speakers using a coaxial compression driver. They could use "off the shelf" (available commercially, no customization needed) parts.

True in that this was done by using a ~70 Hz quadratic horn loaded Altec 604 duplex 5.1 HT system with the sealed rear chamber tuned empirically to get flattest response up to the 1600 Hz XO point [much smaller than anticipated], which later was dropped to the ~ideal 1200 Hz due to more horn gain than anticipated and of course the HF required frequency shaping EQ.

Then there's the Lowther, etc., compression loaded Tractrix horns..........

Hi!

I want to remind my goal Is to replace mackie sa1521 so

Only for outdoor and indoor PA use.

So I think Is a different approach from Altec ,Lowther and k402.

Maybe tomorrow I Will update you with woofer phase plug design.

Ale

I want to remind my goal Is to replace mackie sa1521 so

Only for outdoor and indoor PA use.

So I think Is a different approach from Altec ,Lowther and k402.

Maybe tomorrow I Will update you with woofer phase plug design.

Ale

Greets!

Understood, we're just discussing other coax horn designs while waiting on you 😉, though the K402 coax + mid-bass woofers is what you're doing except making your own horn, right?

Understood, we're just discussing other coax horn designs while waiting on you 😉, though the K402 coax + mid-bass woofers is what you're doing except making your own horn, right?

hr questions

HI everyone!

Sorry but my working week was very busy

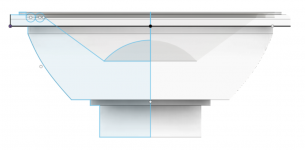

I designed the phase plug measuring real woofer(6mm xmax)and shifting the same cone shape 10mm away but no ports in this time because

I've some questions for HR data:

1.1 If I want to simulate a synergy with reflex ports inside the horn is good to

select "rear vented" and use AP1 and Lpt for this front reflex?

1.2 If yes is ggod to select an "acoustic path lenght" in "combined output" menù with the difference od distance from rear of the woofer cabinet and mouth?

2 what really are VTC and ATC? I used already seen values from another thread...

Maybe I can not translate well hr info

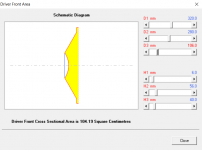

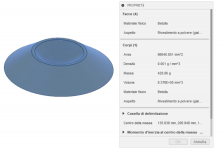

3 I simulate the rcf front volume and cross area

volume is 1970 cc

area is 104 sq cm

my phase plug volume is 878 cc so my atc will be 1970-878=1092?

4 last but not least

how can I calculate front woofer port inside the horn?

Those will be boring questions for you

sorry in advance 😱

Thank you

Ale

HI everyone!

Sorry but my working week was very busy

I designed the phase plug measuring real woofer(6mm xmax)and shifting the same cone shape 10mm away but no ports in this time because

I've some questions for HR data:

1.1 If I want to simulate a synergy with reflex ports inside the horn is good to

select "rear vented" and use AP1 and Lpt for this front reflex?

1.2 If yes is ggod to select an "acoustic path lenght" in "combined output" menù with the difference od distance from rear of the woofer cabinet and mouth?

2 what really are VTC and ATC? I used already seen values from another thread...

Maybe I can not translate well hr info

3 I simulate the rcf front volume and cross area

volume is 1970 cc

area is 104 sq cm

my phase plug volume is 878 cc so my atc will be 1970-878=1092?

4 last but not least

how can I calculate front woofer port inside the horn?

Those will be boring questions for you

sorry in advance 😱

Thank you

Ale

Attachments

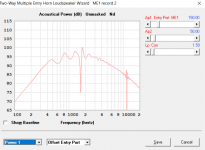

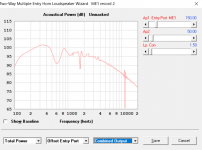

MEH WIZARD HR

HI

I've tried with "meh" in "input wizard" after reading the manual

my version of HR is 52.40

I simulated a tweeter response with thiele small parameters found on the web beacuse b&c not give t/s for dcx464.

I have a bad notch in 1000-2000hz range when I simulate only tweeter power1

and it changes when I change AP1 and AP2 woofer front port.

If I simulate reverse conical front port with ap1 150 ap2 50 the notch is very bad. with cilindrical (I would use 15mm baltic birch) I don't have the notch.

In this case HR simulate some interferences of front port in the horn flare?

I made some errors inputing some parameters?

thank you

Ale

HI

I've tried with "meh" in "input wizard" after reading the manual

my version of HR is 52.40

I simulated a tweeter response with thiele small parameters found on the web beacuse b&c not give t/s for dcx464.

I have a bad notch in 1000-2000hz range when I simulate only tweeter power1

and it changes when I change AP1 and AP2 woofer front port.

If I simulate reverse conical front port with ap1 150 ap2 50 the notch is very bad. with cilindrical (I would use 15mm baltic birch) I don't have the notch.

In this case HR simulate some interferences of front port in the horn flare?

I made some errors inputing some parameters?

thank you

Ale

Attachments

Your phase plug looks great!

I wish i could help more with HR.

I use the MEH input wizard, but only for the low/mid cones response, and don't pay any attention at all to the CD's output range.

HR has helped me get a good idea of the rear volume behind the cones, but past that I've been using measurements and trial and error prototyping.

And i've kinda come to believe with the larger cones like your doing, and i've been doing, just use a port or ports about 1/10th Sd, and either put a pair in the horn corners, or a single round one in the horn center....and as close as possible to the throat.

So for me, not much to model really.

Maybe others with more HR MEH experience will show up...

I wish i could help more with HR.

I use the MEH input wizard, but only for the low/mid cones response, and don't pay any attention at all to the CD's output range.

HR has helped me get a good idea of the rear volume behind the cones, but past that I've been using measurements and trial and error prototyping.

And i've kinda come to believe with the larger cones like your doing, and i've been doing, just use a port or ports about 1/10th Sd, and either put a pair in the horn corners, or a single round one in the horn center....and as close as possible to the throat.

So for me, not much to model really.

Maybe others with more HR MEH experience will show up...

I've built a steel CNC last year to cut Guitars

So I can do cabinet and phase plug phase with CNC.

Do you think 15mm Thick plywood Is good for the strenght of this project output and internal vibrations?

So I can do cabinet and phase plug phase with CNC.

Do you think 15mm Thick plywood Is good for the strenght of this project output and internal vibrations?

I envy your CNC bigtime !!! Good for you !

For the primary horn and secondary flares, I've been using 12mm baltic-birch.

The pyramidal shape seems stronger and less resonant than a box, and doesn't seem to need the customary wall thickness.

(If plywood has significantly fewer plies than BB, i'd probably use 15mm ply.)

For parts of the cabinet that seal the cones in, and complete the box structure, I've used 15mm BB.

For the primary horn and secondary flares, I've been using 12mm baltic-birch.

The pyramidal shape seems stronger and less resonant than a box, and doesn't seem to need the customary wall thickness.

(If plywood has significantly fewer plies than BB, i'd probably use 15mm ply.)

For parts of the cabinet that seal the cones in, and complete the box structure, I've used 15mm BB.

The box without secondary flare should be 21kg plus 13kg for the drivers simulatore on fusion 360 entirely made of 15mm fenolic baltic birch

So i think to buy only 15mm bb to nave Little wasted wood.

The phase plug should be built with many sheets of BB

And 3d milled.

About woofer front ports I Will simulate different locations in the lenght of the horn.

Why do you think I Need to to put the Port near to the cd exit? Xover frequency Will be 600-800 regione and I Will use Active processing so delay Won't be and issue.

In the danley woofer Port are fare away from CD can you explain?

Thank you

Ale

So i think to buy only 15mm bb to nave Little wasted wood.

The phase plug should be built with many sheets of BB

And 3d milled.

About woofer front ports I Will simulate different locations in the lenght of the horn.

Why do you think I Need to to put the Port near to the cd exit? Xover frequency Will be 600-800 regione and I Will use Active processing so delay Won't be and issue.

In the danley woofer Port are fare away from CD can you explain?

Thank you

Ale

It's the whole 1/4 WL notch thingy, which says you'll get a deep null in the mids (low/mids in our cases), at the 1/4WL distance port to throat.

So to keep the notch above 800Hz, 1/4 WL math says keep the port within 10.8cm of throat....and is dang hard to do, huh....?

The phase plugs you built are the common way of trying to milk some higher response. Again, nice work.

So to keep the notch above 800Hz, 1/4 WL math says keep the port within 10.8cm of throat....and is dang hard to do, huh....?

The phase plugs you built are the common way of trying to milk some higher response. Again, nice work.

Was that an Altec product, or a custom job? Asking because I might want something similar, tho it deserves its own thread.True in that this was done by using a ~70 Hz quadratic horn loaded Altec 604 duplex 5.1 HT system with the sealed rear chamber....

They were then current 604s IIRC when he posted it maybe 20 yrs ago?, so maybe the 8K? Pretty sure it had the Mantaray, but can't remember enough now to really search for it, though assume it was either on the AUB or HE Asylum forum and in retrospect think they might be as big as 50 Hz.

Thanks GM. I'd like to put a 12 or 15" coax in a front horn box with pattern control down to about 100Hz. I know that's going to be very large. It's for voice only, but I want to keep the the pattern out of the actor's mics. I'll do some Hornresp work and start another thread.

😀 Quickly 'ballpark' it:

😀 Quickly 'ballpark' it: Horn mouth polar frequency:

c = 10^6/[a*b]

a = wall angle in deg

b = mouth width [or height] in inches

c = -6 dB frequency

Hi

thanks Mark for your answer.

Meanwhile I milled a test tweeter mouth from spare wood to check the roughness and is perfect winhout sanding. in attached picture

With C lateral shapes I can move woofer very near to the hi's.

This week I will buy the baltic birch and start to mill!

Mids are 650rms each so 1300rms per channel.

I've found a used Proel PSW2660 (powersoft IPAL inside) 1300x2 on 4 ohms

for 250euros.

do You think amp power is enough to push to the max output capable?

Ale

thanks Mark for your answer.

Meanwhile I milled a test tweeter mouth from spare wood to check the roughness and is perfect winhout sanding. in attached picture

With C lateral shapes I can move woofer very near to the hi's.

This week I will buy the baltic birch and start to mill!

Mids are 650rms each so 1300rms per channel.

I've found a used Proel PSW2660 (powersoft IPAL inside) 1300x2 on 4 ohms

for 250euros.

do You think amp power is enough to push to the max output capable?

Ale

Attachments

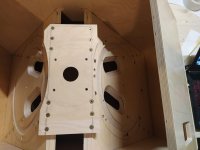

update

hi everyone!

I was very busy

I post some building photos of the first top only for testing: no glue.

i tried a method a strange method to seal parts maybe is already used:

milled canals in joint for o-ring like seals like idraulic cylinders and engine heads. what do you think? is good for testing without anomalies in spectrum or distortion-phase problems?

I think I spent more time doing this cuttings with cnc than if I had done with a simple saw 🙄

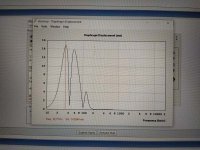

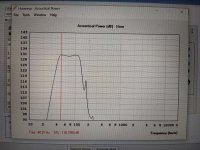

Now I'm thinking about the subs:

the empty space in my car is about 1000x650x550cm so i'm thinking:

2xtham15 loaded with beyma 15lex1600nd 1600w rms 14,5mm xmax

look at hte simulation

4x small br cabs with at least same spl of the thams? any suggestions?

thank you guys!!

Ale

hi everyone!

I was very busy

I post some building photos of the first top only for testing: no glue.

i tried a method a strange method to seal parts maybe is already used:

milled canals in joint for o-ring like seals like idraulic cylinders and engine heads. what do you think? is good for testing without anomalies in spectrum or distortion-phase problems?

I think I spent more time doing this cuttings with cnc than if I had done with a simple saw 🙄

Now I'm thinking about the subs:

the empty space in my car is about 1000x650x550cm so i'm thinking:

2xtham15 loaded with beyma 15lex1600nd 1600w rms 14,5mm xmax

look at hte simulation

4x small br cabs with at least same spl of the thams? any suggestions?

thank you guys!!

Ale

Attachments

-

IMG_20210827_201501.jpg508.7 KB · Views: 437

IMG_20210827_201501.jpg508.7 KB · Views: 437 -

IMG_20210827_203034.jpg584.4 KB · Views: 442

IMG_20210827_203034.jpg584.4 KB · Views: 442 -

IMG_20210829_122655.jpg318.3 KB · Views: 428

IMG_20210829_122655.jpg318.3 KB · Views: 428 -

IMG_20210829_185854.jpg482.3 KB · Views: 244

IMG_20210829_185854.jpg482.3 KB · Views: 244 -

IMG_20210829_191102.jpg28.2 KB · Views: 290

IMG_20210829_191102.jpg28.2 KB · Views: 290 -

THAM15 15LX1600ND AT 2100W EQON.jpg30.8 KB · Views: 300

THAM15 15LX1600ND AT 2100W EQON.jpg30.8 KB · Views: 300 -

THAM15 15LX1600ND AT XMAX EQON.jpg32.1 KB · Views: 236

THAM15 15LX1600ND AT XMAX EQON.jpg32.1 KB · Views: 236

Thanks GM. I'd like to put a 12 or 15" coax in a front horn box with pattern control down to about 100Hz. I know that's going to be very large. It's for voice only, but I want to keep the the pattern out of the actor's mics. I'll do some Hornresp work and start another thread.

you might have more reasonable size if you add cardioid to the solution

Resistive port cardioid active speaker insipired by D&D 8C

Hi Ale, your build looks great !

The precision shows. Makes me wishful for some CNC capability.

Sorry i missed your post/ amp question from June.

Yes, i think that amp will work great with the mb12n351's. I use a PL340 with 1250W @ 4 ohms on a pair of them.

I've been comparing them to Faital 12pr320's on a current syn project and like them better. But their stronger motor adds about 1.75 kg each, and adds more weight than the project can bear. Sigh...

The throat adaptor you made looks especially cool.

Also like your idea for temporary construction. It beats mine of just using drywall screws to hold the horn together until i'm convinced the ports and such is right.

Good news is that i've yet to measure any improvement between the temporary screw job, and permanent glued-up joining.

(Unlike subs where it usually makes a ton of difference.)

The precision shows. Makes me wishful for some CNC capability.

Sorry i missed your post/ amp question from June.

Yes, i think that amp will work great with the mb12n351's. I use a PL340 with 1250W @ 4 ohms on a pair of them.

I've been comparing them to Faital 12pr320's on a current syn project and like them better. But their stronger motor adds about 1.75 kg each, and adds more weight than the project can bear. Sigh...

The throat adaptor you made looks especially cool.

Also like your idea for temporary construction. It beats mine of just using drywall screws to hold the horn together until i'm convinced the ports and such is right.

Good news is that i've yet to measure any improvement between the temporary screw job, and permanent glued-up joining.

(Unlike subs where it usually makes a ton of difference.)

Subs for synergy

Hi

I'm finishing the detachable secondary flare and I'm ready to test.

Meanwhile I'm trying to know which sub(s)

I Need for those tops.

Now i have in mind 1 2x18 ppsl 200l net for 45-120hz at 138db at peak Power.

With maybe 2 18sw115 or 2 lavoce san184.50 (vert Hood simulation)

I Remember Mark made some ppsls.

Any suggestions? My rear car space Is perfect for 2 tham15 so 360 360 Total.

Hi

I'm finishing the detachable secondary flare and I'm ready to test.

Meanwhile I'm trying to know which sub(s)

I Need for those tops.

Now i have in mind 1 2x18 ppsl 200l net for 45-120hz at 138db at peak Power.

With maybe 2 18sw115 or 2 lavoce san184.50 (vert Hood simulation)

I Remember Mark made some ppsls.

Any suggestions? My rear car space Is perfect for 2 tham15 so 360 360 Total.

- Home

- Loudspeakers

- Multi-Way

- 2x12 and 1,4 coax CD Synergy